Patents

Literature

37 results about "Myceliophthora thermophila" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Myceliophthora thermophila is an ascomycete fungus that grows optimally at 45–50 °C (113–122 °F). It efficiently degrades cellulose and is of interest in the production of biofuels. The genome has recently been sequenced, revealing the full range of enzymes this organism uses for the degradation of plant cell wall material.

Functional organic material decomposing agent and preparation method thereof

ActiveCN102337237APromote growthSuppression of soil borne diseasesFungiBacteriaDiseaseResource utilization

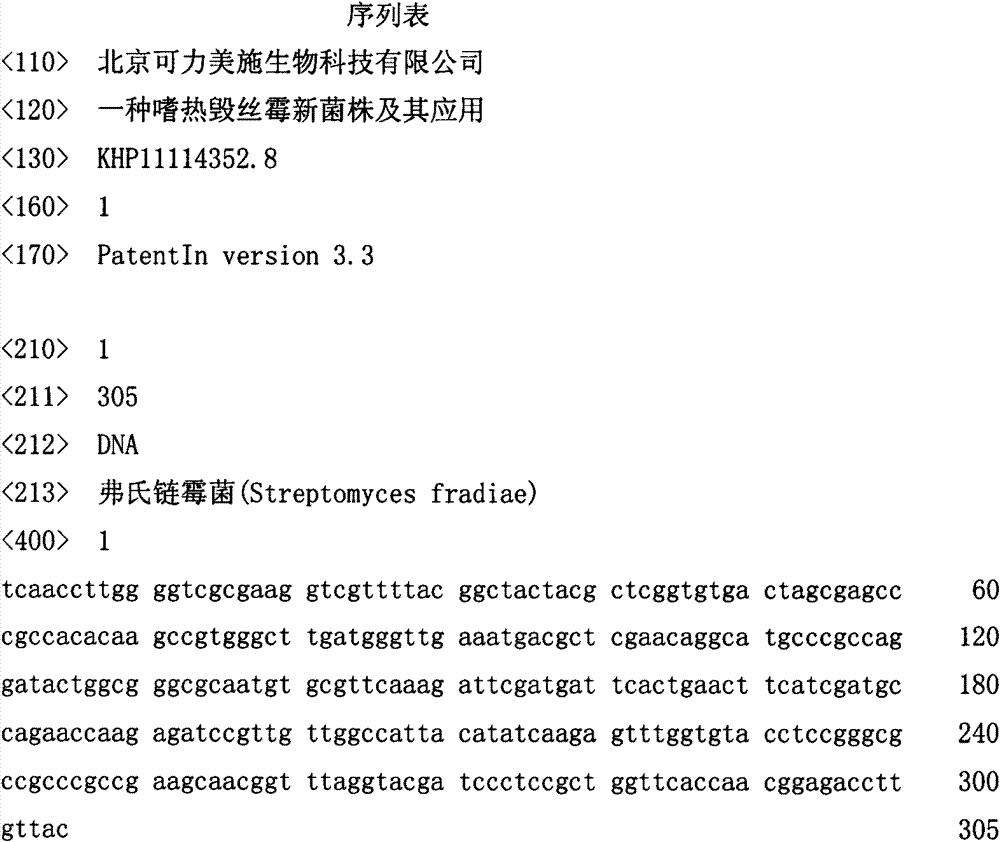

The invention discloses an organic material decomposing agent, which comprises the following components in percentage by weight: 10-50 parts of Streptomyces fradiae CGMCC No.5133 microbial inoculum, 5-20 parts of Myceliophthora thermophila CGMCC No. 5134 microbial inoculum, 0-20 parts of Trichoderma viride microbial inoculum, 0-20 parts of Bacillus subtilis microbial inoculum and 0-20 parts of microzyme inoculum. The invention provides the organic material decomposing agent with auxin accumulation function which utilizes the quick accumulation of auxin generated by the Streptomyces fradiae in the medium temperature stage and the matching of high temperature function of the Myceliophthora thermophila in the anaphase to realize quick treatment and final resource utilization of organic materials, and treated organic solid wastes are fundamentally transformed, embody good performances in improving soil, promoting growth and inhibiting soil-borne diseases and meanwhile are environment-friendly and sanitary.

Owner:廊坊市精耕天下农业科技有限公司

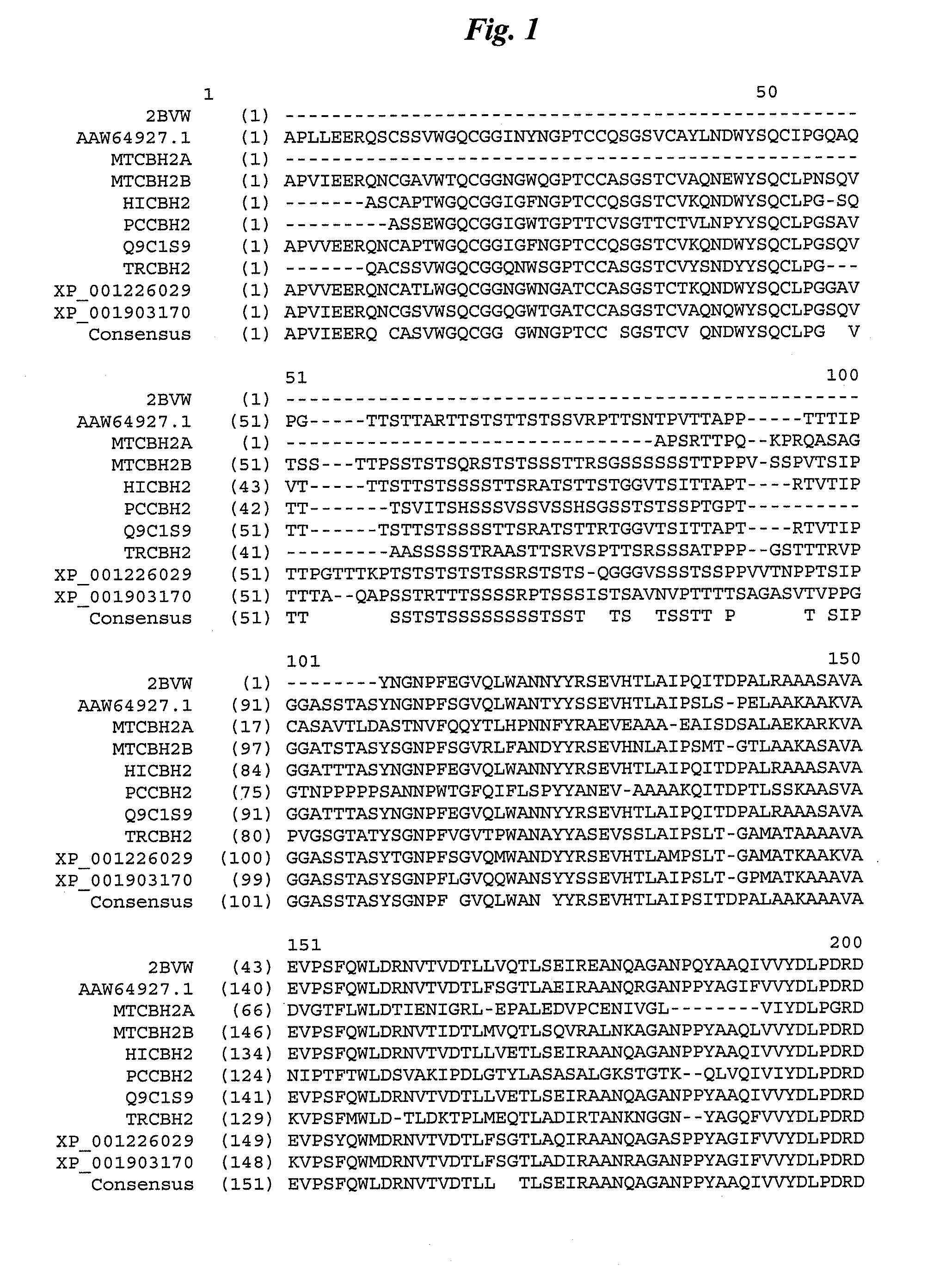

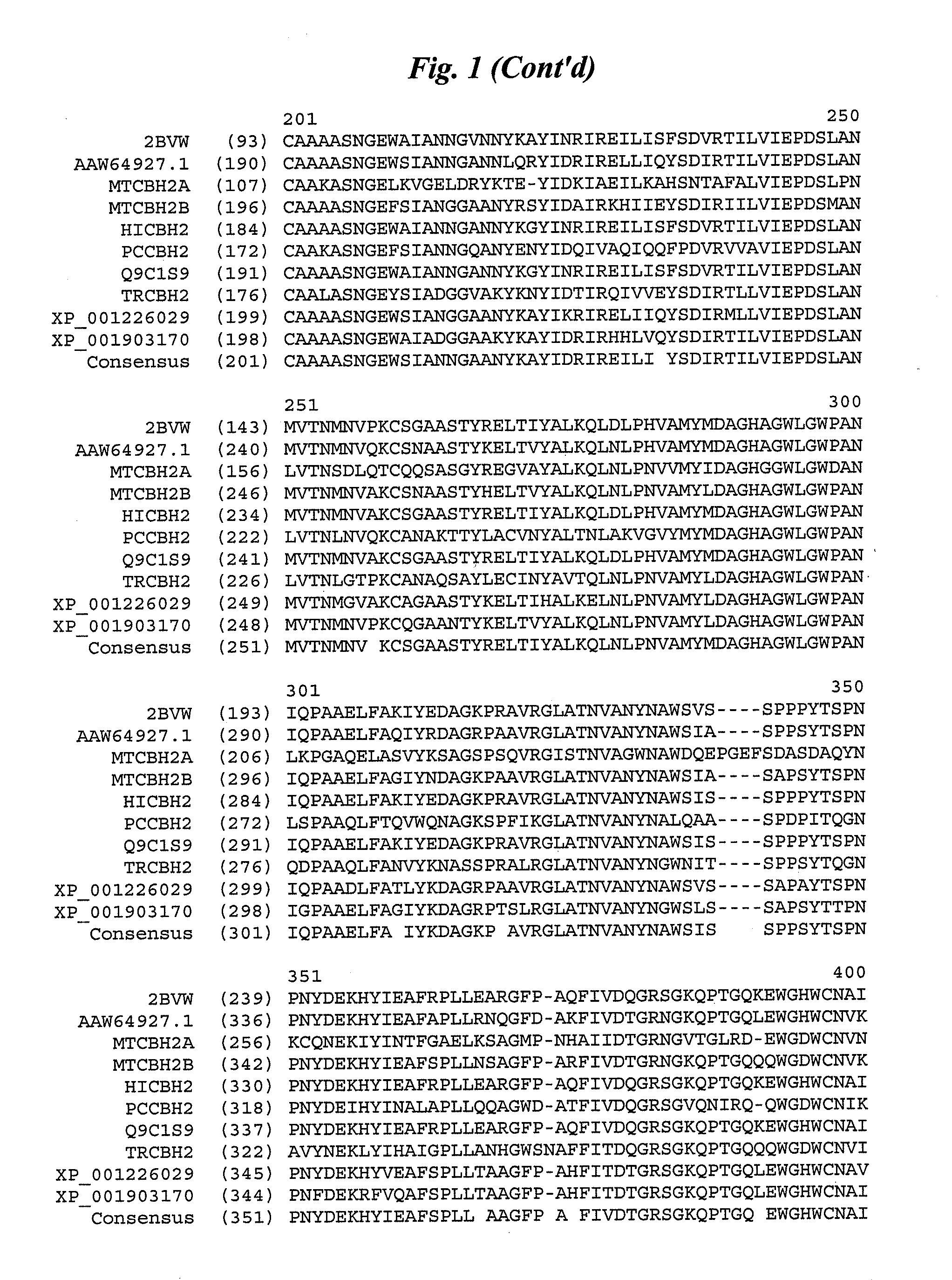

Cellobiohydrolase variants

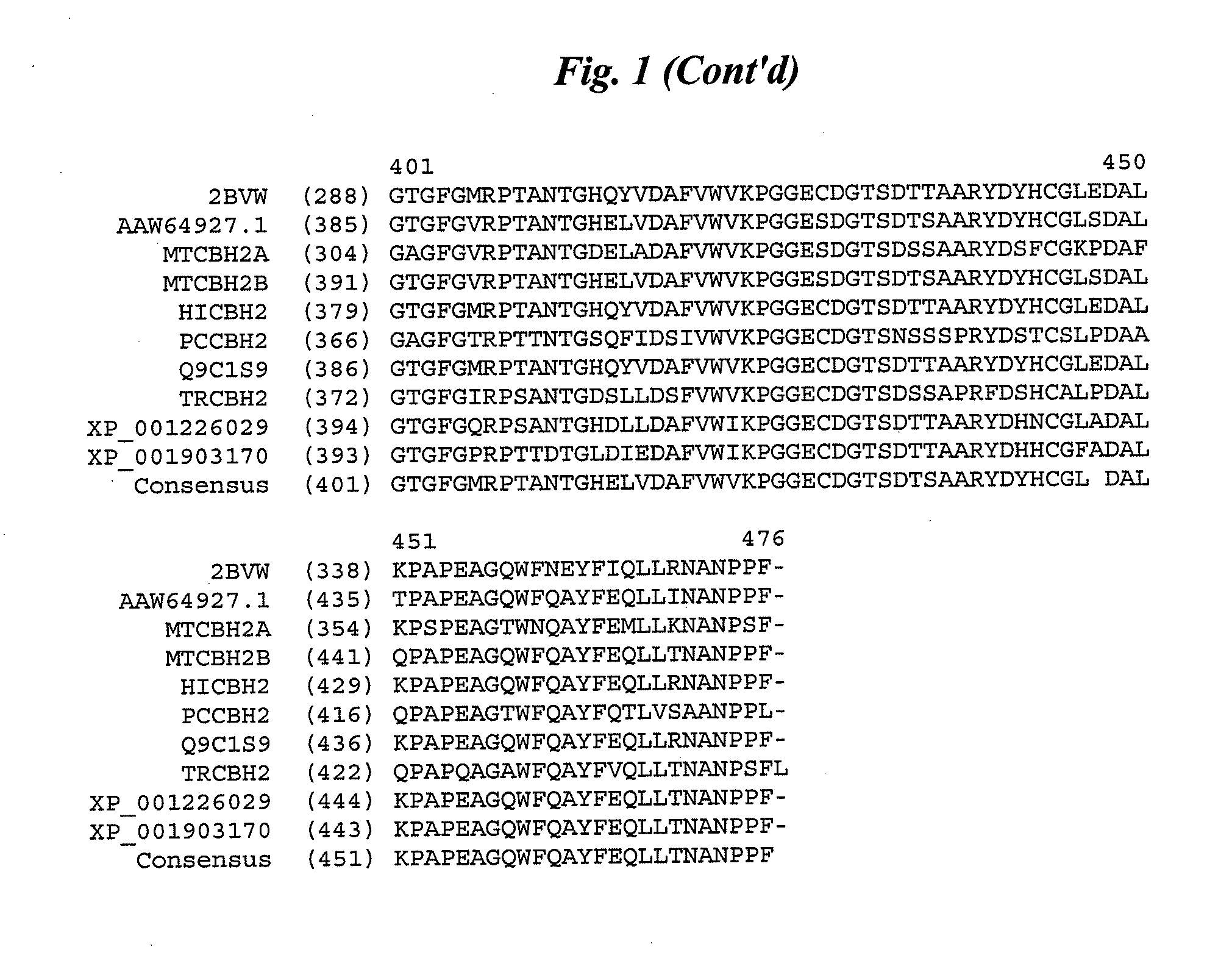

The present invention relates to cellobiohydrolase variants having improved thermostability and / or thermoactivity in comparison to wild-type Myceliophthora thermophila CBH2b.

Owner:SHELL OIL CO

Site-directed mutation modified lytic polysaccharide monooxygenase as well as construction method and application thereof

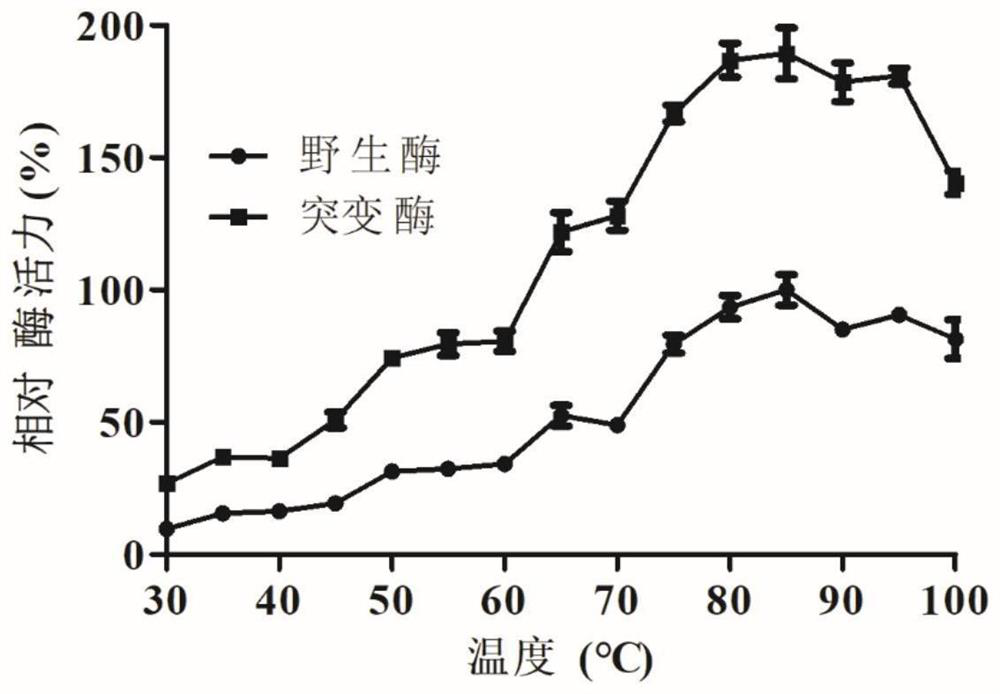

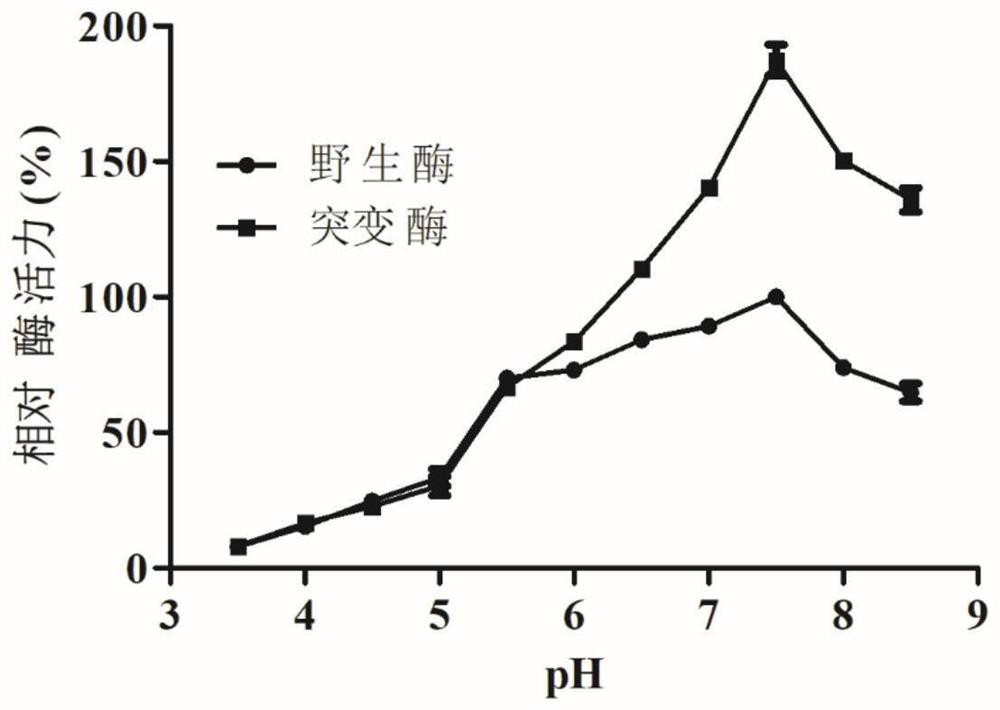

ActiveCN110551699AIncrease enzyme activityIncrease contentFungiMicroorganism based processesWild typeMyceliophthora thermophila

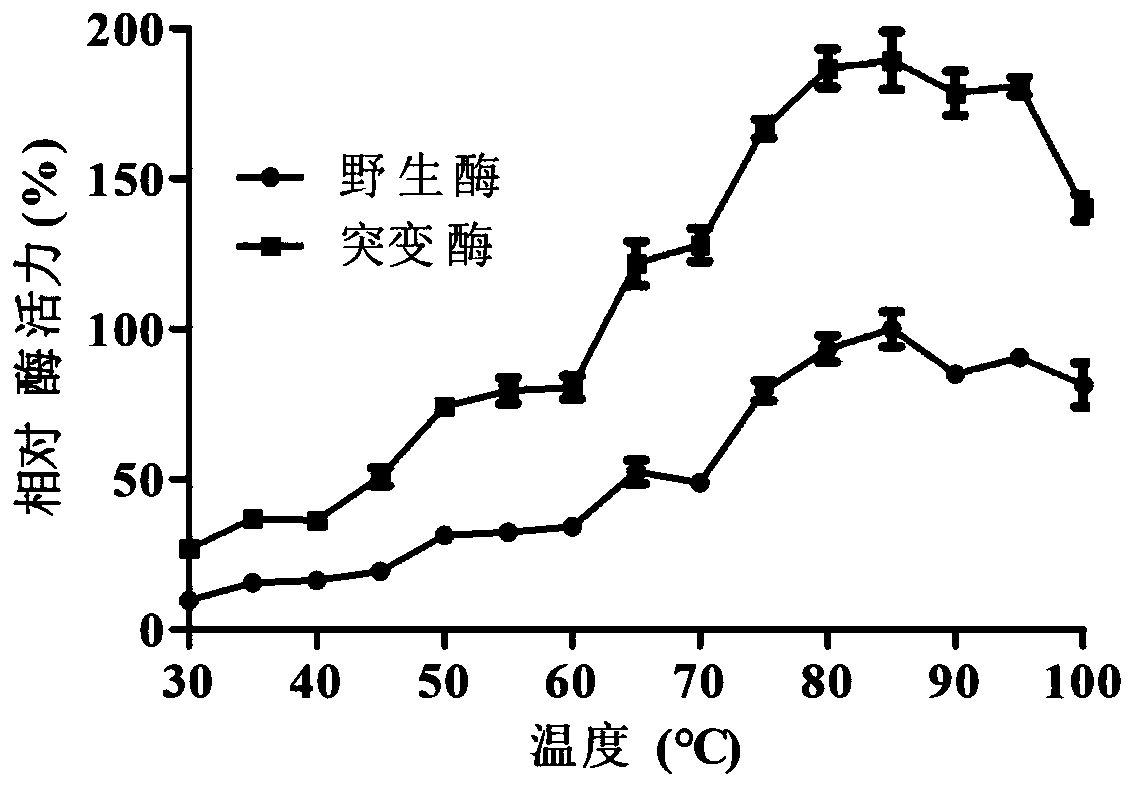

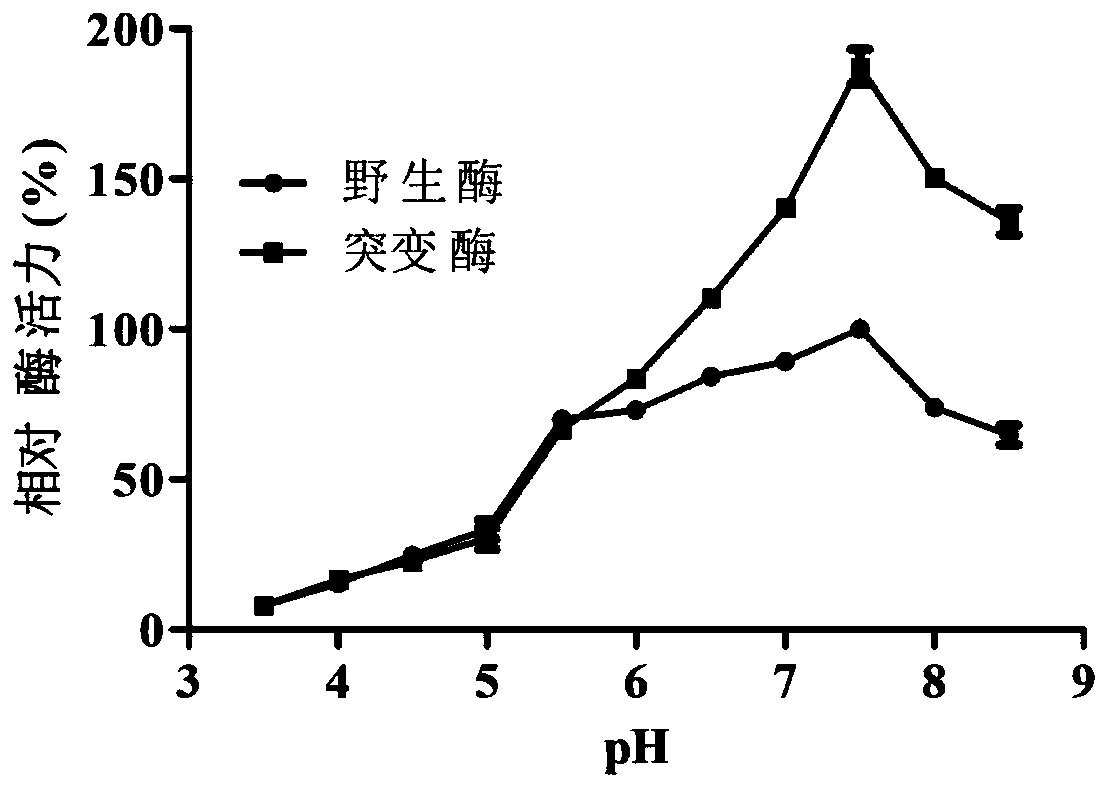

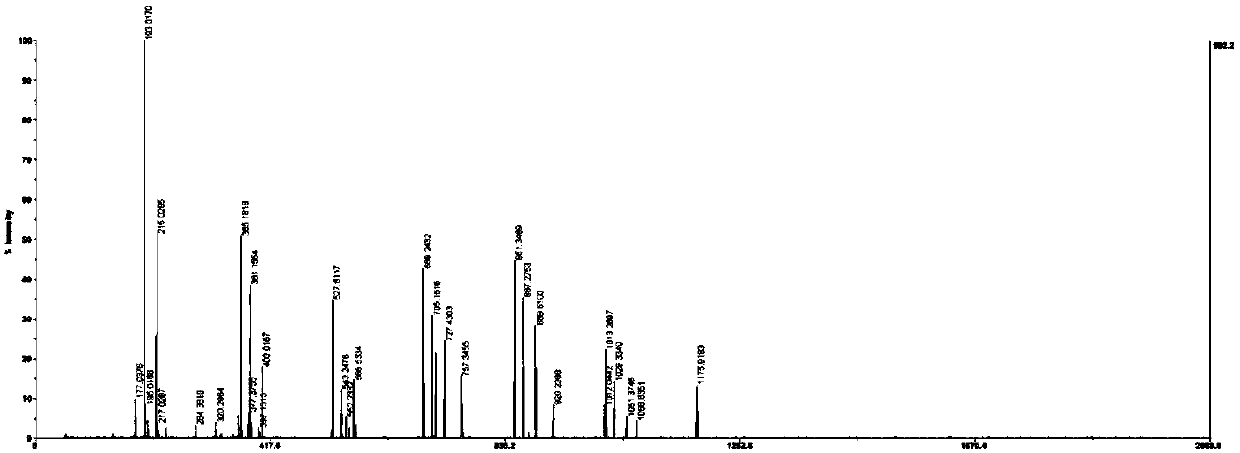

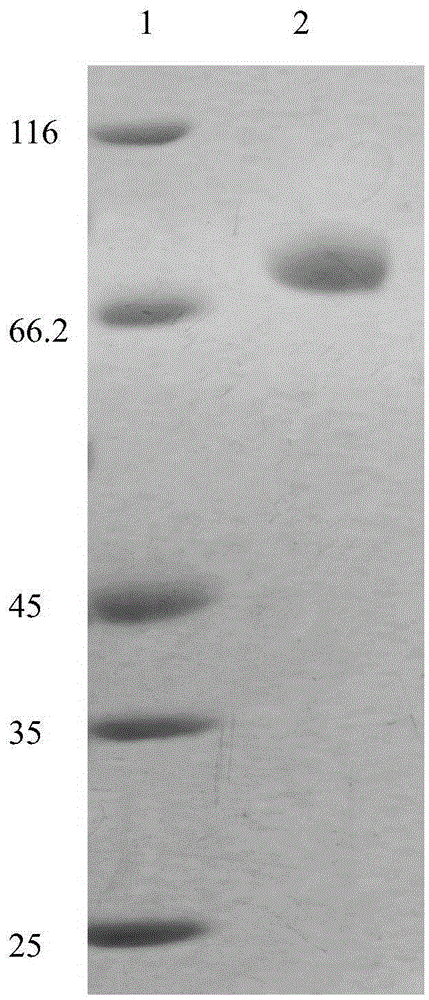

The invention discloses site-directed mutation modified lytic polysaccharide monooxygenase as well as a construction method and application thereof, and belongs to the field of gene engineering. The activity of the site-directed mutation modified lytic polysaccharide monooxygenase provides a degrading function in degradation of crystalline polysaccharide of cellulose. A lytic polysaccharide monooxygenase mutant provided by the invention is formed by mutating Arg into Leu in the 34th site on the basis of the amino acid sequence of lytic polysaccharide monooxygenase of wild type myceliophthora thermophila, wherein the optimum temperature of the mutant enzyme and the wild enzyme is 85 DEG C; the specific activity of the mutant enzyme is significantly increased by about two times compared withthat of the wild enzyme; and when pH is more than 5.5, the specific activity of the mutant enzyme is significantly about two times higher than that of the wild enzyme. When microcrystalline celluloseserves as a substrate, the content of glucose generated through synergistic reaction of cellulase and the mutant enzyme is significantly increased by 48.5 percent compared with that in the method ofdegrading the substrate singly by the celluase, so it is observed that the mutant enzyme significantly improves the enzyme activity and the economic cost of industrial application can be reduced.

