Patents

Literature

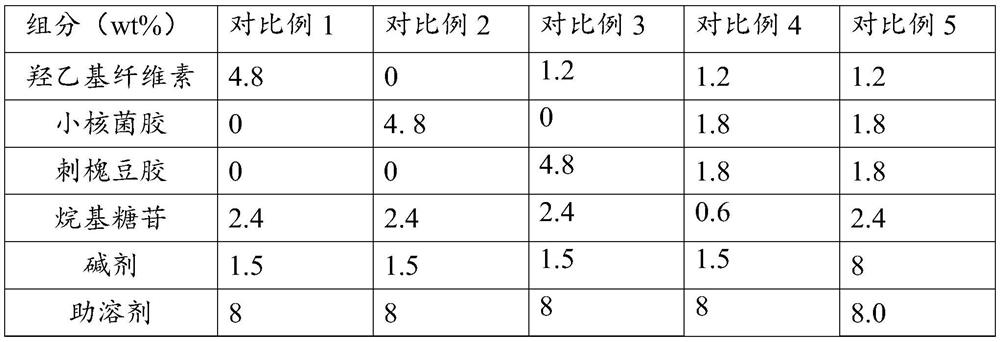

58results about How to "Increase K/S value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pure cotton fabric reduced dye dyeing method

InactiveCN104047186AImprove reducibilityMaintain resilienceBleaching apparatusDyeing processPolymer scienceDioxyethylene Ether

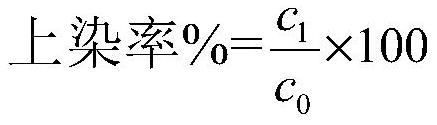

The invention relates to a pure cotton fabric reduced dye dyeing method which comprises the following steps: (1) textile preparation; (2) textile pretreatment; (3) preparation of reduced dye leuco body solution; (4) dip dyeing of reduced dye; (5) soap boiling and (6) after-finishing. The reduced dye leuco body solution is prepared by the following raw materials: 1-10g / L thiourea dioxide, 2-5g / L of iso-tridecanol polyoxyethylene ether, 1-2g / L of glucose, 2-5g / L of sodium silicate, and 1-2g / L of sodium sulfide. The K / S value of the dyed textile is obviously improved.

