A kind of method for continuous dyeing of denim

A technology for denim and dyeing liquid, applied in the field of fabric processing, can solve the problems of unsuitability for mass production, low efficiency and high cost, and achieves the improvement of dyeing rate and color fixing rate, high K/S value, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method of preparing a dispersant, comprising the steps of:

[0052] The weight ratio of 1: 1.5 is 1: 1.5 to add the calculinous mass concentration of 8 wt% aqueous sodium hydroxide, stir well, then warmed to 72 ° C, in the incubation of 10 min intraperitin weight 10% formaldehyde Continue to heat insulation 1.5h. Continue to 95 ° C, adding alkali weight of 10% absolute sodium sulfate, continued to heat insulation 1.5 h, cooled to normal temperature, slowly add 8.2% epoxypropylene chloropropane in ultrasonic mass weight, and stopped after 2 h Heating, using waste heat to evaporase epoxypropylene residual chloropropane, the pH of 9.0 during the reaction, to obtain a dispersant, the dispersant contains the compound of formula I,

[0053] Medium, x = ch 2 SO 3 Na, y = OCH 3 .

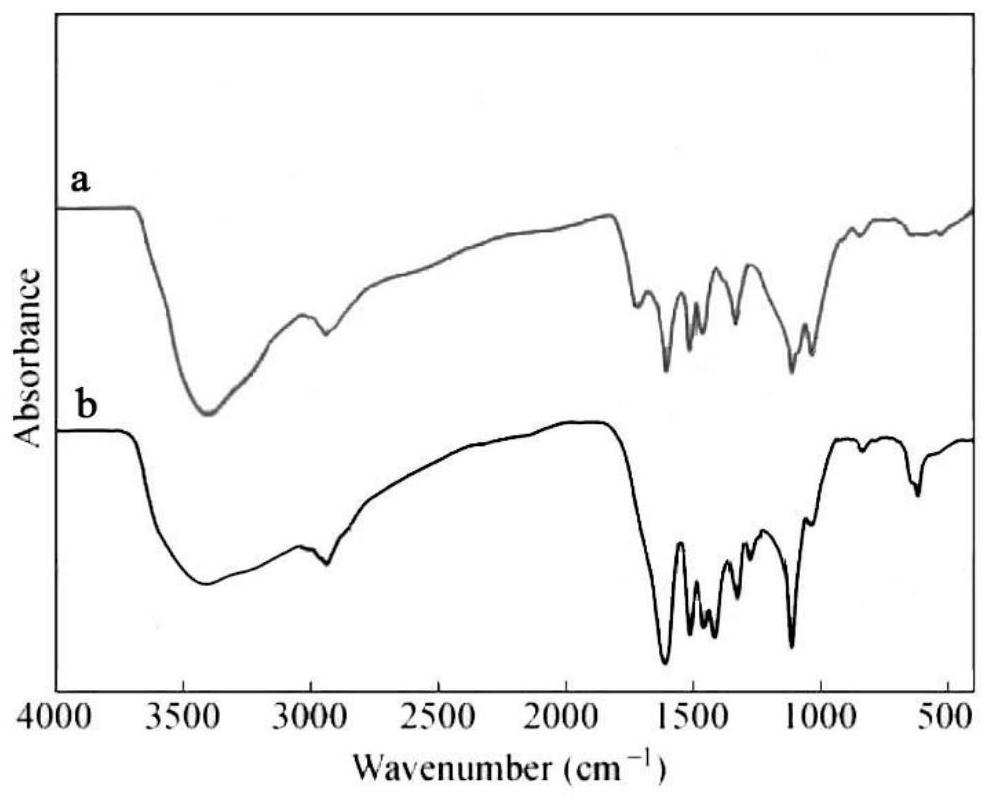

[0054] The infrared spectroscopy of alkali and dispersant is carried out on the Nicolet infrared spectrometer of the American thermo, the scan range is 4000-400cm -1 , Resolution 4cm -1 The mass rati...

Embodiment 2

[0056] A method of preparing a dispersant, comprising the steps of:

[0057] The weight ratio of 1: 1.5 is 1: 1.5 to add the calculinous mass concentration of 8 wt% aqueous sodium hydroxide, stir well, then warmed to 72 ° C, in the incubation of 10 min intraperitin weight 10% formaldehyde Continue to heat insulation 1.5h. Continue to heat up to 95 ° C, adding alkaline weight of 10% absolute sodium sulfate, continued to heat insulation 1.5 h, cool to normal temperature, slowly added 8.2% epoxypropylene chloride in the stirring state, and stop heating after 2 h The residual heat is evaporated to evaporase epoxy chloropropane of the remaining reactive reaction, and the pH is 9.0 during the reaction to obtain a dispersant.

Embodiment 3

[0059] A denim continuous dyeing method, denim contains cotton fibers, including the following steps:

[0060] Step: Press the bath ratio (denim: water) = 1: 100 (g / g) to place the cowboy in a solution containing 8 g / L penetrant JFC, 5g / L, calcined, pretreatment of 1 h at 80 ° C, then Wash 2 times, rinse to the pH of the rinse liquid is 7-7.5;

[0061] Step S2: Press the bath ratio (denim: water) = 1: 20 (g / g) to place the s2 step in a solution containing 30 g / lLINEX SURF Italian auxiliaries, modified at 40 ° C for 30 min;

[0062] S3 step: The dodensus method is used in dodder, and the dye containing 25 g / l TR / 0265 Italian natural color sand dye is dyed, the dyeing rate is 80%, the temperature is 50 ° C; dyed After the denim was 40 min at 60 ° C, 30 g / l LINEX SUP solution, followed by drying at a temperature of 90 ° C × 3 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com