Owner:TIANJIN UNIV OF SCI & TECH

Myceliophthora thermophilia strain and application thereof in aspect of producing keratinase

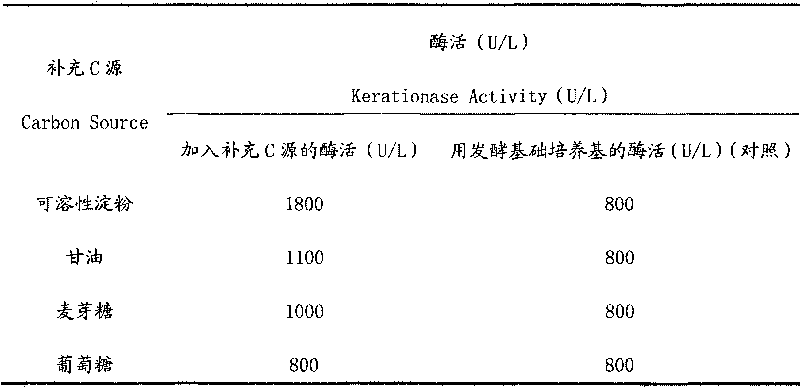

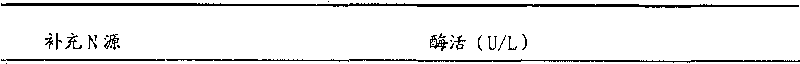

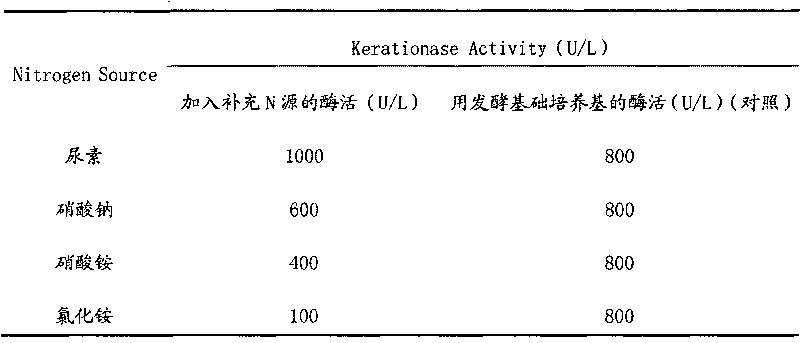

InactiveCN101717727AStrong ability to produce keratinaseGrow fastFungiHydrolasesMyceliophthora thermophilaNitrogen source

The invention discloses Myceliophthora thermophilia strain and an application thereof in the aspect of producing keratinase, the preservation number of Myceliophthora thermophilia strain GZUIFR-H94.1 is CCTCC NO: M 209140. The method for producing keratinase by the Myceliophthora thermophilia strain GZUIFR-H94.1 takes 20.10g / L of chicken feather powder as carbon source, nitrogen source and inductor, takes 0.98g / L of urea as supplement nitrogen source, and takes 5g / L of NaCl, 6g / L of K2HPO4 and 1g / L of KH2PO4 as enzyme-producing culture medium, wherein, the enzyme-producing temperature is 38 DEG C, the initial pH value is 7.9, and the above materials are continuously cultured for 6 days. The strain can grow fast, is thermophilic, and has stronger keratinase producing ability.

Owner:GUIZHOU UNIV

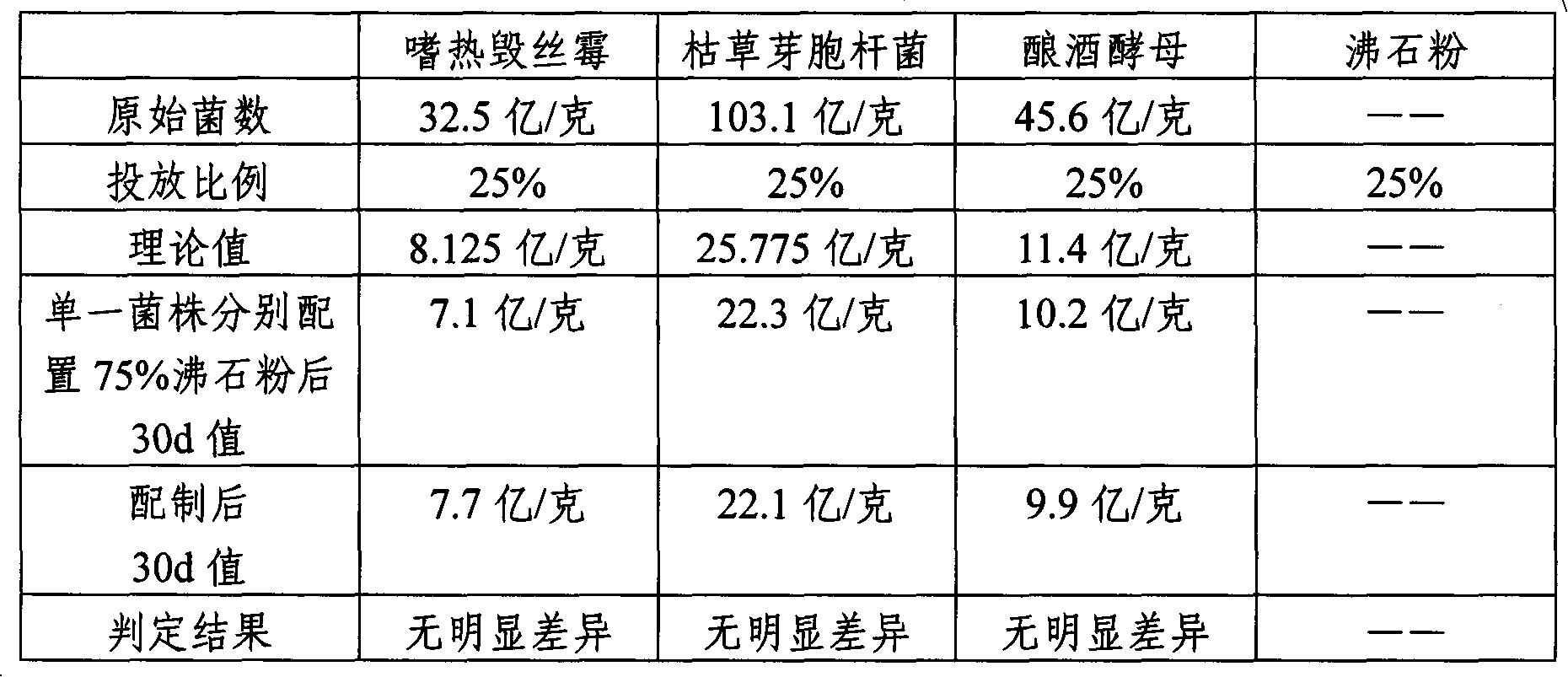

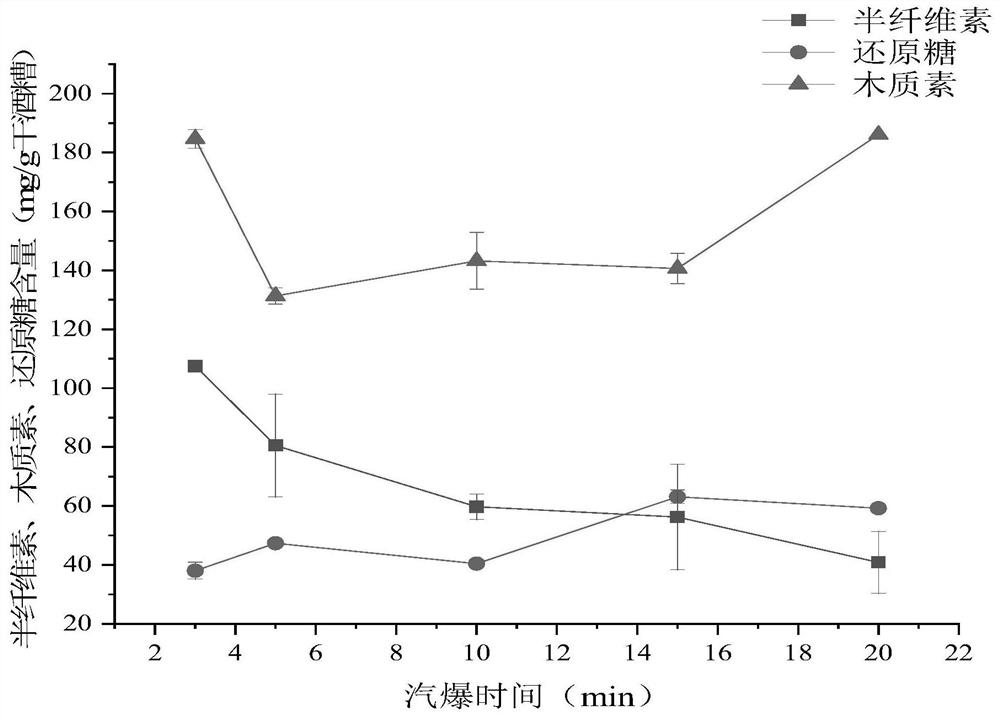

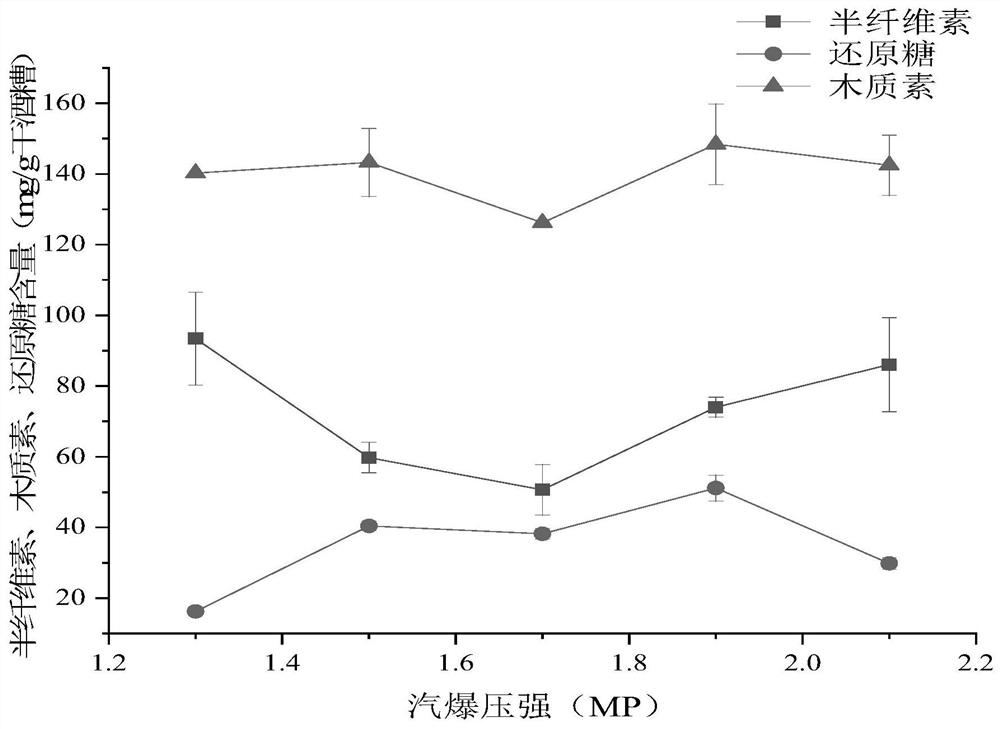

Myceliophthora thermophila as well as solid-state fermentation method and application thereof

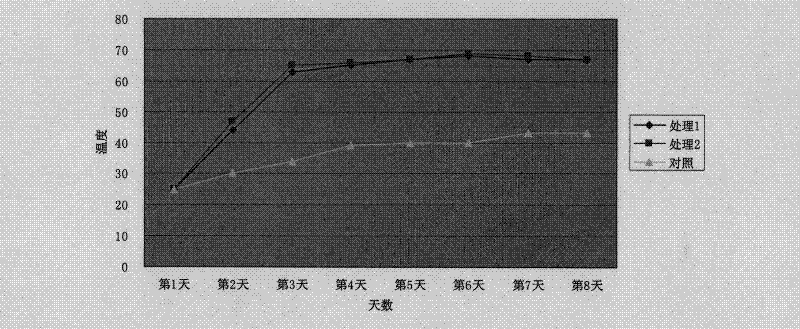

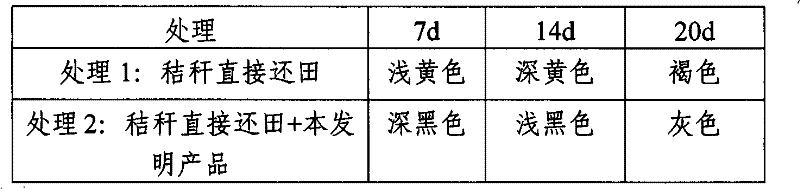

InactiveCN109679856APromote decompositionImprove decomposition rateFungiBacteriaFiberBacillus licheniformis

The invention belongs to the technical field of microorganisms and specifically discloses myceliophthora thermophila as well as a solid-state fermentation method and application thereof. An inventor obtains the myceliophthora thermophila MT1810 (CCTCC (China Center for Type Culture Collection) NO: M2018705) with stable heredity through separating, purifying, carrying out ion beam and cobalt mutagenesis and screening. After a strain is cultured on an optimized fermentation culture medium, the enzyme activity of xylanase can reach 1800 U / g or more and the viable count is greater than 20*10<8> CFU / g. The strain, aspergillus niger, trichoderma reesei, bacillus subtilis, bacillus licheniformis and saccharomyces cerevisiae are compounded according to a certain ratio to prepare a fiber material composting bacterium agent; and when the fiber material composting bacterium agent is used in a corn straw composting experiment, the composting time can be shortened and the content of humus is improved. When the composting bacterium agent is used in a composting process of fiber materials, the composting effect can be enhanced; the quality of products is improved; and the composting bacterium agent has a wide application prospect.

Owner:湖北新保得生物科技有限公司

Expression of Recombinant Beta-Xylosidase Enzymes

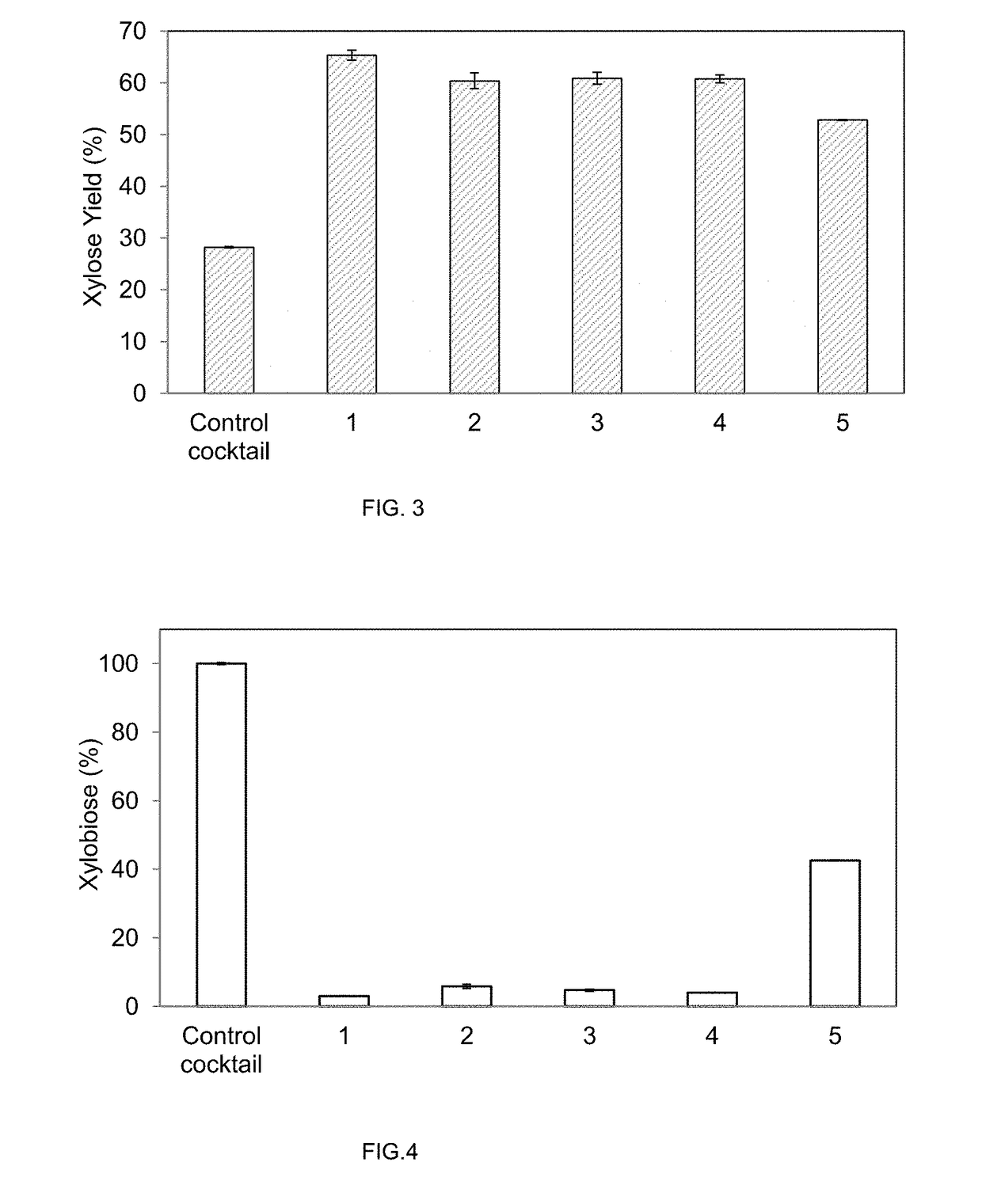

InactiveUS20160272956A1Improve hydrolysis efficiencyIncrease productionBiofuelsFermentationBioproductsMyceliophthora thermophila