Owner:福建金苑服饰有限公司

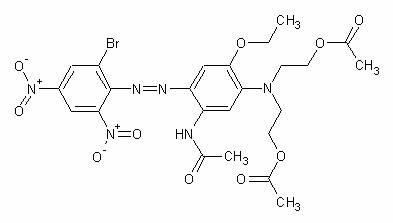

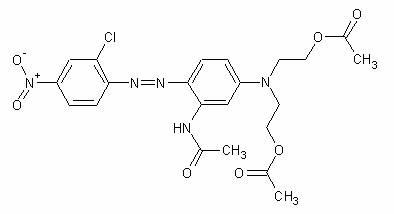

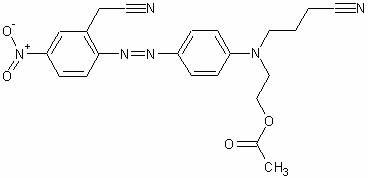

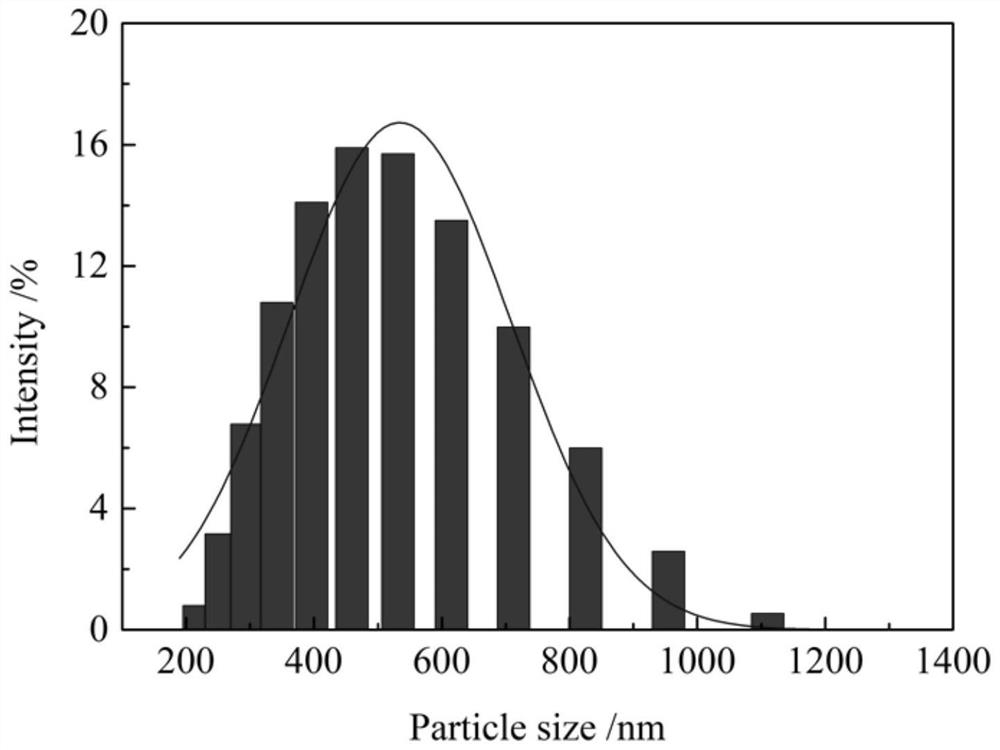

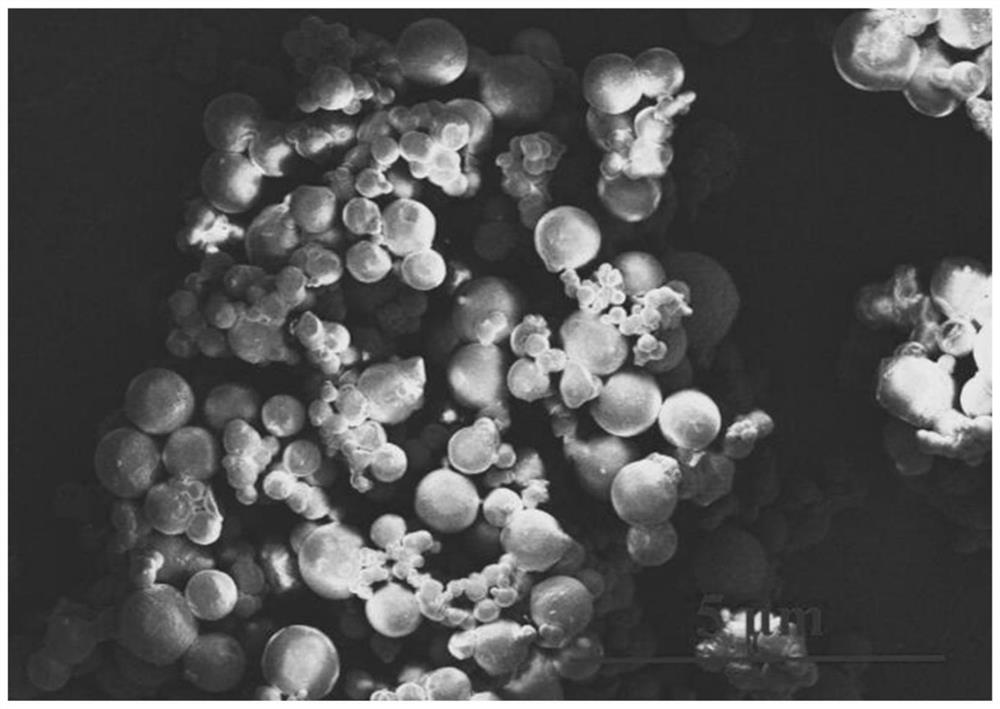

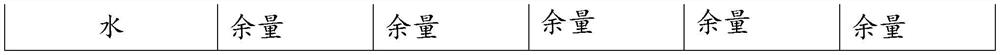

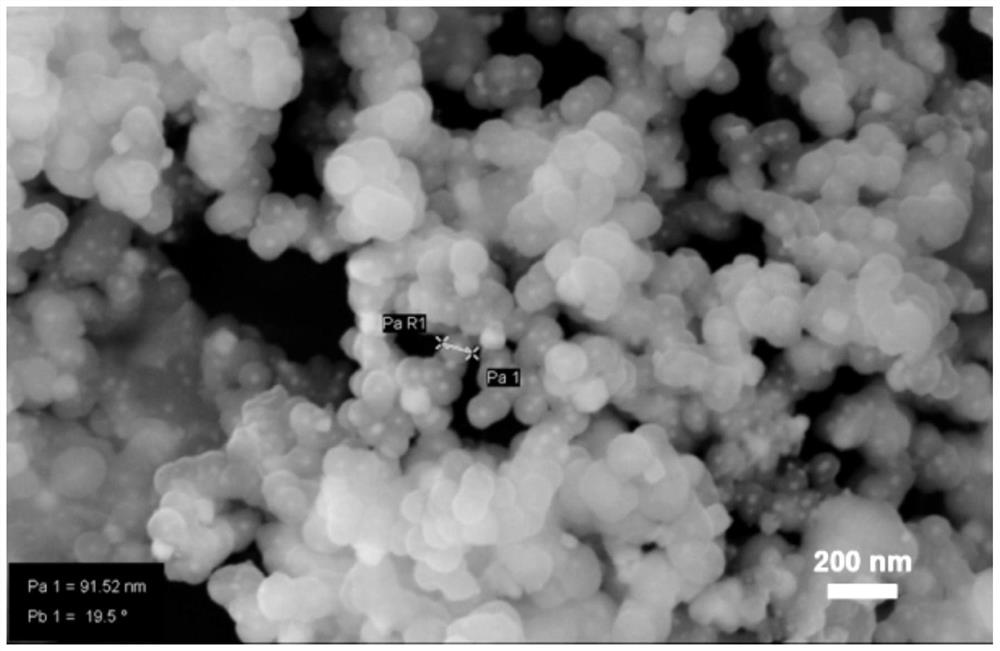

Nano disperse black combined dye and preparation method thereof

The invention discloses a nano disperse black combined dye and a preparation method thereof, and relates to the field of processing in dye and intermediate industries. The combined dye comprises a dye and an aid, the mass ratio of the dye to the aid is 1: (1-4.5), and the dye is one or more of compounds shown as a formula I; the aid is formed by mixing anionic surfactant and nonionic surfactant in a mass ratio of (100-85)%: (0-15)%; in the formula I, R1 is H, Cl, Br or CN; R2 is H, Cl or NO2; R3 is H or OCH3; R4 is H or NHCOCH3; and R5 and R6 are mutually independent C2H5, C2H4OCOCH3, C2H4OCH3 or C2H4CN. Under the same dyeing condition, compared with the conventional black disperse dye for dyeing a polyester fabric, the nano disperse black combined dye has the advantages that the L value of the fabric is reduced by 21.3 percent, and the K / S value is improved by 18.6 percent.

Owner:SHAOXING UNIVERSITY

Cotton fiber based non-reactive type modified natural dye staining method

The invention relates to the field of textile dye staining technology, in particular to a cotton fiber based non-reactive type modified natural dye staining method. The staining method mainly comprises the steps of pretreatment of a cotton fabric, non-reactive type modified treatment of the cotton fabric and staining treatment of the modified cotton fabric, wherein cationic compound modifier is adopted to modify the cotton fabric in the step of the non-reactive type modified treatment of the cotton fabric, so that the modified cotton fabric can still have good whiteness, high strength and good moisture absorption performance; and the K / S value of the stained cotton fabric can be greatly improved, and good leveling property and color fastness are achieved.

