Purple lyocell fabric dyed by animal dye lac and preparation method of purple lyocell fabric

A technology of animal dyes and lac insects, applied in dyeing, textiles and papermaking, etc., to achieve the effects of less environmental pollution, mild dyeing conditions, and large resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

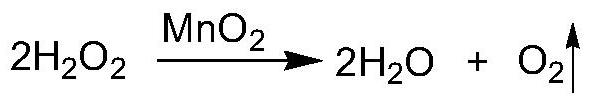

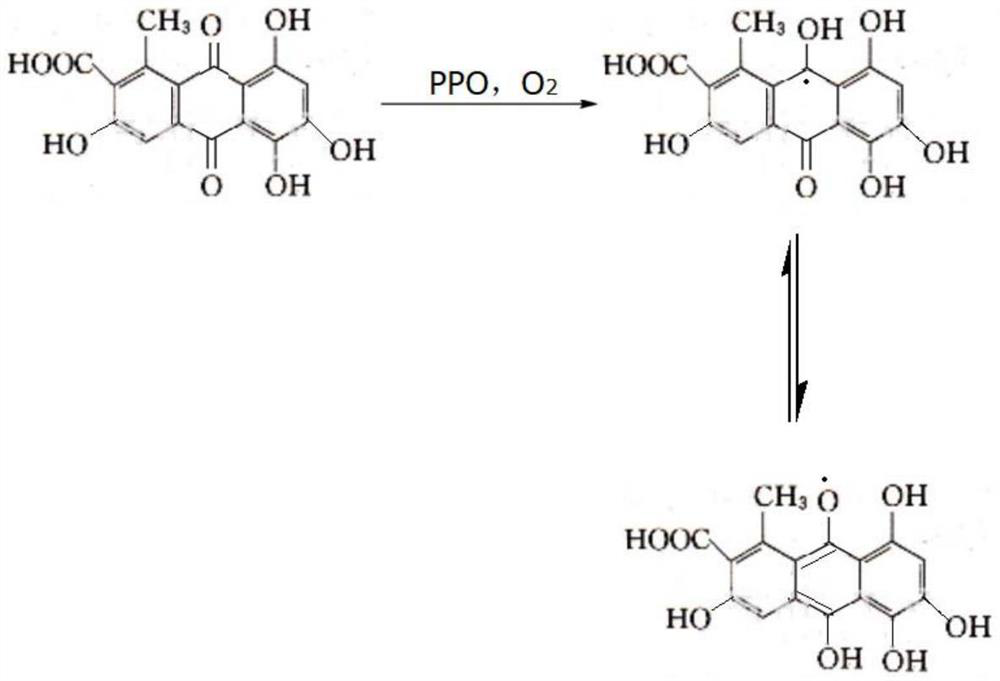

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of the purple lyocell fabric obtained by dyeing the animal dye lac insect, the specific method comprises the following steps:

[0037] (1) Extraction of pigment: Grind lac worms with water, and the ratio of material to liquid is 1:3 (g / mL); then extract twice with 7 times of water, centrifuge the extract to remove slag, add to the extract A mixed solution of 0.2mol / L sodium hydroxide and 0.2mol / L calcium chloride, the amount of the mixed solution is 5% of the amount of the extract, add 3wt% hydrochloric acid to adjust the pH value to 2.5, stand for 3.5h, and filter to collect the filtrate; Add 10wt% sulfuric acid to the filtrate until no more pigment crystals are precipitated, then filter with filter paper. After the filtrate is allowed to stand for 2.5 d, the pigment crystals are precipitated, filtered and washed with water for 3 times, and dried at 55°C to obtain the lac worm purple pigment.

[0038] (2) Preparation of enzyme solution: Preparation...

Embodiment 2

[0043] The preparation method of the purple lyocell fabric obtained by dyeing the animal dye lac insect, the specific method comprises the following steps:

[0044] (1) Extraction of pigment: Grind lac worms with water, and the ratio of material to liquid is 1:2 (g / mL); then extract twice with 5 times of water, centrifuge the extract to remove slag, add to the extract A mixed solution of 0.1mol / L sodium hydroxide and 0.1mol / L calcium chloride, the amount of the mixed solution is 4% of the amount of the extract, add 3wt% hydrochloric acid to adjust the pH value to 2.0, stand for 3h, filter and collect the filtrate; Add 10wt% sulfuric acid until no more pigment crystals are precipitated, filter with filter paper, and precipitate the pigment crystals after the filtrate is allowed to stand for 2 d, filter and wash with water for 3 times, and dry at 50°C to obtain lac worm purple pigment.

[0045] (2) Preparation of enzyme solution: Preparation of polyphenol oxidase solution: Disso...

Embodiment 3

[0050] The preparation method of the purple lyocell fabric obtained by dyeing the animal dye lac insect, the specific method comprises the following steps:

[0051] (1) Extraction of pigment: Grind lac worms with water, and the ratio of material to liquid is 1:4 (g / mL); then extract twice with 10 times of water, centrifuge the extract to remove slag, add to the extract A mixed solution of 0.3mol / L sodium hydroxide and 0.3mol / L calcium chloride, the amount of the mixed solution is 6% of the amount of the extract, add 3wt% hydrochloric acid to adjust the pH value to 3.0, stand for 4h, filter and collect the filtrate; Add 10wt% sulfuric acid until no more pigment crystals are precipitated, filter with filter paper, after the filtrate is allowed to stand for 3 days, the pigment crystals are precipitated, filter and wash with water for 3 times, and dry at 60 ° C to obtain the purple pigment of lac worms.

[0052] (2) Preparation of enzyme solution: Preparation of polyphenol oxidase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com