Catechin-containing ramie large biofiber and preparation method thereof

A technology of biological fiber and ramie fiber, applied in plant fiber, biochemical fiber treatment, fiber treatment, etc., can solve the problems of ramie fiber wrinkle resistance, low dyeing rate and color fixation rate, increase anti-virus, etc., and achieve water fastness The effect of improving the strength, improving the wrinkle resistance, and improving the K/S value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

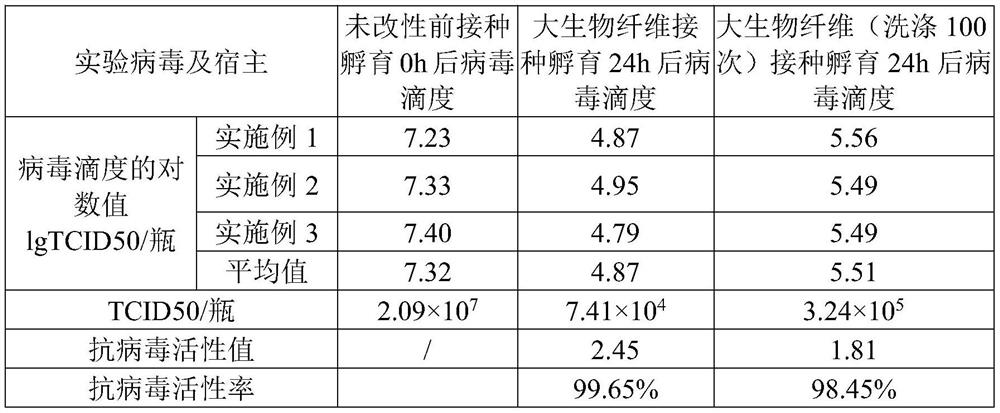

Examples

Embodiment 1

[0028] A kind of preparation method of the big ramie biological fiber containing catechin, comprises the following steps:

[0029] (1) Preparation of catechin microcapsules: catechin microcapsules were prepared with catechin as the core material and chitosan as the wall material, wherein the mass ratio of the core material to the wall material was 3:1;

[0030] (2) Alkali soaking: After washing the ramie fiber, keep the water content at 50%, put it into a high-pressure cooking pot and use a sodium hydroxide solution with a concentration of 180g / L to cook it, wherein the bath ratio is 1:12, and the temperature 70℃, time is 5h, pressure is 1.9×10 5 Pa.

[0031] (3) dealkalization: the ramie fiber after soaking in alkali is put into deionized water and washed three times, each washing 10min;

[0032] (4) Alkali neutralization: soak the ramie fiber after dealkalization in the dilute sulfuric acid solution of 2g / L and neutralize excess alkali, then rinse with deionized water to r...

Embodiment 2

[0041] A kind of preparation method of the big ramie biological fiber containing catechin, comprises the following steps:

[0042] (1) Preparation of catechin microcapsules: catechin microcapsules were prepared with catechin as the core material and chitosan as the wall material, wherein the mass ratio of the core material to the wall material was 3:1;

[0043] (2) Alkali soaking: After washing the ramie fiber, keep the water content at 50%, put it into a high-pressure cooking pot and use a sodium hydroxide solution with a concentration of 200g / L to cook, wherein the bath ratio is 1:12, the temperature 70℃, time is 5h, pressure is 1.9×10 5 Pa.

[0044] (3) dealkalization: the ramie fiber after soaking in alkali is put into deionized water and washed three times, each washing 15min;

[0045] (4) alkali neutralization: the ramie fiber after dealkalization is soaked in the dilute sulfuric acid solution of 3.5g / L and excess alkali is neutralized, (5) oxidation: the ramie fiber t...

Embodiment 3

[0050]A kind of preparation method of the big ramie biological fiber containing catechin, comprises the following steps:

[0051] (1) Preparation of catechin microcapsules: catechin microcapsules were prepared with catechin as the core material and chitosan as the wall material, wherein the mass ratio of the core material to the wall material was 3:1;

[0052] (2) Alkali soaking: After washing the ramie fiber, keep the water content at 50%, put it into a high-pressure cooking pot and use a sodium hydroxide solution with a concentration of 220g / L to cook, wherein the bath ratio is 1:10, and the temperature 70℃, time is 5h, pressure is 1.9×10 5 Pa.

[0053] (3) dealkalization: the ramie fiber after soaking in alkali is put into deionized water and washed three times, each washing 10min;

[0054] (4) Alkali neutralization: soak the ramie fiber after dealkalization in 2-3.5g / L dilute sulfuric acid solution to neutralize the excess alkali, then rinse with deionized water to remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com