Owner:HAIAN COUNTY FUXING BLEACHING & DYEING

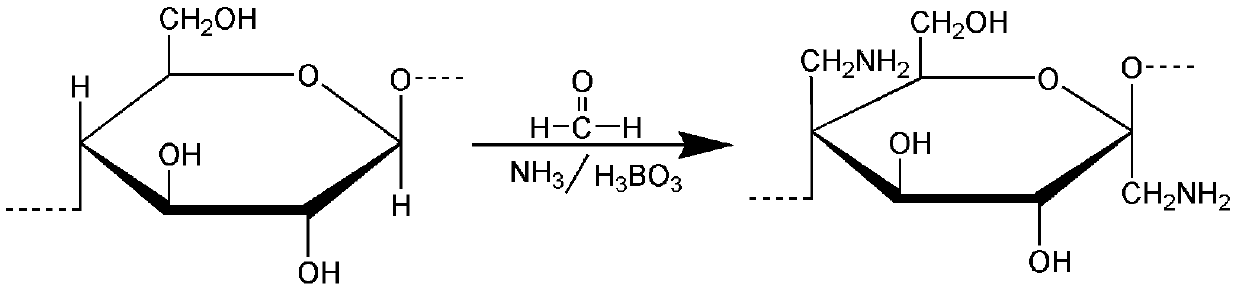

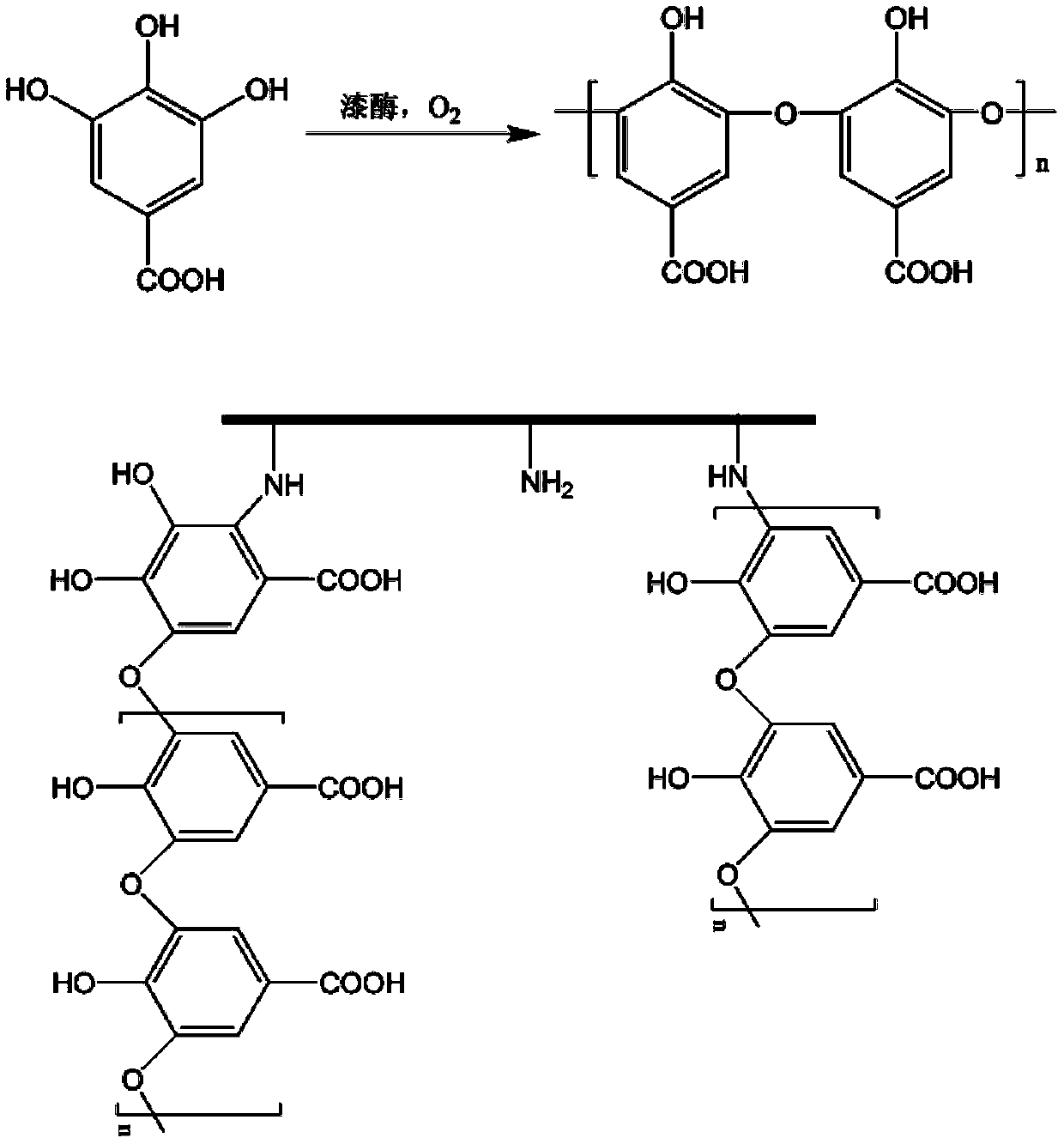

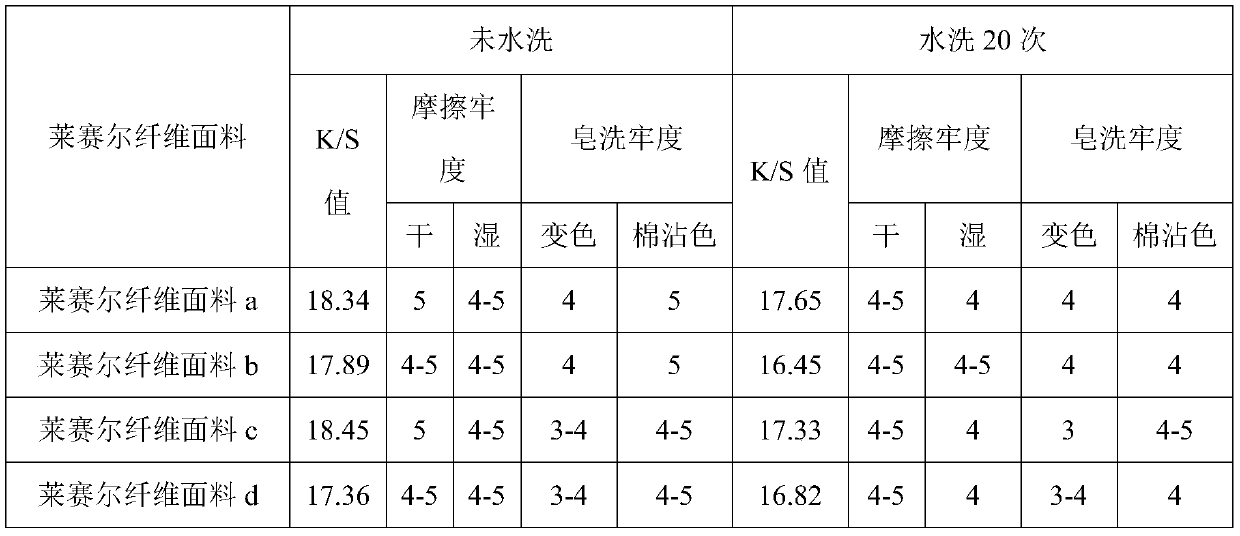

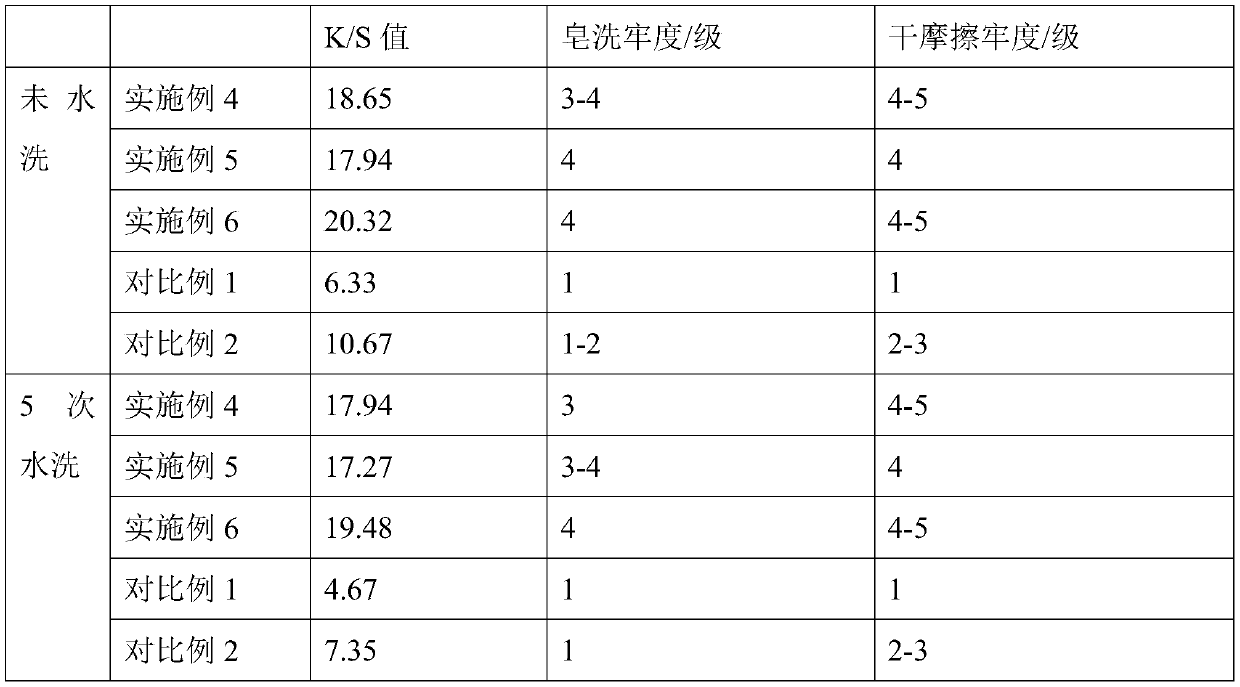

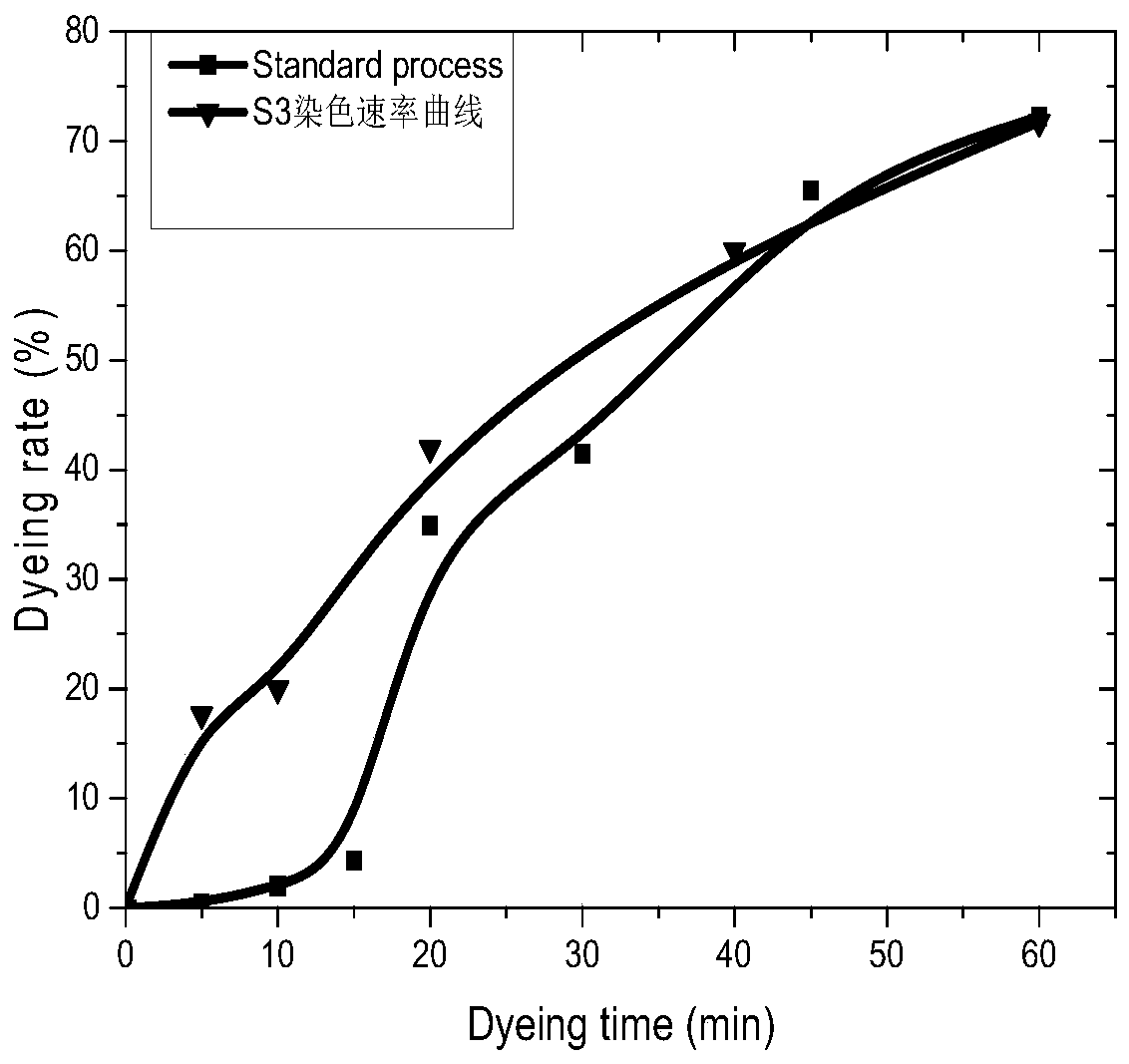

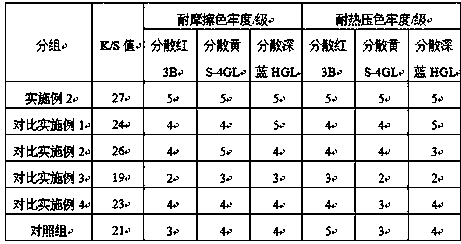

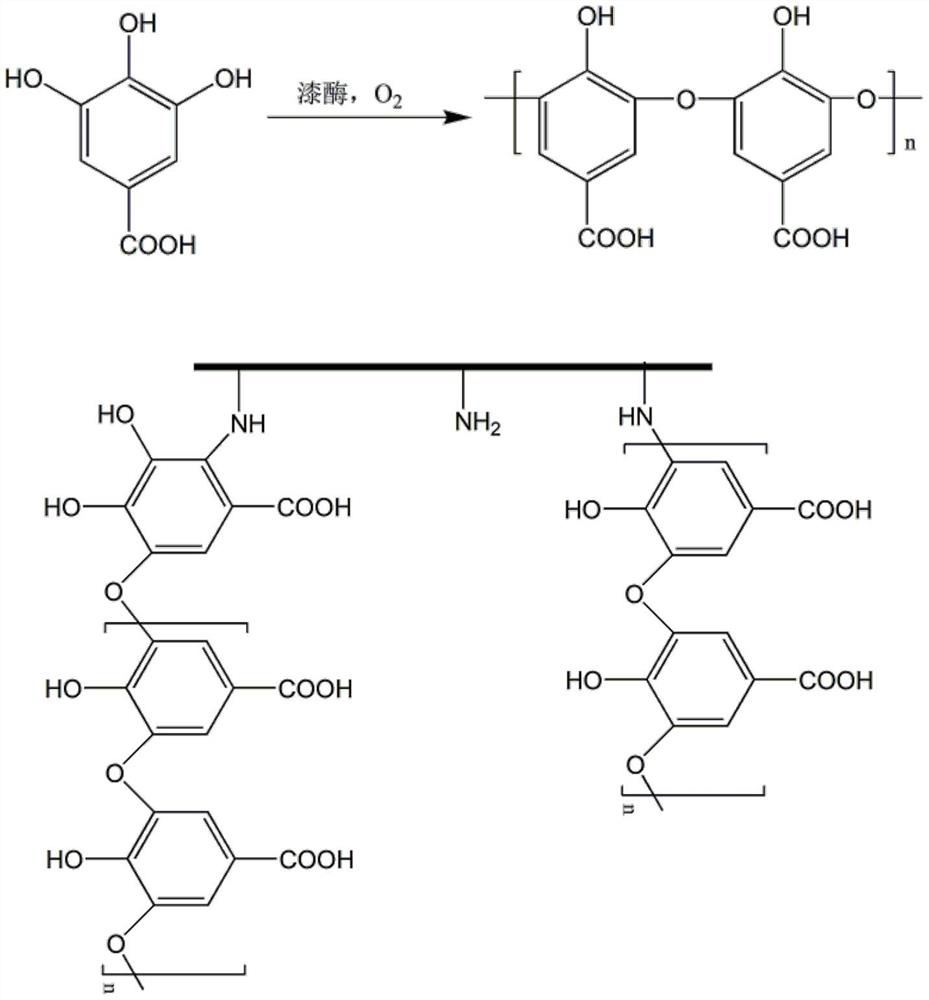

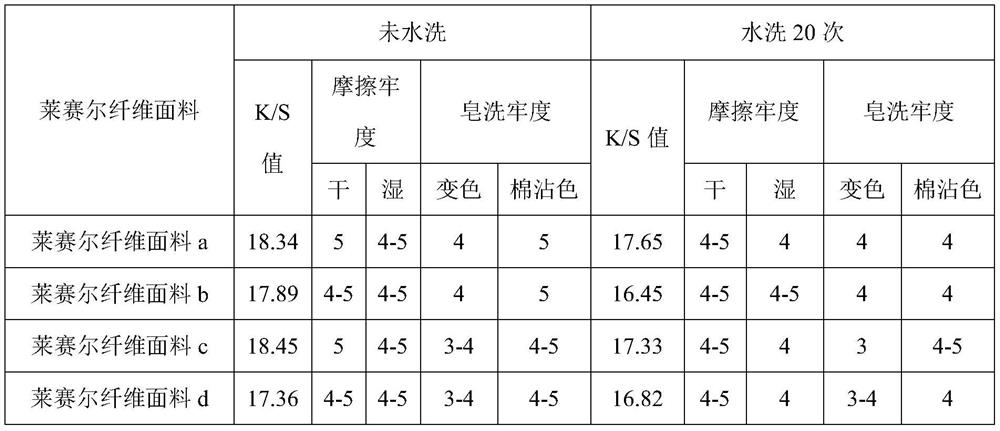

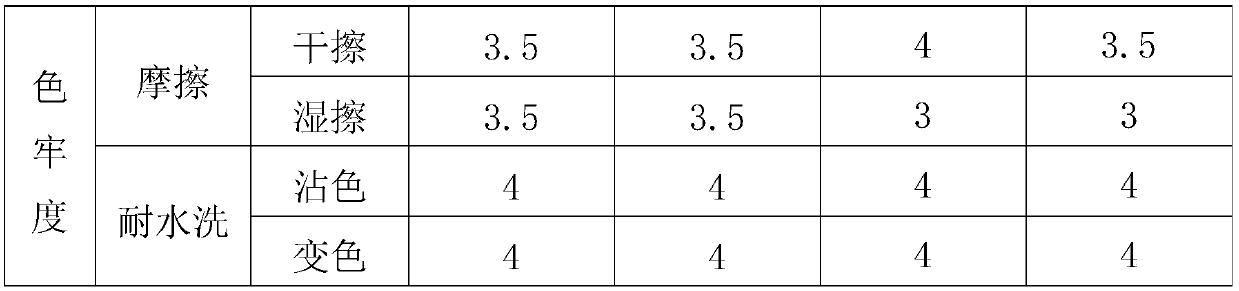

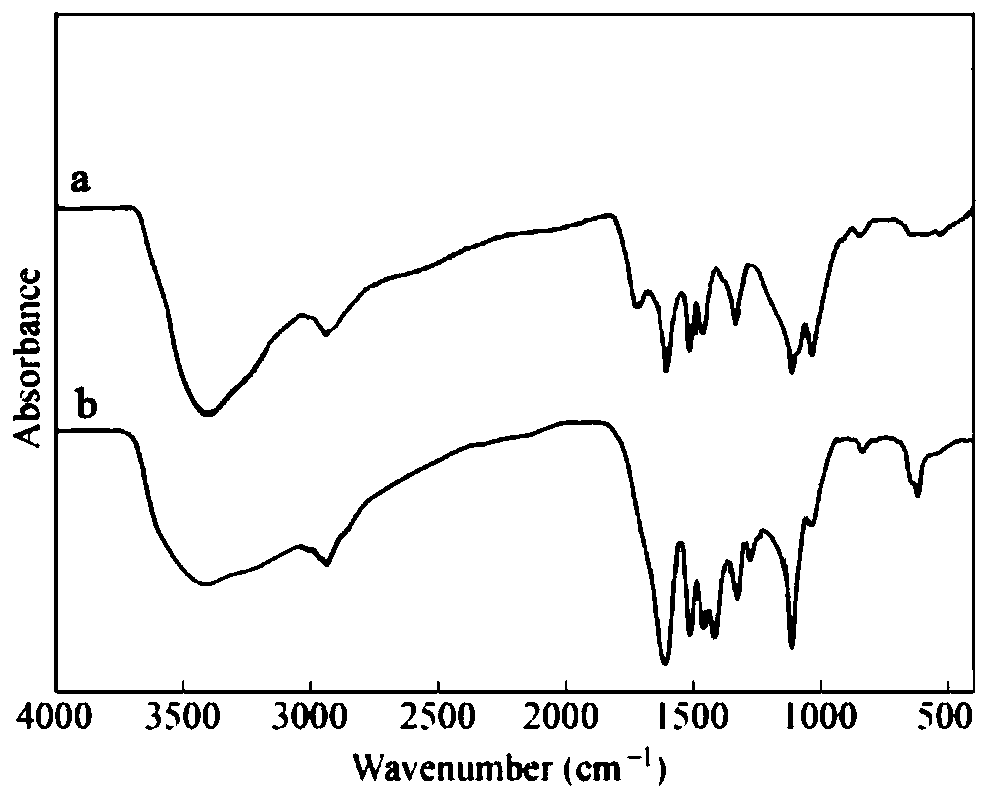

Enzyme staining Lyocell fiber fabric and preparation method thereof

The invention relates to an enzyme staining Lyocell fiber fabric and a preparation method thereof. A Lyocell fiber fabric is ammonified and modified, the ammonified and modified Lyocell fiber fabric is cultured in laccase and organic monomer environments, and organic monomers are polymerized and grafted to the Lyocell fiber fabric under the action of laccase to prepare the enzyme staining Lyocellfiber fabric. The rubbing fastness and the soaping fastness of the enzyme staining Lyocell fiber fabric are at optimal level and cannot be obviously reduced after the enzyme staining Lyocell fiber fabric is washed for 20 times. Successful application of enzyme staining provides a selectable scheme for substituting synthetic dyes for staining, and the staining method is almost free from wastewaterdischarge and of great significance for environmental protection and sustainable development of resources.

Owner:WUHAN TEXTILE UNIV

