Fiber oxidase composition for changing and improving fiber property, and papermaking method and application

A fiber oxidase and composition technology, which is applied in the directions of oxidoreductase, textiles and papermaking, biochemical equipment and methods, etc., can solve the problems of reducing fiber yield, increasing paper density, increasing product quantification, etc., and improving water filtration. performance, reducing freeness, and reducing the effect of beating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Example 1 Effects of Fiber Oxidase and Oxidase Combined Treatment on Mechanical Hardwood Pulp on Paper Strength

[0082] 1. Purpose of the experiment

[0083] The effect of fiber oxidase composition on mechanical hardwood pulp on its paper strength was evaluated by comparative analysis.

[0084] 2. Experimental method

[0085] (1) Test material preparation

[0086] The mechanical hardwood pulp mentioned in this experiment was provided by the pulp mill of Shandong Wanguo Paper Co., Ltd. No. 26 machine.

[0087] Fiber oxidase (PMO) is GH61 provided by Dyadic Company of the United States. This enzyme is produced from the strain Myceliophthora thermophila. Its amino acid sequence is described in detail in US Patent No. 8,298,795 and US Patent Application USA2012 / 0083019.

[0088] Laccase and cellobiose dehydrogenase are commercial products of Genencor, a DuPont group.

[0089] (2) Papermaking method

[0090] A, pulping: 200 grams of pulp plates and 1300 grams of deioni...

Embodiment 2

[0108] Example 2 Effects of Fiber Oxidase and Laccase Combined Treatment on Recycled OCC Pulp on Paper Strength

[0109] 1. Purpose of the experiment

[0110] The effect of fiber oxidase composition on OCC pulp on its paper strength was evaluated by comparative analysis.

[0111] 2. Experimental method

[0112] (1) Test material preparation

[0113] Recycled OCC waste paper pulp is obtained from the fine pulp tank of the multi-disk thickener of Guangdong Tomorrow Paper Industry, with a pulp concentration of 4.8-5%;

[0114] Fiber oxidase (PMO) is GH61 provided by Dyadic Company of the United States. This enzyme is produced from the strain Myceliophthora thermophila. Its amino acid sequence is described in detail in US Patent US8,298,795 and US Patent Application USA2012 / 0083019;

[0115] Laccase is a commercial product of Genencor, a subsidiary of DuPont Group.

[0116] (2) Papermaking method

[0117] A. Response:

[0118] (1) Take 400 grams of the prepared slurry above,...

