Patents

Literature

86 results about "Alpha ketoglutarate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

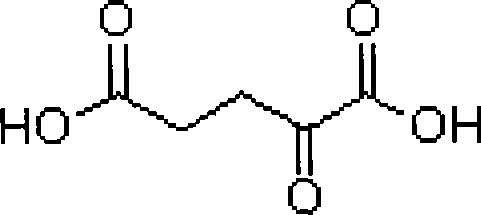

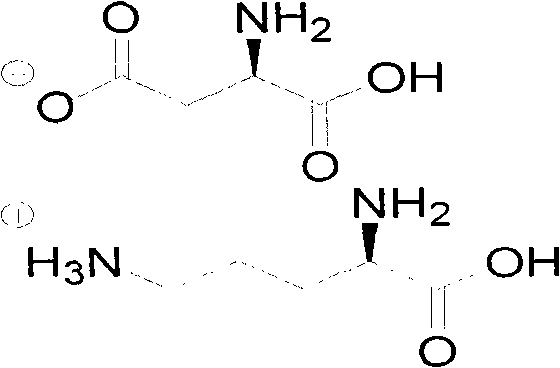

Intermediate in the Krebs' cycle; also produced from glutamate in amino group transfer reactions and by oxidative deamination.

Human adipose-derived stem cell serum-free basic medium

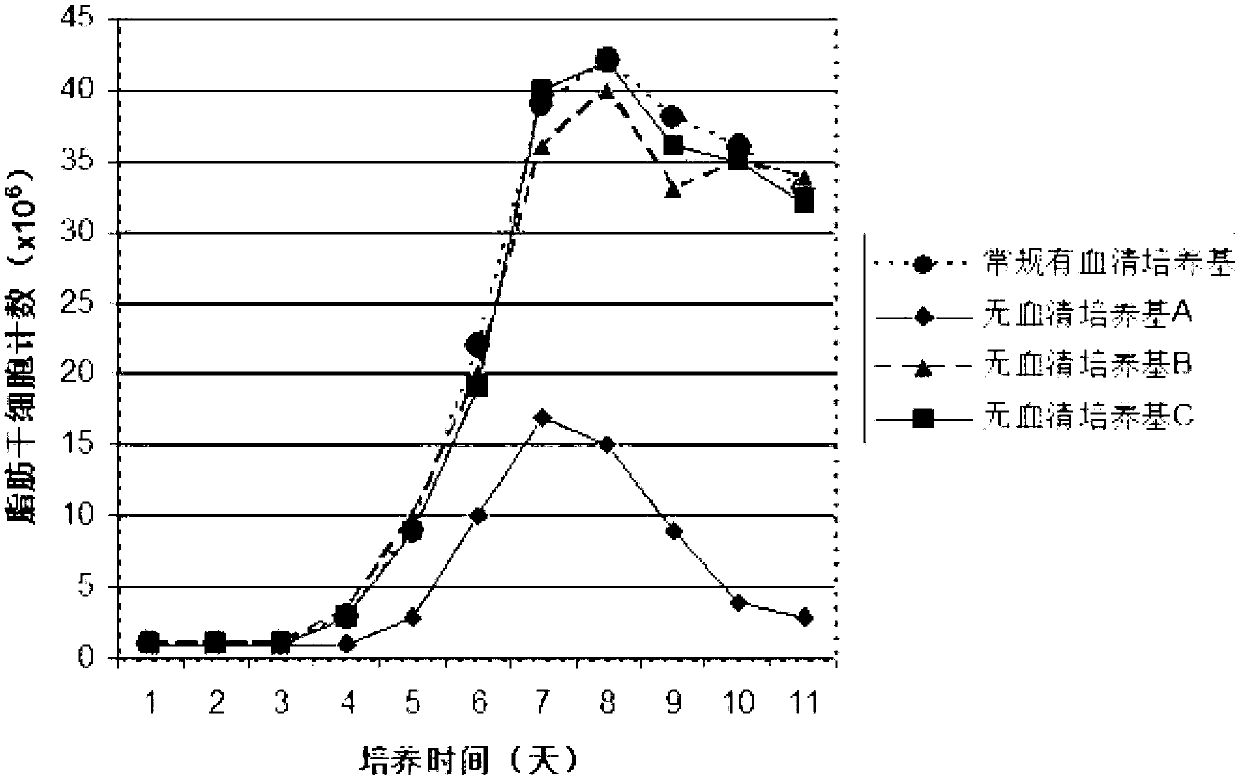

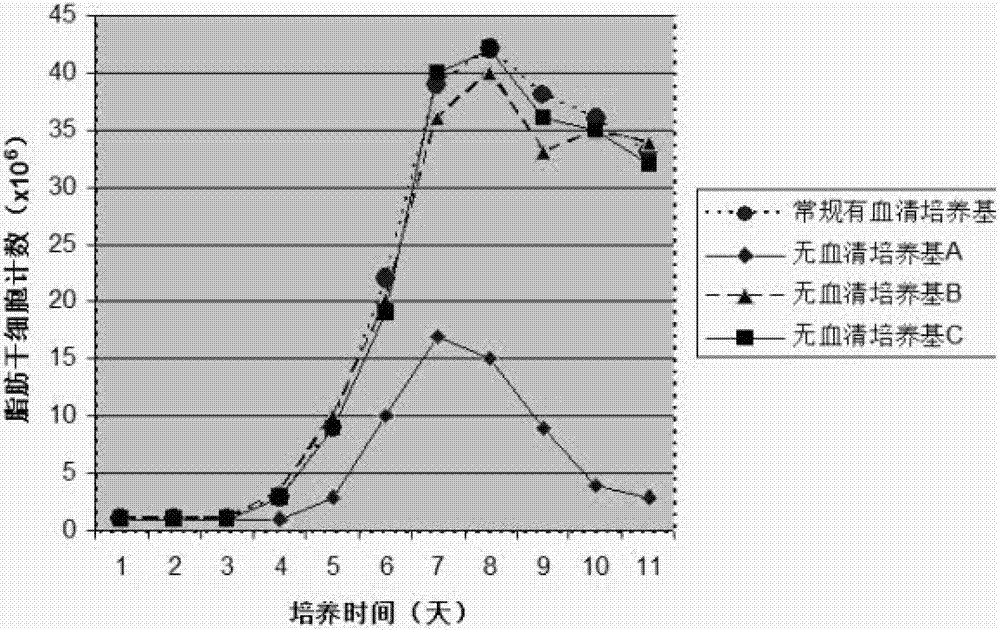

ActiveCN102732477BOvercome riskSkeletal/connective tissue cellsMineral ascorbatesAscorbic acid 2-sulfate

The invention discloses a human adipose-derived stem cell serum-free basic medium. The medium uses a serum substitute, and is composed of a high glucose type DMEM basic medium, human serum albumin, transferrin, taurine, reduced glutathione, ceruloplasmin, L-ascorbic acid-2-sulfate, alpha-tocopherol succinate, linoleic acid, alpha-ketoglutarate and selenium. The serum-free basic medium can exempt potential threats caused by animal serum in conventional serum-containing mediums to human health, and the adipose-derived stem cells cultured by the medium is more suitable for clinical application.

Owner:JIANGSU RE STEM BIOTECH

Human adipose-derived stem cell serum-free basic medium

ActiveCN102732477AIncrease viscosityFree from mechanical damageSkeletal/connective tissue cellsAscorbic acid 2-sulfateMineral ascorbates

The invention discloses a human adipose-derived stem cell serum-free basic medium. The medium uses a serum substitute, and is composed of a high glucose type DMEM basic medium, human serum albumin, transferrin, taurine, reduced glutathione, ceruloplasmin, L-ascorbic acid-2-sulfate, alpha-tocopherol succinate, linoleic acid, alpha-ketoglutarate and selenium. The serum-free basic medium can exempt potential threats caused by animal serum in conventional serum-containing mediums to human health, and the adipose-derived stem cells cultured by the medium is more suitable for clinical application.