Extraction method of microbial pigment and method for dyeing lyocell fibers by adopting same

ActiveCN111471316AGood compatibilityEffective approachNatural dyesDyeing processBiotechnologyMicrobiology

The invention discloses an extraction method of a microbial pigment and a method for dyeing lyocell fibers by using the same. The extraction method of the microbial pigment comprises the following steps: inoculating bacteria into a seed culture solution, culturing on a shaking table, inoculating the bacterium seed solution into a fermentation culture solution, culturing on the shaking table; afterthe fermentation is finished, centrifuging the fermentation solution, extracting the centrifugal product by using ethyl acetate; and finally, concentrating and drying the extract to obtain the microbial pigment powder. When the pigment is used for dyeing the lyocell fibers; lyocell fibers are added into a water solution containing the microbial pigment at the room temperature; dyeing is carried out for 20 to 40 minutes, the bath ratio is 1: (20-30), then alum is added, the temperature is raised to 80 DEG C, then triethanolamine is added, the temperature is maintained for dyeing for 20-40 minutes, finally a color fixing agent is added, cooling is conducted after the color fixing treatment is finished, and the fibers are taken out, washed with cold water, soaped, washed with water, and dried to obtain dyed lyocell fibers. The dyeing of the microbial pigment on the surface of the lyocell fibers is realized.