Embodiment 3

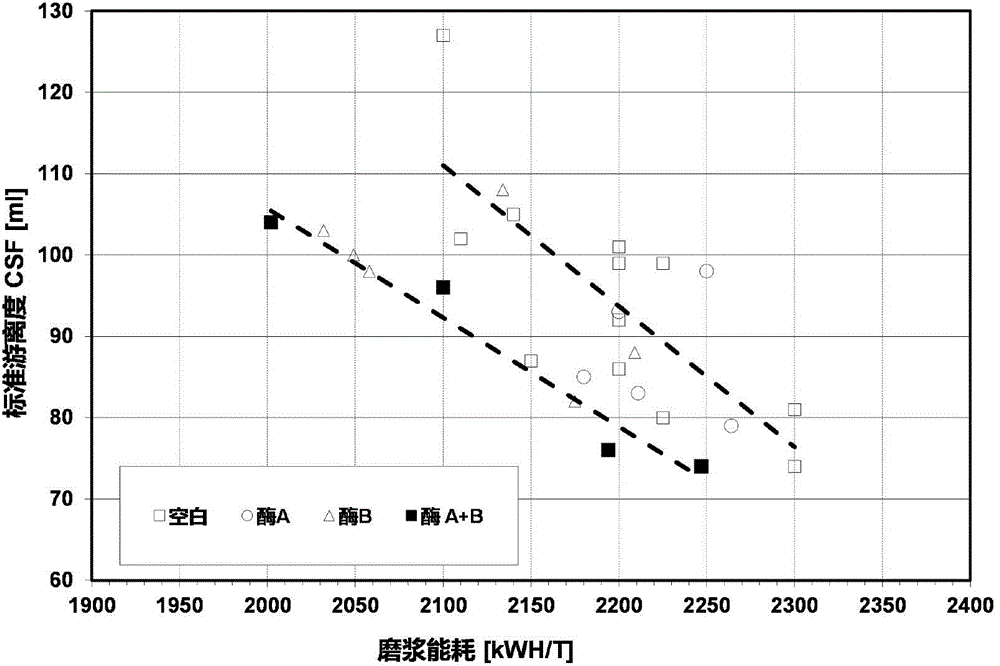

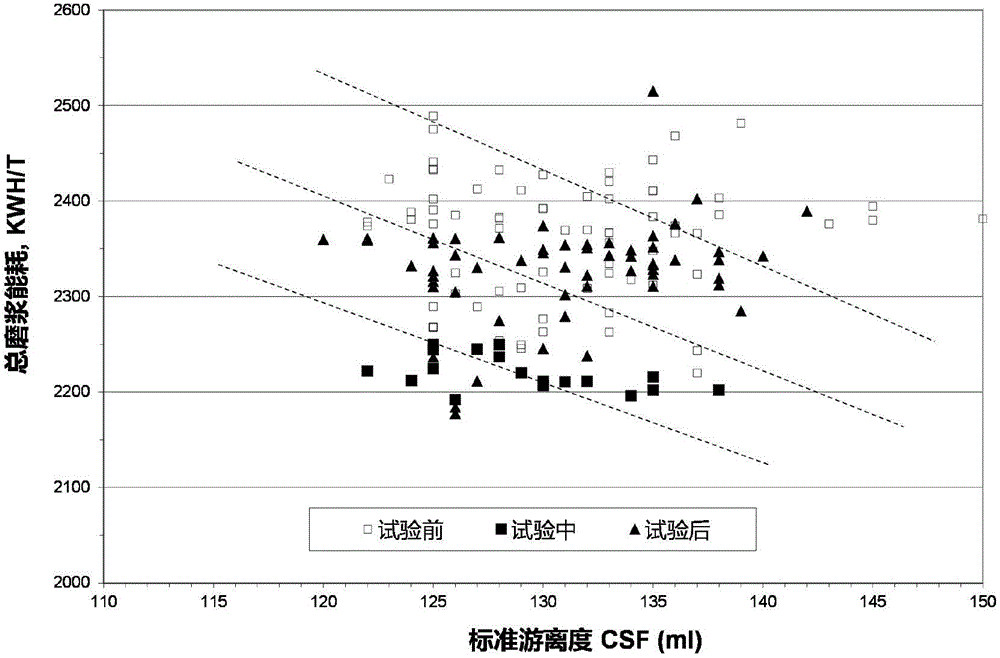

[0132] Example 3 Effect of Fiber Oxidase and Its Different Compositions Treating Wood Chips on Energy Consumption of Pulping

[0133] 1. Purpose of the experiment

[0134] The effects of fiber oxidase and its different compositions on the energy consumption of pulping were evaluated by comparative analysis.

[0135] 2. Experimental method

[0136] (1) Test material

[0137] Fiber oxidase (PMO) is produced from the strain Myceliophthora thermophila, and its amino acid sequence is described in detail in US Patent No. 8,298,795 and US Patent Application USA2012 / 0083019.

[0138] The cellulolytic enzyme is the commercial product FiberZymeG200 of Dyadic Company.

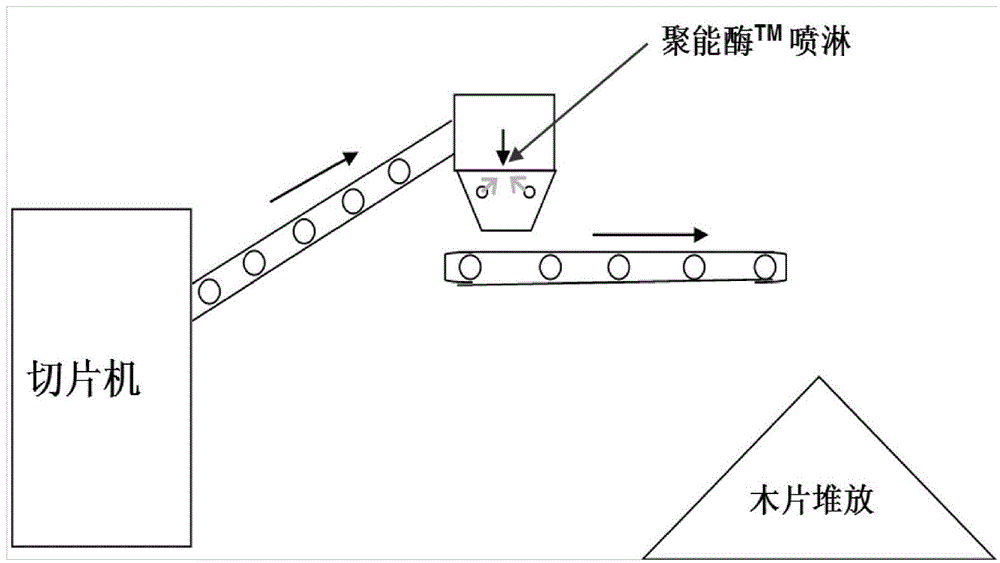

[0139] (2) Pulping wood chip preparation: A paper mill uses southern pine wood to make TMP. The wood is debarked, cut into wood chips by a slicer, and enters the wood chip storage warehouse or stacking yard.

[0140] (3) Biological enzyme treatment: Before the wood chips enter the storage bin, the biological enzymes o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com