Owner:JIANGSU RE STEM BIOTECH

Water-soluble strontium salts for use in treatment of cartilage and/or bone conditions

InactiveUS20060122274A1Weight increaseReduce morbidityBiocideHeavy metal active ingredientsDiseaseSolubility

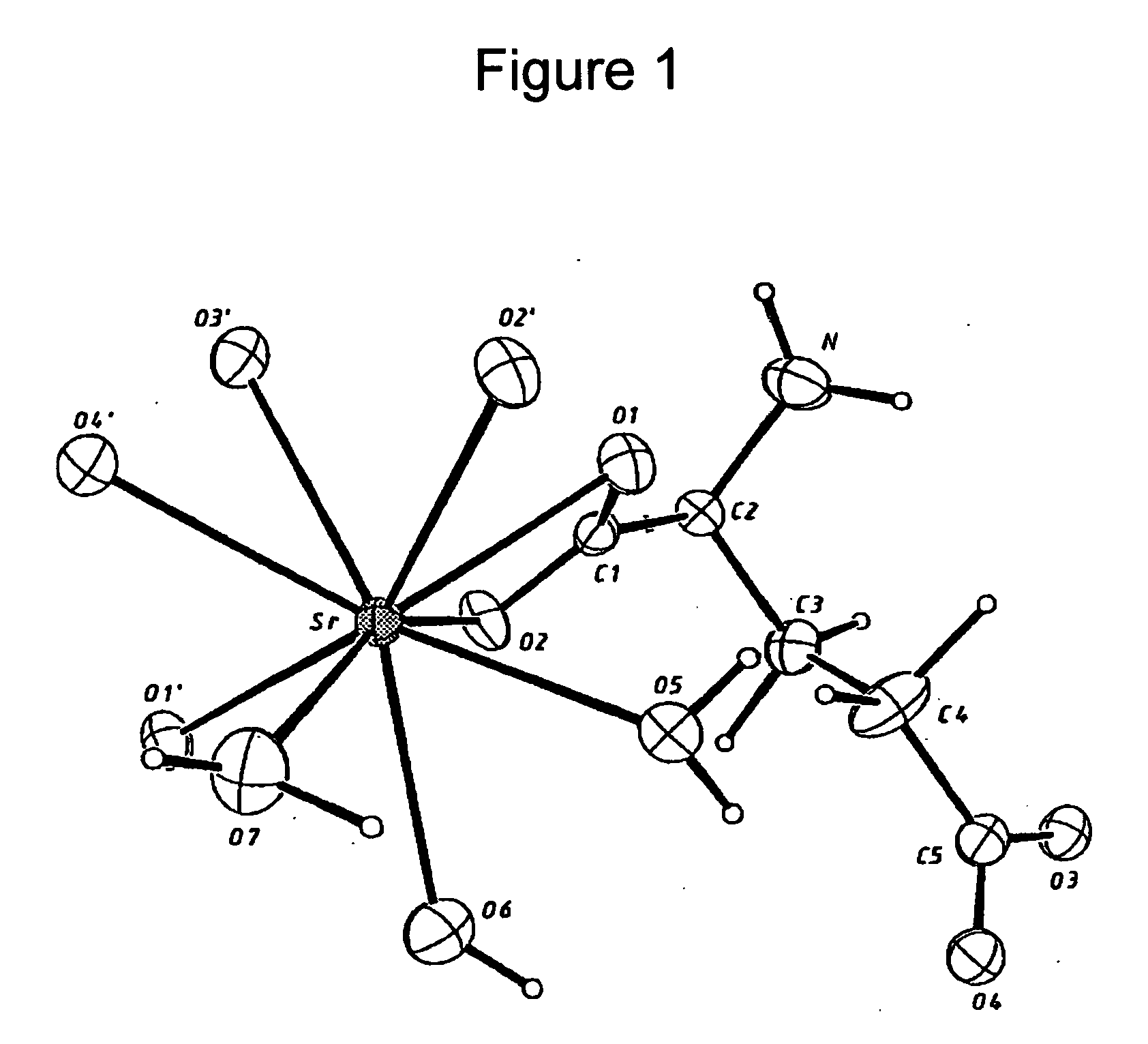

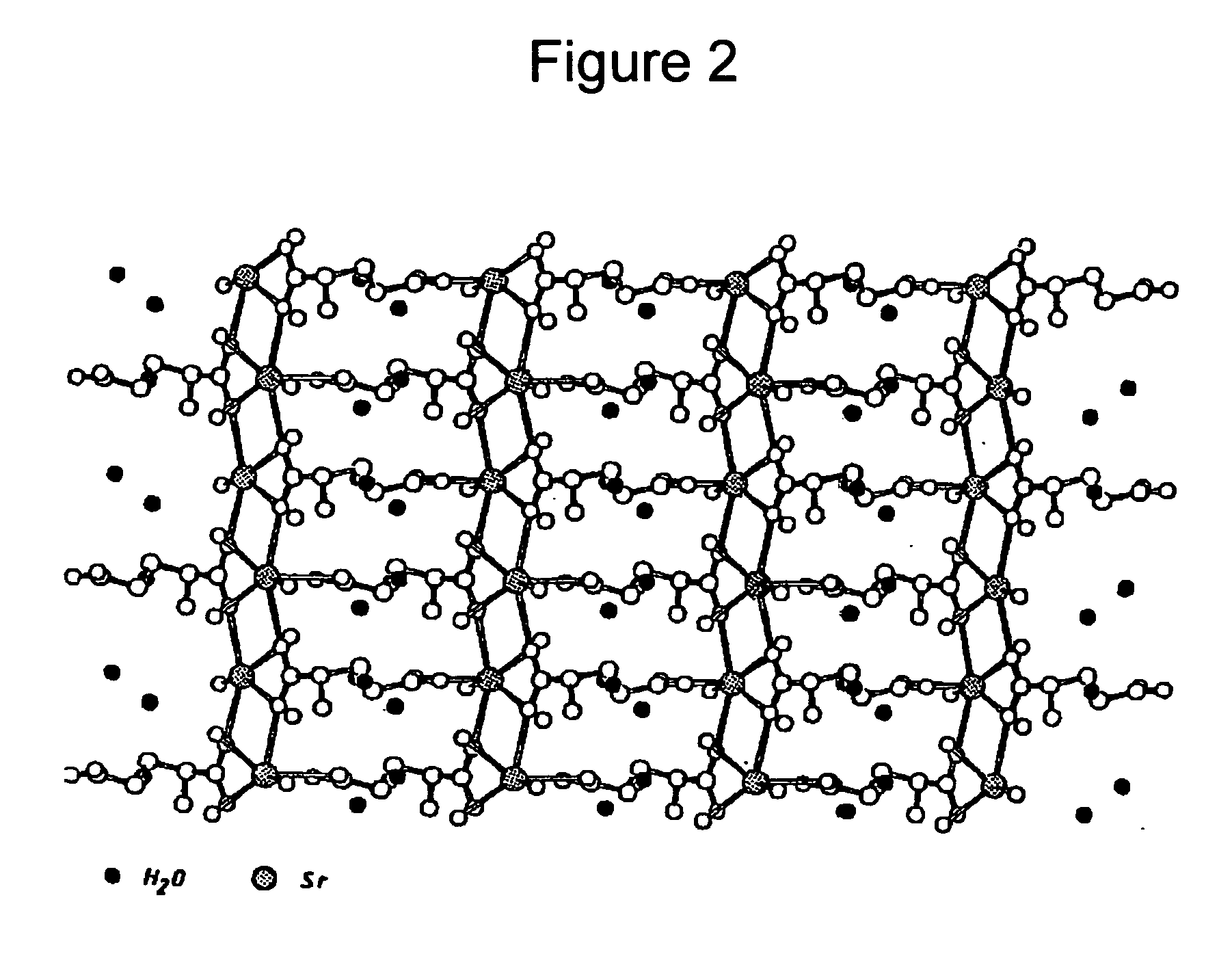

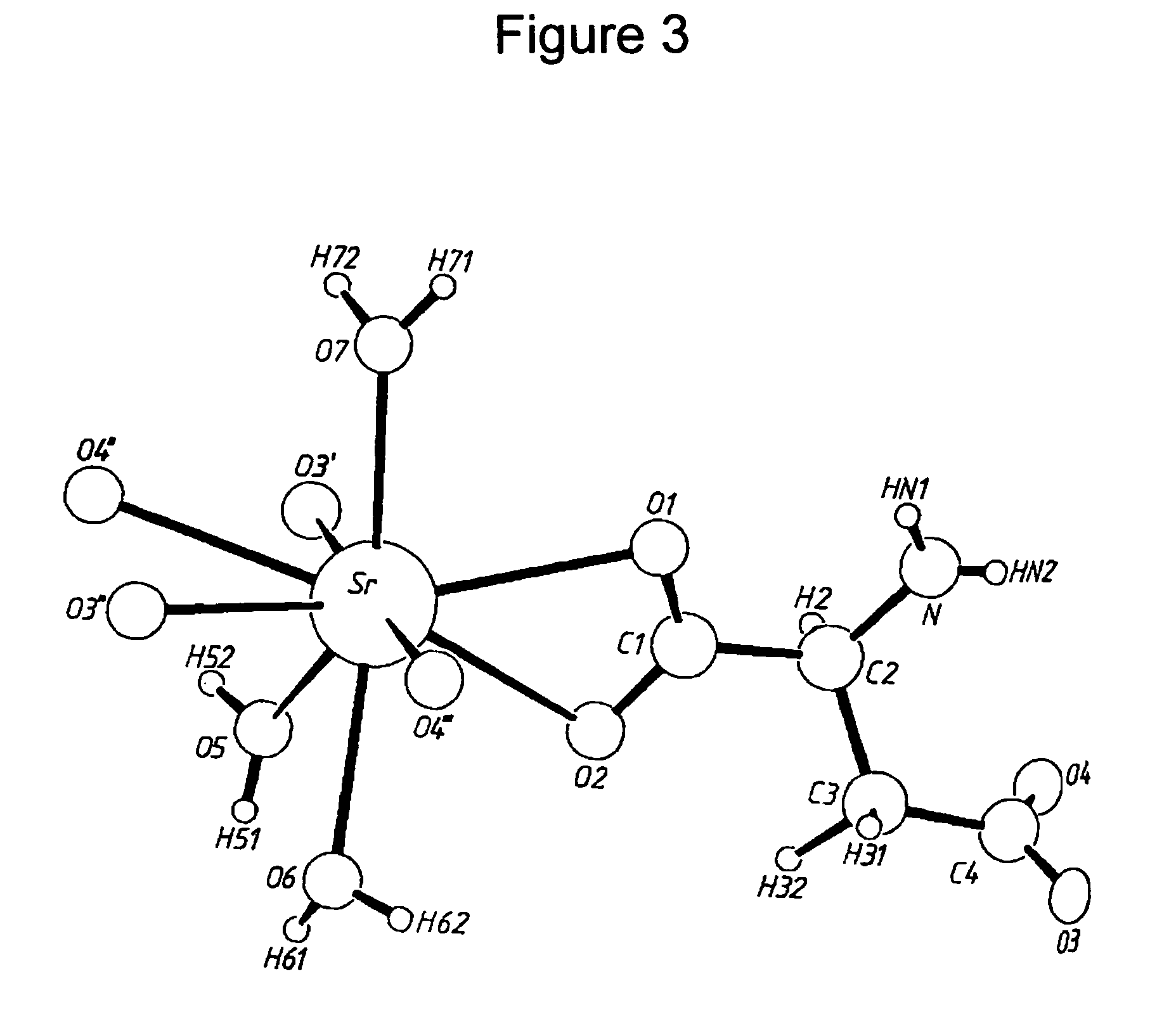

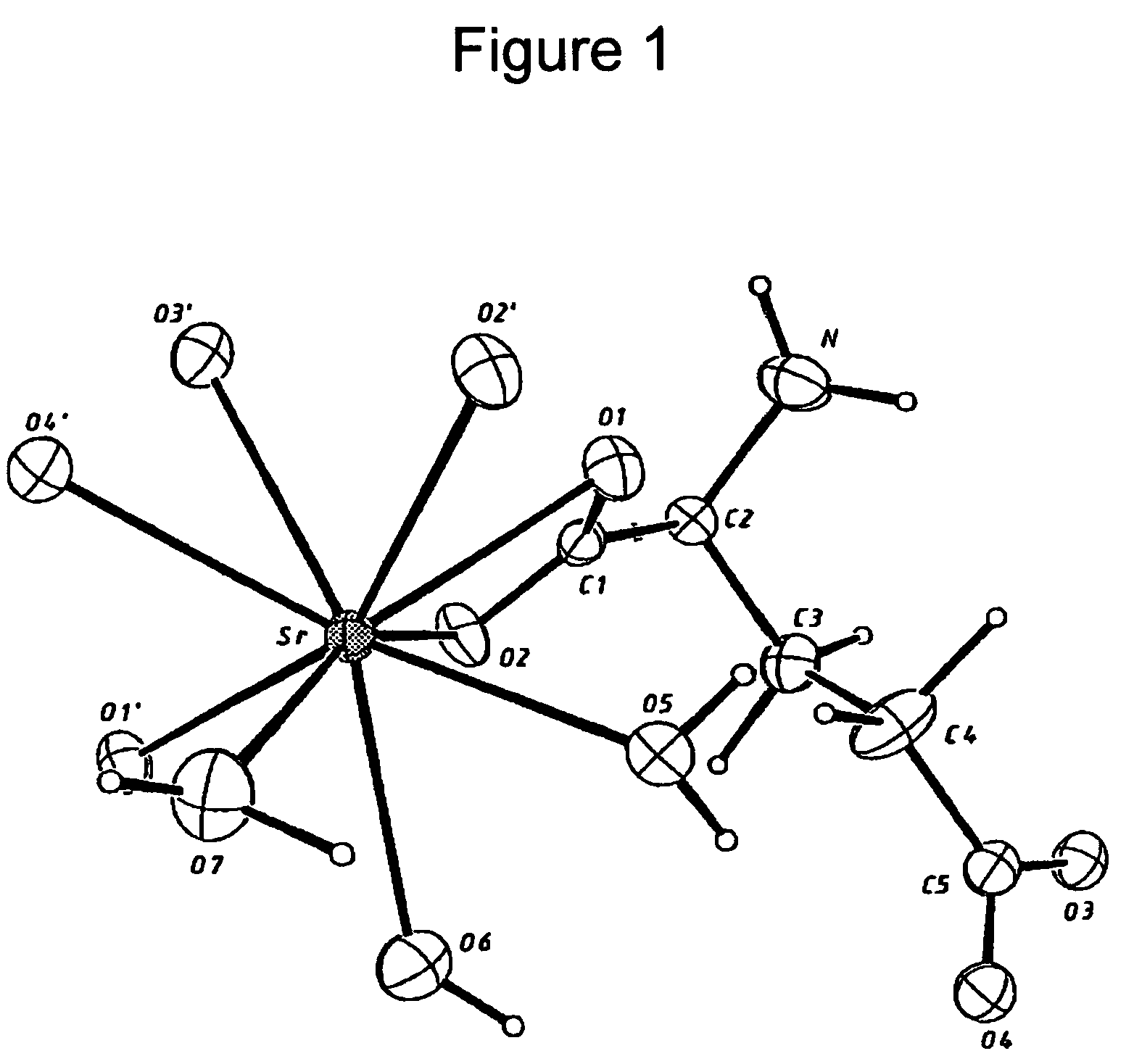

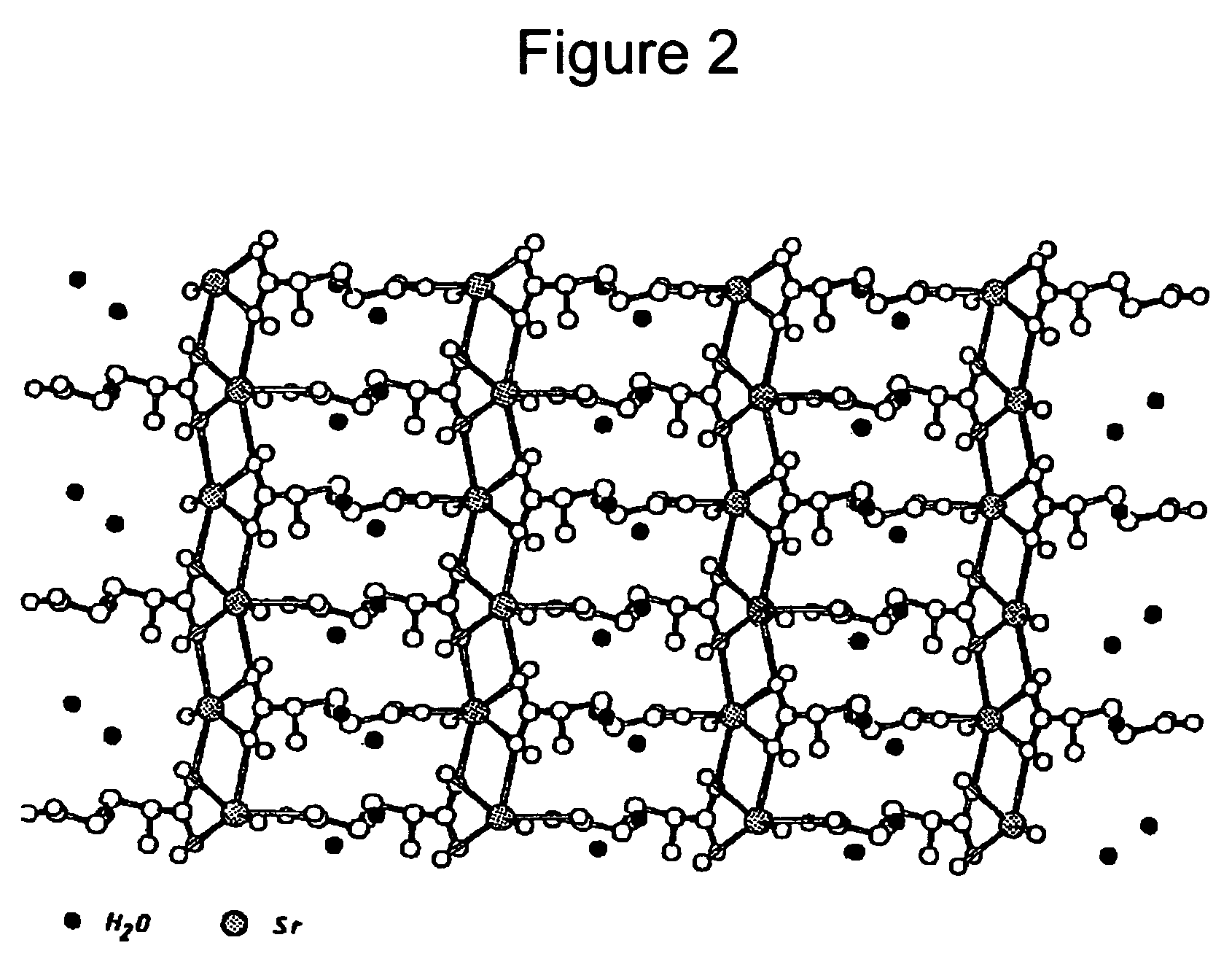

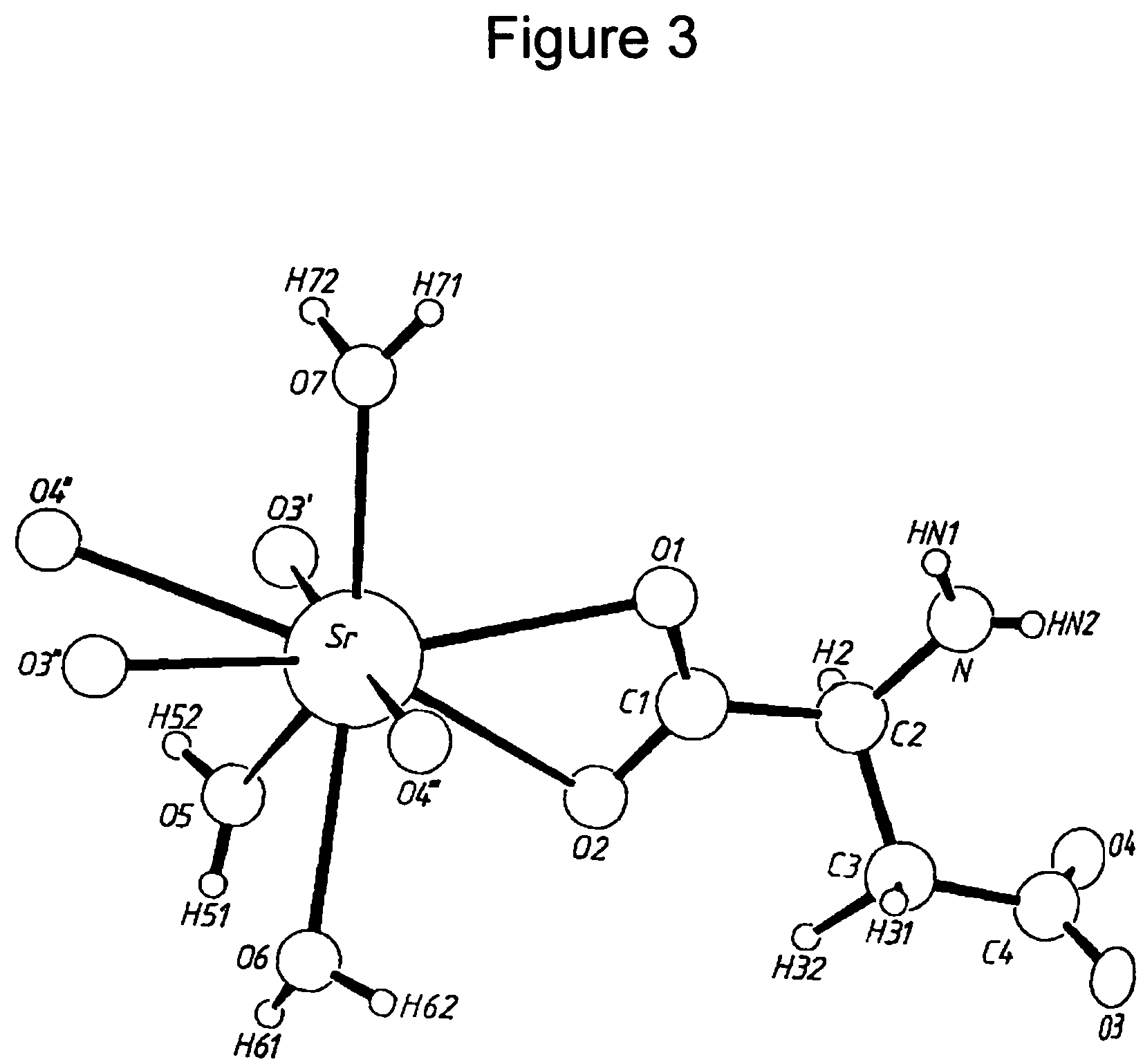

Compounds and pharmaceutical compositions for use in the treatment and / or prophylaxis of cartilage and / or bone conditions and for methods of treating such condition. The compounds are salts of strontium that have a water-solubility of from about 1 g / l to about 100 g / l at room temperature, especially amino acid salts of strontium or dicarboxylic acid salts of strontium. Examples of novel water-soluble strontium salts are e.g. strontium glutamate and strontium alpha-ketoglutarate. The present invention also relates to an improved method for preparing the strontium salt of glutamic acid.

Owner:OSTEOLOGIX AS