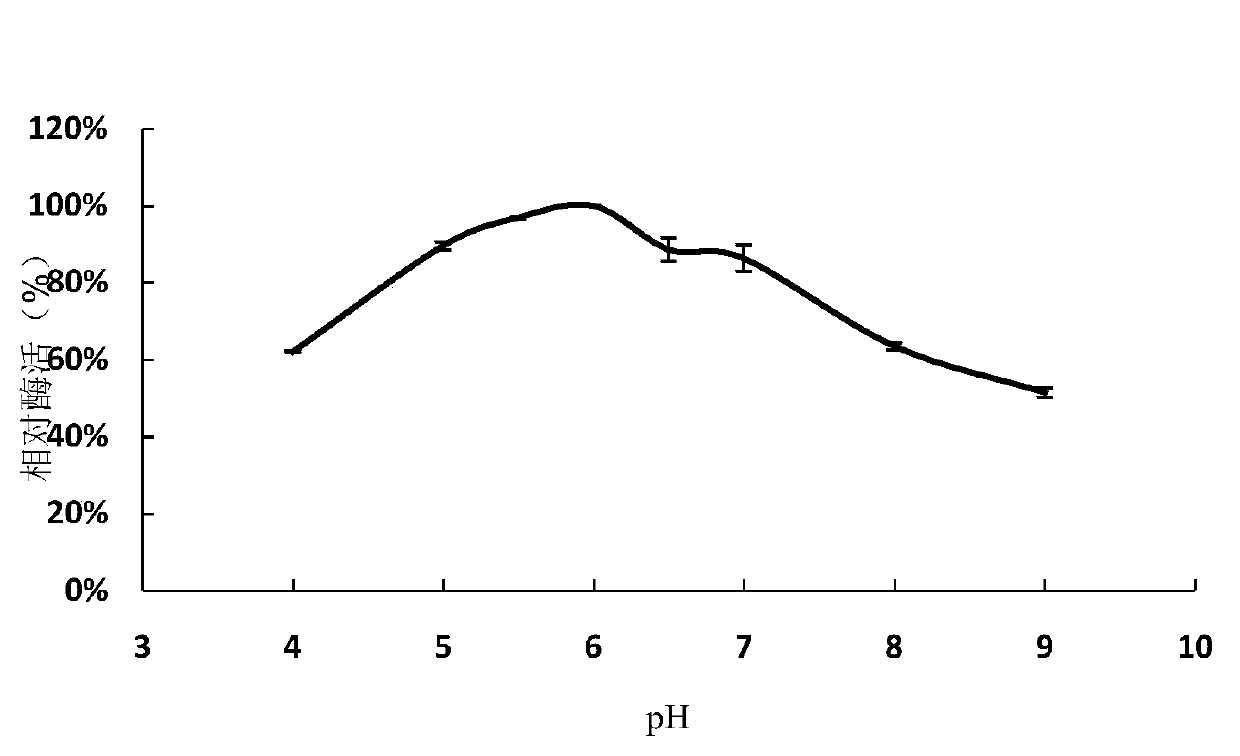

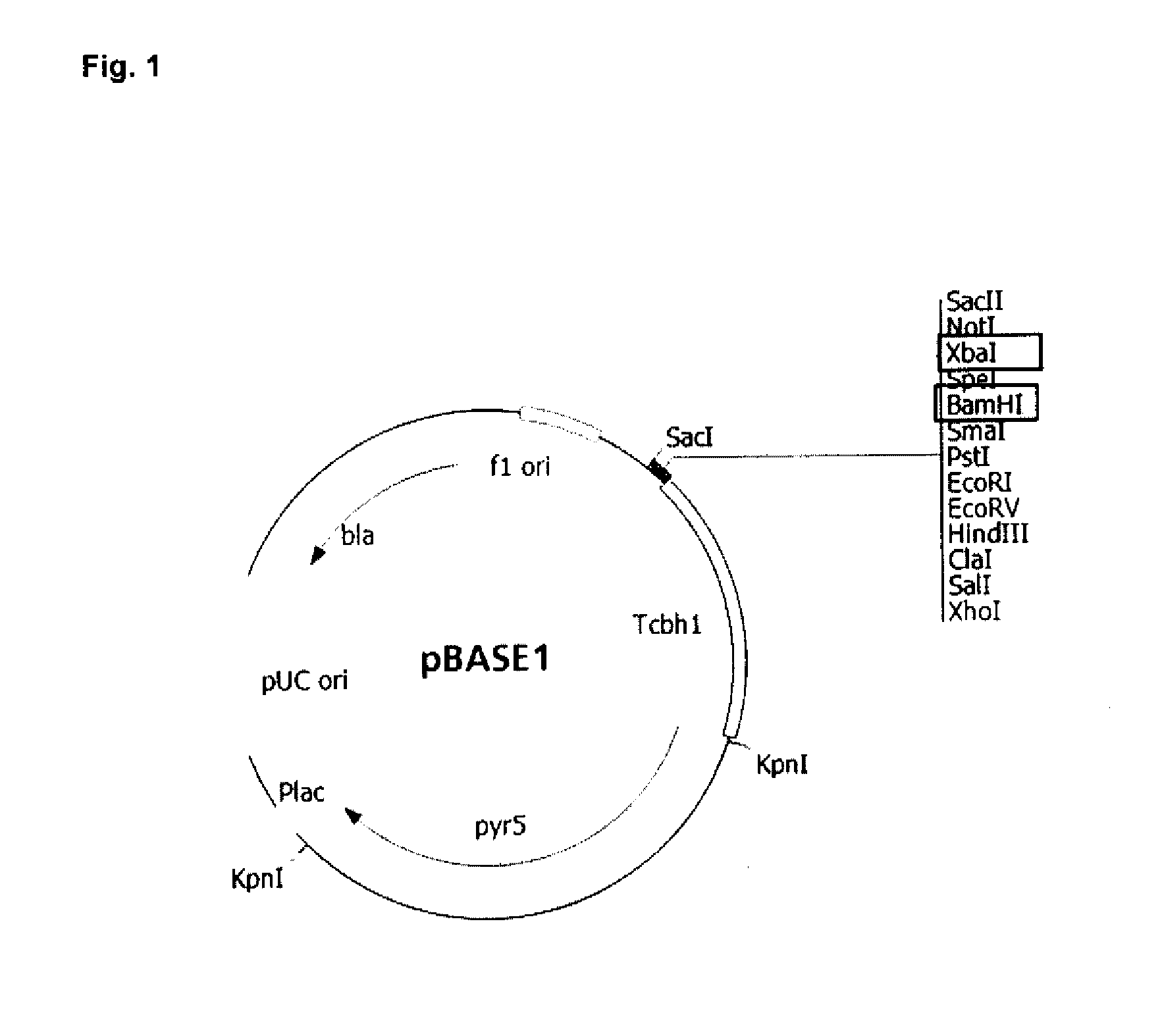

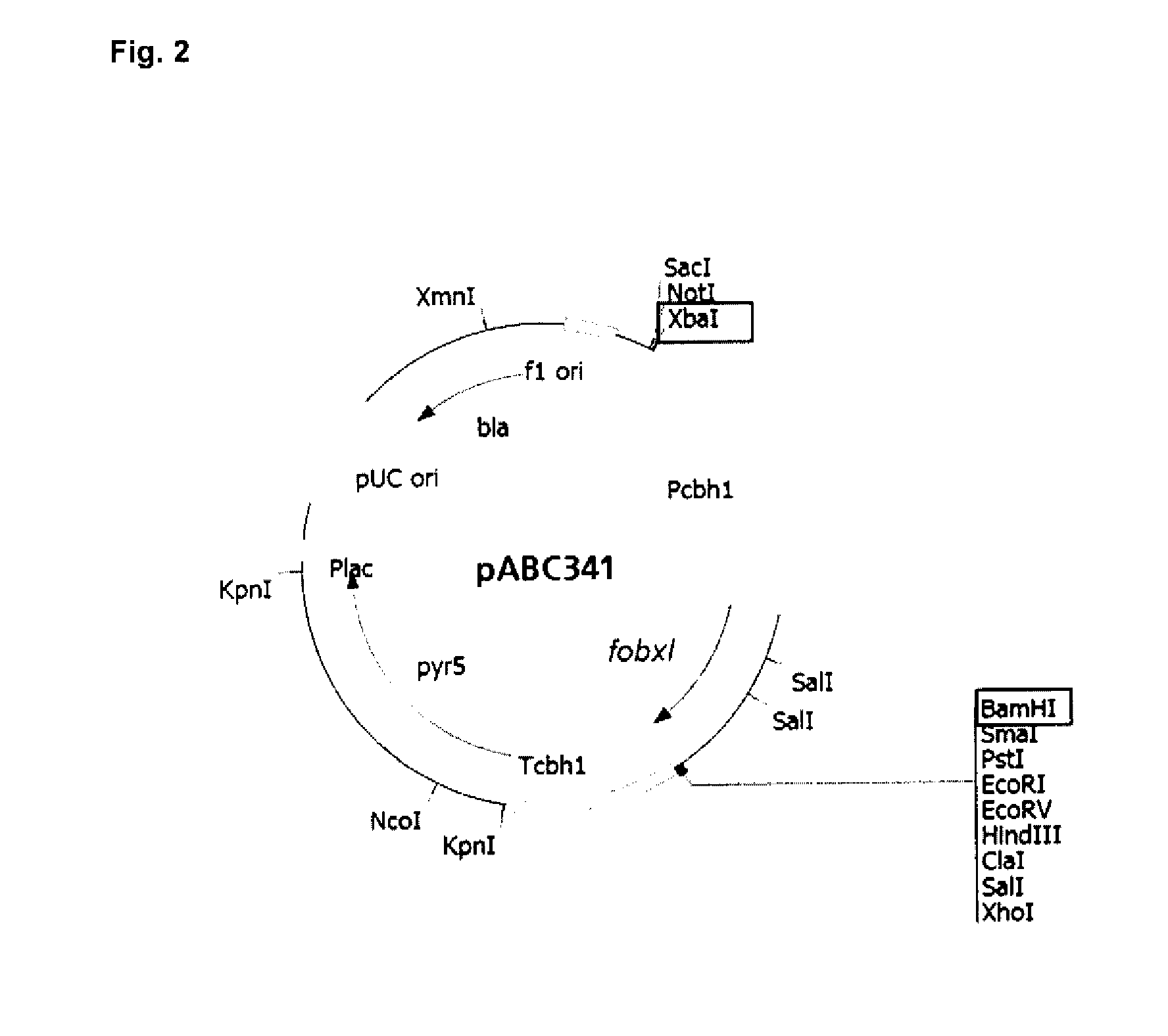

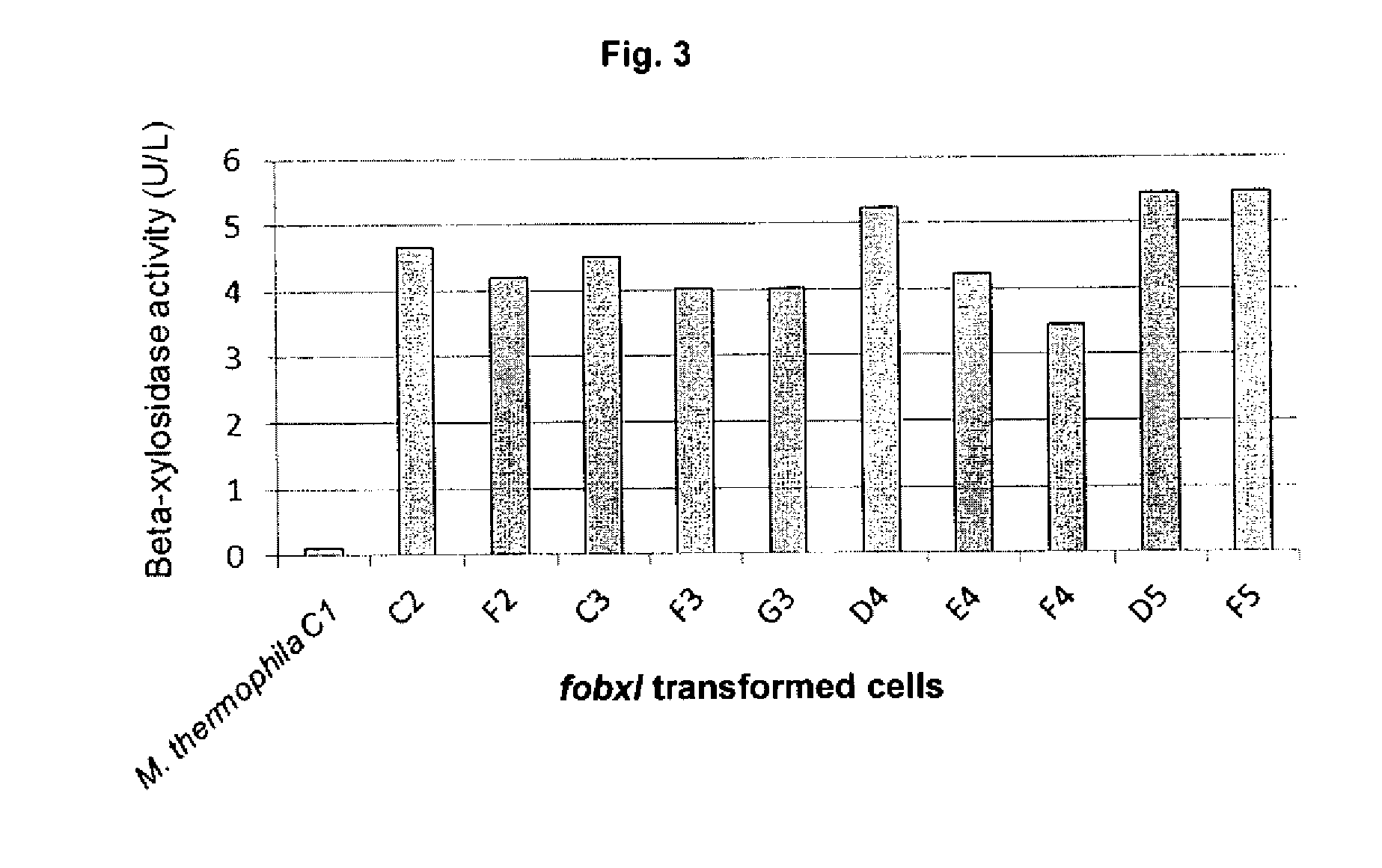

The present invention relates to a host cell, preferably Myceliophthora thermophila cell, which expresses recombinant enzymes with beta-xylosidase activity, an enzymatic composition comprising said cell and / or the recombinant enzyme with beta-xylosidase activity expressed by said cell, the use of this host cell, the recombinant enzyme with beta-xylosidase activity expressed by said cell or the composition for the degradation of biomass and a method of producing bioproducts, preferably bioethanol, which comprises the use of said host cell, the recombinant enzyme with beta-xylosidase activity expressed by said cell or said composition.

Owner:ABENGOA BIOENERGIA NUEVAS TECHAS

Polysaccharide cracking monooxygenase LPMO 9D coding gene and enzyme and preparation and application thereof

The invention discloses a method for preparing a polysaccharide cracking monooxygenase LPMO 9D coding gene derived from myceliophthora thermophila and an enzyme thereof, and an application thereof. The polysaccharide cracking monooxygenase LPMO 9D of the present invention is derived from Thermomyxomyces thermophila ATCC 42464. The invention also provides a method for preparing the novel polysaccharide cracking monooxygenase, which is characterized in that the gene of the new polysaccharide cracking monooxygenase is cloned into a Pichia pastoris expression vector by using a genetic engineeringmethod to obtain a recombinant strain of Pichia pastoris capable of performing heterogenous expressing of the enzyme, and the polysaccharide cracking monooxygenase LPMO 9D prepared by heterologous expression of the strain can degrade PASC (phosphorylated microcrystalline cellulose) to produce cellooligosaccharide and cellooligosaccharide. The polysaccharide cracking monooxygenase LPMO 9D providedby the invention can be widely used in the fields of chemical industry, agriculture, feed addition and medicine, and has great production potential and economic value.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Novel myceliophthora thermophila strain and application thereof

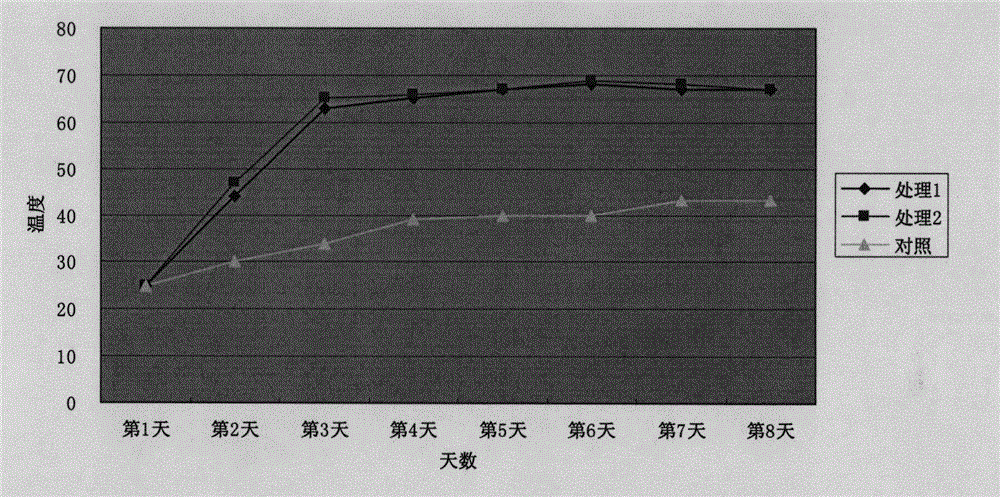

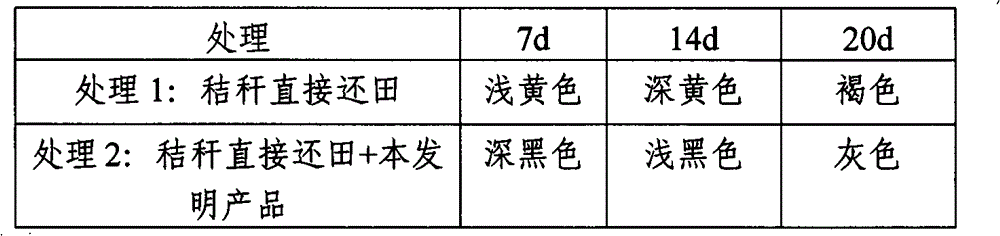

ActiveCN102352320AImprove proliferation efficiencySignificantly rapid fermentation temperature riseFungiMicroorganism based processesMicroorganismCellulose

The invention discloses a novel myceliophthora thermophila strain (CLIMAX-VMT). The preservation number of the novel myceliophthora thermophila strain is CGMCC No.5134, the preservation date is August 12th, 2011, and the preservation unit is General Microbiology Center of China Microbial Strain Preservation Management Committee. The invention also discloses a microbial inoculum containing the strain. The novel myceliophthora thermophila strain (CLIMAX-VMT) provided by the invention has very obvious fast fermentation temperature rise and cellulose decomposition performance and is innocuous and harmless to people and livestock. When the strain is used for fermenting organic solid waste materials, the fast temperature rise in 24h can be reached, and the temperature is raised to a value higher than 60 DEG C in 48h and can be maintained for more than 5 days. The strain does not have the obvious antagonism action on most low-temperature germs, i.e. the universality and the matching with other strains of the microbial inoculum are very good.

