Wash-free high color fastness pad dyeing process of heavy polyester blanket

A technology with high color fastness and no water washing, applied in the field of printing and dyeing technology, can solve the problems of destroying the original style of the blanket, and achieve the effect of short-process dyeing, high color fastness, color fastness and color brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

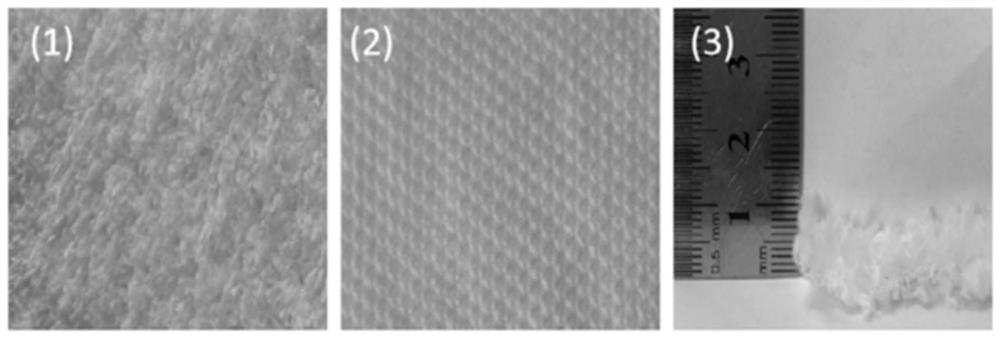

[0039] The no-wash high color fastness pad dyeing process of heavy polyester blanket fabric includes the following steps:

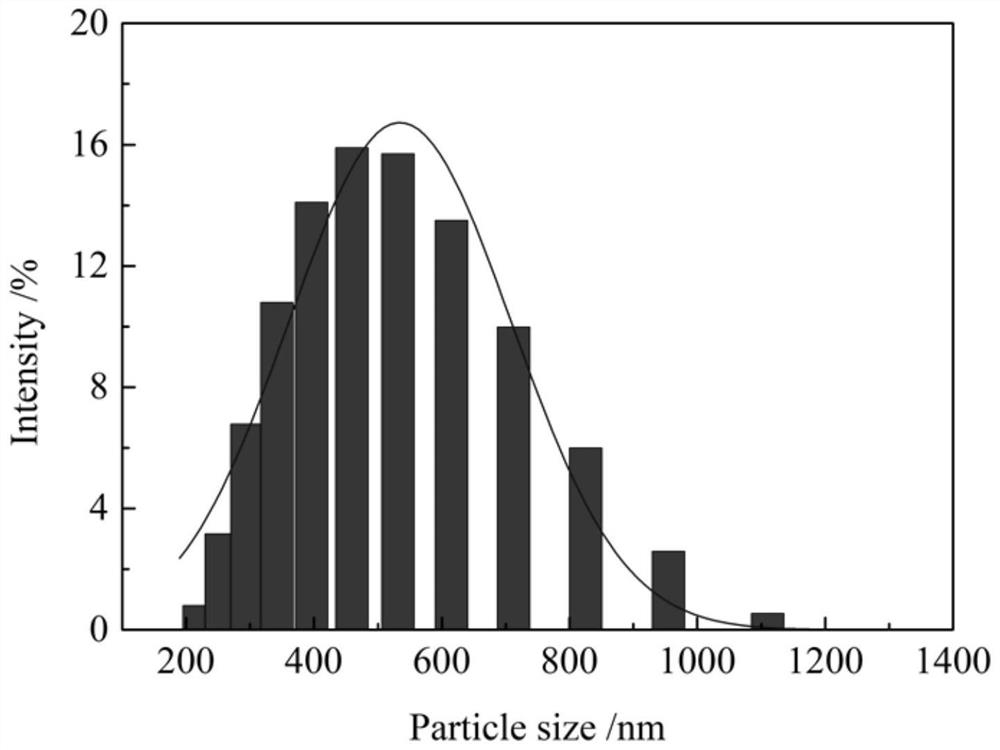

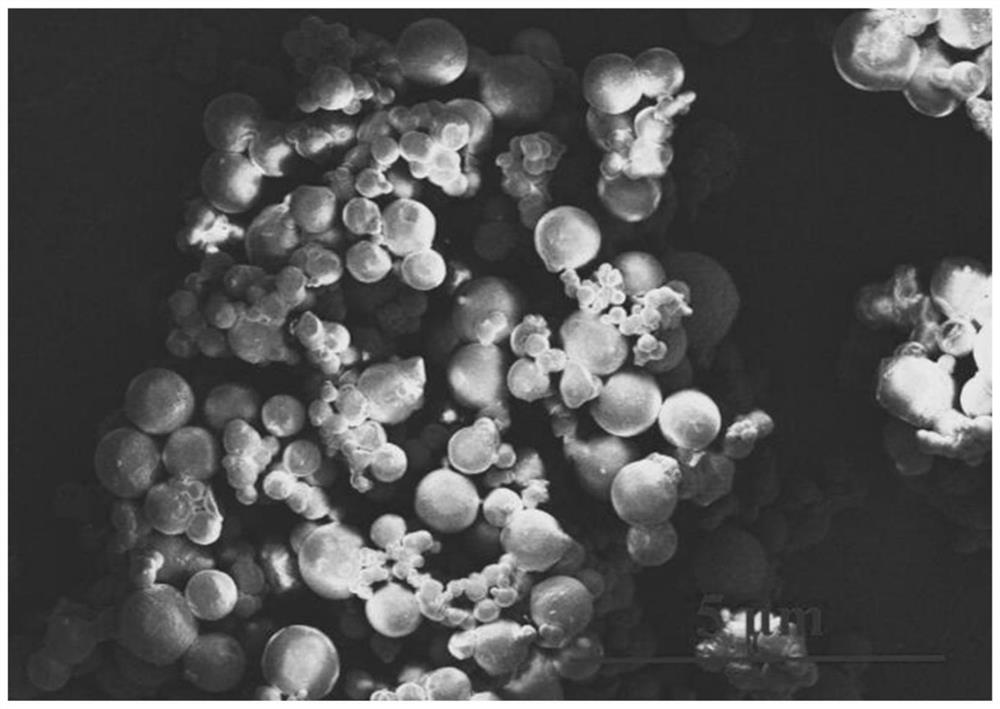

[0040]1) Preparation of microcapsule-like liquid dyes: put 100g of dry powder disperse dye (red 4RL) filter cake in a ball mill, grind it to fine powder for 20min at a high speed of 1200r / min, add 6g of dispersant NNO and continue to follow The above-mentioned speed was ball-milled for 10min, then controlled at a feeding speed of 30g / min, and then added polybutene powder 10g and glycerin 3g, continued to be ball-milled at the above-mentioned speed for 30min, added ultrapure water to the ball-milled powder, under ultrasonic 300W, 2*10 4 Under the condition of HZ ultrasonic for 30 minutes, the microcapsule-like liquid dye with a concentration of 50% by mass was prepared.

[0041] The liquid dye prepared by the above method is a microcapsule-like type, and the particle size distribution is between 300-820 nm. The particle size distribution is figure 2 As...

Embodiment 2

[0048] Except that the concentration of the penetrant in the dyeing paste is different, others are the same as in Example 1. Change the penetrant concentration to be 0, 0.3, 0.5g / L respectively, carry out pad dyeing to polyester blanket cloth according to the same pad dyeing process as Example 1, complete blanket cloth dyeing; The side with fluffy and full hand) was tested for color index, and its color fastness was evaluated. The results are shown in Table 1.

[0049] Table 1 Dyeing properties of blankets with different concentrations of penetrant

[0050]

[0051] It can be seen from Table 2 that the amount of penetrant has a significant effect on the levelness of color paste-dyed polyester blankets, and with the increase of the amount of penetrant, the levelness gradually improves. When the amount of penetrant is 0.1g / L (Example 1), the levelness reaches the best; however, as the amount of the penetrant increases, the levelness gradually deteriorates. This is mainly be...

Embodiment 3

[0063] Except for the dyeing and baking temperature, the rest are the same as in Example 1, and the baking and color development temperature is changed to 170°C respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com