Water-soluble strontium salts for use in treatment of cartilage and/or bone conditions

Compounds and pharmaceutical compositions for use in the treatment and / or prophylaxis of cartilage and / or bone conditions and for methods of treating such condition. The compounds are salts of strontium that have a water-solubility of from about 1 g / l to about 100 g / l at room temperature, especially amino acid salts of strontium or dicarboxylic acid salts of strontium. Examples of novel water-soluble strontium salts are e.g. strontium glutamate and strontium alpha-ketoglutarate. The present invention also relates to an improved method for preparing the strontium salt of glutamic acid.

Owner:OSTEOLOGIX AS

Corynebacterium glutamicum and production method of alpha-ketoglutarate through fermentation thereof

ActiveCN102391977AReduce manufacturing costThe fermentation process is simpleBacteriaMicroorganism based processesMethotrexateNitrogen source

Belonging to the technical field of bioengineering, the invention relates to corynebacterium glutamicum and a production method of alpha-ketoglutarate through fermentation of corynebacterium glutamicum. The bacterial strain of the invention is corynebacterium glutamicum GKG-047, with a preservation number of CGMCC No. 5481. With a strain of glutamic acid producing strain GDK-9 as a parent, the bacterial strain of the invention is a mutant strain that is screened out through mutagenesis and sensitive to methotrexate. Under the circumstance of a limited nitrogen source supply, the bacterial strain can accumulate alpha-ketoglutarate. During fermentation, the bacterial strain is characterized by aerobic fermentation, fast bacterium growth, and rapid acid production rate. After fermentation of the bacterial strain for 32h in a fermentation tank of 10L, the maximum output of alpha-ketoglutarate can be 47.2g / L. The method provided in the invention has the advantages of simple and easily controllable fermentation process, and low production cost of alpha-ketoglutarate, thus being in favor of the popularization and application of industrial production.

Owner:江苏澳创生物科技有限公司

Method for microbial fermentation synthesis of ª‡- ketoglutaric acid

InactiveCN1544642AIncrease carbon molar ratioIncrease concentrationFermentationHigh concentrationIncreased biotin

