Myceliophthora thermophila as well as solid-state fermentation method and application thereof

A thermophilic Myceliophthora thermophila and solid-state fermentation technology, applied in the field of microorganisms, can solve the problems of difficult rapid and effective degradation, long decay period, unbalanced nutrients, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Screening and identification of Myceliophthora thermophila:

[0030] 1) Dilute the obtained soil sample with sterile water, then spread it on a PDA plate containing penicillin, and after culturing at 40°C for 3 days, select mold colonies and transfer them to the PDA plate to obtain a single mold colony.

[0031] The total DNA of the mold was extracted by the CTAB method, and then amplified by PCR with fungal universal primers ITS1 and ITS4. The product was detected by 1% agarose gel electrophoresis and then sequenced. The sequencing results were analyzed and compared on NCBI, and the strain was determined to be thermophilic myceliophthora. mold.

[0032] 2) Mutagenesis and breeding of high-yield xylanase strain Myceliophthora thermophila MT1810.

[0033] Fermentation medium: Miscanthus 5.0g and nutrient solution 10ml, sterilized at 121°C for 30min.

[0034] Nutrient solution: (NH 4 ) 2 SO 4 3.5g, KH 2 PO 4 3.0g, MgSO 4 ·7H 2 O0.5g, CaCl 2 0.5g, Tween80 10.0g a...