Owner:BEIJING JINGGENG TIANXIA AGRI TECH

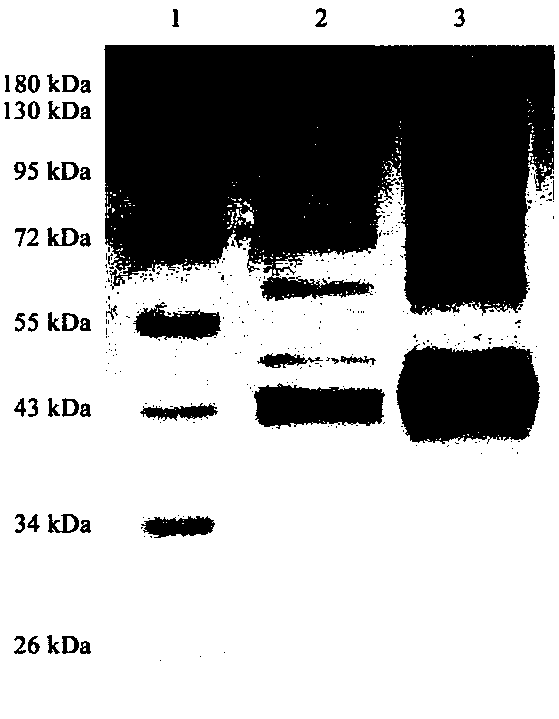

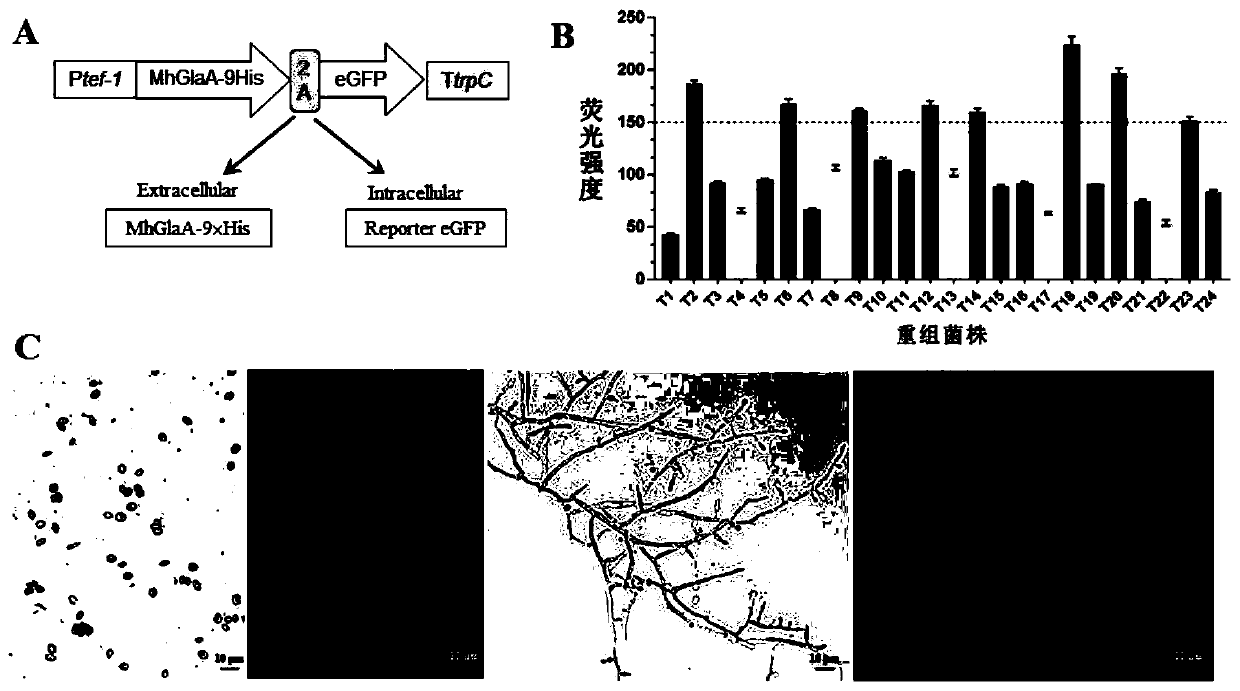

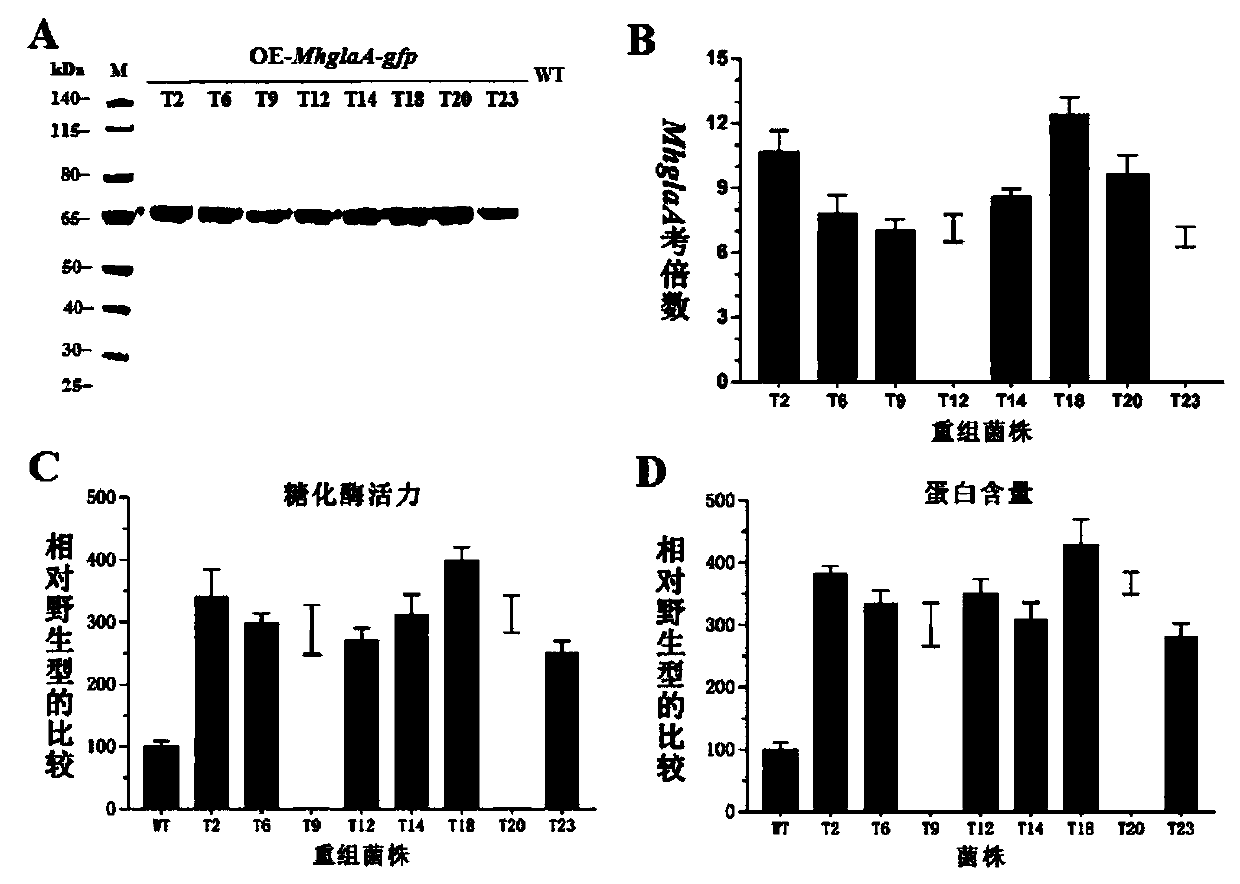

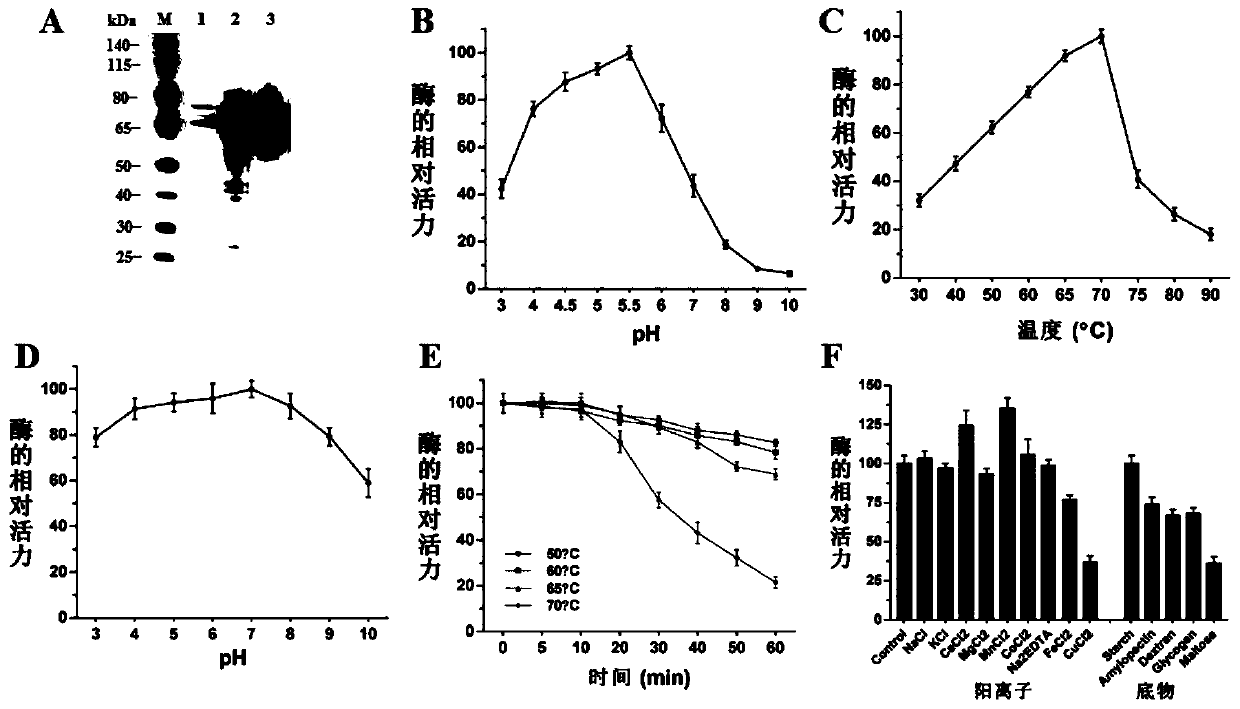

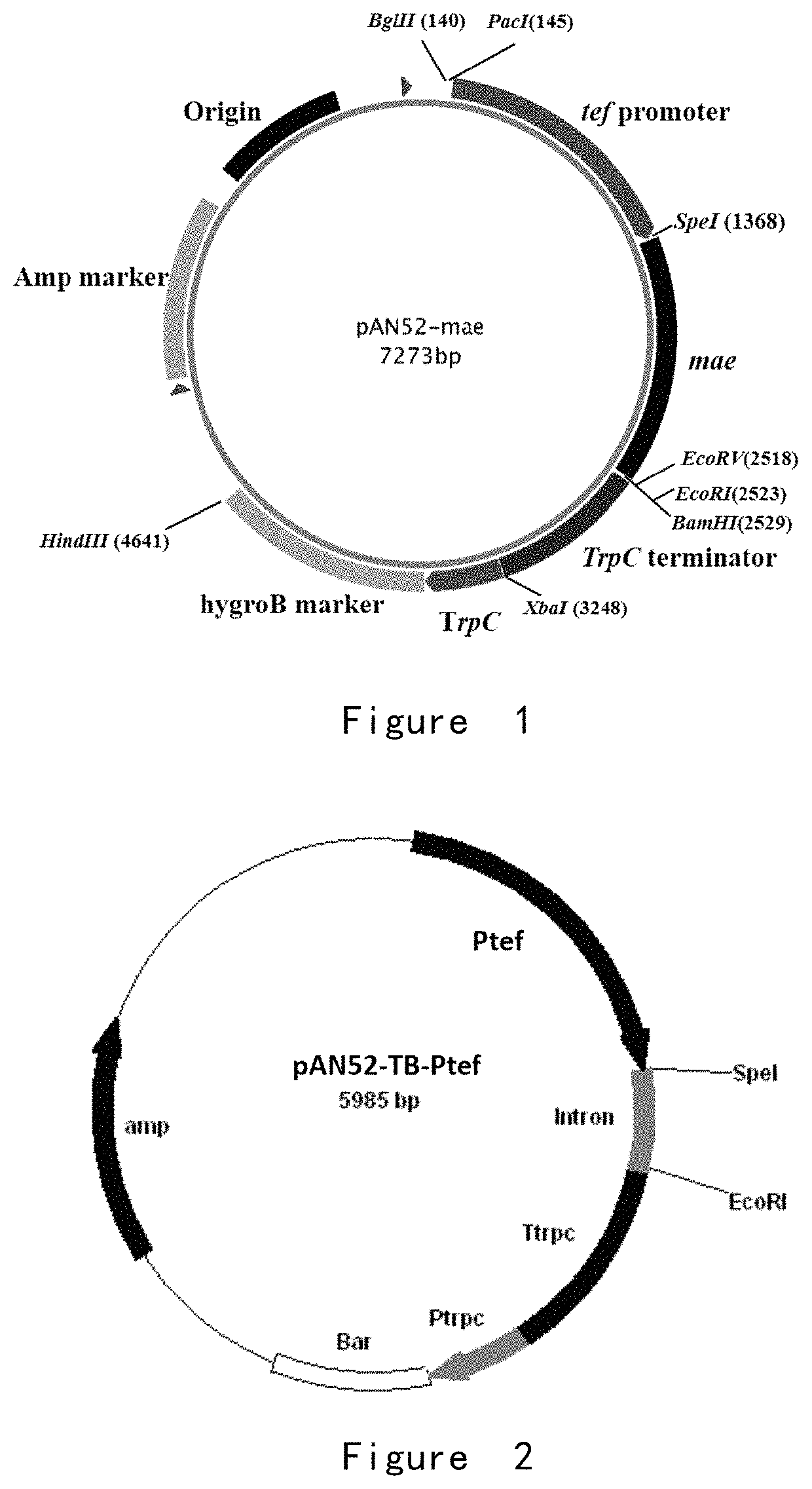

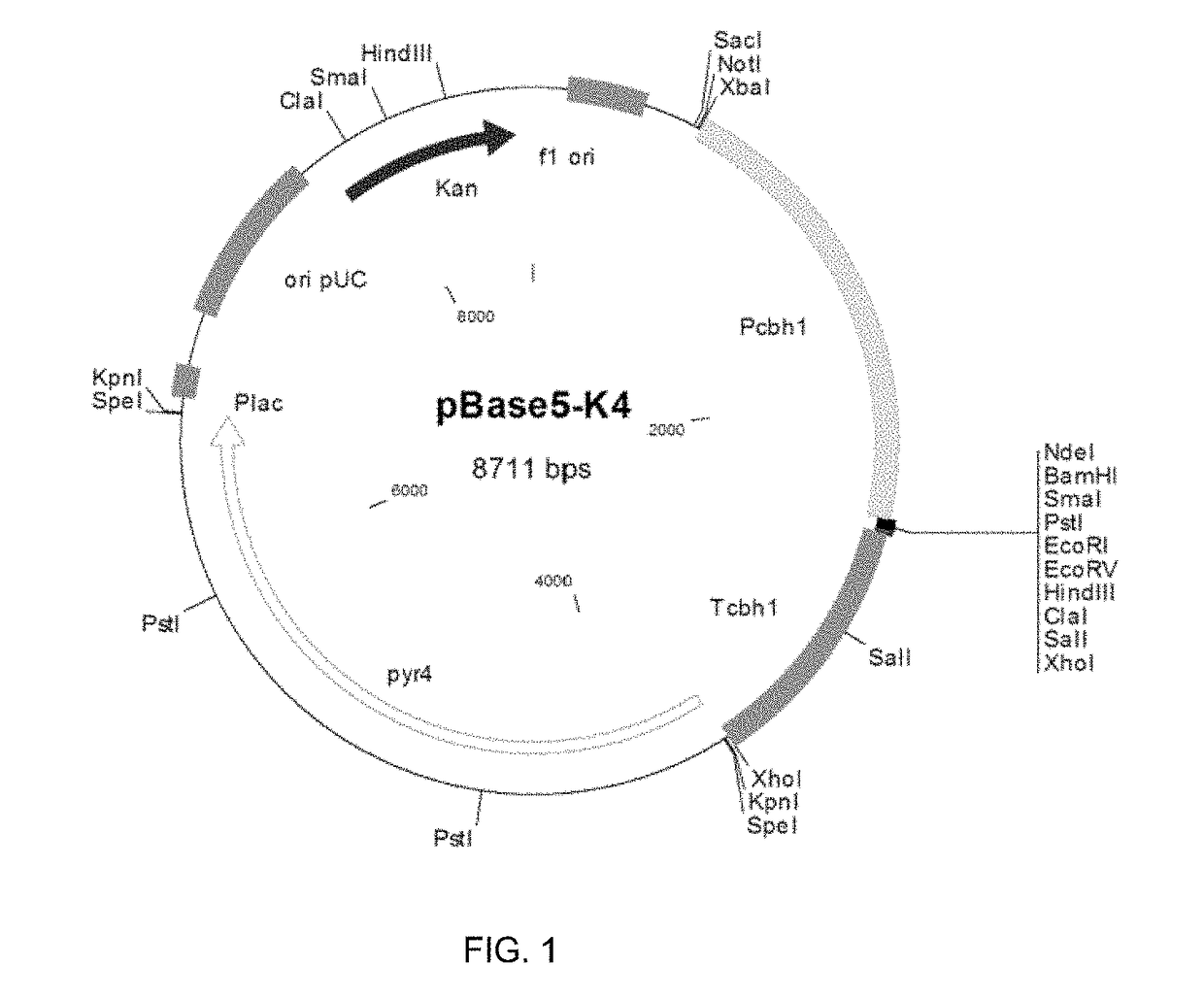

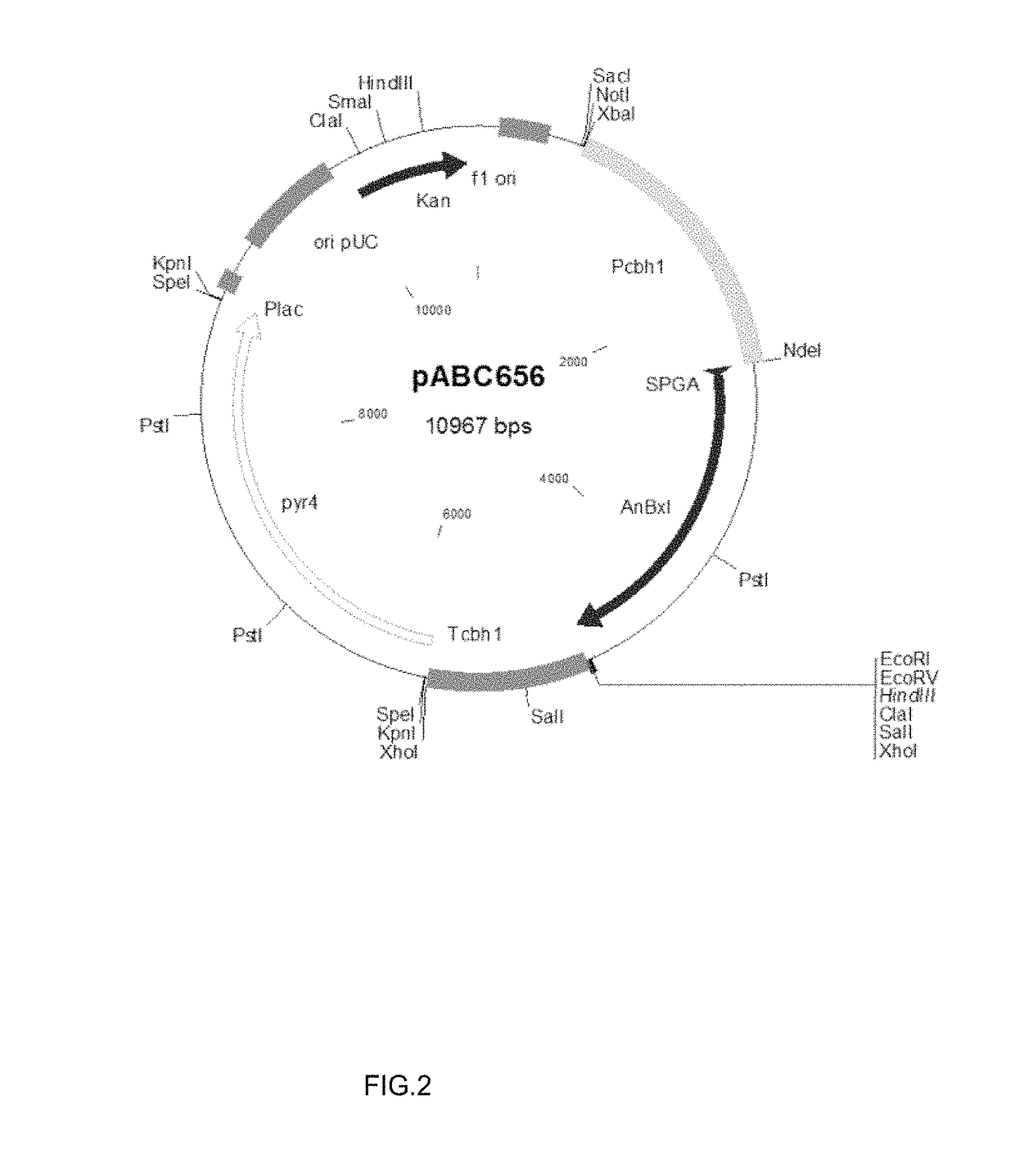

Glucoamylase MhglaA from myceliophthora heterothallica, gene for coding glucoamylase MhglaA, and application of glucoamylase MhglaA to glucose production

ActiveCN111378674AImprove heat resistanceFast preparationFermentationVector-based foreign material introductionMyceliophthora thermophilaCarbohydrase

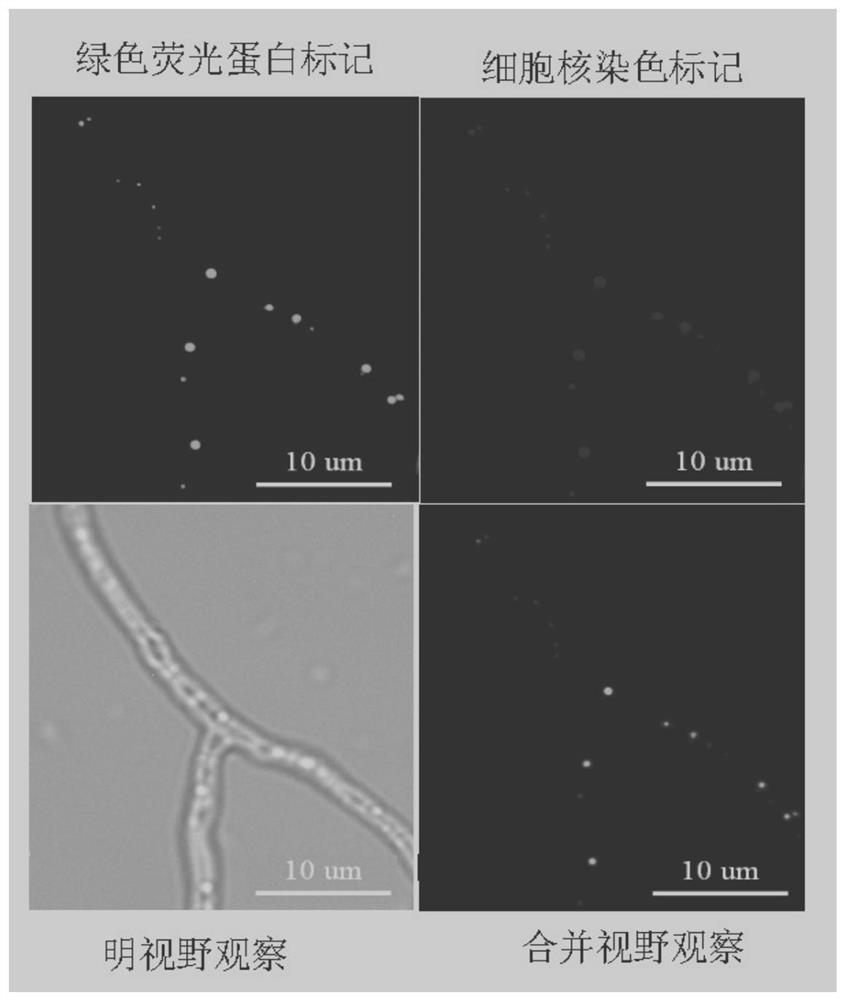

The invention discloses a thermophilic fungus glucoamylase MhGlaA having an amino acid sequence as shown in SEQID NO.1, a gene for coding the thermophilic fungus glucoamylase MhGlaA, an expression boxmediated with FMDV 2A peptide and containing the gene and a GFP gene, and a recombinant expression carrier, and further discloses a method for increasing yield of glucoamylase through myceliophthorathermophila, and an application of the glucoamylase to hydrolyzed starch. The glucoamylase provided by the invention is wide in pH value application range, good in heat stability and notable in hydrolyzing effects on starch; particularly, the yield of the glucoamylase produced through an obtained optimal myceliophthora thermophila recombinant strain is increased by about 12.5 times than that of the glucoamylase produced through a wild strain, the vitality of the glucoamylase produced through the optimal myceliophthora thermophila recombinant strain is improved by about 8.5 times than that of the glucoamylase produced through the wild strain, and the starch hydrolyzing effects of the fermentation liquid of the glucoamylase produced through the optimal myceliophthora thermophila recombinantstrain are notably better than those of the fermentation liquid of the glucoamylase produced through the wild strain, and therefore, the thermophilic fungus glucoamylase MhGlaA has higher applicationvalue.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Polysaccharide cleavage monooxygenase encoding gene and enzyme thereof, and preparation method and applications

PendingCN109957571ASolve the problem of high conversion production costsFungiMicroorganism based processesCellulosePichia pastoris

The present invention discloses a polysaccharide cleavage monooxygenase encoding gene and an enzyme thereof derived from myceliophthora thermophila, and a preparation method and applications. A genetic engineering technical method is used to clone the gene of the polysaccharide cleavage monooxygenase into pichia pastoris expression vectors to obtain a pichia pastoris recombinant strain capable ofheterologously expressing the enzyme. The polysaccharide cleavage monooxygenase heterologously expressed by the strain can efficiently degrade cellulose (oxidative cleavage of beta-1,4-glycosidic bonds). The provided polysaccharide cleavage monooxygenase can be widely applied to the fields of energy, agriculture, food, feed additives, medicines, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

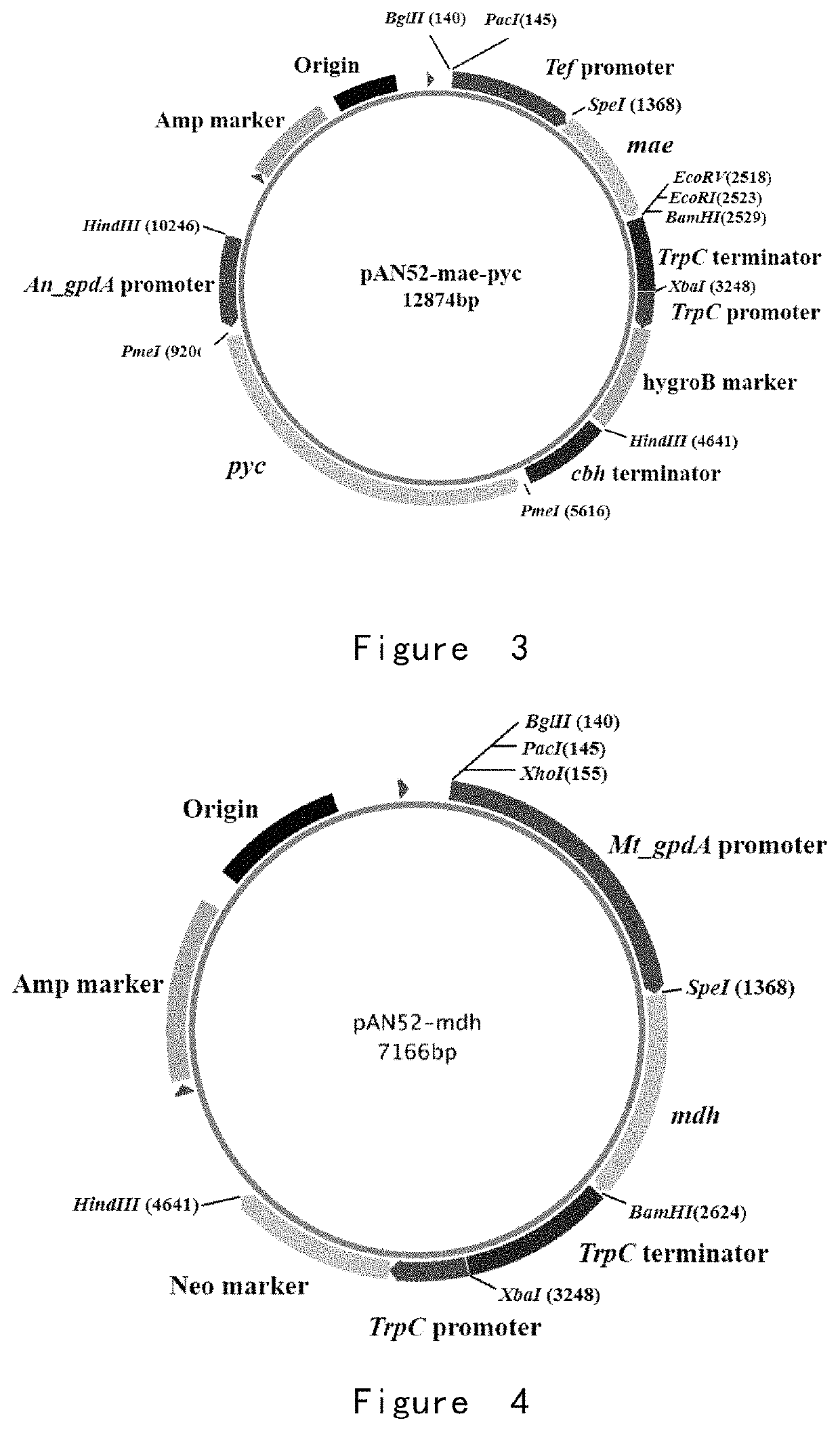

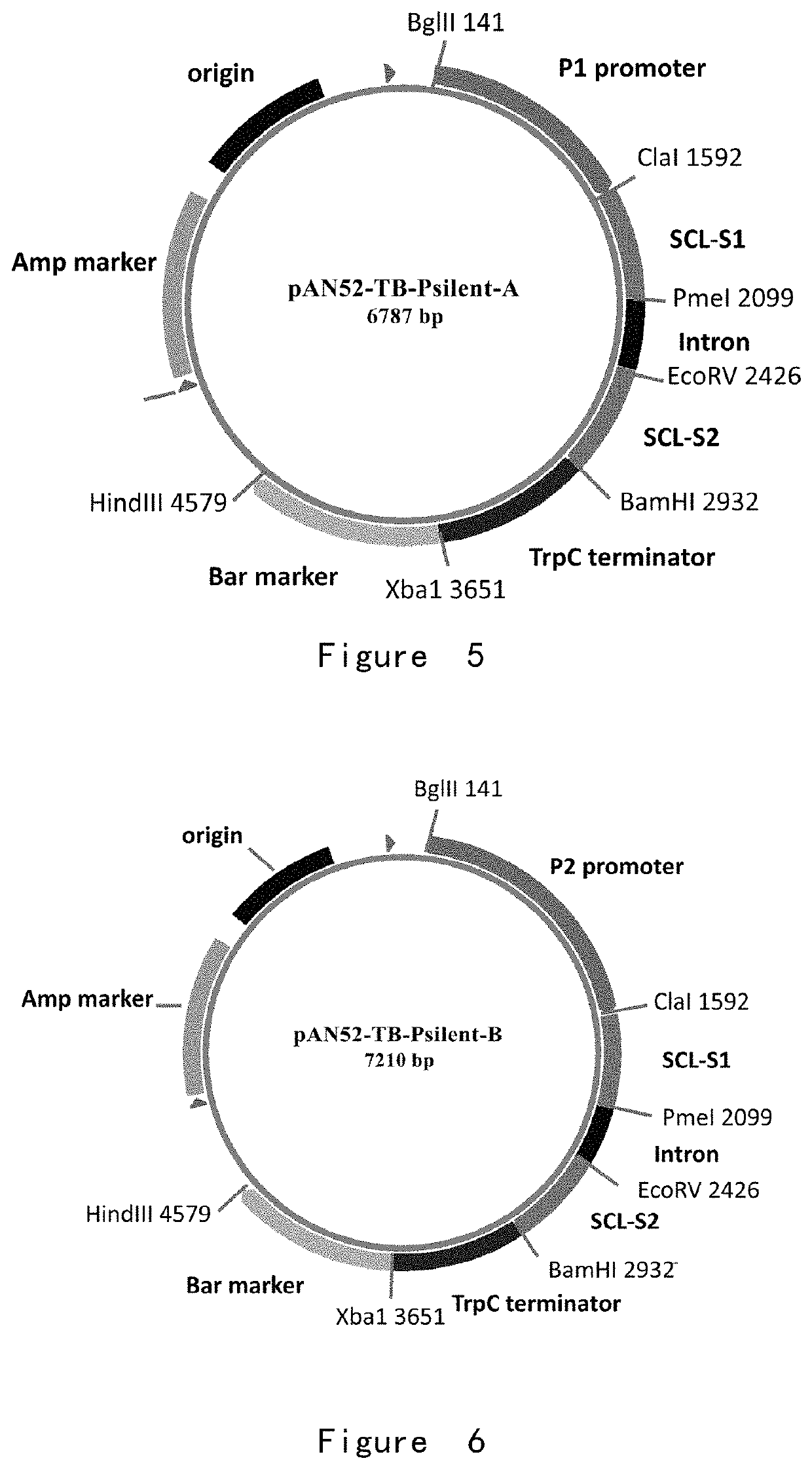

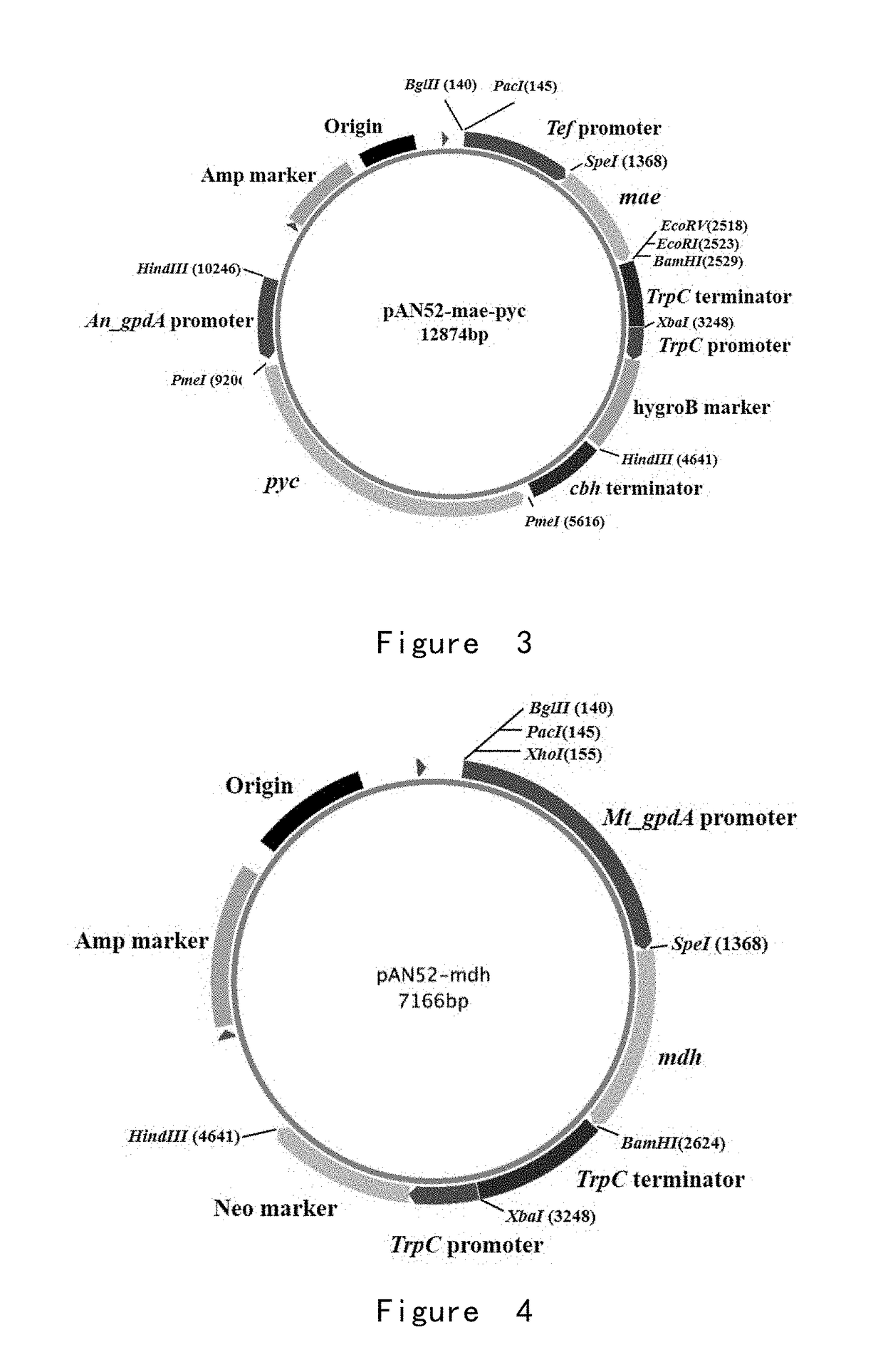

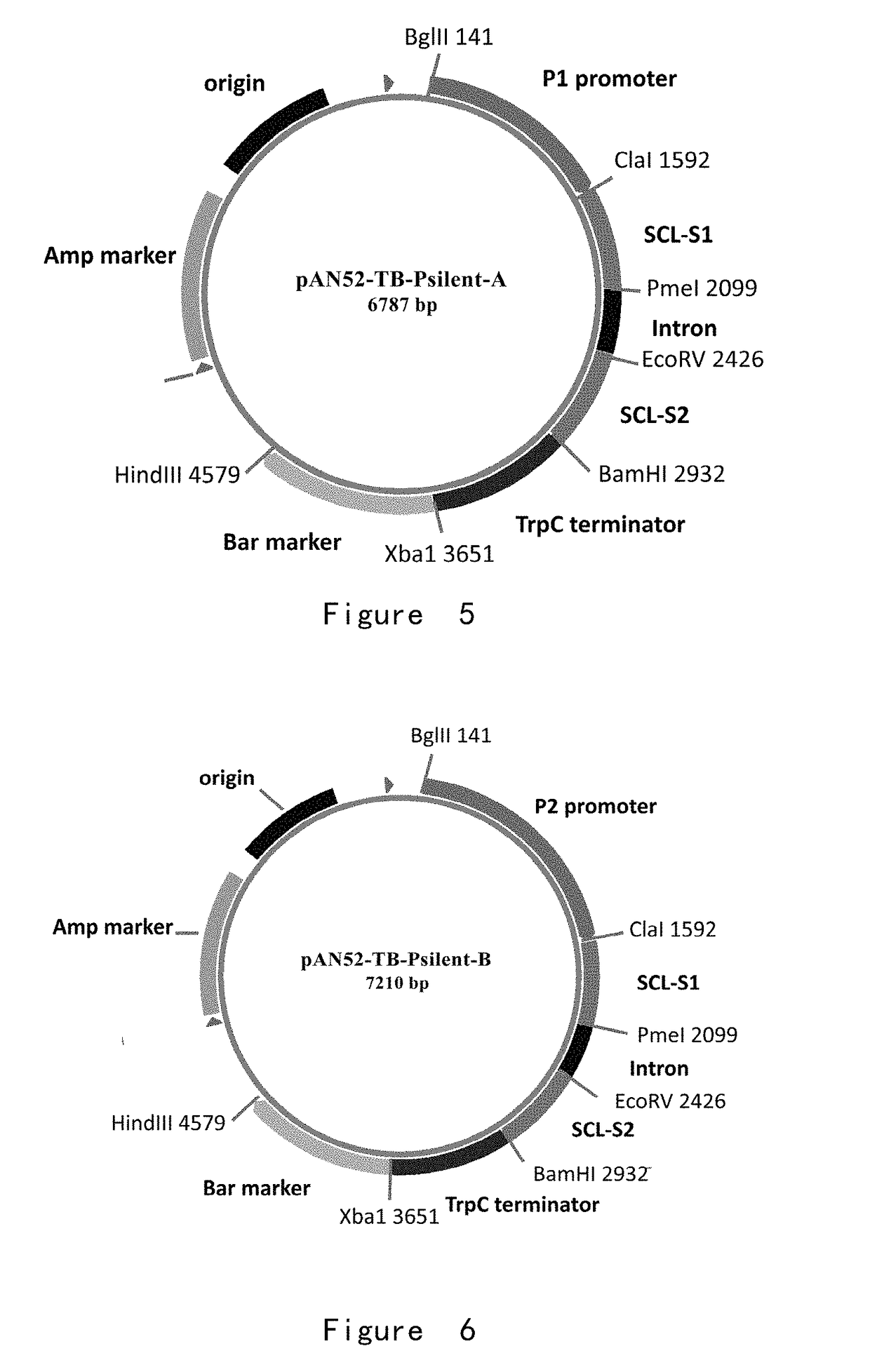

Dibasic organic acid producing strain and preparation and application of same

ActiveUS10781462B2Raise the level of fermentationLow costMicroorganismsTransferasesMyceliophthora thermophilaPyruvate synthesis