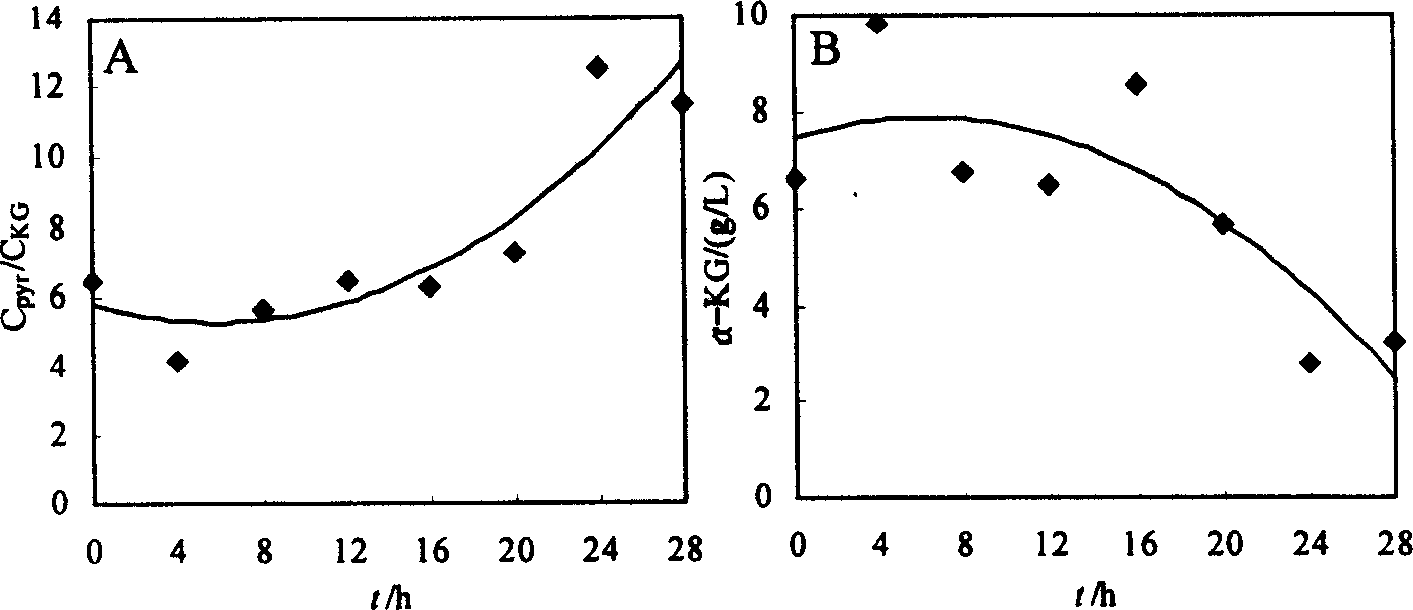

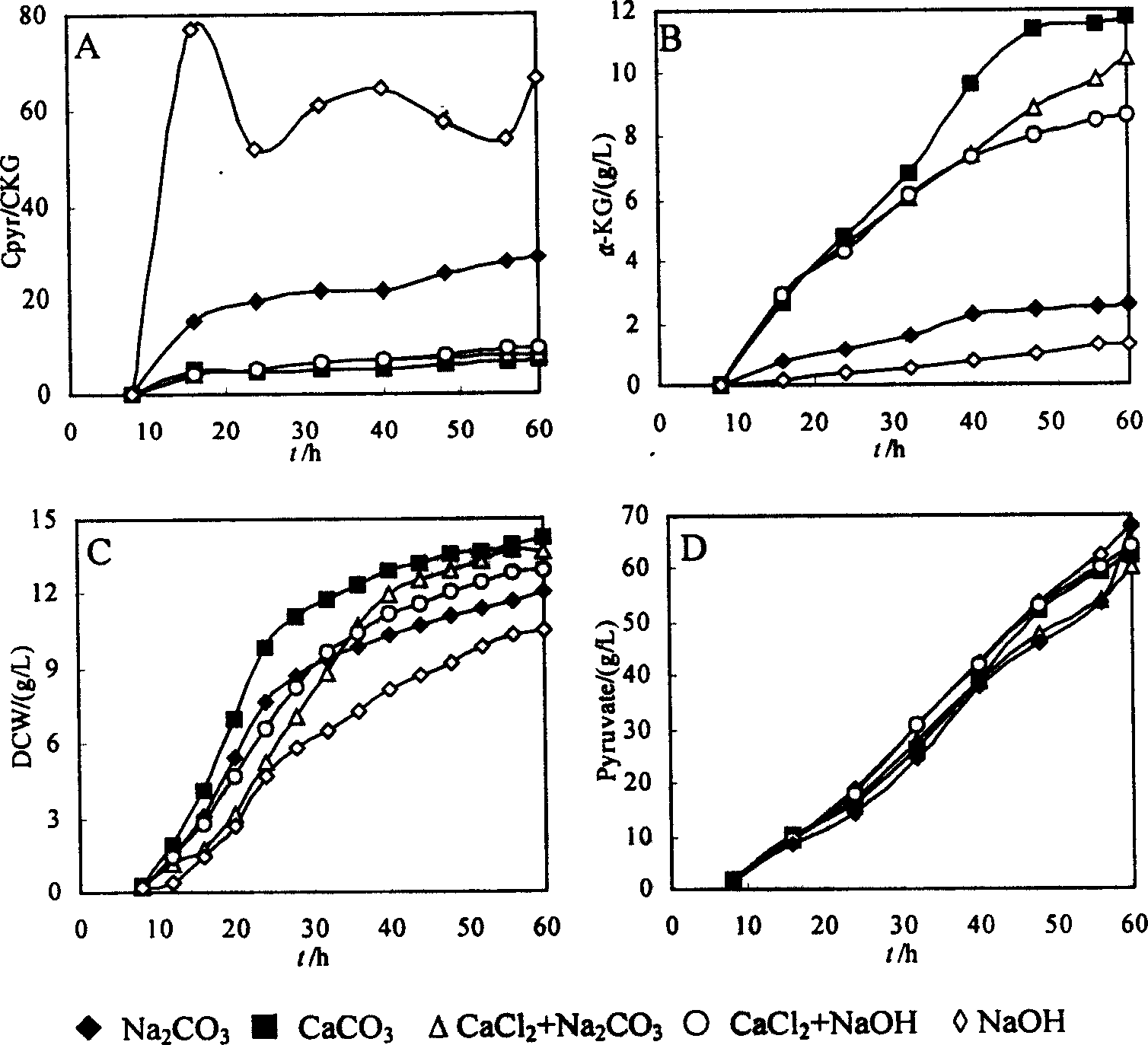

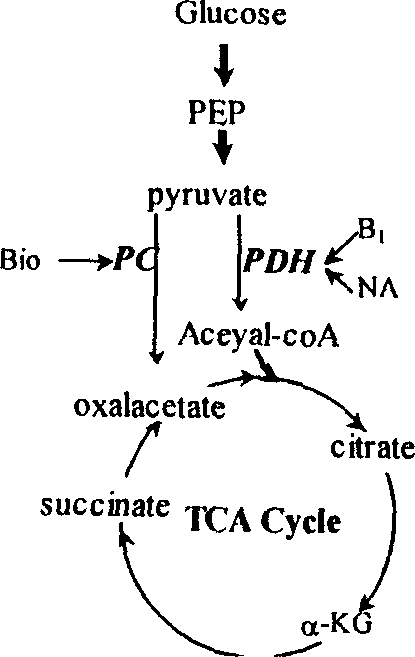

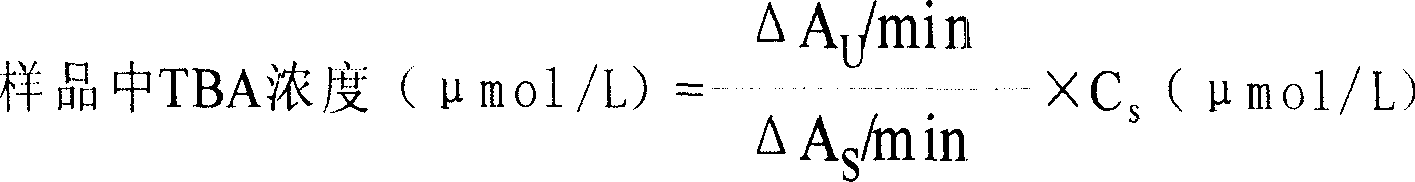

The invention is a method of synthesizing alpha-ketoglutarate by fermenting microbes, promoting to produce a large amount of alpha-ketoglutarate in fermenting course by adding CaCO3 to the culture medium and increasing biotin concentration. in the course of fermenting candida glabrata CCTCC M202019 to producing pyruvic acid, the delay of time of adding CaCO3 will inhibit the generation of alpha-ketoglutarate and increase the carbon mole ratio of pyruvic acid to alpha-ketoglutarate (CPYR / CKG), and increase of CaCO3 concentration in the culture medium will promote accumulation of a large amount of alpha-ketoglutarate, when the CaCO3 concentration is 40g / L, it is most beneficial to alpha-ketoglutarate generation. Keeping the CaCO3 concentration in the culture medium but increasing biotin concentration in the culture medium so as to promote the continuous increase of the alpha-ketoglutarate concentration but continuous decrease of CPYR / CKG value, and when biotin concentration is 60mum g / L, accumulated quantity of alpha- ketoglutarate is 23.5g / L. when Ca2+ exists, in-cell phosphoenolpyruvate carboxylase activity can be increased by 40%, and the activity of pyruvic acid dehydrogenase system does not change obviously. The increase of the Ca2+ and biotin concentration can remarkably the activity of enhance pyruvic acid dehydrogenase, thus making T.glabrata transfer from production of pyruvic acid by fermenting to synthesis of high-concentration alpha-ketoglutarate.

Owner:JIANGNAN UNIV

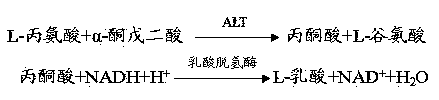

Kit for diagnosing diseases in system of liver and gall

InactiveCN101003831AExtended storage timeUndisturbedMicrobiological testing/measurementBiological testingDisease causePolymer

This invention relates to a test kit for diagnosing hepatic and biliary diseases. The test kit has such advantages as high stability, high accuracy and high sensitivity. The test kit comprises two reagents. Reagent 1 comprises oxidized thio coenzyme, buffer solution, preservative, and anti-interference agent. Reagent 2 comprises 3alpha-HSD, reduced coenzyme, buffer solution, preservative, complexing agent, polymer accelerator, stabilizer, and one of formate dehydrogenase-formic acid-NAD, glutamate dehydrogenase-glutamic acid-oxidized nicotinamide coenzyme, glucose-6-phosphate dehydrogenase-glucose-oxidized nicotinamide coenzyme, glucose dehydrogenase-xylose-oxidized nicotinamide coenzyme, lactate dehydrogenase-alpha-ketoglutarate-oxidized nicotinamide coenzyme, and glycerol dehydrogenase-ethylene glycol-oxidized nicotinamide coenzyme.