Owner:当阳市鸿阳新材料科技有限公司

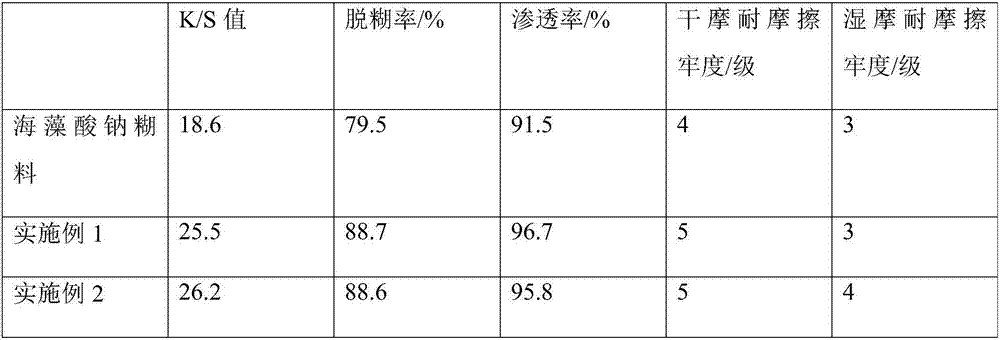

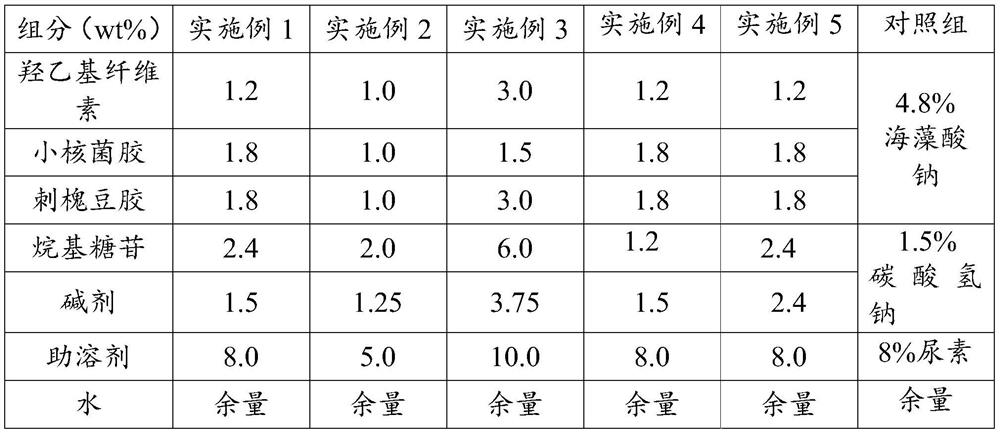

Modified sodium alginate paste material and preparation method thereof

The invention discloses a modified sodium alginate paste material, and relates to the technical field of printing and dyeing, wherein the modified sodium alginate paste material includes the followingingredients in parts by weight: 25-35 parts of sodium alginate, 75-100 parts of crosslinked carboxymethyl starch, 5-10 parts of urea, 3-5 parts of sodium hydrogen carbonate, 10-12 parts of guar gum,8-10 parts of bentonite, 12-15 parts of carboxymethylcellulose, 5-8 parts of sodium polyacrylate, 5-8 parts of a mildew-proof antibacterial agent, and the balance water. The modified sodium alginate paste material can improve the storage stability and increase a printing quality.

Owner:苏州天亦辰针织有限公司

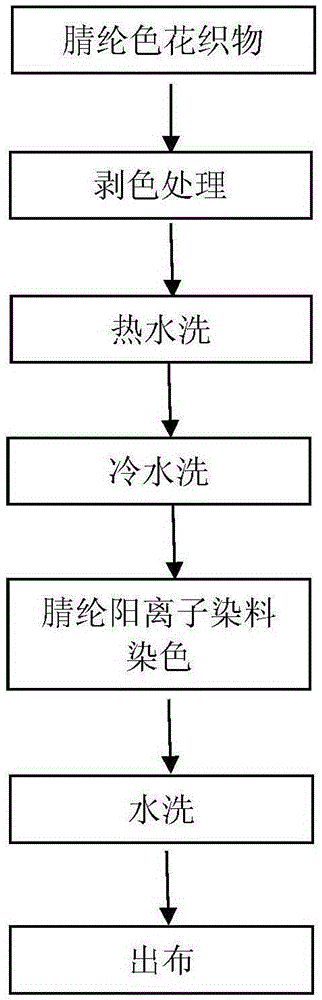

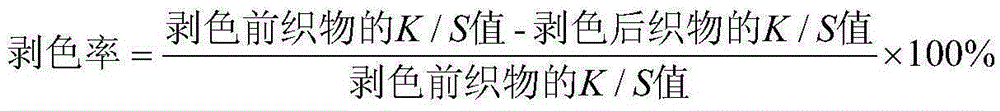

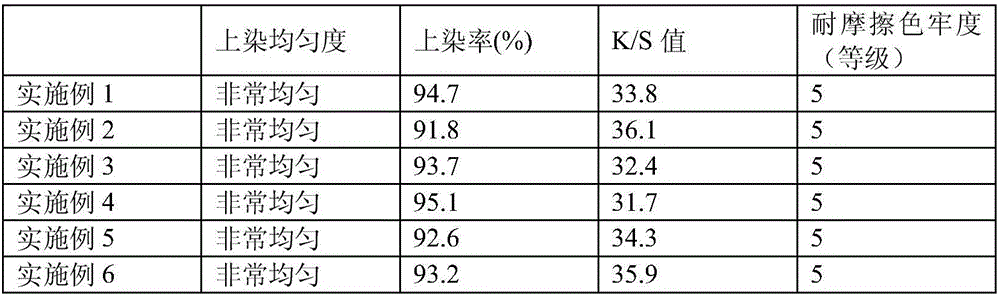

Stripping agent for cationic dye dyed acrylic fabric and stripping method

ActiveCN105256619AFacilitate dissociationSolve the problem of not being able to dye dark againDyeing processEconomic benefitsPVA - Polyvinyl alcohol

The invention provides a stripping agent for cationic dye dyed acrylic fabric. The stripping agent comprises components in percentage by weight as follows: 40%-50% of high fatty acid salt, 5%-10% of a permeating agent, 10%-15% of a dispersing agent and the balance of water, wherein the high fatty acid salt adopts sodium salt of C16-C18 fatty acid; the permeating agent adopts an anionic surfactant; the dispersing agent adopts one of a polyether nonionic surfactant and polyvinyl alcohol. A stripping method adopting the stripping agent comprises steps as follows: a stripping liquid containing 4-8 g / L of the stripping agent is prepared, and a bath ratio is 1: (20-30); the temperature is increased to 100 DEG C at a speed of 2-3 DEG C / min, and stripping treatment is performed for 20-30 min; the fabric is rinsed completely. With the adoption of the method, the stripping rate can be up to 40%-60%, the fabric after stripping is redyed, the K / S value of the dyed fabric is increased by 5%-10% compared with that of the fabric before stripping, the use quantity of the dye can be reduced, and the economic benefit is increased.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE

Method for preparing multifunctional polymer-based nanometer ZnO composite tanning agent

InactiveCN103074455AEasy to prepareImprove stabilityTanning treatmentZinc Acetate DihydratePolymer chemistry

A method for preparing a multifunctional polymer-based nanometer ZnO composite tanning agent is characterized by comprising the following steps: preparing modified ZnO soils by taking zinc acetate as a nanometer particle precursor and diallyldimethylammonium chloride as a modifying agent, and preparing a polymer-based nanometer ZnO composite tanning agent for a leather retanning procedure through a soil-in-situ polymerization method. Through adoption of the method, nanometer ZnO is uniformly dispersed in a polymeric matrix, so that the stability of the polymer-based nanometer ZnO composite tanning agent is improved. When the method is applied to the leather retanning procedure, the dyeing depth of the leather can be greatly increased so that the K / S value of the dyed leather is increased by 98.26 %, the fullness of the leather is improved so that the tanned leather is thickened by 20.88 %, and the leather is endowed with good antibacterial property and aging resistance.

Owner:SHAANXI UNIV OF SCI & TECH

Dyeing process of cotton/aloe fiber blended yarns

InactiveCN106223043AUniform colorLower dyeing temperatureBiochemical treatment with enzymes/microorganismsDyeing processFiberYarn

The invention discloses a dyeing process of cotton / aloe fiber blended yarns. The dyeing process comprises the following steps: (1) performing pretreatment: selecting raw materials: the cotton / aloe fiber blended yarns, and preparing a pretreatment liquid: 0.8 to 1.1 g / L of polyphenol oxidase, 0.5 to 0.8 g / L of phytase, 1 g / L of cellulase, 2 g / L of silk fibroin and 2.3 to 2.8 g / L of trimethylglycine, wherein the enzyme activity of the polyphenol oxidase is 350 u / g and the enzyme activity of the phytase and the cellulase is 500 u / g; the treatment parameters are as follows: 3 to 5% (owf), the time is 35 to 45 minutes and the temperature is 35 to 40 DEG C; (2) performing dyeing treatment: completely rinsing the pretreated cotton / aloe fiber blended yarns, drying, and performing one-bath one-step dyeing on aloe fiber knitted fabric by selecting reactive dye and by a dip dyeing method, wherein the specific dyeing process flows are as follows: wetting, dyeing, soaping, dehydrating and drying.

Owner:长兴卫峰纺织有限公司

Pure cotton fabric vat dye dyeing method

A pure cotton fabric vat dye dyeing method includes the following steps of firstly, preparing fabric; secondly, conducting pretreatment on the fabric; thirdly, preparing a vat dye leuco body solution; fourthly, conducting dip dyeing on vat dye; fifthly, conducting soaping; sixthly, conducting after treatment, wherein dip dyeing is conducted on vat dye in the fourth step, deoxygenation is conducted in a dyeing device, nitrogen is introduced into the dyeing device, the dyeing device is then sealed, pure cotton fabric where pretreatment is conducted is placed in the leuco body solution of vat dye, the temperature is raised to 60 DEG C at the temperature rise speed of 1 DEG C per minute, heat preservation is conducted for 12minutes, 2.5 g / L salt is added, dyeing continues to be conducted for 12 minutes, dyeing is finished, and dyed pure cotton fabric is oxidized in air and then washed through cold water.

Owner:耿云花

Active-dye low-salt dip dyeing method for cotton fabric

InactiveCN104278553AGood dyeing effectReduce processing stepsDyeing processSalt substitutePerspiration

The invention relates to an active-dye low-salt dip dyeing method for cotton fabric. A one-step process employed by the technology is excellent in dyeing effect, and in the one-step process technology, a salt substitute is applied to a pretreatment technology, pretreatment does not need individually performing, and the processing process is shortened and water and energy are saved. Also, BOD5 and CODCr of a processing raffinate of the one-step process technology are reduced compared with routine pretreatment, and the one-step process technology is environment-friendly. The low-salt dyeing technology is capable of reducing the usage amount of anhydrous sodium sulfate in the dyeing process by 50%, is excellent in dyeing effect, has the dyed fabric K / S value higher than that of a routine dyeing technology, and is uniform in obtained color. The soaping fastness and the perspiration fastness are both high and are both 4-5 grade or more, the solarization fastness is 4 grade or more, and the dry / wet friction fastness is 4 grade or more. The improving capacity of the low-salt dyeing technology is better than that of a routine dyeing technology, in other words, the usage amount of a dye is less when same chroma is obtained, and the dye uptake of the low-salt dyeing technology is far higher than that of a routine dyeing technology.