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

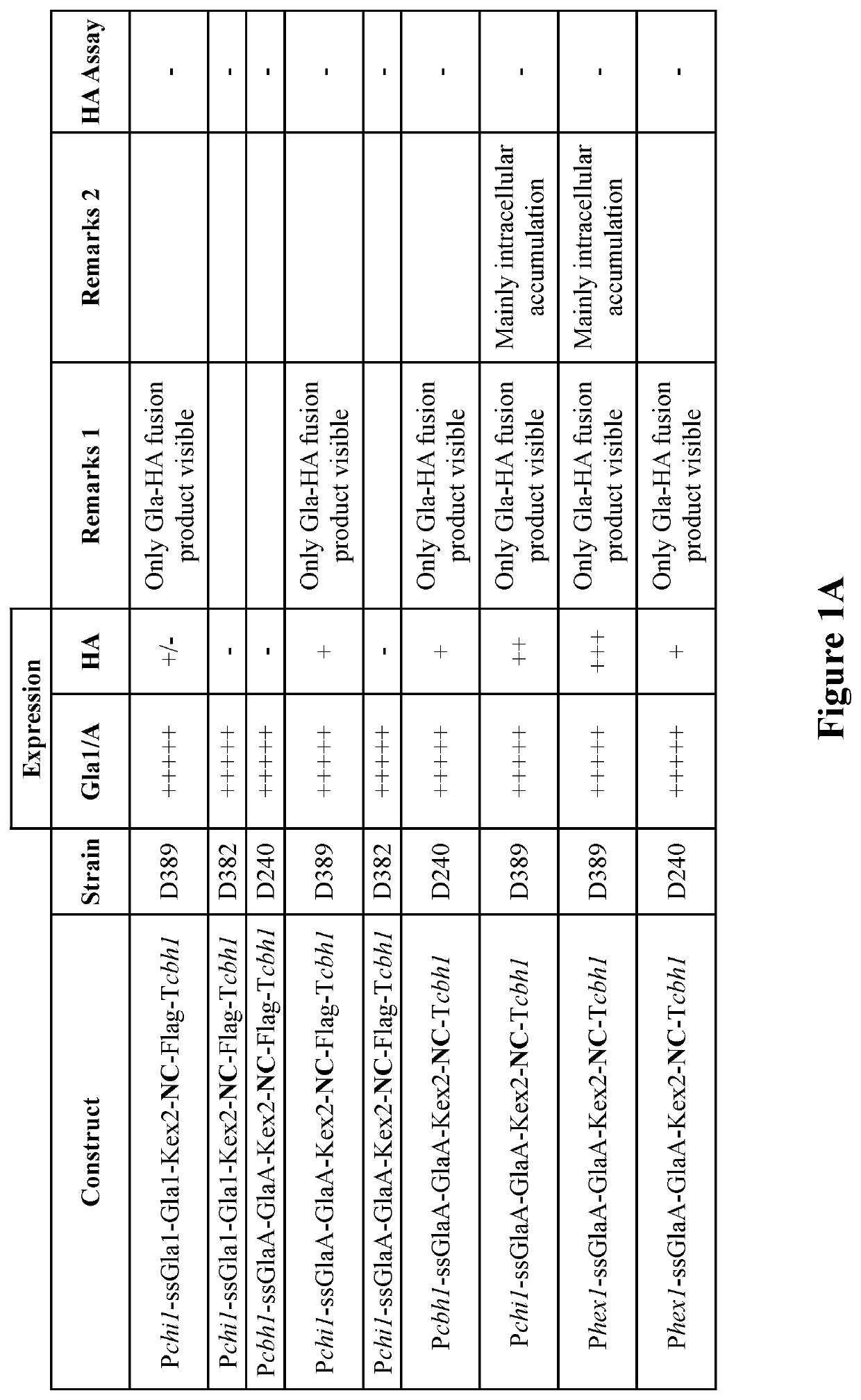

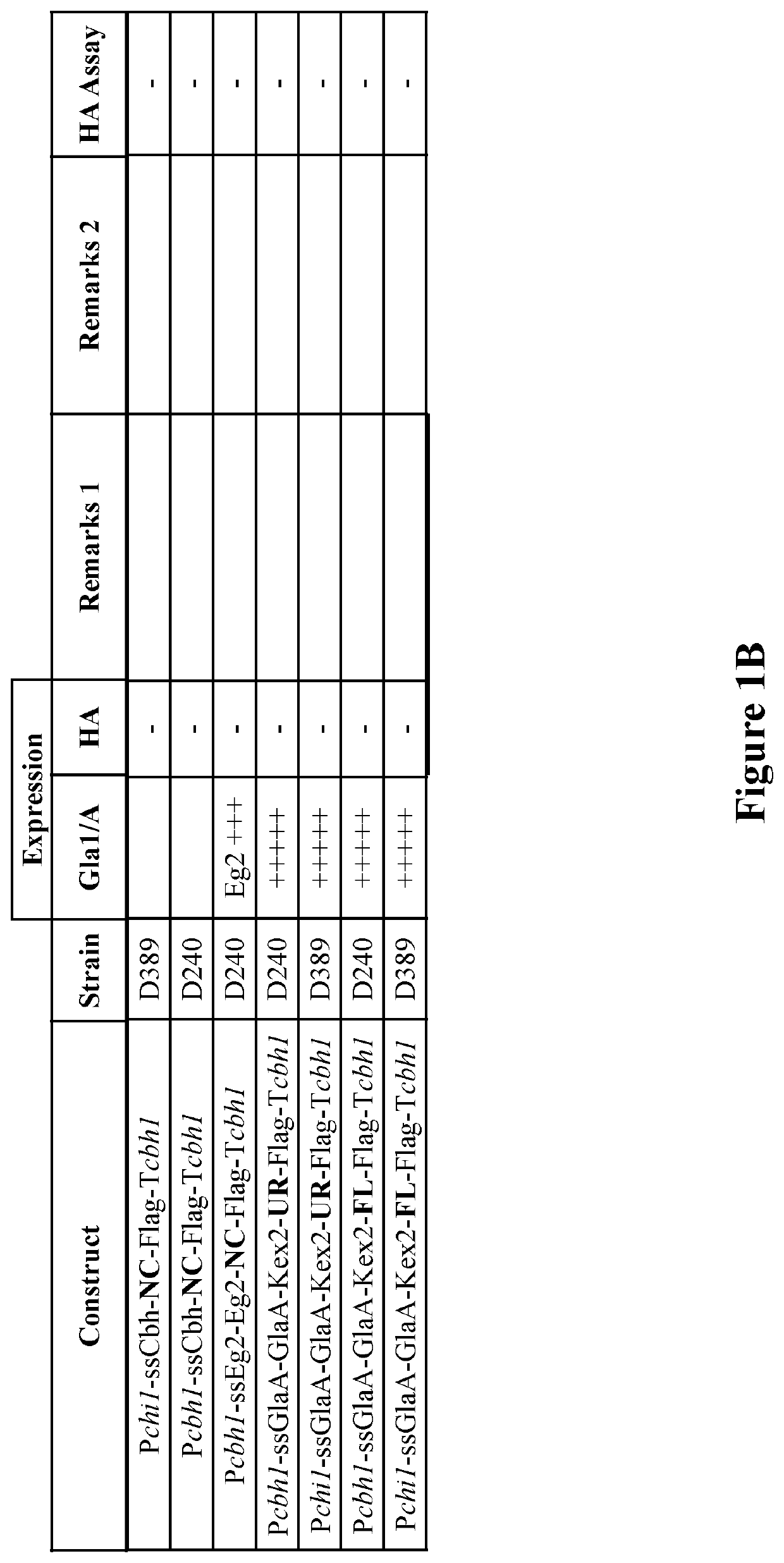

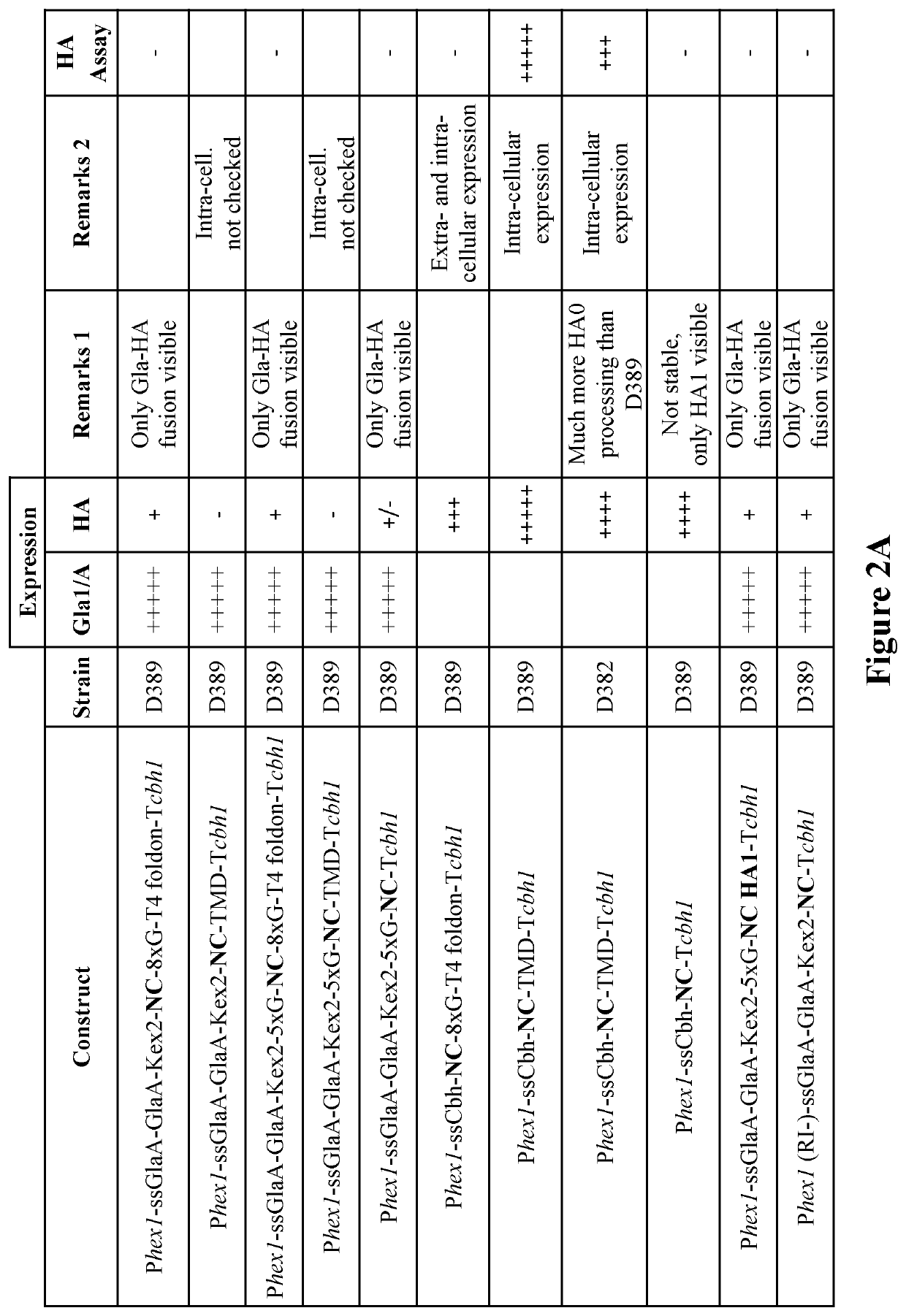

Production of flu vaccine in myceliophthora thermophila

PendingUS20200215183A1High yieldSuitableSsRNA viruses negative-senseViral antigen ingredientsMyceliophthora thermophilaMicrobiology

Recombinant expression of influenza vims surface proteins in the fungus Myceliophthora thermophila strain Cl is provided. The recombinant proteins are for use in influenza vaccine compositions.

Owner:DYADIC INT

Myceliophthora thermophila ferment as well as preparation method and application thereof

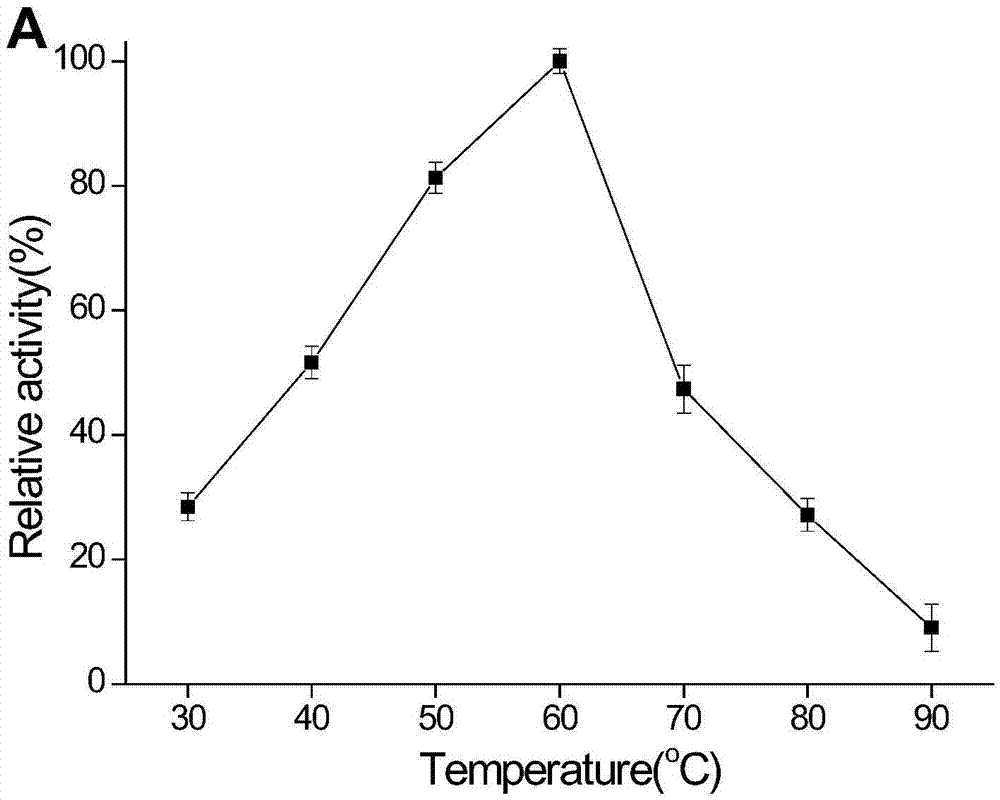

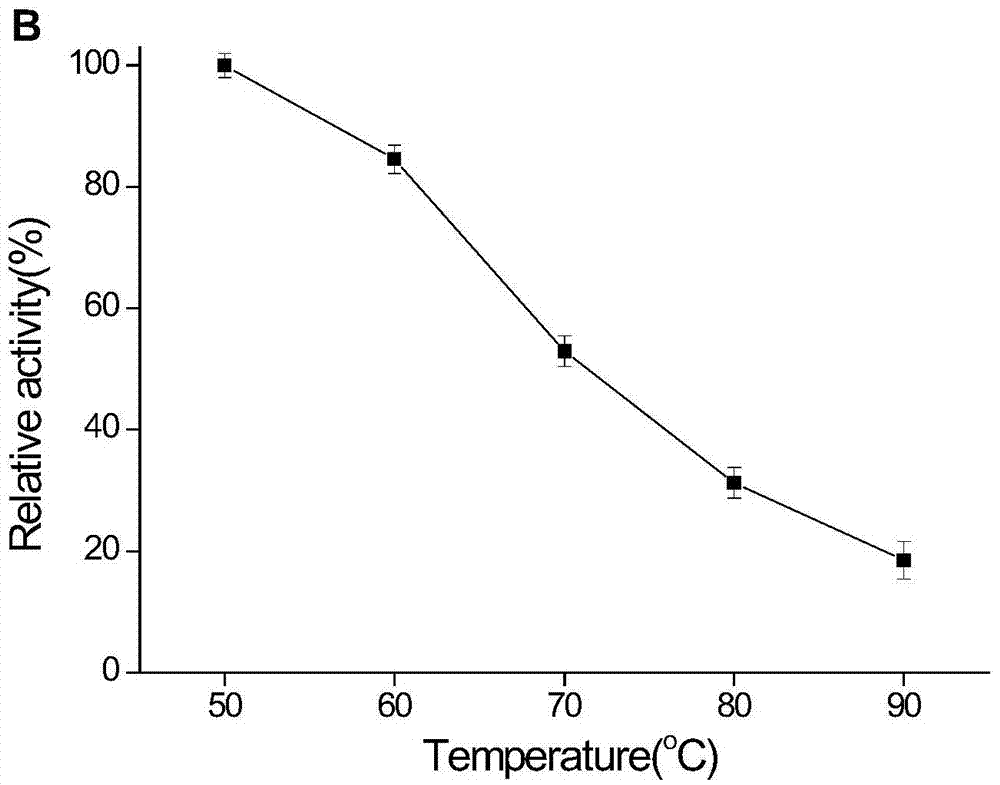

ActiveCN103497942AImprove temperature stabilityIncrease enzyme activityMicroorganism based processesGlycosylasesHydrogenMyceliophthora thermophila

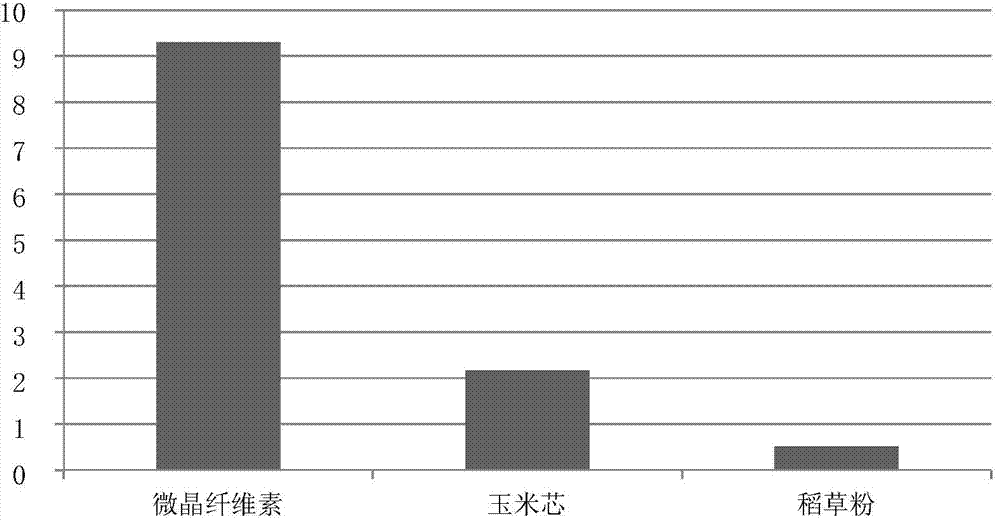

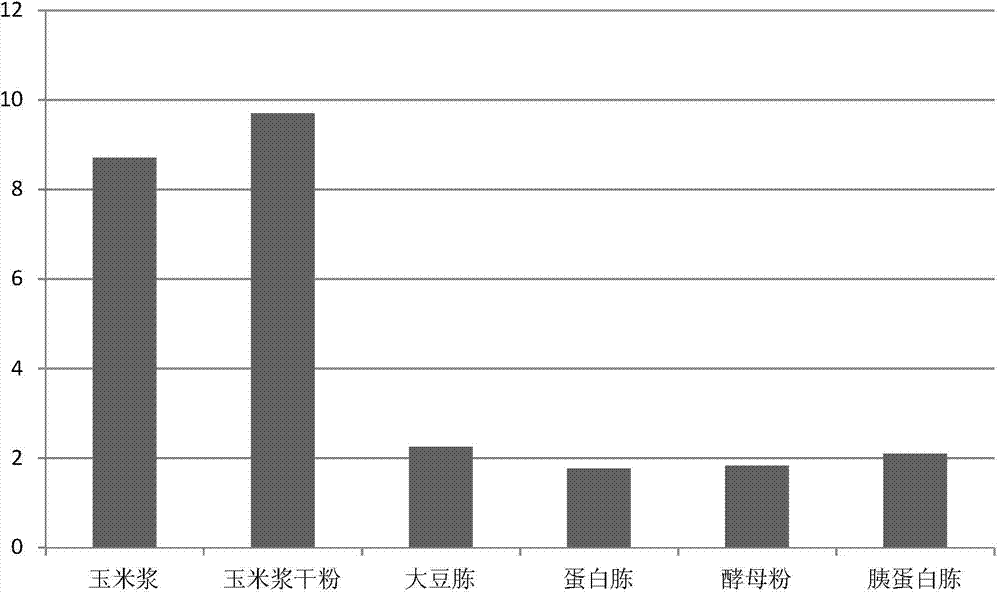

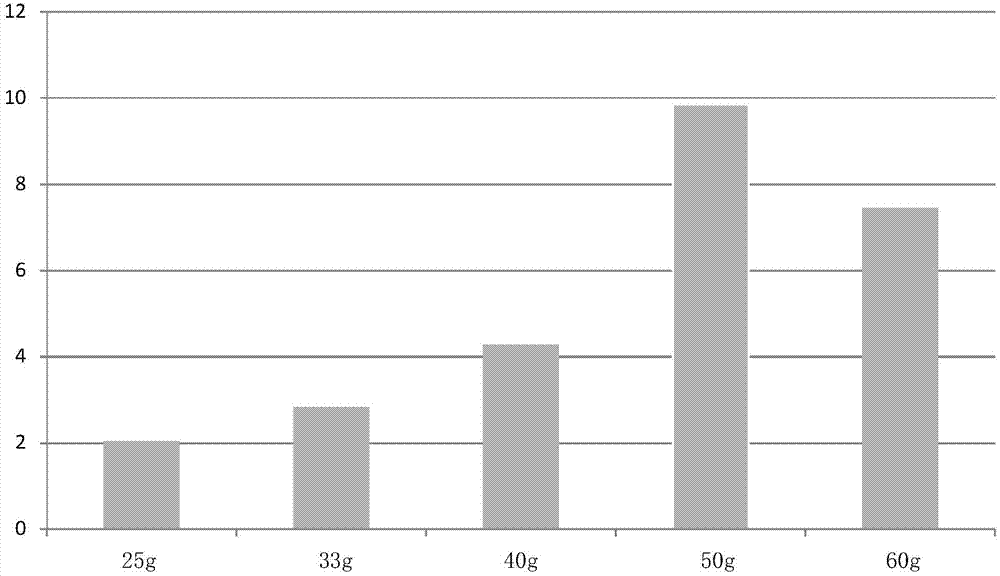

The invention discloses a myceliophthora thermophila ferment as well as a preparation method and an application thereof. The invention provides a method for preparing the ferment, wherein the method comprises the following steps: inoculating the myceliophthora thermophila ACCC No. 30572 into a fermenting culture medium, vibrating and culturing for 5-9 days under the condition of 40-55 DEC and 100-300rpm; the fermenting culture medium is prepared by the method comprising the following steps: mixing a carbon source, a nitrogen source, ammonium sulfate, monopotassium phosphate, calcium carbonate, magnesium sulfate, glycerol and tween-80 with water, thus obtaining the fermenting culture medium, wherein the concentration of the carbon source is 25-60g / L, the concentration of the nitrogen source is 10-40g / L, the concentration of the ammonium sulfate is 1-10g / l, the concentration of the monopotassium phosphate is 1-10g / L, the concentration of the calcium carbonate is 1-4g / L, the concentration of the magnesium sulfate is 0.5-4g / L, the concentration of the glycerol is 1-4g / L, and the concentration of the tween-80 is 0.5-3g / L. The ferment provided by the invention has the activity of cellulose, has excellent temperature stability and pH (potential of hydrogen) stability, namely, has higher enzyme activity under a high-temperature condition, and has higher enzyme activity within a wider pH scope.

Owner:ANHUI NEW SIMON BIOTECH CO LTD

Method for producing heat-resistant superoxide dismutase (SOD) by using myceliophthora thermophila

InactiveCN104694493AImprove heat resistanceSolve the shortcomings of heat intoleranceMicroorganism based processesOxidoreductasesMyceliophthora thermophilaSuperoxide dismutase

The invention relates to a method for producing superoxide dismutase (SOD) by using myceliophthora thermophila and belongs to the technical field of bioengineering. According to the method, SOD is produced from myceliophthora thermophila under the condition of liquid-state fermentation and is an ectoenzyme. The yield of heat-resistant SOD can reach 2000U / ml to the maximum, so that the method has a good industrial application prospect.