Owner:王贤理

Method for separating alpha-ketoglutaric acid from conversion solution

ActiveCN104529755ARealize multiple recyclingAchieve recyclingOrganic compound preparationChemical industryUltrafiltrationSulfate

The invention discloses a method for separating alpha-ketoglutaric acid from a conversion solution, which comprises the following steps: sequentially carrying out ceramic filtration, ultrafiltration and reverse osmosis on the conversion solution to obtain an alpha-ketoglutaric acid concentrated solution; reacting the obtained concentrated solution with calcium superchloride, and filtering to obtain alpha-ketoglutarate; adding the alpha-ketoglutarate and ethanol into a reaction kettle, slowly and dropwisely adding sulfuric acid, stopping adding the acid when the pH value of the ethanol solution is 1.3-1.5, stirring to react to generate a calcium sulfate precipitate, filtering, and collecting the filtrate which is a ketoglutaric acid ethanol solution; eluting the residual alpha-ketoglutaric acid from the calcium sulfate with ethanol, and collecting the eluting solution; and mixing the filtrate and eluting solution, and heating and concentrating under reduced pressure to precipitate the alpha-ketoglutaric acid crystal. The membrane filtration technique is adopted to avoid abundant water evaporation; and thus, the method has the advantages of energy saving, high production yield, favorable crystal form, light color of the crystal grain, and stable product quality, and can easily implement industrialized large-scale production.

