A kind of enzyme-dyed lyocell fiber fabric and preparation method thereof

A fabric and fiber technology, applied in the field of lyocell fiber, can solve the problems of less technology, high dyeing cost, limited source of raw materials, etc., to achieve good skin-friendly performance and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

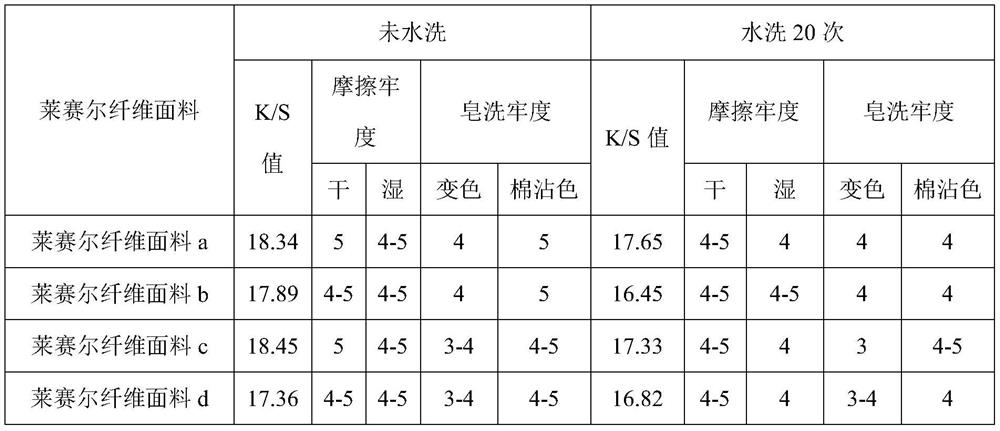

Embodiment 1

[0024] In this embodiment, an enzyme-dyed lyocell fiber fabric is prepared by the following method, including the following steps:

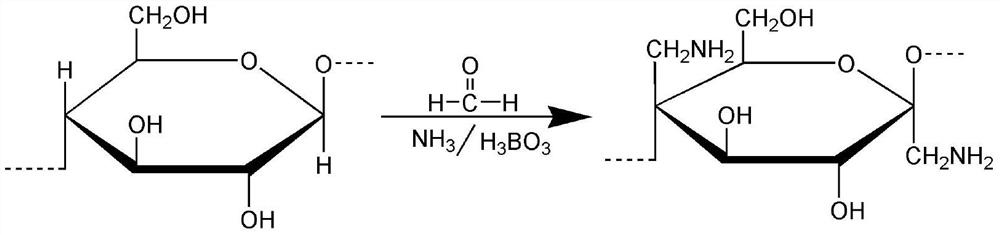

[0025] (1) Ammonification modification: prepare a mixed solution, immerse 100g lyocell fiber fabric into 1000mL mixed solution, immersion time is 3.5 hours, immersion temperature is 55°C, stir the reaction solution system every 30 minutes after immersion; after the reaction , washed with water, and dried; the preparation method of the mixed solution is as follows: 1000mL concentration of 10% formaldehyde solution, 100mL concentration of 4% ammonia solution and 15g of boric acid are mixed and stirred evenly.