Embodiment 2

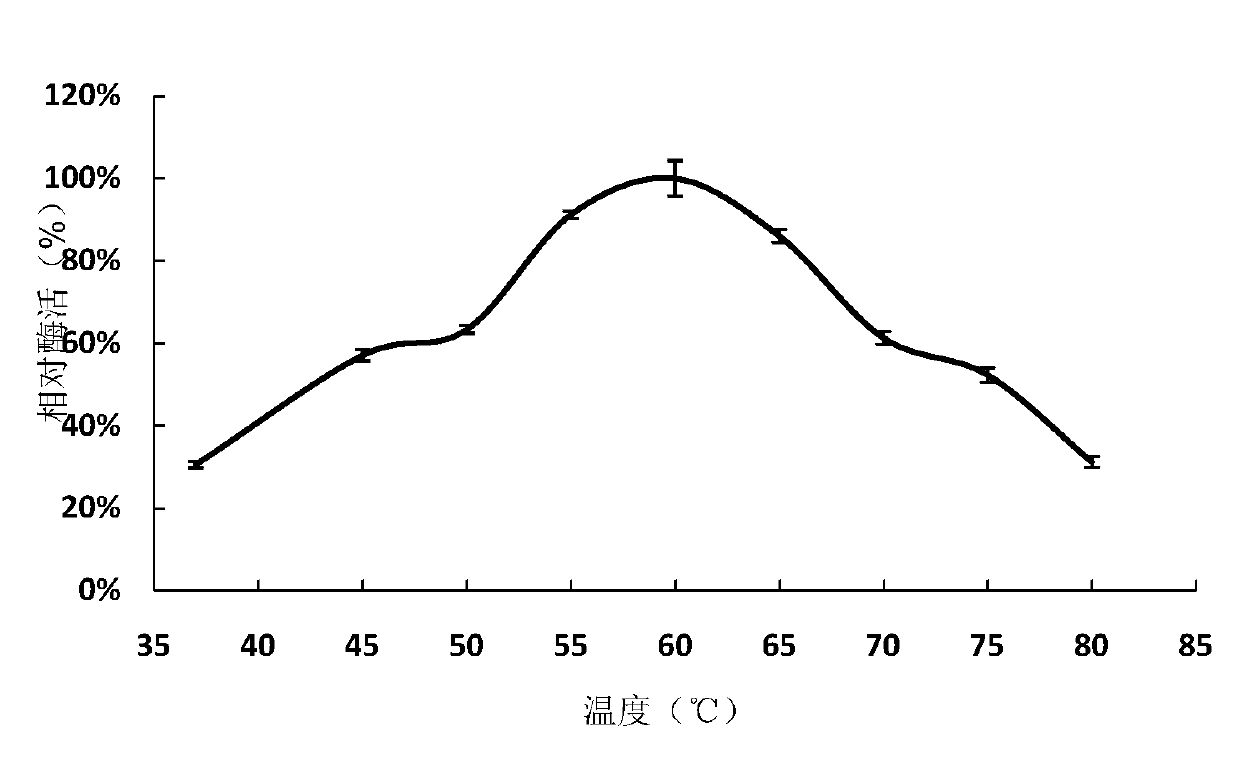

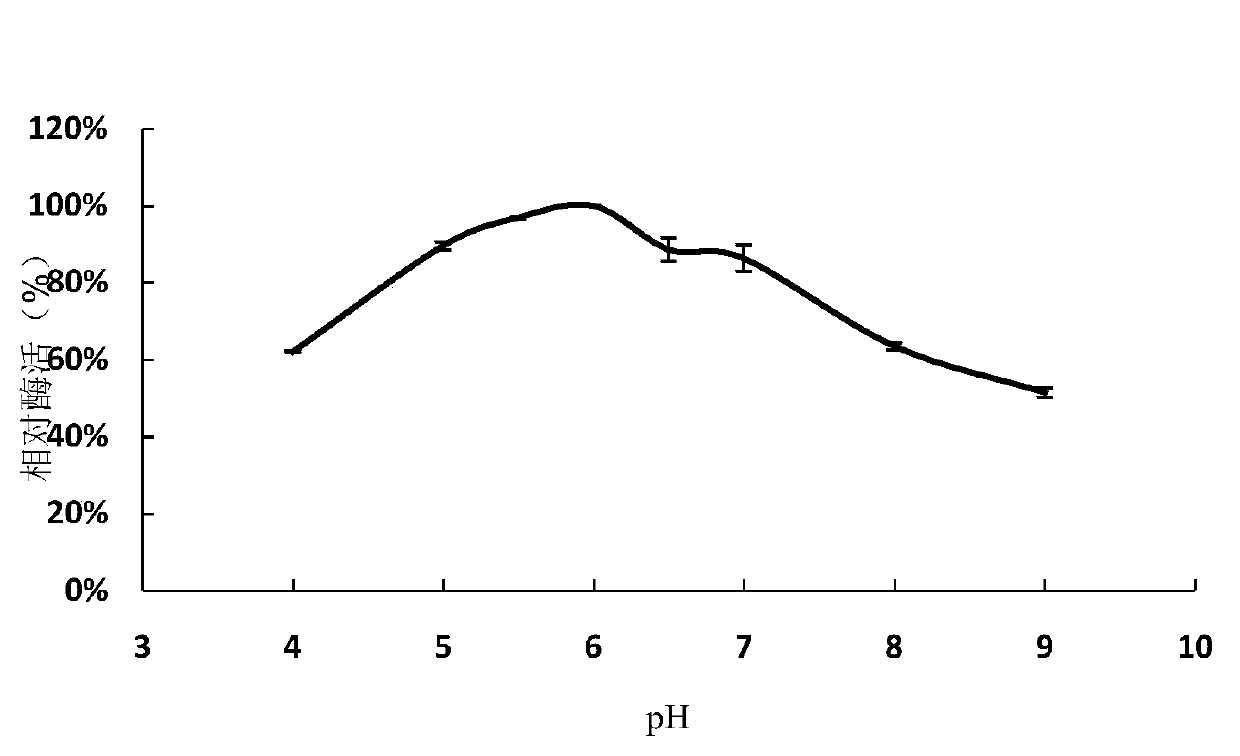

[0057] Solid-state fermentation method and enzymatic properties of Myceliophthora thermophila MT1810 with high xylanase production:

[0058] Solid-state fermentation medium: 70 parts of wheat bran, 3 parts of yeast extract, 10 parts of ammonium sulfate, 7 parts of potassium dihydrogen phosphate, 10 parts of glucose, the ratio of material to water is 1:1.5, and the initial pH is 7.5-8.0.

[0059] Every 100g of the above-mentioned solid-state fermentation medium was inoculated with 2ml of the spore suspension (the number of spores was 5×10 7 pcs / ml), stirred evenly, 30 ℃ static culture for 3 days, 50 ℃ cold air drying to moisture 12%, recorded xylanase enzyme activity 1860U / g, the number of viable bacteria 2.3 billion CFU / g.

[0060] Prepare Myceliophthora thermophila MT1810 spore suspension: the culture medium is YPD plate or YPD slant bottle, after inoculation with Myceliophthora thermophila MT1810, culture aseptically at 40±3°C for 4-6 days, then use sterile water (> 15ml, C...

Embodiment 3

[0072] Application of Myceliophthora thermophila MT1810 in the preparation of decomposing agent:

[0073] For the decomposing experiment of rice straw, 2kg of rice straw was cut to less than 3cm, and the ingredients of rice straw used were: 32.56% cellulose, 18.23% hemicellulose, 15.03% lignin, 3.56% crude protein, 1.38% crude fat, and 13.24% ash . Add 3% urea by weight of straw, 1% potassium dihydrogen phosphate, and adjust the moisture content to 70%. The spore suspension of Myceliophthora thermophila MT1810 was inoculated in 1kg rice straw powder, the inoculum size was 5×10 5 straw per g; 1 kg grass powder not inoculated with Myceliophthora thermophila was used as the control group. Afterwards, the grass powder was put into nylon mesh bags and placed in a 40°C incubator to decompose, and there was no need to turn the pile during this period.

[0074] After 30 days, the decomposing experiment was finished. After inoculation with Myceliophthora thermophila and decomposing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com