Owner:JING JING PHARMA

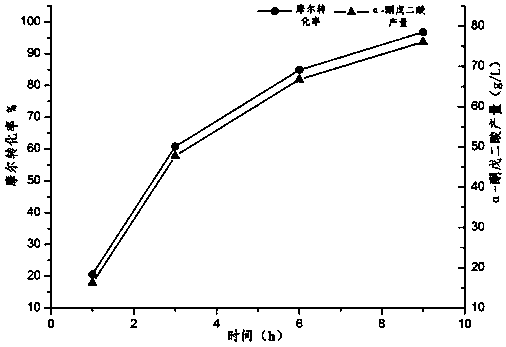

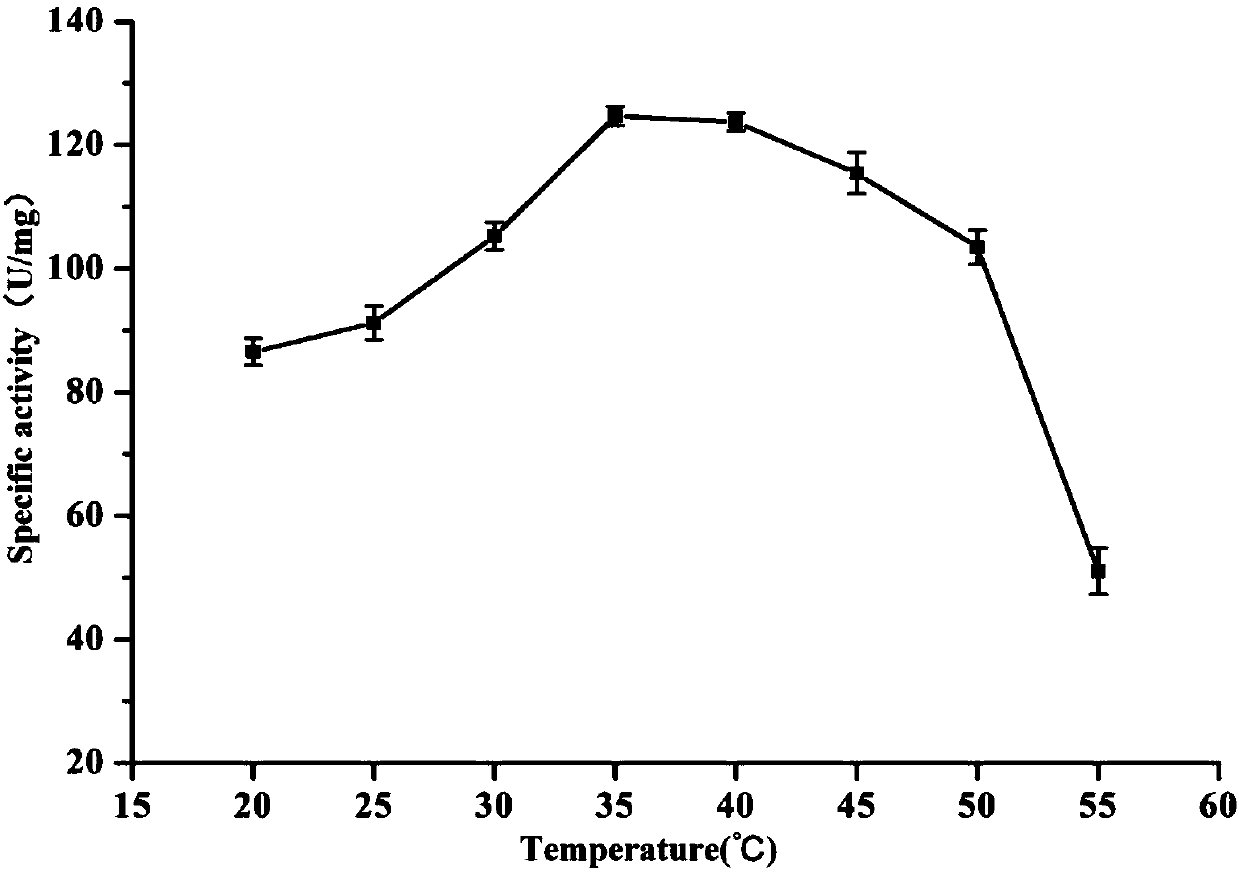

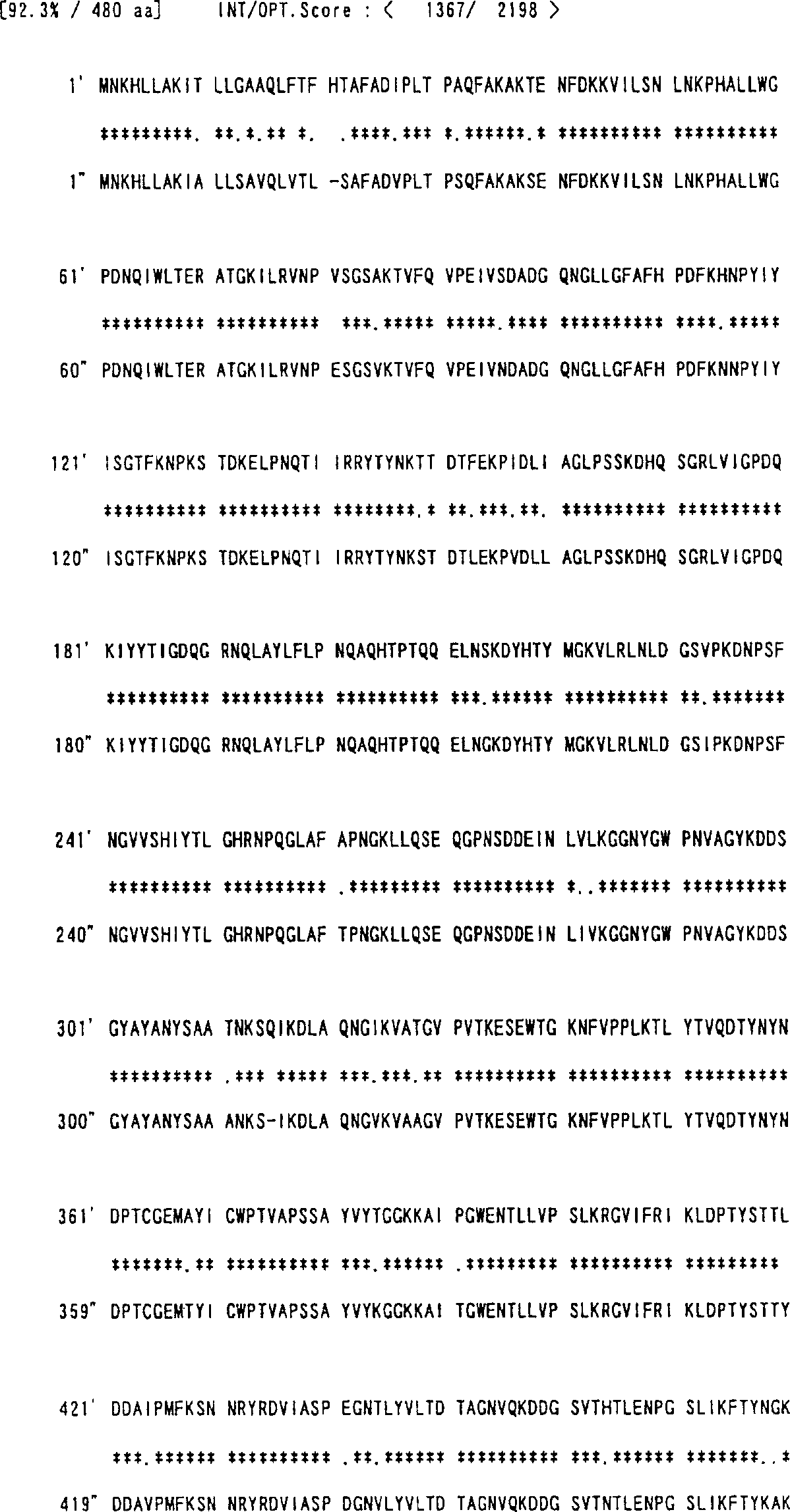

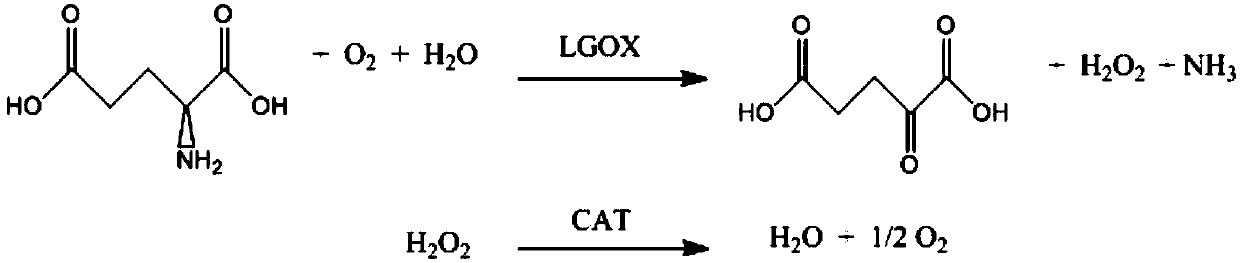

Method by using co-expression recombinant bacteria strain to convert and produce alpha-ketoglutarate

ActiveCN107686850AHigh yieldSolve the problem that a large amount of catalase needs to be added from an external sourceBacteriaMicroorganism based processesEscherichia coliStreptomyces