Owner:WUXI XINGLIN DYEING ENVIRONMENTAL PROTECTION EQUIP

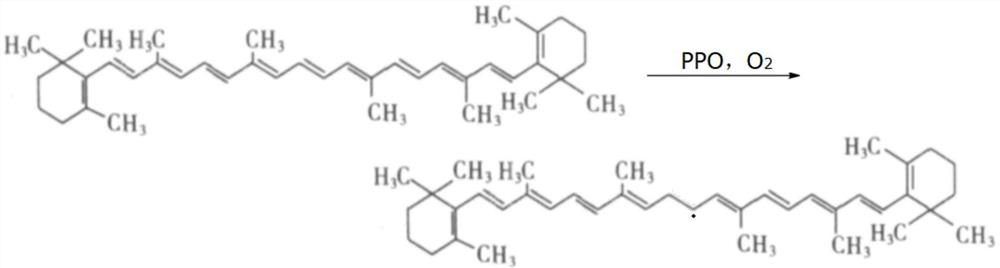

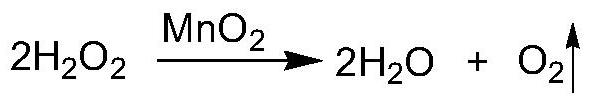

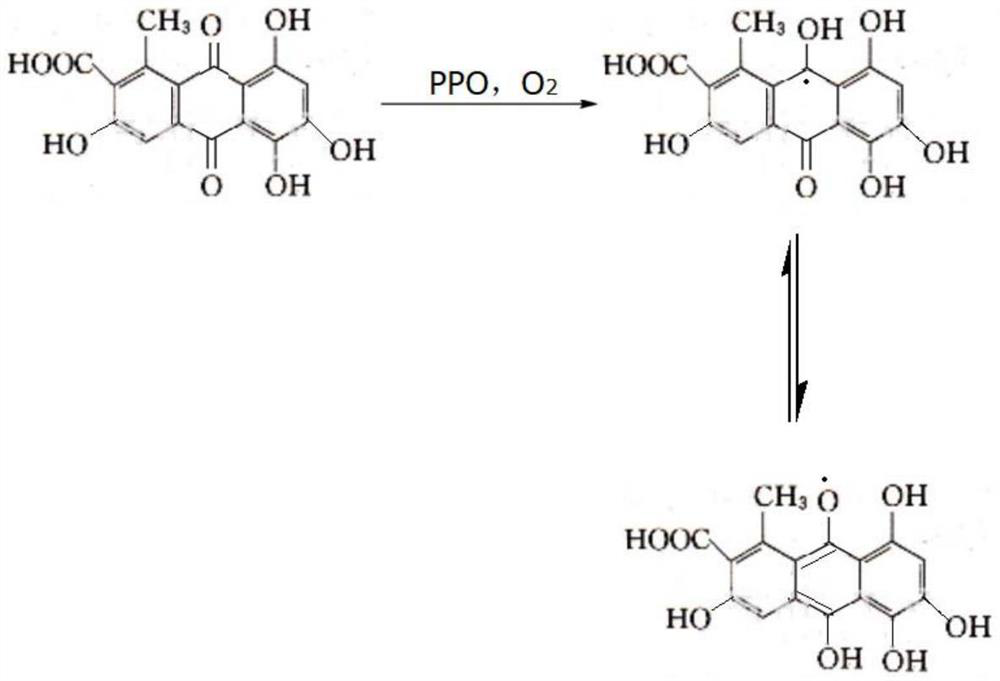

Yellow lyocell fabric prepared by dyeing with blakeslea trispora fermentation extract and preparation method thereof

PendingCN113756111AReactive activationDoes not damage the molecular structureFungiMicroorganism based processesPolymer scienceBlakeslea trispora

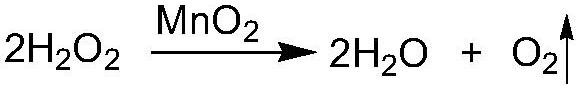

The invention relates to a yellow lyocell fabric prepared by dyeing with a blakeslea trispora fermentation extract and a preparation method thereof. The method comprises the following steps of fermenting blakeslea trispora, culturing and purifying to obtain beta-carotenoid; and preparing a phenol oxidase solution and a cellulase solution, preparing a dyeing solution from the beta-carotenoid, the phenol oxidase solution, the cellulase solution, an H2O2 solution and the like, putting manganese dioxide, a lyocell fabric and a dyeing solution into a dyeing machine for dyeing, performing enzyme deactivation on the dyed lyocell fabric, washing with tap water, and drying to obtain the yellow lyocell fabric. According to the yellow lyocell fabric prepared by dyeing with the blakeslea trispora fermentation extract and the preparation method thereof provided by the invention, cellulose and the beta-carotenoid are respectively activated by selecting cellulase and polyphenol oxidase, so that graft polymerization reaction of the cellulose and the beta-carotenoid is realized. The dyeing conditions are mild, so that the pollution to the environment is small; and the dyed yellow lyocell fabric has a relatively high K / S value, and the soaping fastness and the dry rubbing fastness grade are relatively high.

Owner:芽米科技(广州)有限公司

Dyeing promoter for reactive dye and using method of dyeing promoter

InactiveCN104727168AReduce dosageRealize environmental protection and low salt reactive dyeingDyeing processEthylene diamineInorganic salts

The invention discloses a dyeing promoter for reactive dye. The dyeing promoter comprises ethylenediaminetetraacetic acid ionic salt, specifically at least one of ethylenediaminetetraacetic acid tetrasodium salt, ethylenediaminetetraacetic acid disodium salt, dipotassium ethylene diamine tetraacetate, tripotassium ethylenediaminetetraacetic acid, ethylenediaminetetraacetic acid dilithium salt, ethylenediaminetetraacetic acid calcium disodium salt, ethylenediaminetetraacetic acid disodium zinc salt tetrahydrate and ethylenediaminetetraacetic acid ammonium salt. The invention further discloses a using method of the dyeing promoter. According to the method, the ethylenediaminetetraacetic acid ionic salt is adopted as the dyeing promoter of inorganic salt, the dye-uptake and fixation rate of reactive dyeing can be remarkably improved, the use amount of dyeing promoter neutral inorganic salt can be reduced, traditional reactive dyeing equipment is not required to be transformed, and dyeing technical parameters of various reactive dyes are not changed, so that the environment-friendly effect is improved, the production cost is reduced, and the environment-friendly low-salt reactive dyeing is realized.

Owner:WUYI UNIV

Super-bright polyester drawn yarn and preparation method thereof

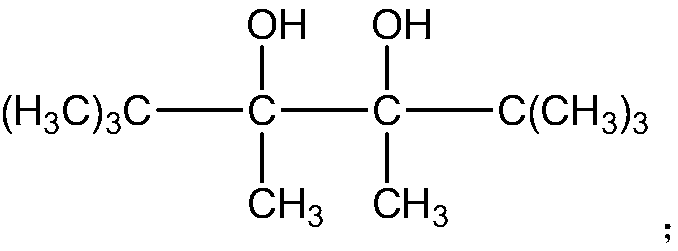

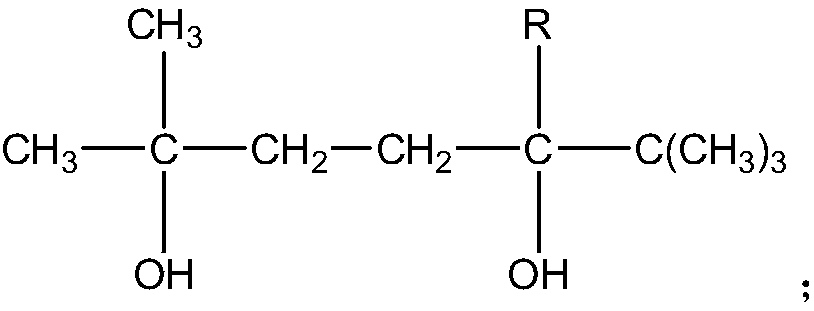

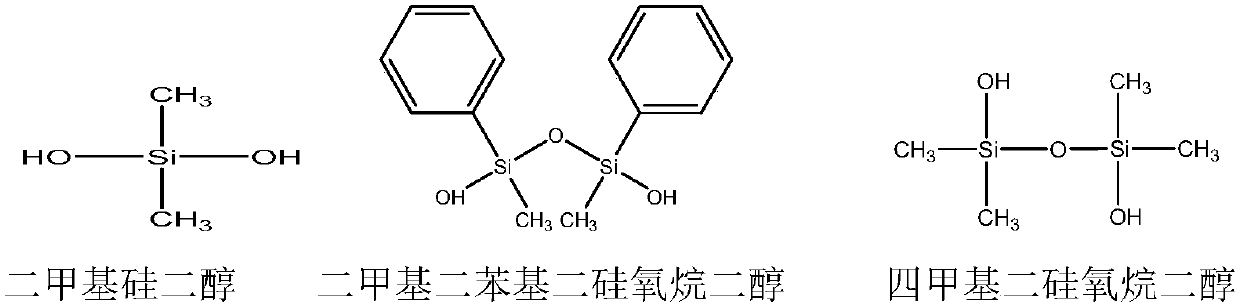

The invention relates to super-bright polyester drawn yarn and a preparation method thereof. The preparation method includes the step that a modified polyester melt is prepared into modified polyesterFDY yarn through an FDY technology by using a triangular or a straight-line-shaped spinneret plate to obtain the super-bright polyester drawn yarn. Modified polyester is prepared in the steps that terephthalic acid, ethylene glycol, 2,2,3,4,5,5-hexamethyl-3,4-hexanediol, heptanediol with tert-butyl side groups, dihydric alcohol with a main chain containing silicon and binary acid with tert-butylside groups are evenly mixed and subjected to an esterification reaction and a polycondensation reaction in sequence. Under the temperature condition of 125 DEG C, the dye uptake of the prepared product is 89.3-92.2%, the K / S value is 22.55-24.36, the fastness to soaping reaches the fifth level, the fastness to dry rubbing reaches the fifth level, and the fastness to wet rubbing is higher than thefourth level. The preparation method is simple in process, and the prepared product is good in dyeing performance and high in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Composite accelerating agent of reactive dyes