Owner:JIANGNAN UNIV

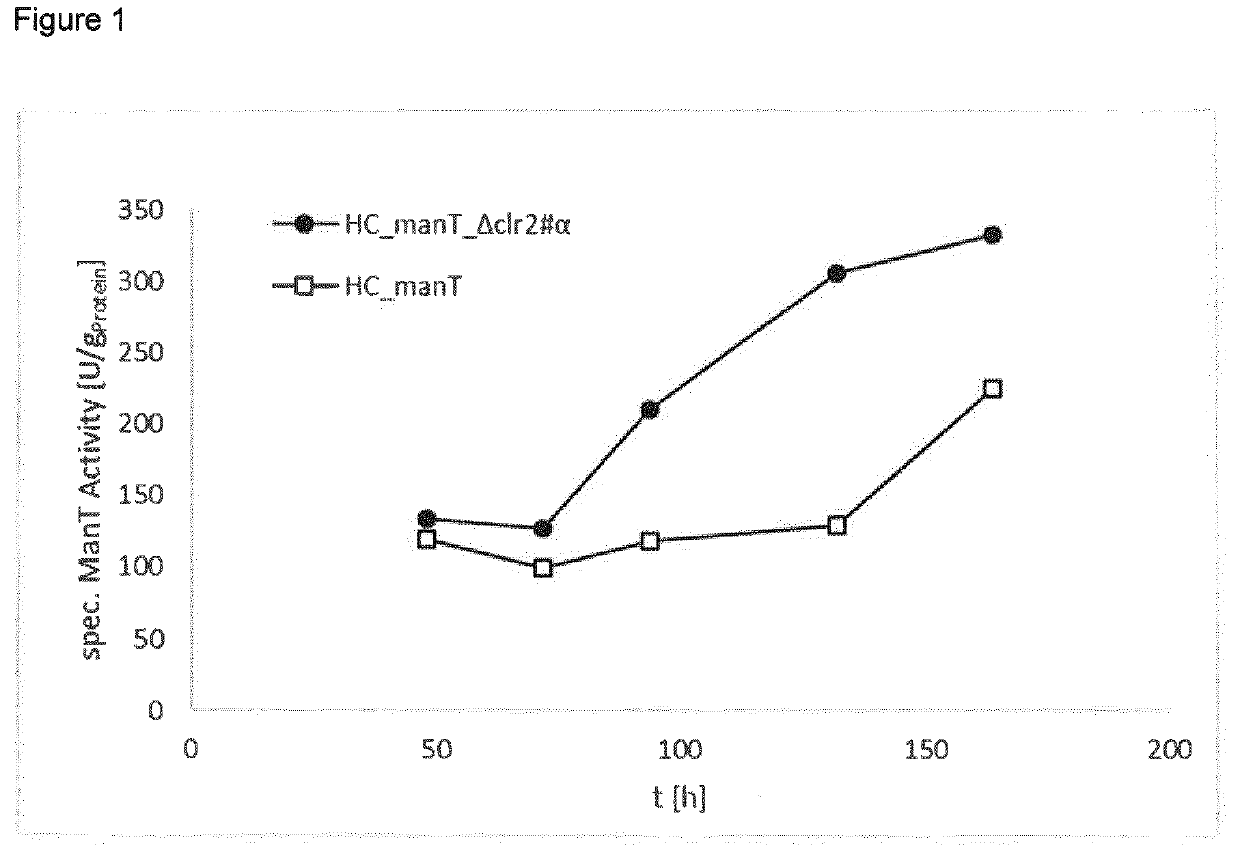

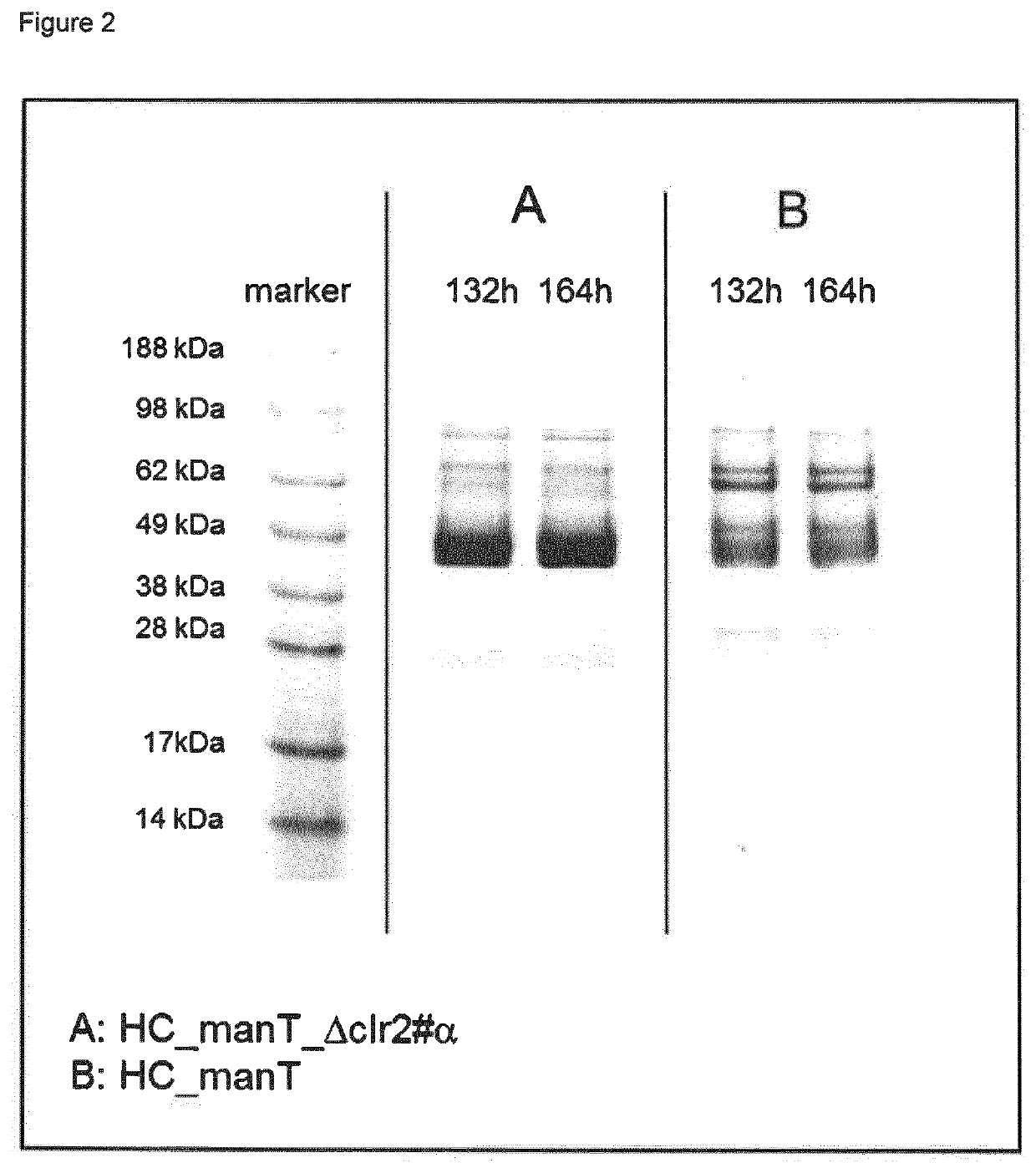

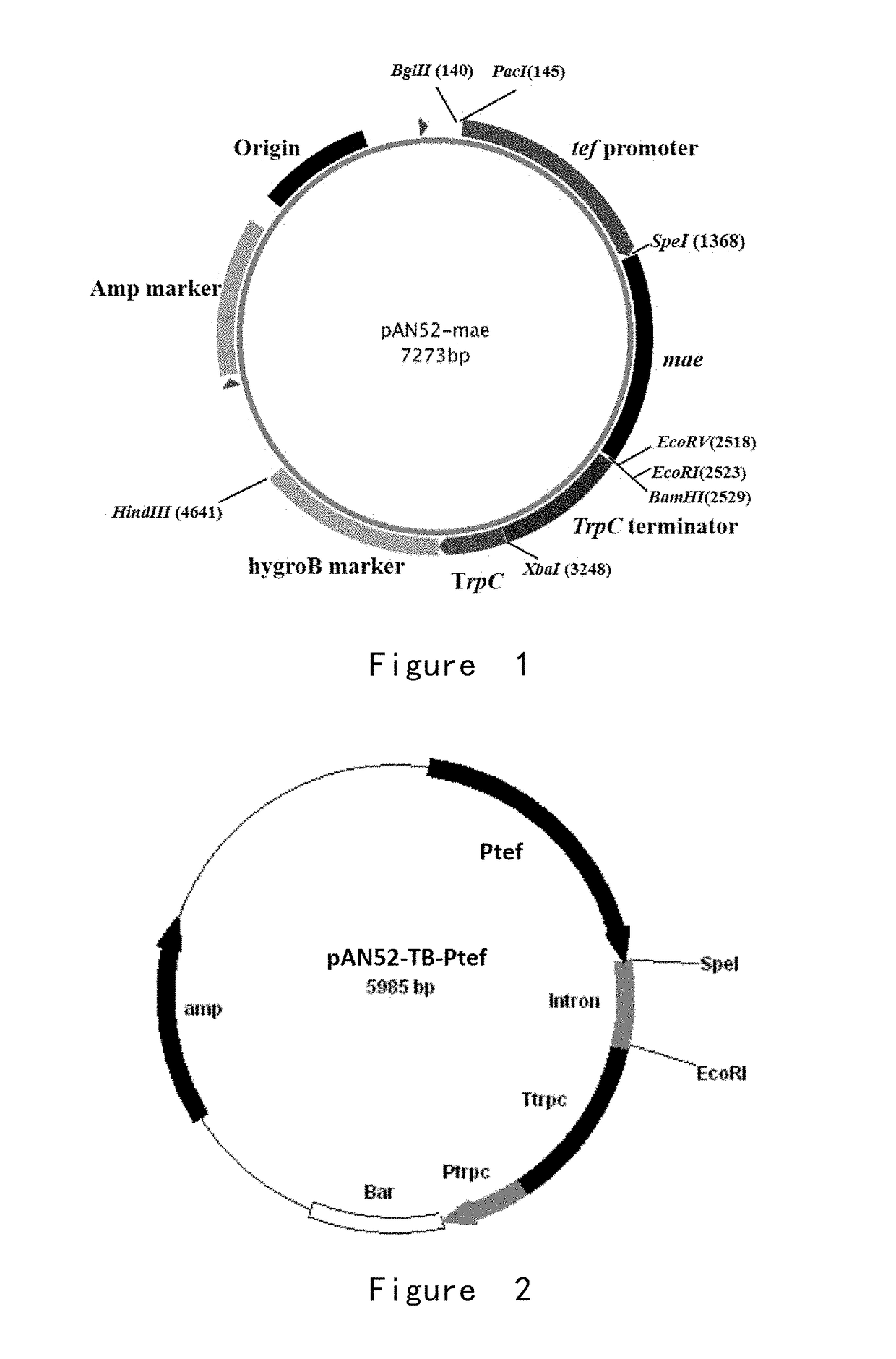

Method of producing proteins in filamentous fungi with decreased clr2 activity

ActiveUS20200308235A1Decrease and eliminate activityDecrease and eliminate activity of proteaseDepsipeptidesFermentationMyceliophthora thermophilaCellulase

The present invention relates to a method of producing a recombinant polypeptide a filamentous fungus which is genetically modified to decrease or eliminate the activity of cellulase regulator 2 (CLR2) and to express said recombinant polypeptide. The method further relates to a filamentous fungus Myceliophthora thermophila, which is genetically modified to decrease or eliminate the activity of CLR2 and the use of this filamentous fungus in the production of a recombinant polypeptide.

Owner:BASF AG

Dibasic organic acid producing strain and preparation and application of same

ActiveUS20180171369A1Raise the level of fermentationReduce fermentation costsMicroorganismsTransferasesGlutaric acidRhizopus

Provided are an engineered strain for synthesizing a dibasic organic acid and preparation and application of same. The engineered strain introduces or up-regulates expression of a positive regulator gene for synthesis of a dibasic organic acid, and / or down-regulates expression of a negative regulator gene for synthesis of a dibasic organic acid, as compared with the origin strain of the engineered strain, the producing capability for producing the dibasic organic acid is improved. The dibasic organic acid comprises malic acid, succinic acid, fumaric acid, oxaloacetic acid, glutaric acid, and adipic acid; the expression product of the positive regulator gene comprises aspartate aminotransferase, glutamic acid-aspartate transporter, C4-dicarboxylic acid transporter, pyruvate carboxylase and malate dehydrogenase, glucose transporter; the expression product of the negative regulatory gene comprises succinyl-CoA synthase, and malic acid-alpha ketoglutarate transporter, and the original strain comprises myceliophthora thermophila, thielavia terrestris, aspergillus, and rhizopus.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

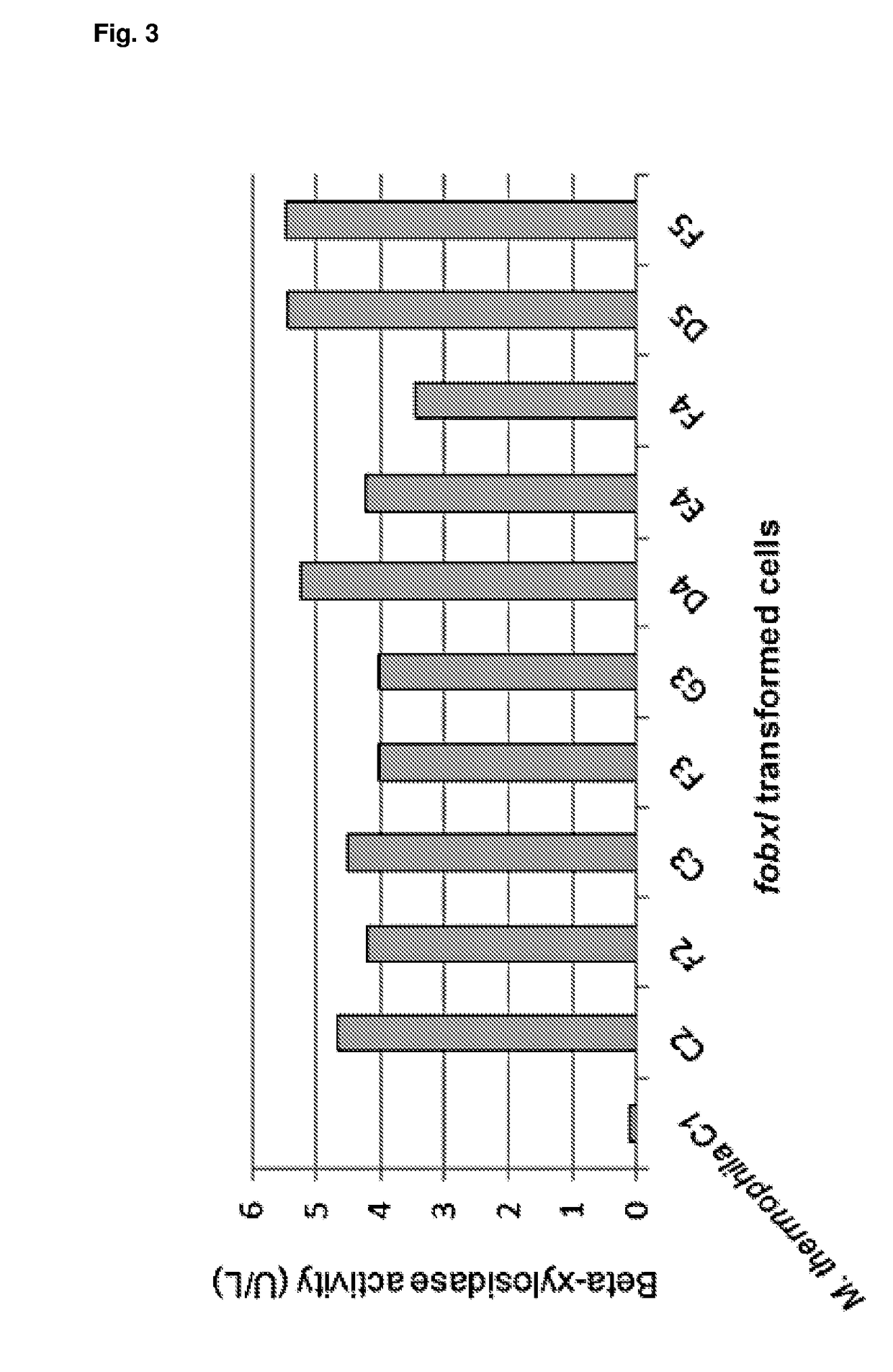

Expression of recombinant beta-xylosidase enzymes

InactiveUS20180230446A1Improve hydrolysis efficiencyIncrease productionFungiBiofuelsNucleotideMyceliophthora thermophila

The present invention relates to a Myceliophthora thermophila cell, which expresses a nucleotide sequence that codifies a recombinant beta-xylosidase enzyme comprising an amino-acid sequence having at least 70% identity with SEQ ID NO: 1, an enzymatic composition comprising said cell and / or the recombinant enzyme with beta-xylosidase activity expressed by said cell, the use of this host cell, the recombinant enzyme with beta-xylosidase activity expressed by said cell or the composition for the degradation of biomass, and a method of producing biological products, preferably bioethanol, comprising the use of said host cell, the recombinant enzyme with the beta-xylosidase activity expressed by said cell or said composition.

Owner:ABENGOA BIOENERGIA NUEVAS TECHAS

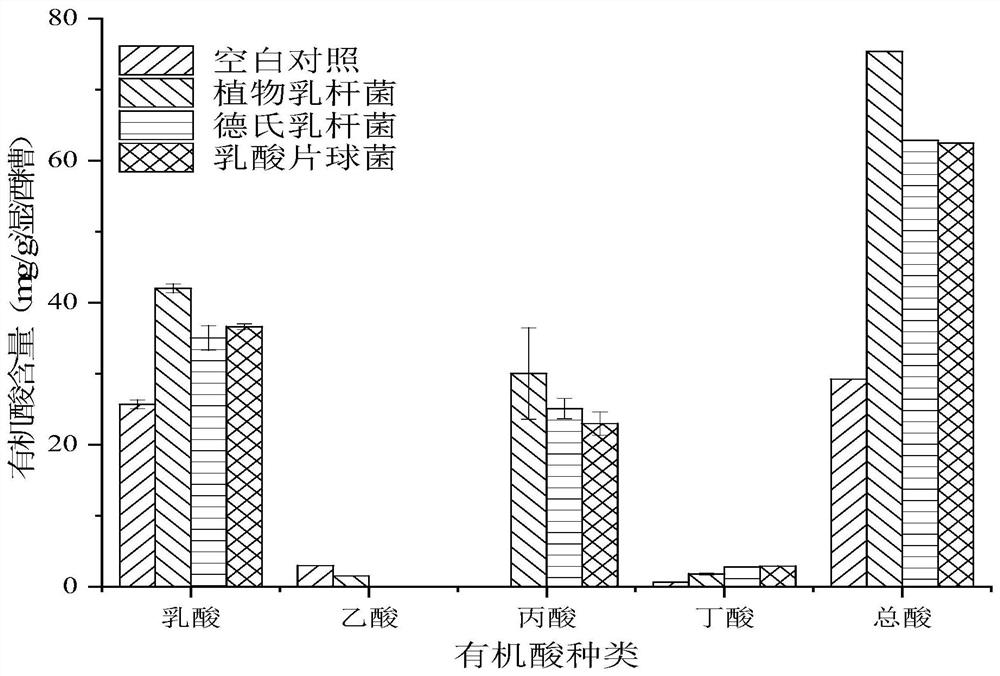

Method for producing multifunctional distiller's grain feed

PendingCN112205514AImprove reuse efficiencyRealize rational utilizationAnimal feeding stuffFood processingNutritional deficiency[Candida] apicola

The invention provides a method for producing a multifunctional distiller's grain feed, which mainly comprises the following steps: pretreating raw material vinasse, and inoculating microbial strainsto ferment by using the pretreated vinasse as a fermentation substrate, thereby obtaining the multifunctional distilled spirit vinasse feed, wherein the microbial strains consist of saccharomyces cerevisiae, candida utilis, lactobacillus plantarum, bacillus subtilis, trichoderma koningii, aspergillus niger CICC 2103, aspergillus niger CICC 2041 and Myceliophthora thermophila. Various functional microorganisms are mixed to ferment the vinasse, so that the problems of insufficient nutrition and single function of the vinasse feed can be solved, and the vinasse feed has the functions of promotinganimal growth, improving animal immunity, improving feed palatability and the like, and can also enrich animal intestinal beneficial flora.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