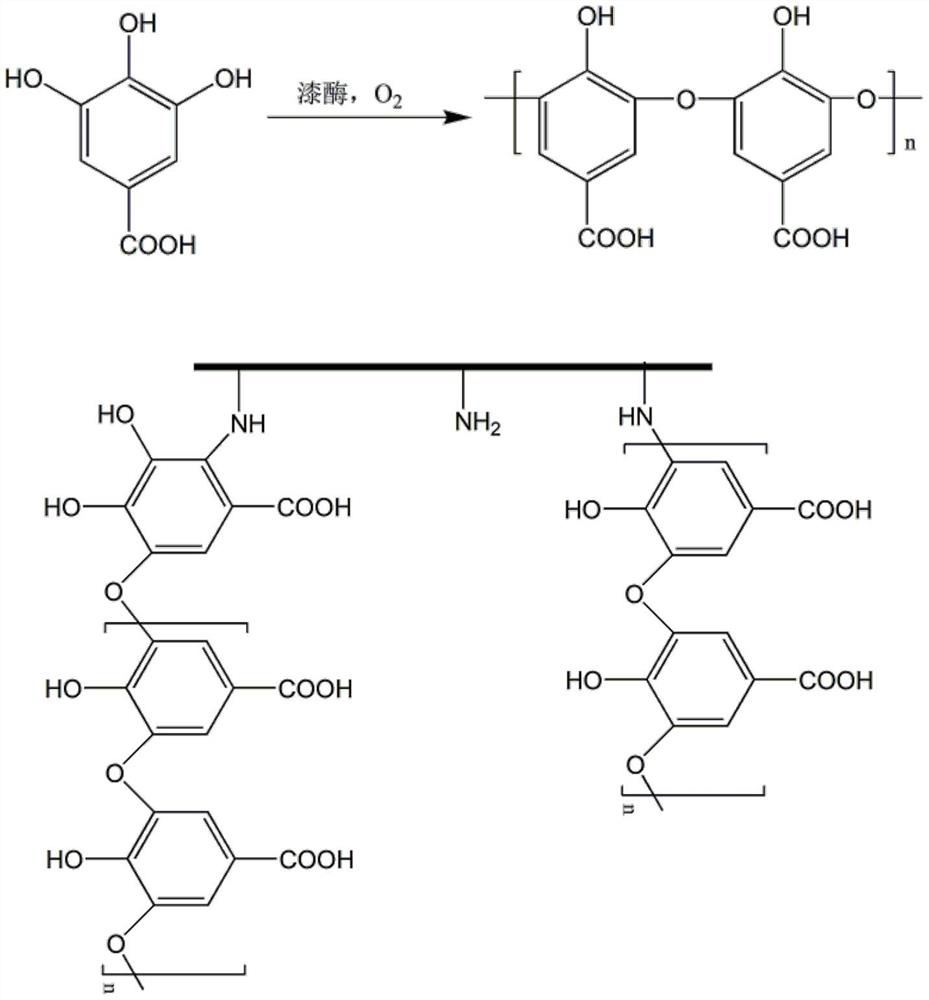

[0026] (2) Enzyme dyeing: 100g of lyocell fabric treated in step (1) is immersed in 1000mL of aqueous solution of laccase and 2,3,4-trihydroxybenzoic acid for cultivation, laccase and 2,3,4 - The concentrations of trihydroxybenzoic acid are: 25mg / L and 150mg / L respectively; the cultivation time is 6.5 hours, and the cultivation temperature i...

Embodiment 2

[0028] In this embodiment, an enzyme-dyed lyocell fiber fabric is prepared by the following method, including the following steps:

[0029] (1) Ammonification modification: prepare a mixed solution, immerse 100g lyocell fiber fabric into 800mL mixed solution, immerse for 3 hours, immerse in a temperature of 50°C, stir the reaction solution system every 30 minutes after immersion; after the reaction , washed with water, and dried; the preparation method of the mixed solution is as follows: 1000 mL of 8% formaldehyde solution, 100 mL of 3% ammonia solution and 20 g of boric acid are mixed and stirred evenly.

[0030] (2) Enzyme dyeing: immerse 100g of lyocell fabric treated in step (1) into 800mL aqueous solution of laccase and p-diphenol for cultivation, the concentrations of laccase and p-diphenol are respectively: 20mg / L, 100mg / L; the cultivation time is 5 hours, and the cultivation temperature is 20°C; after the cultivation, the lyocell fiber fabric is washed with clear wate...

Embodiment 3

[0032] In this embodiment, an enzyme-dyed lyocell fiber fabric is prepared by the following method, including the following steps:

[0033] (1) Ammonification modification: prepare a mixed solution, immerse 100g lyocell fiber fabric into 1200mL mixed solution, immerse for 4 hours, immerse in a temperature of 60°C, stir the reaction solution system every 30 minutes after immersion; after the reaction , washed with water, and dried; the preparation method of the mixed solution is as follows: 1500 mL of 10% formaldehyde solution, 150 mL of 4% ammonia solution and 20 g of boric acid are mixed and stirred evenly.

[0034] (2) Enzyme dyeing: 100g of lyocell fiber fabric treated in step (1) was immersed in 1200mL aqueous solution of laccase and 3-amino-4-hydroxybenzenesulfonic acid for cultivation, laccase and 3-amino-4 The concentrations of -hydroxybenzenesulfonic acid are: 30mg / L and 200mg / L respectively; the cultivation time is 8 hours, and the cultivation temperature is 25°C; aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com