InactiveCN104818631ARealize environmentally friendly and efficient reactive dyeingImprove environmental performanceDyeing processSodium acetateCarboxylic acid

The invention discloses a composite accelerating agent of reactive dyes. The composite accelerating agent of the reactive dyes is three combinations including the combination of carboxylate without amino and carboxylate containing amino, a combination of ammonium salt, the carboxylate without amino and the carboxylate containing amino, and a combination of sulfamate, the carboxylate without amino and the carboxylate containing amino, wherein the carboxylate without amino is sodium acetate, sodium oxalate, sodium citrate, sodium tartrate, sodium polycarboxylic acid, potassium acetate, potassium citrate or potassium tartrate; the carboxylate containing amino is the ionic salt of ethylene diamine tetraacetic acid; the ammonium salt is ammonium chloride, ammonium sulfate, ammonium carbonate, ammonium phosphate, ammonium formate or ammonium acetate. The composite accelerating agent of the reactive dyes has the advantages of being degradable, small in amount, efficient, environmentally friendly and low in price and can obviously improve the dye uptake and the fixation rate of the reactive dyes, thereby having a great application prospect and high promotional values.

Owner:WUYI UNIV

Low-salt dyeing method of reactive dye

ActiveCN111005245AHigh affinityIncrease color depthDyeing processCotton fibrePulp and paper industry

The invention relates to a low-salt dyeing method of a reactive dye. The dyeing method does not change the conventional dyeing equipment and basic dyeing process of cotton textiles, and is easy to implement and control. Compared with a traditional dyeing method of a reactive dye to cotton textiles, the dyeing method can reduce the dosage of a dyeing electrolyte by 50% or above, and the cotton textile dyed by adopting the low-salt dyeing method of the reactive dye disclosed by the invention has obviously higher color rendering depth, high dyeing fastness and excellent dyeing reproducibility, and can be used for reactive dye dyeing processing of various cotton fibers and products thereof, so that the use amount of the dyeing electrolyte is remarkably reduced, the environment is protected, and the dyeing method has good application effect and bright market prospect.

Owner:WUHAN TEXTILE UNIV

Dyeing method for improving color fastness of polyester woven ribbon

Owner:界首市远航织带有限公司

A kind of enzyme-dyed lyocell fiber fabric and preparation method thereof

The invention relates to an enzyme-dyed lyocell fiber fabric and a preparation method thereof. The lyocell fiber fabric is first ammoniated and modified, and then the ammoniated lyocell fiber fabric is treated with laccase and It is cultivated in the environment of organic monomers, and under the action of laccase, the organic monomers are polymerized and grafted to lyocell fiber fabrics. The rubbing fastness and soaping fastness of the enzyme-dyed lyocell fiber fabrics are at a relatively high level. After 20 times of washing, the rubbing fastness and soaping fastness are not significantly reduced. The successful application of enzyme dyeing provides an alternative to dyeing with synthetic dyes. This dyeing method has almost no waste water discharge, which is of great significance to environmental protection and sustainable development of resources.

Owner:WUHAN TEXTILE UNIV

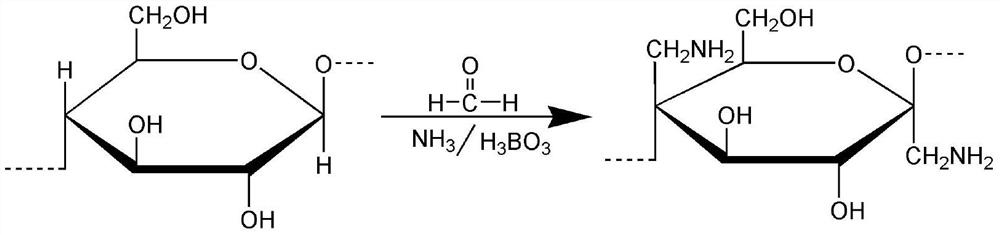

Low-salt and low-alkali dyeing process of cellulose fiber fabrics with medium-temperature reactive dyes

ActiveCN103556498BIncrease dye seatFacilitated DiffusionDyeing processVegetal fibresCellulose fiberPolymer chemistry

The invention relates to a low-salt and low-alkali dyeing process with a mesothermal type active dye of a cellulosic fiber fabric. The low-salt and low-alkali dyeing process comprises the following steps: modifying a cellulosic fiber fabric to be dyed by a fiber modifying agent to prepare a partially-aminated modified cellulosic fiber fabric to be dyed; modifying the mesothermal type active dye by a dye modifying agent to prepare an activated and modified mesothermal type active dye; and carrying out low-salt and low-alkali dyeing on the cellulosic fiber fabric, namely carrying out the low-salt and low-alkali dyeing on the partially-aminated modified cellulosic fiber fabric to be dyed by the activated and modified mesothermal type active dye in the presence of neutral electrolyte, inorganic alkalis and water. According to the dyeing technology, the use amount of the neutral electrolyte and the inorganic alkalis can be reduced and the dyeing temperature can be reduced by about 10 DEG C; the dyed cellulosic fiber fabric has high coloring depth, good dyeing fastness and excellent dyeing reproducibility; the low-salt and low-alkali dyeing process can be used for dyeing various cellulosic fiber fabrics by the mesothermal type active dye.

Owner:佛山市马大生纺织有限公司

A kind of reactive dye exhaust dyeing process of cotton fabric

ActiveCN106245369BHigh color fixing rateIncrease profitBiochemical treatment with enzymes/microorganismsDyeing processThermal insulationRoom temperature

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

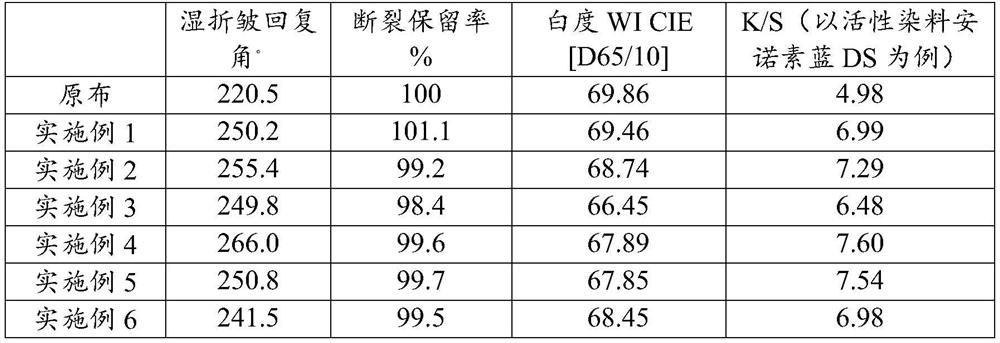

Method for preparing anti-wrinkle real silk fabric

PendingCN113584883AIncrease K/S valueImprove dyeing effectWrinkle resistant fibresAnimal fibresPyrimidineReactive dye

The invention provides a method for preparing an anti-wrinkle real silk fabric, and belongs to the field of surface grafting modification of textiles. The method specifically comprises the steps that firstly, the real silk fabric is pretreated, pyrimidine derivatives are adopted to modify the real silk fabric, the pyrimidine derivatives are grafted to the real silk fabric, and the wet-state wrinkle resistance of the real silk fabric is improved; and in addition, the K / S value of the real silk fabric obtained after dyeing modification of the reactive dye is improved, it is indicated that the modified real silk fabric has good dyeing performance, and the dyeability of the cotton fabric can be improved.

Owner:JIANGSU HUAJIA SILK +1

Denim continuous dyeing method

ActiveCN111118924A4.0 dry resistance4.0 Color fastness to wet rubbingDyeing processDenimCotton fibre

The invention provides a denim continuous dyeing method, and belongs to the technical field of fabric processing. The denim contains cotton fibers, and the continuous dyeing method comprises the following steps of carrying out pretreatment on the denim by a solution containing a penetrating agent and caustic soda, and performing water washing for 2-3 times; carrying out modification treatment on the denim obtained in the step 1 by a dyeing assistant; and carrying out dyeing on the denim by a dyeing liquor containing a natural mineral dye by adopting a twice-dipping and twice-rolling method, and performing color fixing and dying. By adoption of the method, continuous dyeing of the denim is realized by the natural mineral dye, the obtained denim has relatively high K / S value, high level dyeing property and excellent color fastness to rubbing, and the water washing residual liquid chrominance after hot water washing is relatively low. According to the method, the dyeing rate and color fixing rate of the natural mineral dye are improved by a dispersant, damage to the fibers in the dyeing process is lowered, and the gloss and softness of the denim are improved.