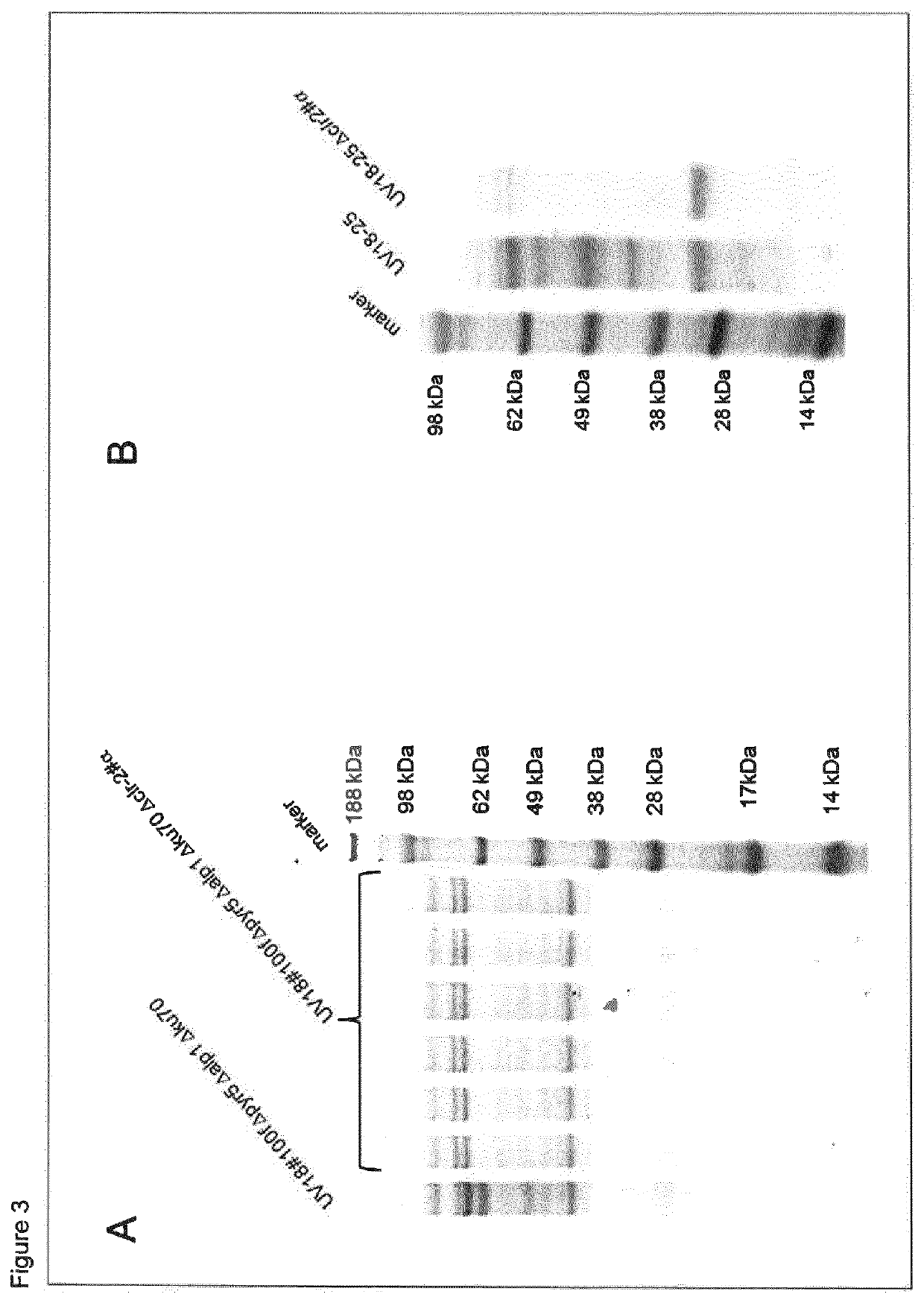

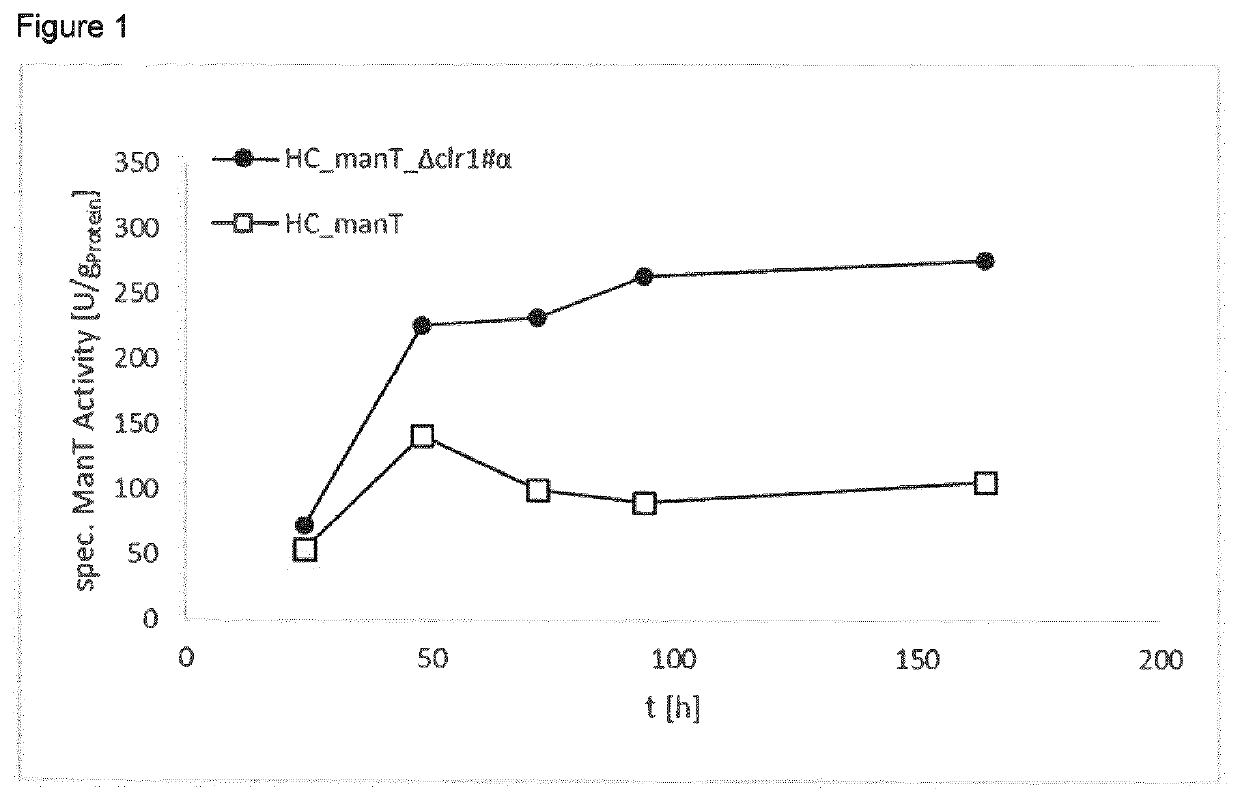

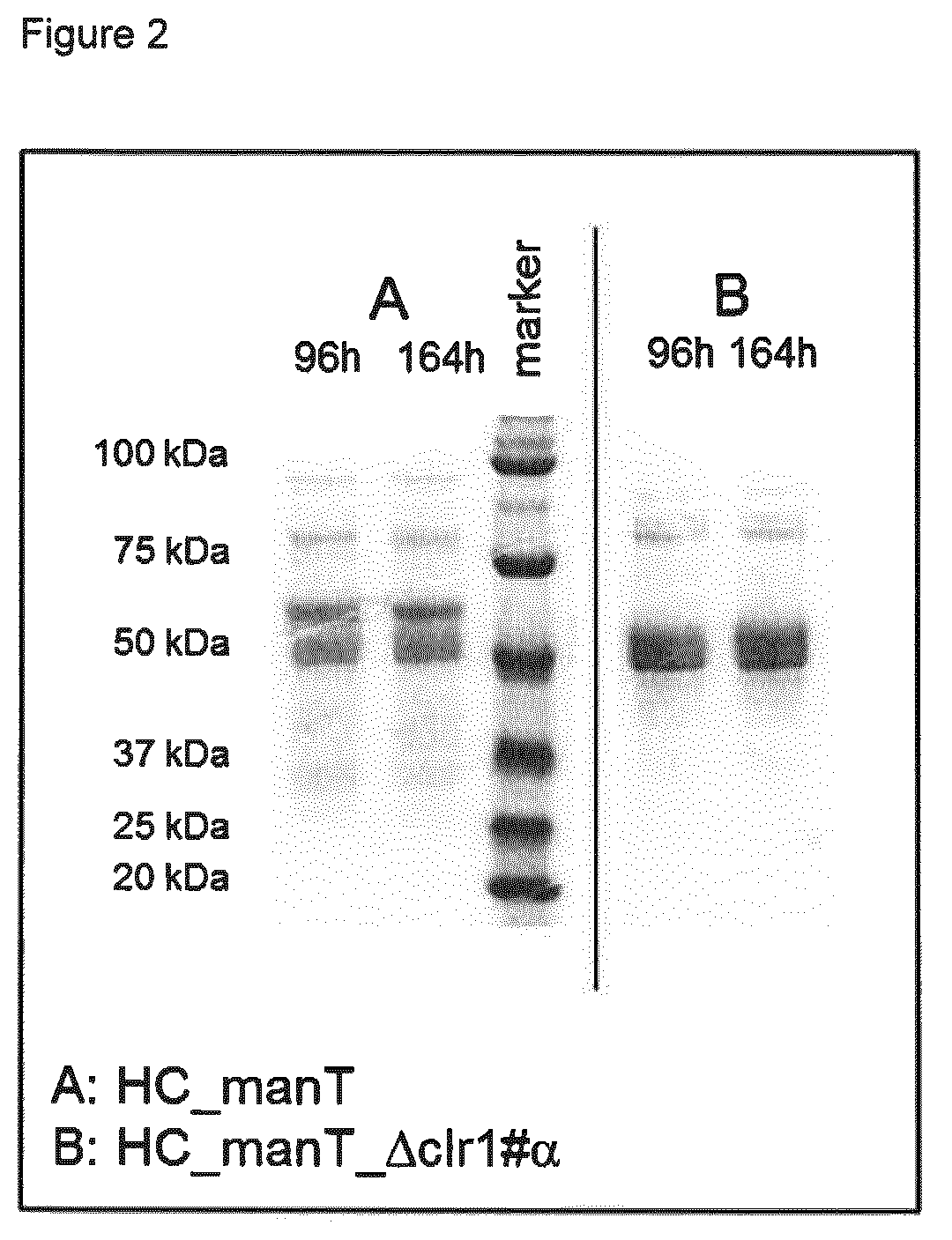

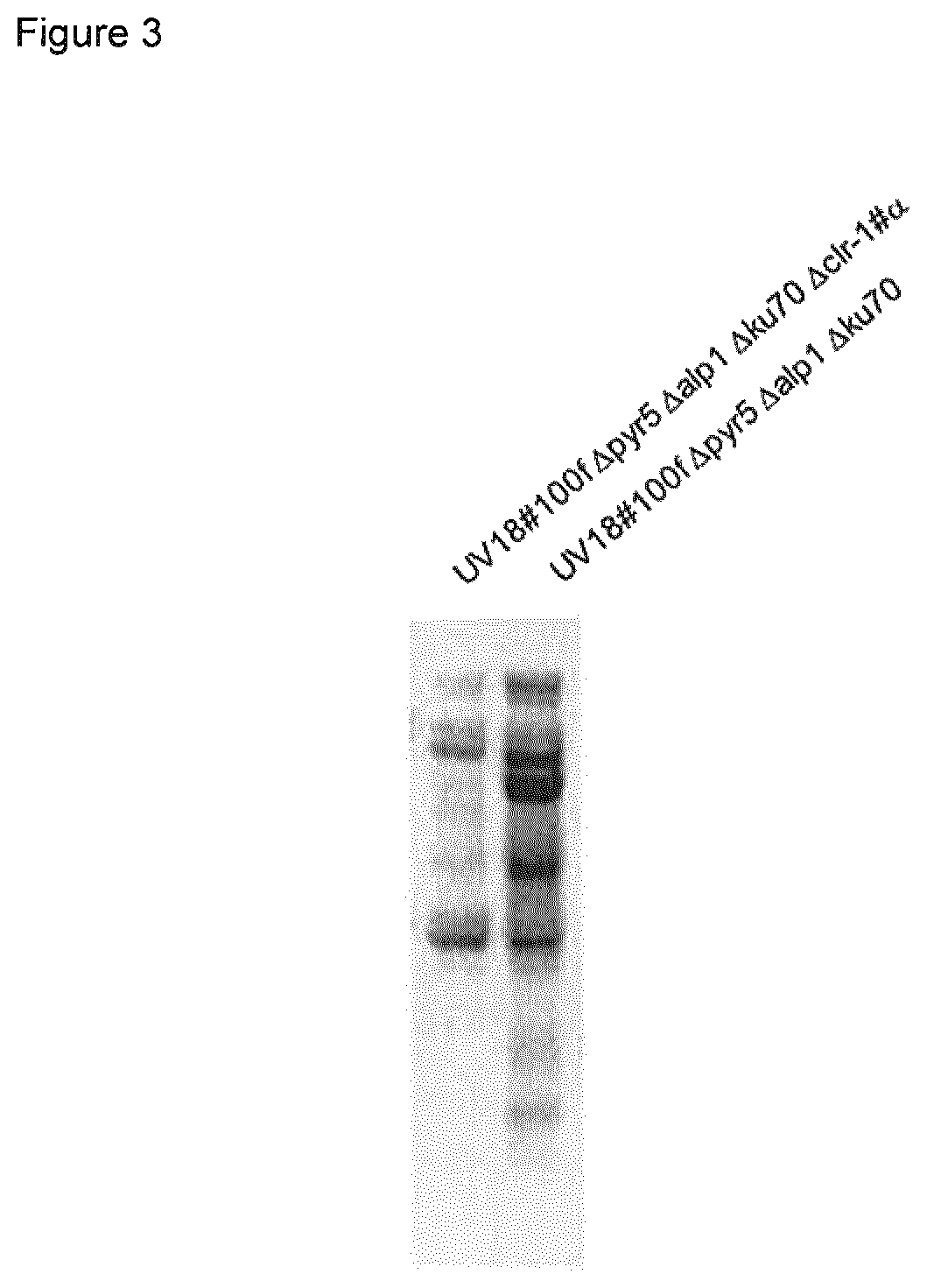

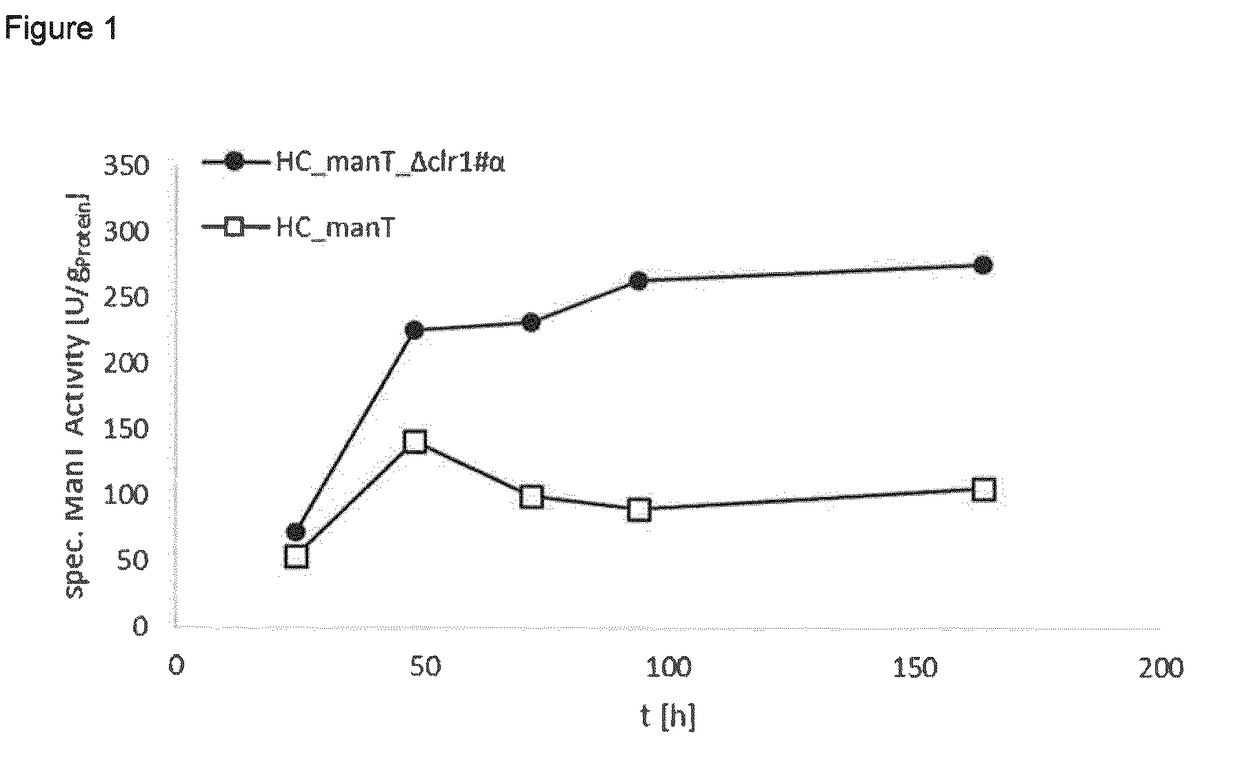

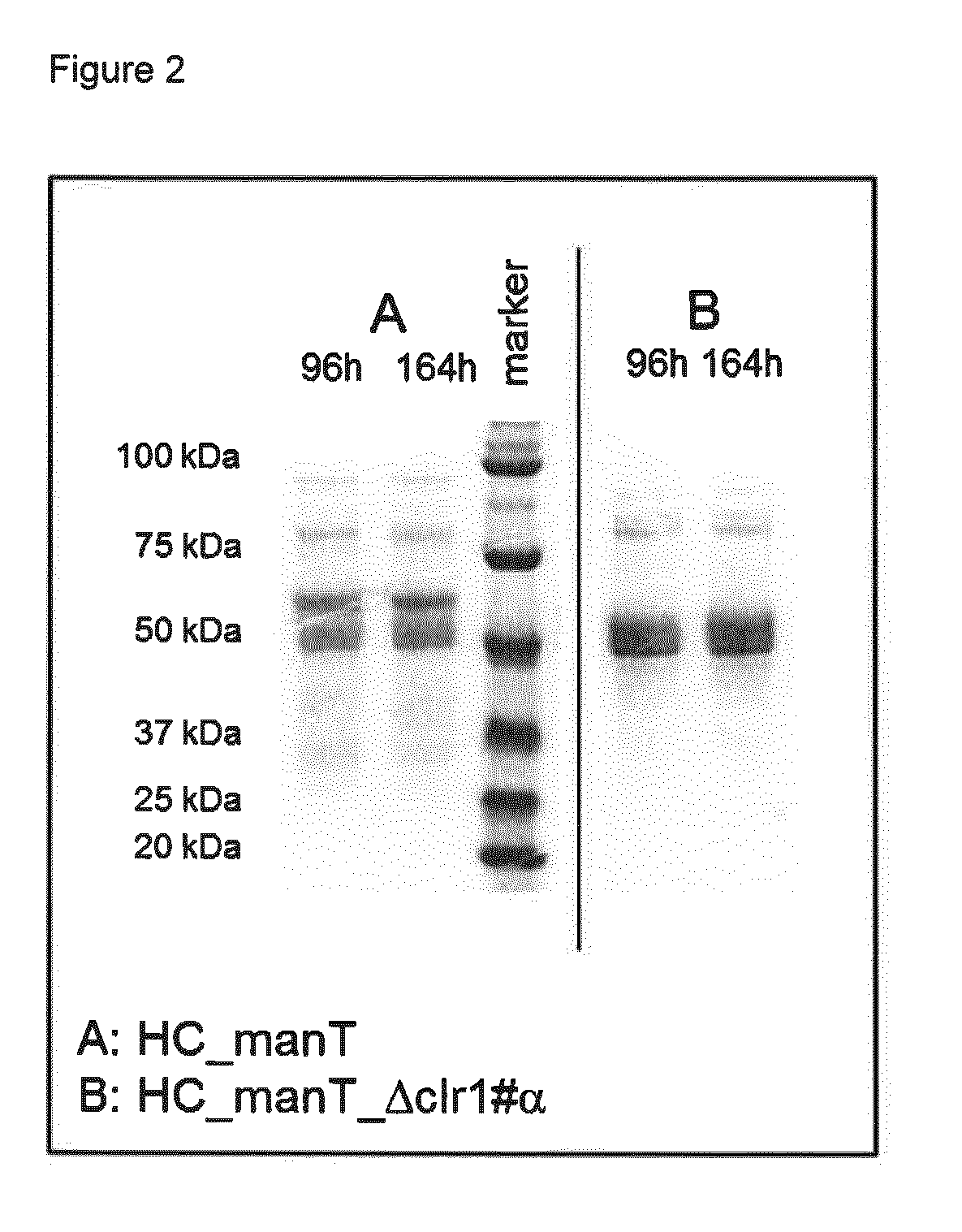

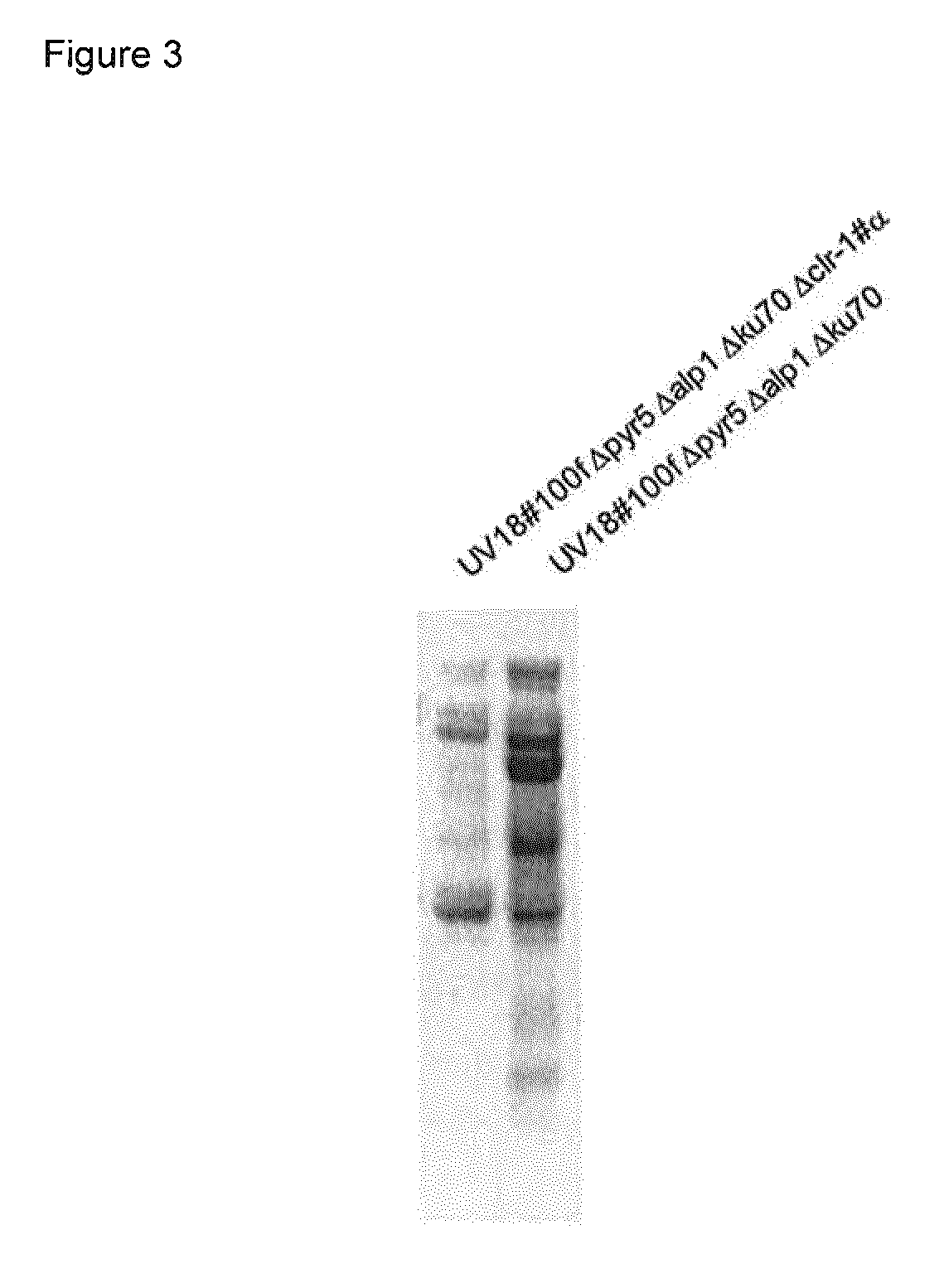

Method of producing proteins in filamentous fungi with decreased CLR1 activity

ActiveUS10597429B2Decrease and eliminate activityReduce the amount of solutionFungiHydrolasesMyceliophthora thermophilaCellulase

Owner:BASF SE

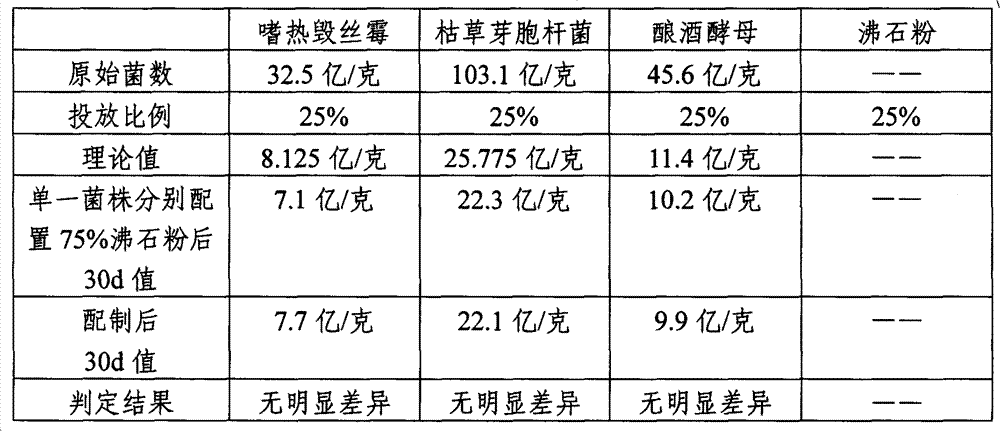

Novel myceliophthora thermophila strain and application thereof

ActiveCN102352320BImprove proliferation efficiencyImprove biological activityFungiMicroorganism based processesCelluloseMicroorganism

The invention discloses a novel myceliophthora thermophila strain (CLIMAX-VMT). The preservation number of the novel myceliophthora thermophila strain is CGMCC No.5134, the preservation date is August 12th, 2011, and the preservation unit is General Microbiology Center of China Microbial Strain Preservation Management Committee. The invention also discloses a microbial inoculum containing the strain. The novel myceliophthora thermophila strain (CLIMAX-VMT) provided by the invention has very obvious fast fermentation temperature rise and cellulose decomposition performance and is innocuous andharmless to people and livestock. When the strain is used for fermenting organic solid waste materials, the fast temperature rise in 24h can be reached, and the temperature is raised to a value higher than 60 DEG C in 48h and can be maintained for more than 5 days. The strain does not have the obvious antagonism action on most low-temperature germs, i.e. the universality and the matching with other strains of the microbial inoculum are very good.

Owner:BEIJING JINGGENG TIANXIA AGRI TECH

Functional organic material decomposing agent and preparation method thereof

ActiveCN102337237BPromote growthSuppression of soil borne diseasesFungiBacteriaDiseaseResource utilization

The invention discloses an organic material decomposing agent, which comprises the following components in percentage by weight: 10-50 parts of Streptomyces fradiae CGMCC No.5133 microbial inoculum, 5-20 parts of Myceliophthora thermophila CGMCC No. 5134 microbial inoculum, 0-20 parts of Trichoderma viride microbial inoculum, 0-20 parts of Bacillus subtilis microbial inoculum and 0-20 parts of microzyme inoculum. The invention provides the organic material decomposing agent with auxin accumulation function which utilizes the quick accumulation of auxin generated by the Streptomyces fradiae inthe medium temperature stage and the matching of high temperature function of the Myceliophthora thermophila in the anaphase to realize quick treatment and final resource utilization of organic materials, and treated organic solid wastes are fundamentally transformed, embody good performances in improving soil, promoting growth and inhibiting soil-borne diseases and meanwhile are environment-friendly and sanitary.

Owner:廊坊市精耕天下农业科技有限公司

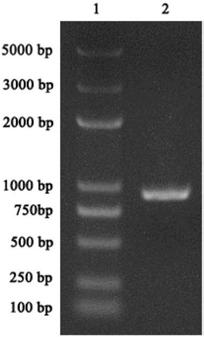

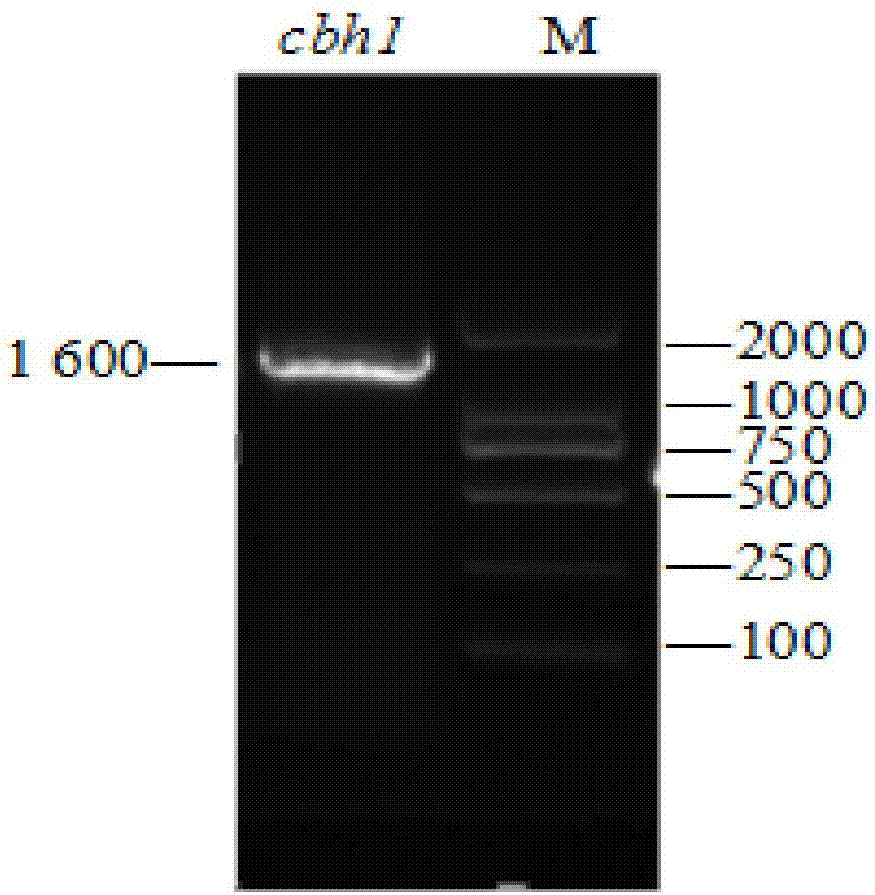

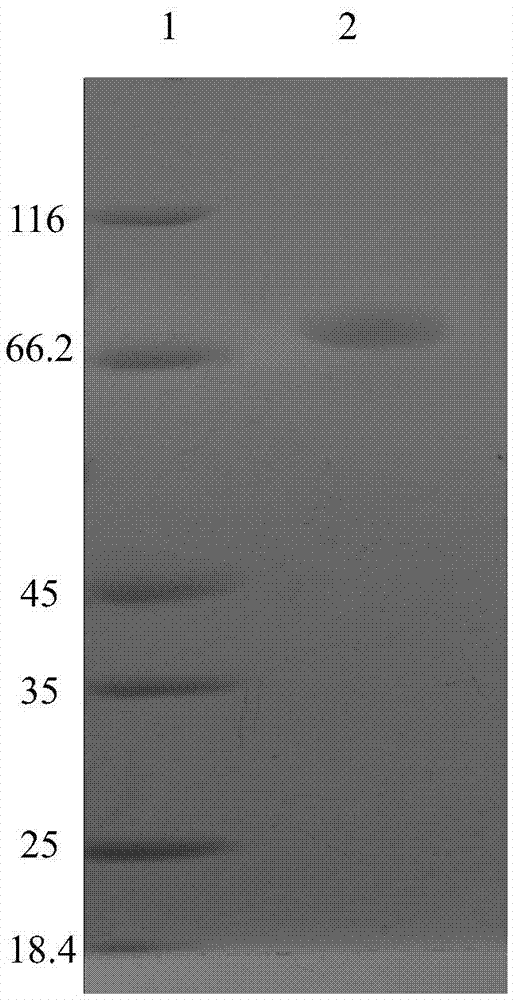

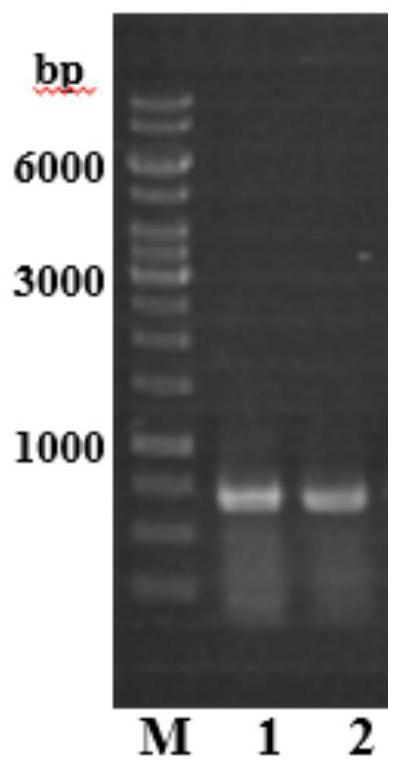

Novel heat-resisting glucoside hydrolase MtCel1 and coding sequence and application thereof

The invention provides novel thermally stable Myceliophthora thermophila glucoside hydrolase MtCel1 and a coding sequence and application thereof. An RT-PCR method is adopted to obtain a DUF4360 superfamily glycoside hydrolase gene MtCel1 from Myceliophthora thermosphacta, the gene is cloned and inserted into a pichia pastoris integrated expression vector pPIC9K, then the obtained glycoside hydrolase gene MtCel1 expression vector pPIC9K / MtCel1 is introduced into pichia pastoris GS115, and then a yeast engineering bacterium GS-MT-Cel1 expressing the glycoside hydrolase gene MtCel1 is screened out and expresses that the produced glycoside hydrolase MtCel1 has very high incision hydrolase activity to cellulose. The MtCel1 has good thermal stability and strong cellulose hydrolysis capability, can be widely applied to fiber waste and other industrial fields and has great economic value and social value.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