Owner:邢台恒进纺织有限公司

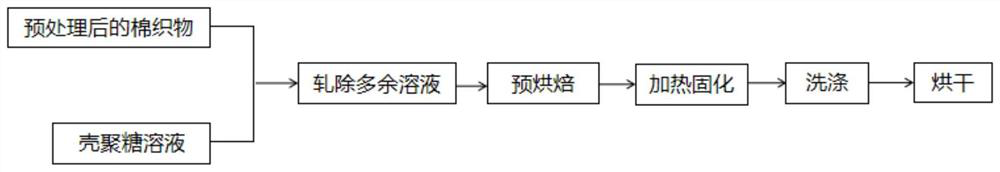

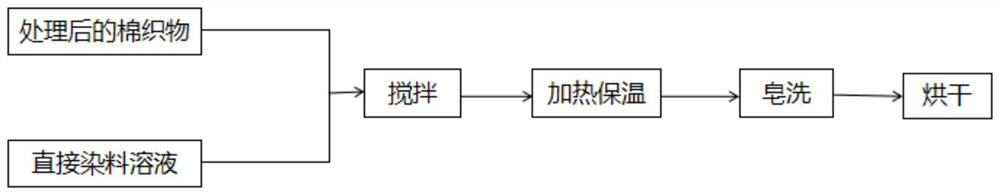

Method for improving dye-uptake of direct dyes on cotton fabrics

The invention relates to the field of textile printing and dyeing, and discloses a method for improving the dye-uptake of direct dyes on cotton fabrics. The method comprises the following steps that (1) the cotton fabrics are treated by a chitosan solution, specifically, the pretreated cotton fabrics are completely immersed in the chitosan solution, then an excess solution is rolled out, pre-roasting is conducted, heating and solidifying are conducted, then washing is conducted in a weakly acidic solution, and then drying is conducted; and (2) dyeing is conducted, specifically, the treated cotton fabrics obtained in step (1) are placed in a direction dye solution for stirring, then heating and heat preservation are conducted, and the cotton fabrics are soaped and dried; wherein in the step(1), the preparation method of the chitosan solution comprises the steps that chitosan is dissolved in a citric acid solution with the concentration of 40-50 g / L; and the concentration of the chitosan solution is 10-15 g / L. According to the method, citric acid is used as a crosslinking agent, the chitosan is crosslinked on the cotton fabrics, and the dye-uptake of the direct dyes on the cotton fabrics is improved.

Owner:WUHAN TEXTILE UNIV +1

A non-fading dye

ActiveCN103711004BImprove bindingNot easy to fadeDyeing processTrimethylolpropaneDibutyltin dilaurate

The invention discloses a stain not easy to fade, which is prepared from the following raw materials in parts by weight: 20-30 parts of dibutyl phthalate, 40-50 parts of diphenyl ether tetracarboxylic dianhydride, 20-30 parts of dimethylformamide, 20-40 parts of diethylaminoethyl methacrylate, 20-50 parts of dibutyltin dilaurate, 10-20 parts of calcium sulfate, 20-50 parts of triethanolamine, 50-60 parts of hydroxymethyl cellulose, 10-20 parts of iron blue, 20-30 parts of trimethylolpropane, 20-25 parts of hexamethoxy methyl melamine, 10-20 parts of an initiator, 10-20 parts of a surfactant, and 50-80 parts of water. The soaping fastness of the stain disclosed by the invention is grade 4.5-5.0, the strain is strong in combination and not easy to fade, the K / S value is as high as 8.215, and the dyeing performance is good.

Owner:JIANGSU ZHONGXIN RESOURCES GRP

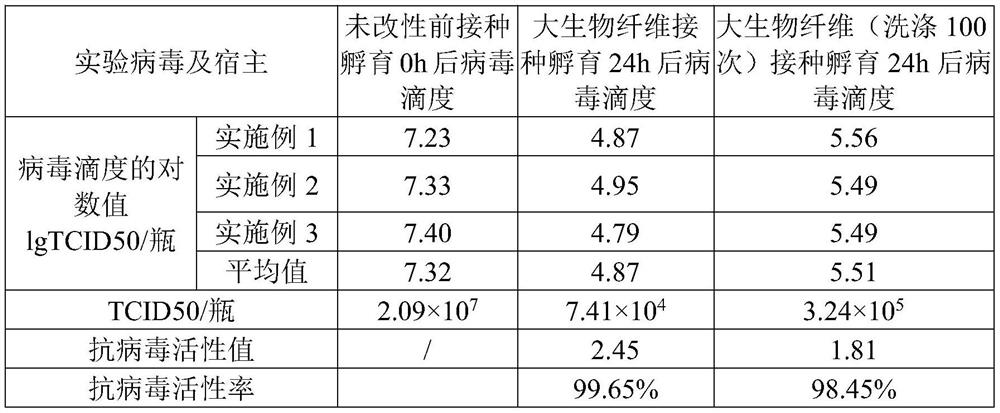

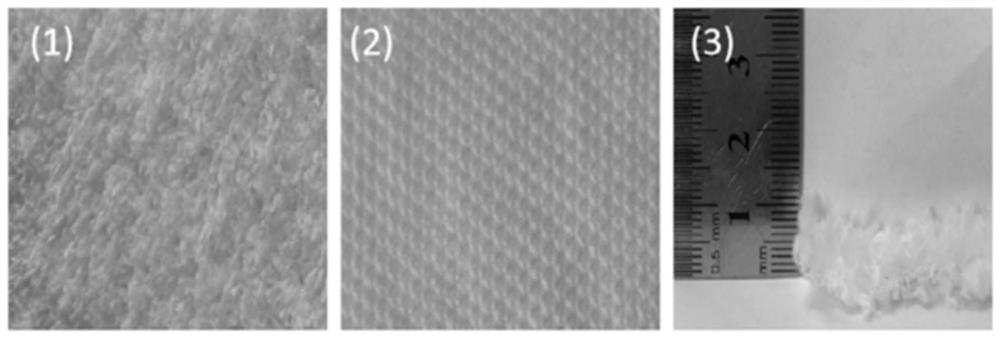

Catechin-containing ramie large biofiber and preparation method thereof

InactiveCN113186728AImprove wrinkle resistanceImprove bindingBiochemical fibre treatmentVegetal fibresPolymer sciencePolymer chemistry

The invention provides a preparation method of catechin-containing ramie large biofiber, and relates to the technical field of functional fiber processing. According to the method, firstly, ramie fiber is treated with alkali, cleaned and oxidized, and then the ramie fiber is modified with microencapsulated catechin, so that the combining capacity of the catechin and the ramie fiber is improved, and the ramie large biofiber with the good antiviral function is produced. The large biofiber prepared by the method not only has the antiviral function, but also improves the washing color fastness of the ramie fiber.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD +2

Wash-free high color fastness pad dyeing process of heavy polyester blanket

The invention provides a water-free high color fastness pad dyeing process for heavy polyester blankets, comprising the following steps: 1) preparation of microcapsule-like liquid dyes: after ball-milling powder disperse dyes, adding dispersants to continue ball-milling, and then adding Polybutene powder and glycerin, continue ball milling, add water to obtain microcapsule-like liquid dye; 2) prepare dyeing paste; 3) padding; 4) pre-bake; ~210s. Compared with the prior art, the present invention relies on the high penetrability of the nano-particle size of the liquid dye particles to realize the deep penetration dyeing of the polyester polymer polymer; in addition, the pad dyeing process designed by the invention enables the dyeing fabric to have the highest K / S value. , excellent color fastness and color brightness.

Owner:绍兴皂树纺织科技有限公司

Flame-retardant superfine fiber suede leather with excellent dyeing performance and preparation method thereof

ActiveCN107287918BImprove dye uptakeIncrease K/S valueTextiles and paperColour fastnessPolymer science

The invention discloses flame-retarding superfine fiber suede leather with excellent dyeing property and a preparation method of the flame-retarding superfine fiber suede leather. The preparation method comprises the following steps: (1) suede leather base cloth with primary flame retardance is prepared from modified polyurethane as a starting material; then the suede leather base cloth with primary flame retardance is subjected to finishing after super dyeing, and flame-retarding base cloth is obtained; (2) the flame-retarding base cloth obtained in the step (1) is impregnated with a first flame retardant and dried, and flame-retarding suede leather base cloth is prepared, wherein the first flame retardant is of a decabromodiphenyl ethane structure; (3) the flame-retarding suede leather is coated with a second flame retardant in a rolling manner, flame-retarding superfine fiber suede leather with excellent dyeing property is obtained, and the second flame retardant contains a flame retardant 2 which is prepared from the decabromodiphenyl ethane structure and antimony(III) oxide by compounding. The dye-uptake of the base cloth is increased, the dyed base cloth is uniform in color, and the K / S value and the color fastness are high.

Owner:江苏华峰超纤材料有限公司

Purple lyocell fabric dyed by animal dye lac and preparation method of purple lyocell fabric

PendingCN114753170AReactive activationDoes not damage the molecular structureDyeing processPolymer scienceOxidative enzyme

The invention relates to a purple lyocell fabric dyed by animal dye lac and a preparation method of the purple lyocell fabric. The method comprises the following steps: extracting purple pigment from lac through an aqueous solution to prepare lac purple pigment, preparing a phenol oxidase solution and a cellulase solution, preparing a dyeing solution from the lac purple pigment, the phenol oxidase solution, the cellulase solution, an H2O2 solution and the like, and putting manganese dioxide, lyocell fabric and the dyeing solution into a dyeing machine for dyeing. The dyed lyocell fabric is subjected to enzyme deactivation, then washed with tap water and dried, and the purple lyocell fabric is obtained. Cellulase and polyphenol oxidase are selected to activate the cellulose and the purple pigment respectively, so that graft polymerization reaction of the cellulose and the purple pigment is realized. The dyeing conditions are mild, and the pollution to the environment is small; the dyed purple lyocell fabric has a relatively high K / S value, and the soaping fastness and the dry rubbing fastness are relatively high in grade.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com