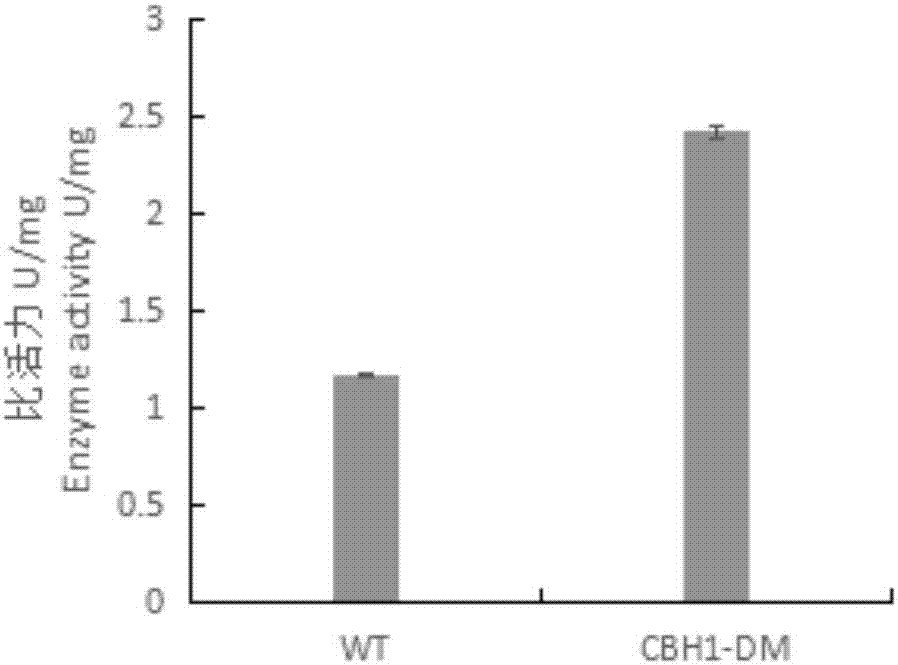

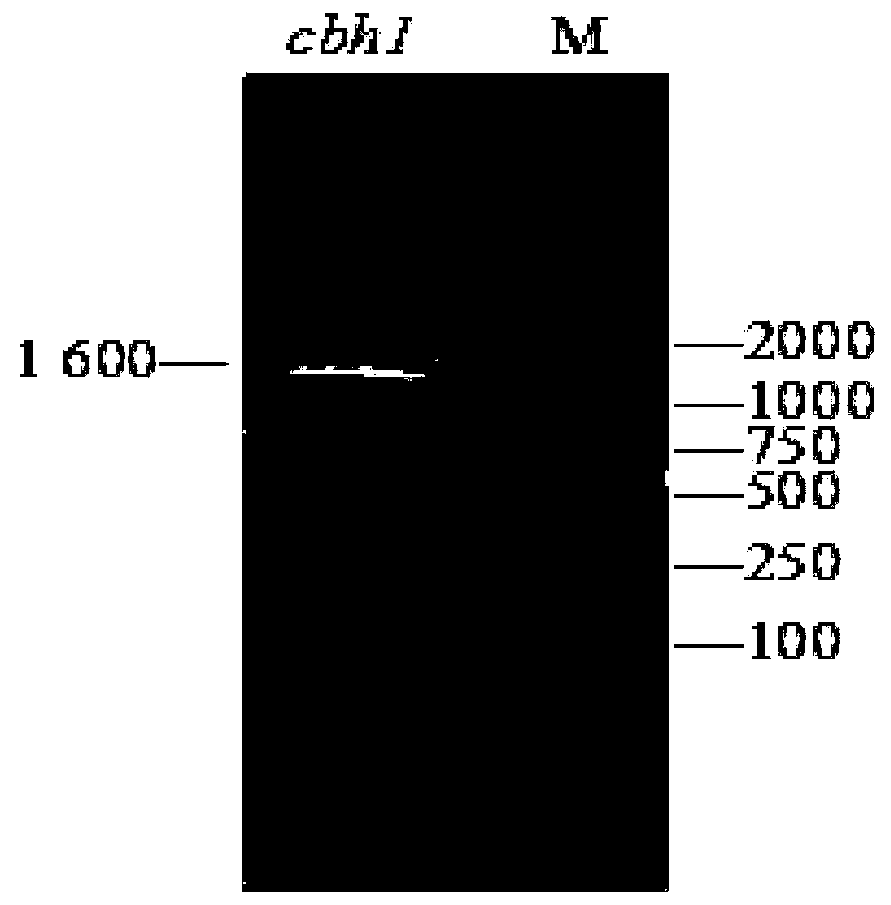

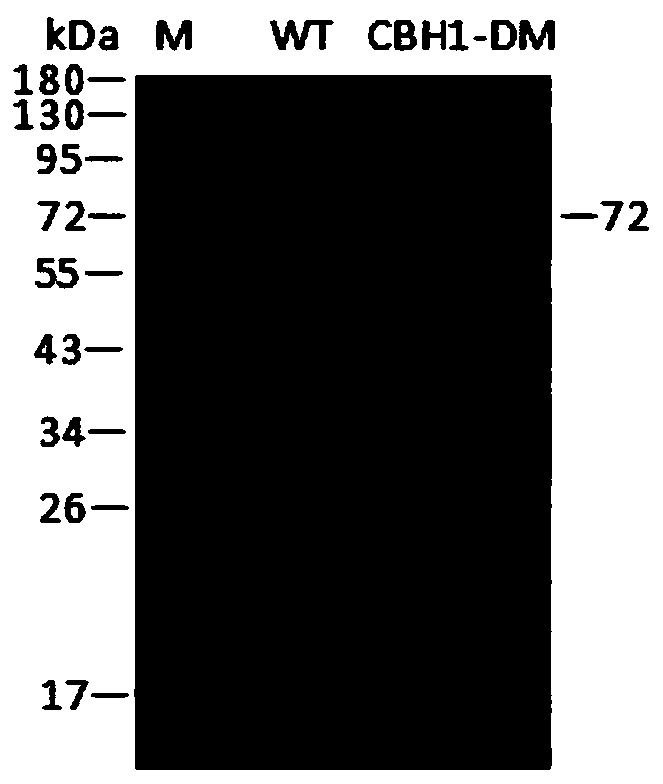

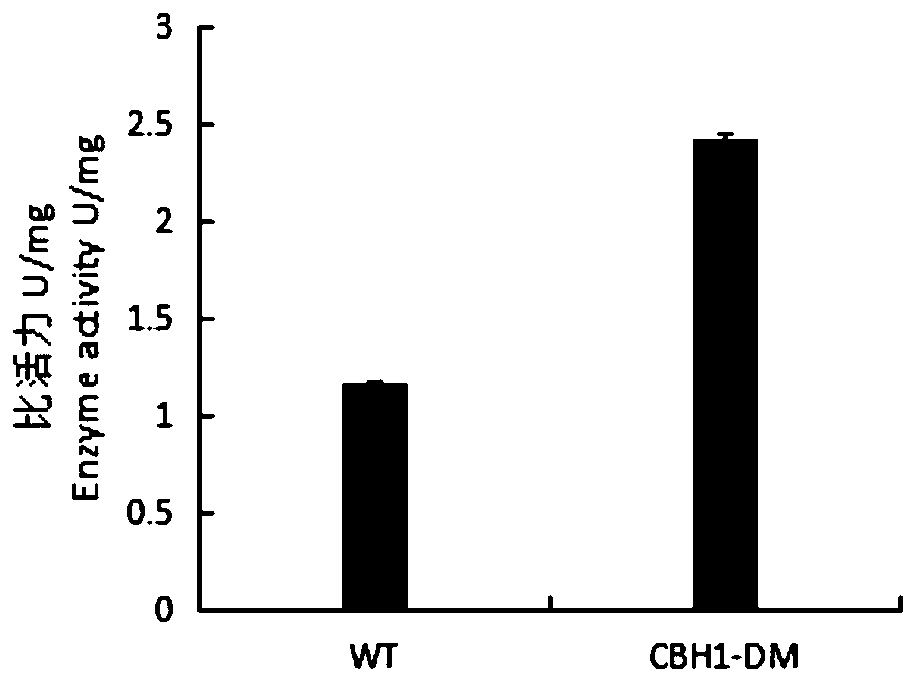

Myceliophthora thermophila exoglucosidase mutant and application thereof

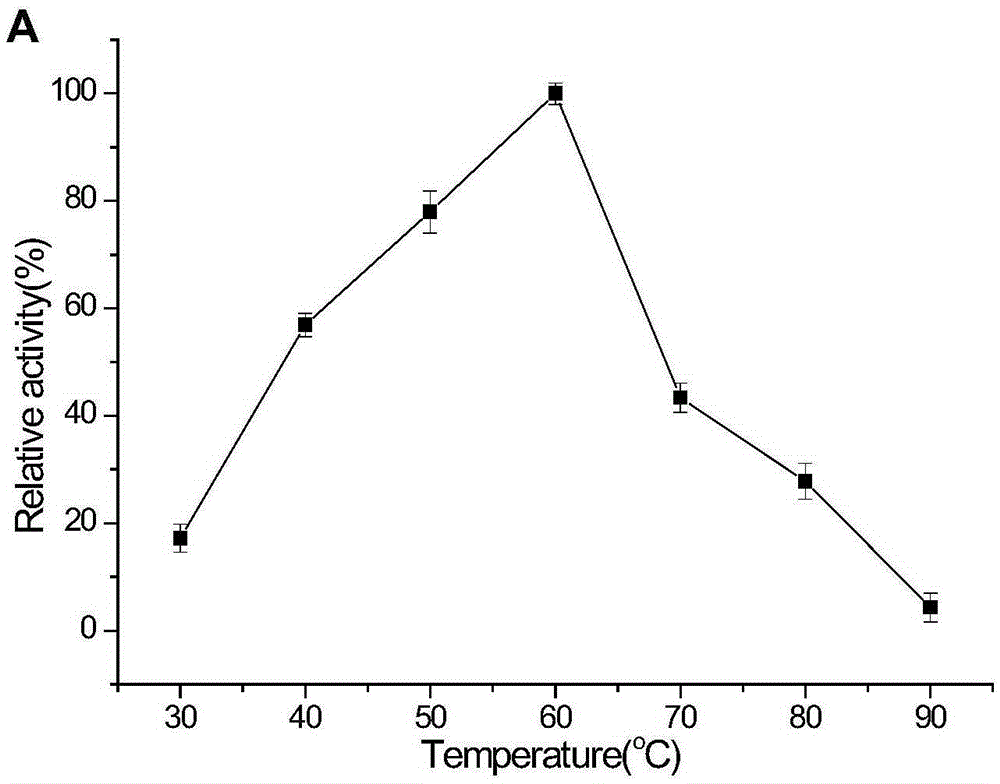

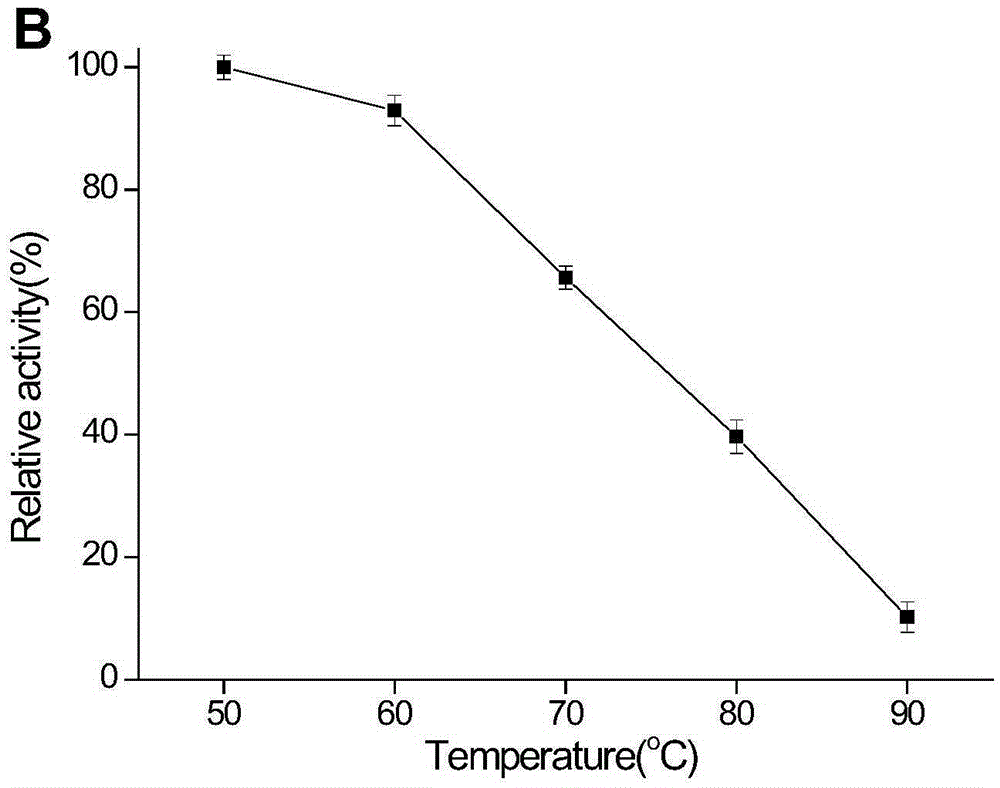

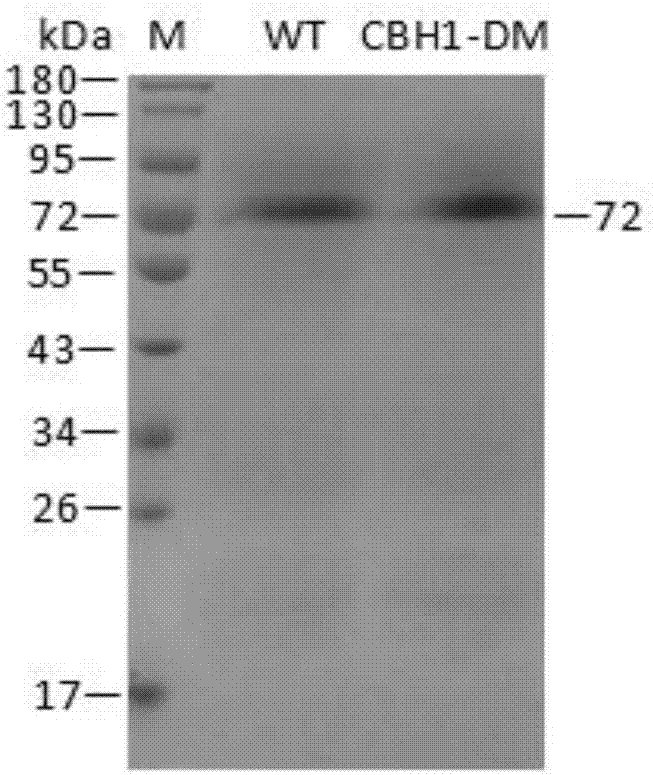

InactiveCN107988182AHigh catalytic efficiencyImprove release efficiencyFermentationGlycosylasesWild typeMyceliophthora thermophila

The invention discloses a myceliophthora thermophila exoglucosidase mutant and application thereof. A protein of the invention is named as CBH1-DM and is one of the following proteins (a) and (b): (a)a protein composed of amino acid sequences shown in SEQ ID NO.2 in a sequence table; and (b) a fusion protein obtained by connecting a label at an N terminal or / and C terminal of (a). Compared with awild type, the myceliophthora thermophila exoglucosidase mutant disclosed by the invention has the advantages that enzymatic specific activity is improved by 2.1 times, catalysis efficiency is improved by 8.6 times, and thermal stability is improved by 2 times, so that the myceliophthora thermophila exoglucosidase mutant has a better industrial application prospect.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method of producing proteins in filamentous fungi with decreased clr1 activity

ActiveUS20180354999A1Decrease and eliminate activityDecrease and eliminate activity of proteaseFungiHydrolasesBiotechnologyMyceliophthora thermophila

The present invention relates to a method of producing a recombinant polypeptide in a filamentous fungus which is genetically modified to decrease or eliminate the activity of cellulase regulator 1 (CLR1) and to express the recombinant polypeptide. The method further relates to a filamentous fungus Myceliophthora thermophila, which is genetically modified to decrease or eliminate the activity of CLR1 and to the use of this filamentous fungus in the production of a recombinant polypeptide.

Owner:BASF AG

Novel heat-resistant dual-function glucoside hydrolase MtCel2 and encoding sequence and application thereof

The invention relates to novel and heat-stable heat-resistant dual-function glucoside hydrolase MtCel2 of Myceliophthora thermophila and an encoding sequence and application thereof. A DUF4360 superfamily glucoside hydrolase gene MtCel2 is obtained from the Myceliophthora thermophila through a RT-PCR method and is cloned and inserted into a pichia pastoris integrative expression vector pPIC9K; then the obtained glucoside hydrolase gene MtCel2 expression vector pPIC9K / MtCel2 is transferred into pichia pastoris GS115, engineering saccharomycetes GS-MT-Cel2 expressing the glucoside hydrolase gene MtCel2 screened out, and the glucoside hydrolase gene MtCel2 generated by expression of the engineering saccharomycetes GS-MT-Cel2 has high endonuclease hydrolase activity to hydrolase and xylan. MtCel2 has good heat stability and high cellulose hydrolysis capacity, can be widely applied to the field of fiber waste materials and other industrial fields and has significant economic value and social value.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

A lytic polysaccharide monooxygenase modified by site-directed mutation and its construction method and application

ActiveCN110551699BIncrease enzyme activityIncrease contentFungiMicroorganism based processesOxygenaseMyceliophthora thermophila

The invention discloses a lytic polysaccharide monooxygenase modified by site-directed mutation, its construction method and application, and belongs to the field of genetic engineering. The enzyme activity provides a degradative function in the degradation of crystalline polysaccharides of cellulose. The lytic polysaccharide monooxygenase mutant of the present invention is based on the amino acid sequence of the lytic polysaccharide monooxygenase of wild-type Myceliophthora thermophila, and the 34th position is mutated from Arg to Leu. The optimal temperature of the wild enzyme and the wild enzyme is both 85°C, and the specific activity of the mutant enzyme is about 2 times higher than that of the wild enzyme, and when the pH is greater than 5.5, the specific activity of the mutant enzyme is about 2 times higher than that of the wild enzyme. When microcrystalline cellulose was used as the substrate, the glucose content produced by the synergistic reaction of cellulase and mutant enzyme was significantly increased by 48.5% compared with the substrate degraded by cellulase alone. It can be seen that the mutant enzyme significantly improved the enzyme activity, which can Lower economic costs for industrial applications.

Owner:TIANJIN UNIV OF SCI & TECH

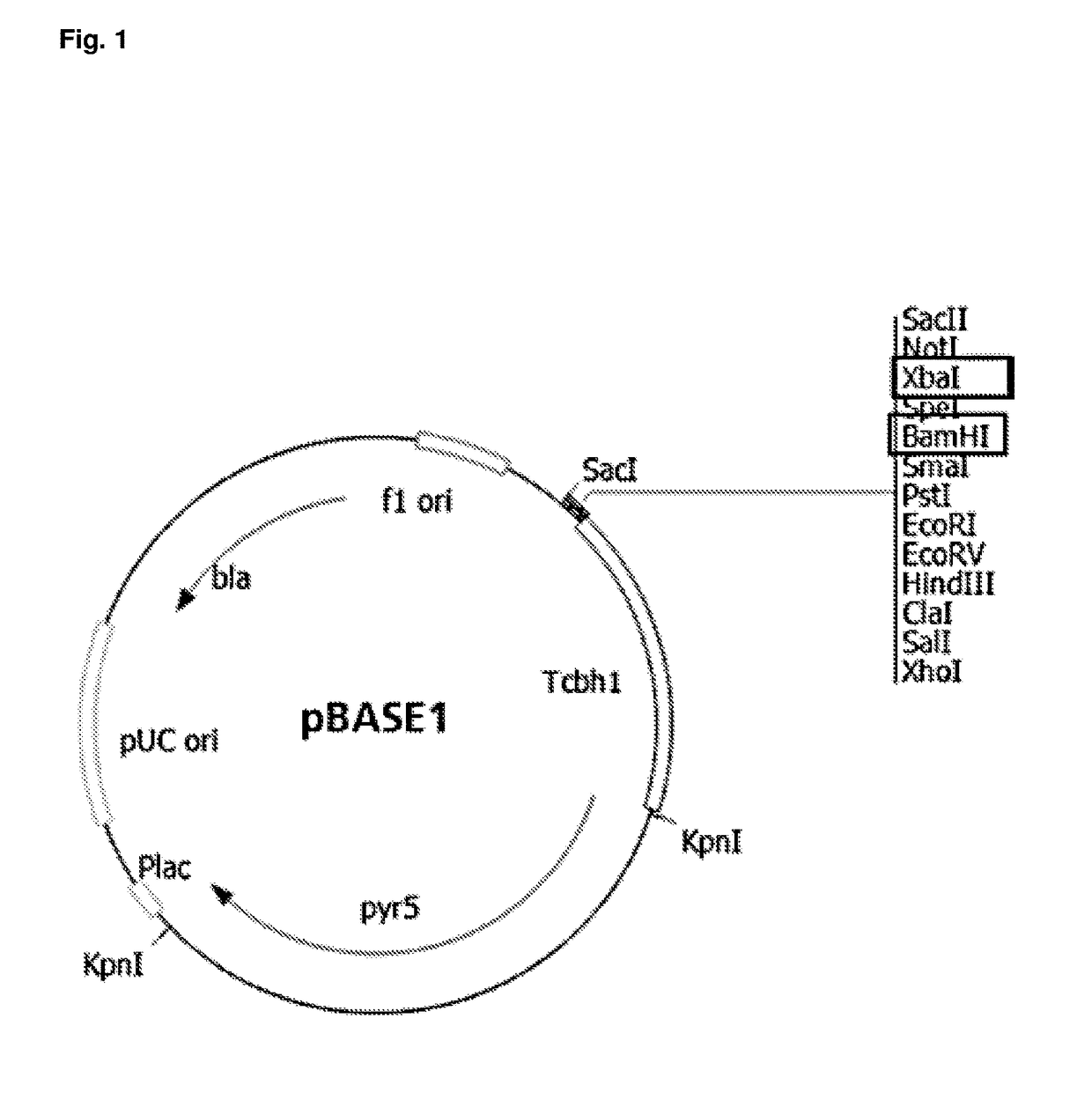

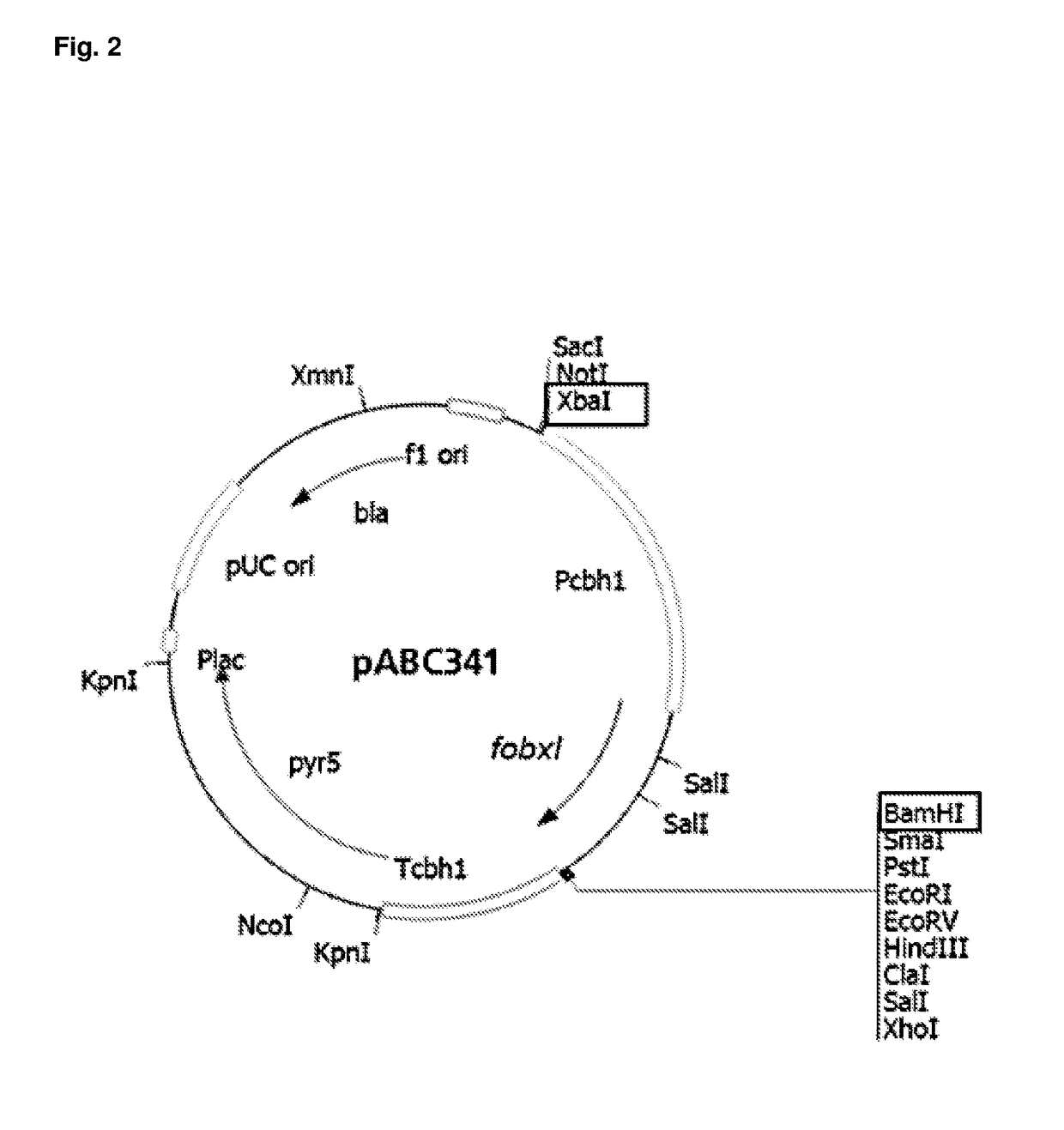

Expression of recombinant beta-xylosidase enzymes

InactiveUS9834763B2Improve hydrolysis efficiencyIncrease productionBacteriaBiofuelsFusarium oxysporumBioproducts

The present invention relates to a Myceliophthora thermophila host cell which expresses a recombinant enzymes from Fusarium oxysporum with beta-xylosidase activity. The invention also refers to an enzymatic composition comprising the host cell of the invention and / or the recombinant enzyme with beta-xylosidase activity expressed by the host cell of the invention. The invention further relates to the use of the host cell of the invention, the recombinant enzyme with beta-xylosidase activity expressed by the host cell of the invention or the composition of the invention for the degradation of biomass and to a method of producing bioproducts, preferably bioethanol, which comprises the use of the host cell of the invention, the recombinant enzyme with beta-xylosidase activity expressed by the host cell of the invention or the composition of the invention.

Owner:ABENGOA BIOENERGIA NUEVAS TECHAS

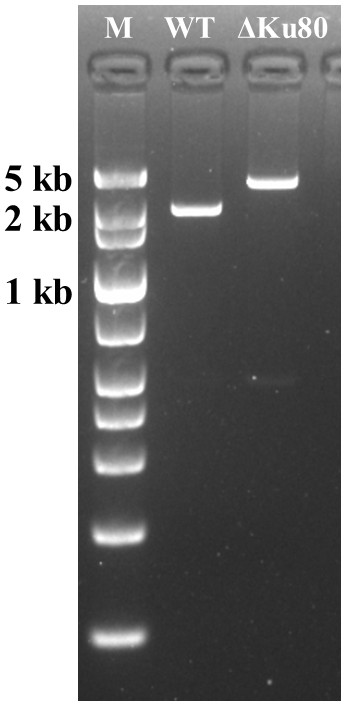

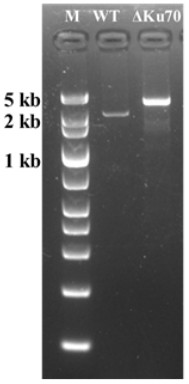

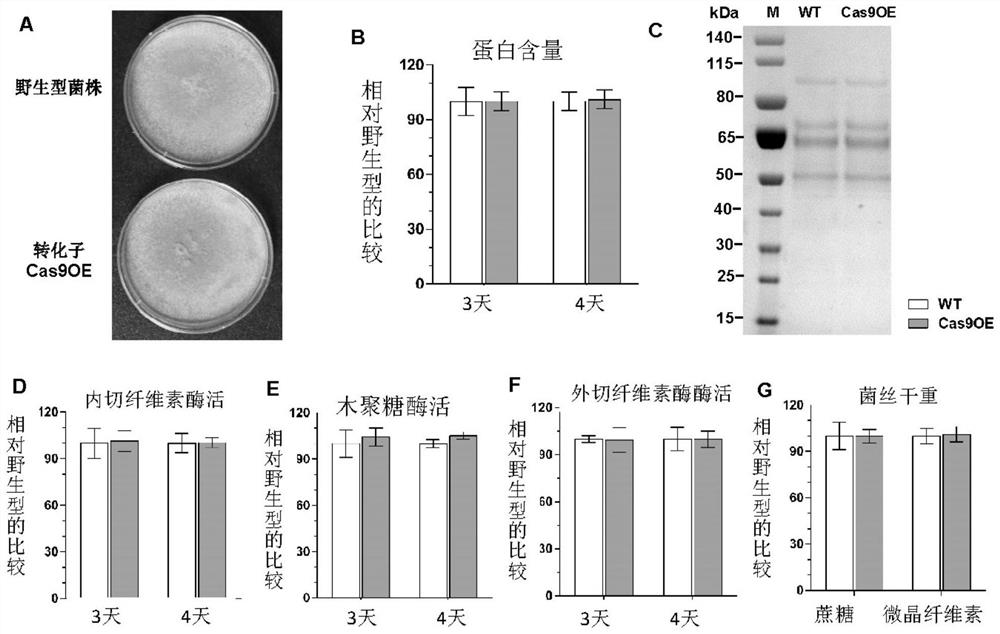

Method for constructing thermophilic mycelia strain with high homologous recombination efficiency and application of thermophilic mycelia strain

InactiveCN114591849AReduce workloadHigh homologous recombination efficiencyFungiHydrolasesMyceliophthora thermophilaWild type

The invention relates to the technical field of gene engineering, in particular to a method for constructing a thermophilic mycelia strain with high homologous recombination efficiency and application of the thermophilic mycelia strain. According to the mutant strain delta Ku80 obtained by the invention, the homologous recombination efficiency of a trichoderma thermophile CRISPR-Cas9 gene editing system can be improved to 86% from 57% of a wild type, the workload of genetic transformation of the trichoderma thermophile is reduced, and the homologous recombination efficiency is improved.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

A kind of myceliophthora thermophila exoglucosidase mutant and its application

InactiveCN107988182BHigh catalytic efficiencyImprove release efficiencyFermentationVector-based foreign material introductionMyceliophthora thermophilaGlucan

Owner:SHANDONG AGRICULTURAL UNIVERSITY

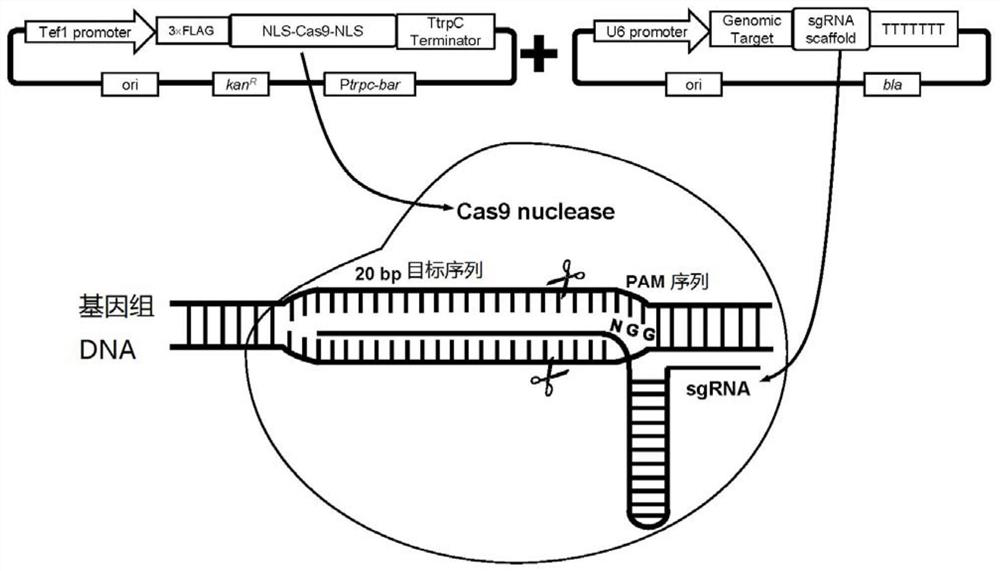

A genome editing vector, its composed genome editing system and application

ActiveCN108148853BRealize simultaneous editingIncrease production capacityHydrolasesMicroorganism based processesGenes mutationFungal gene

The present invention relates to a genome editing carrier, its composed genome editing system and its application, in particular to a thermophilic fungal genome editing carrier, its composed genome editing system CRISPR / Cas9 and its editing method and application, the genome editing carrier Including the promoter that starts the transcription of the coding DNA of the sgRNA, the promoter is the RNA polymerase III type U6 type promoter, and the application of the genome editing system can significantly improve the genome editing efficiency of Myceliophthora strains M.thermophile and M.heterothallica, Simultaneous editing of multiple sites in the Myceliophthora genome can be realized, and then multi-gene mutant strains can be obtained. This series of mutant strains can significantly improve the production capacity of cellulase, and can be used for the genetic engineering of thermophilic fungi with high cellulase production; The genome editing system can also promote the research on the function of the Myceliophthora thermophila gene, and at the same time, it is of great significance to the genome-directed editing and metabolic engineering transformation of the thermophilic industrial cellulase production strain.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com