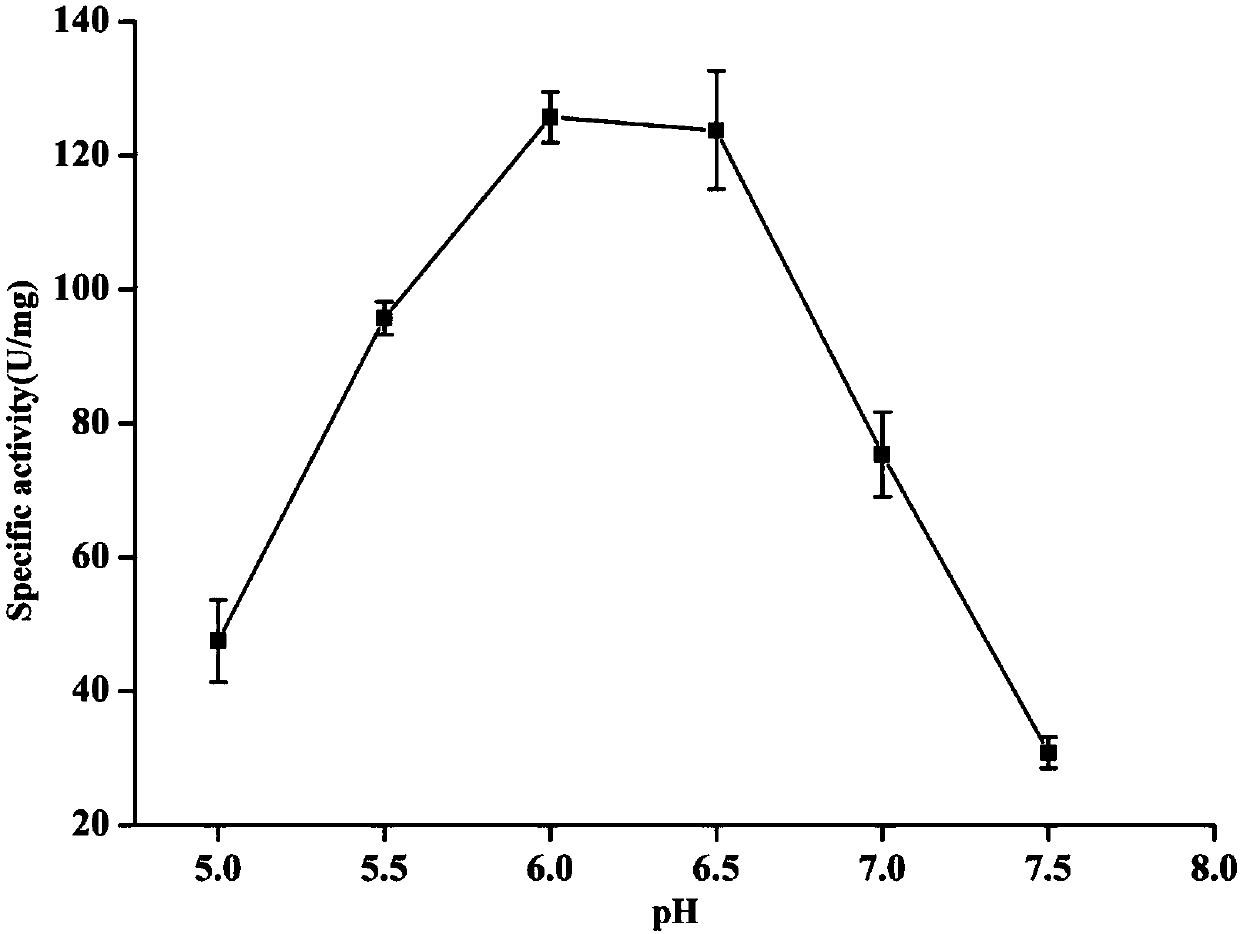

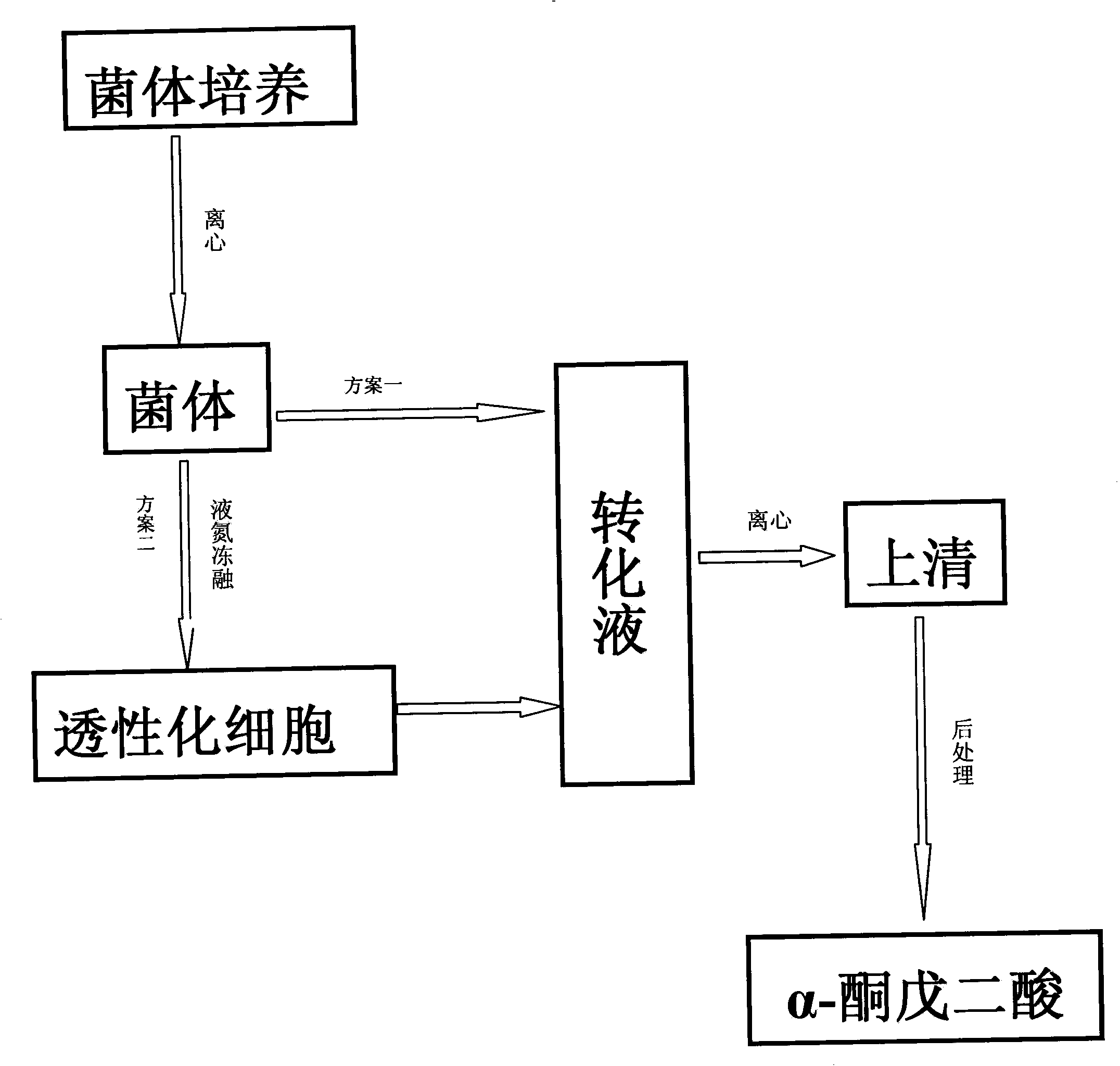

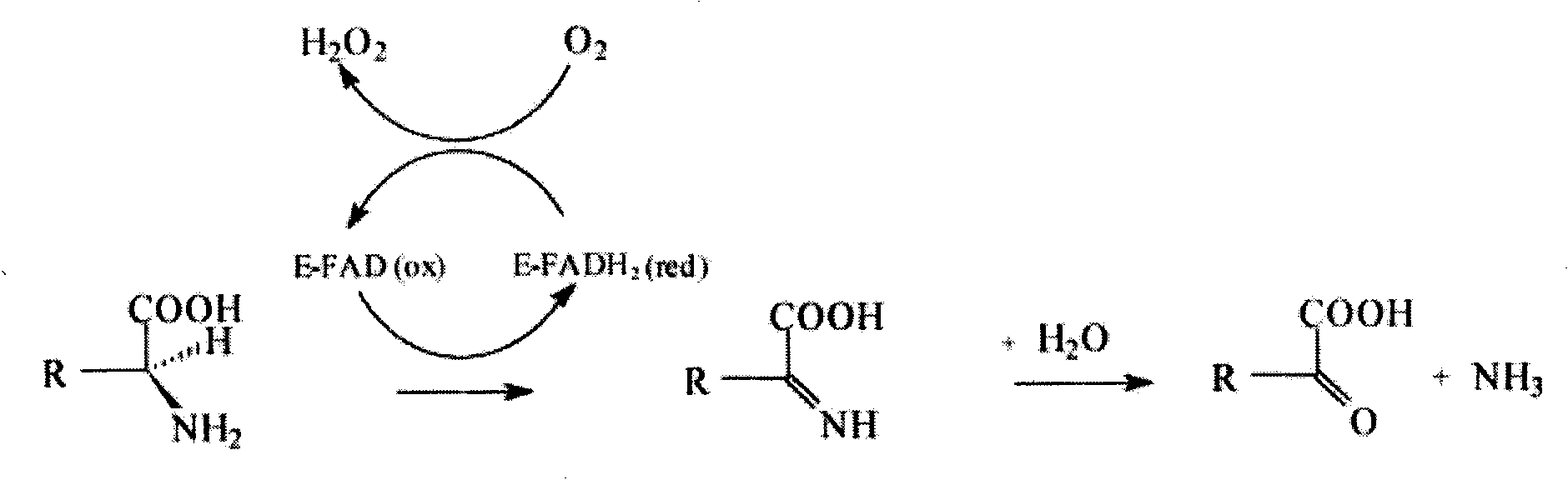

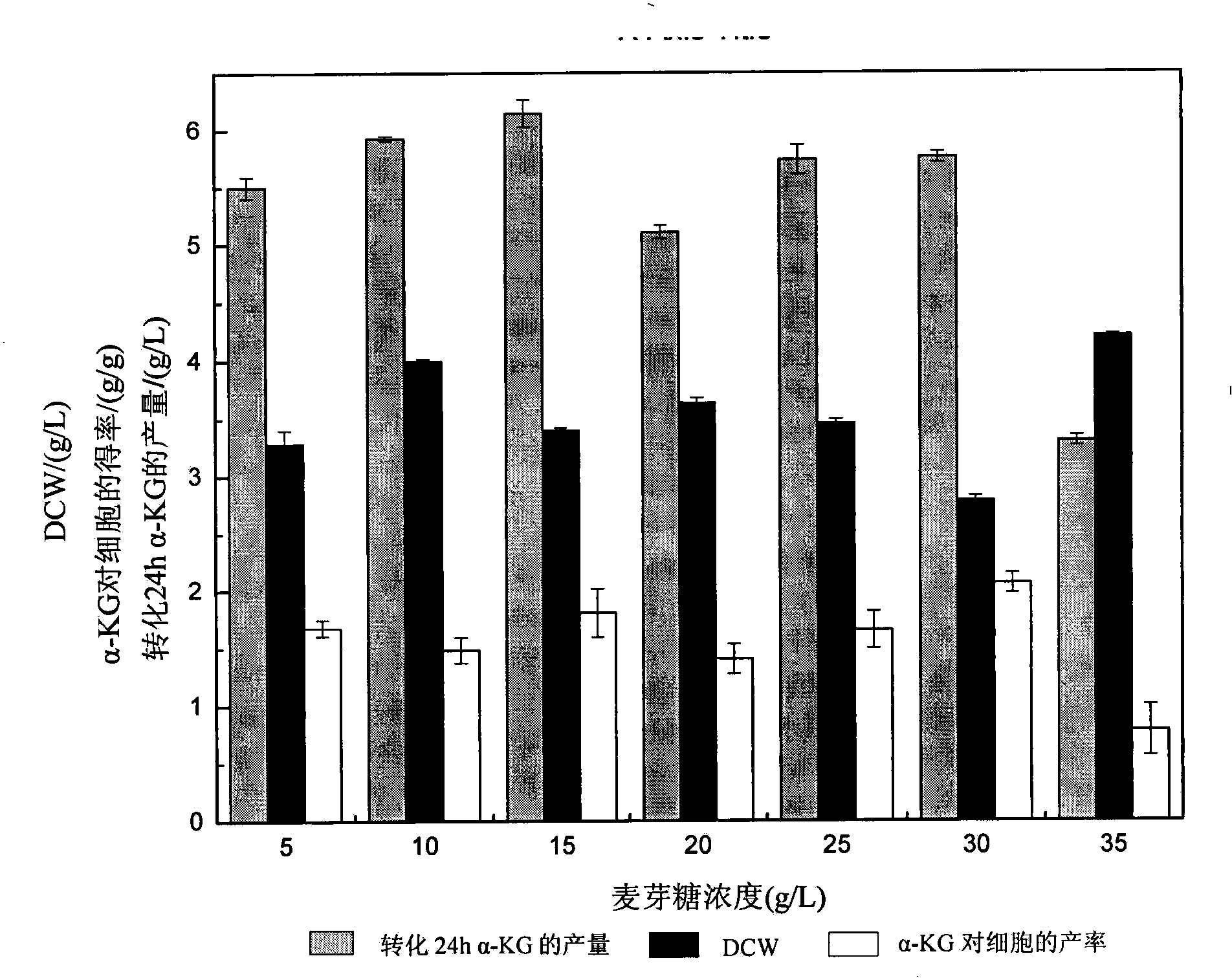

The invention discloses a method by using a co-expression recombinant bacteria strain to convert and product alpha-ketoglutarate, and belongs to the technical field of biology. The method is characterized in that novel L-glutamic oxidase is screened from streptomycete and is induced to express and purify in escherichia coli, and the enzymatic property is studied; when the pH (potential of hydrogen) value is 5.5 to 7.0, the enzyme has higher activity, the most suitable reaction temperature is 30 to 45 DEG C, Vmax is 100 to 150U / mg, and Km is 8 to 10mM; the original gene sequence of the L-glutamic oxidase is subject to codon optimization, and the plasmid co-expression with a catalase gene from the escherichia coli is performed, so as to construct the co-expression recombinant bacteria strain; the recombinant bacteria strain is used as a whole-cell catalyst to convert the L-glutamic acid (salt), the output of alpha-ketoglutarate reaches 76.08g / L after reacting for 9h, and the molar conversion rate is 96.8%. The method has the advantages that the problems of complicated production steps, low yield, pollution to environment and the like in the alpha-ketoglutarate production process aresolved, the high-yield and one-step type production of the alpha-ketoglutarate is realized, and the industrial application value is higher.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Biocatalysis method for preparing Alpha ketoglutarate from L-soda glutamate

ActiveCN103352058AImprove conversion rateMicroorganism based processesFermentationL-amino-acid oxidaseSodium Glutamate

The invention expounds a biocatalysis method for preparing Alpha ketoglutarate from L-soda glutamate, and belongs to the biotechnological field. The method comprises the following steps: utilizing strains (Rhodococcus opacus) producing L-amino acid oxidase, performing fermentation for 48 hours, collecting thallus, weighing and pouring 12 g / L (calculating by dry weight) thallus into a 10 g / L L-soda glutamate contained conversion solution, performing conversion at the temperature of 35 DEG C and the pH of 8.4 for 10 hours, adding 4.3 g / L L-soda glutamate into a reaction system every 6 hours, and performing continuous conversion for 24 hours, where the output of Alpha-ketoglutarate reaches 16.8 g / L, and the conversion rate reaches more than 90 percent.

Owner:JIANGNAN UNIV +1

Method for realizing excessive accumulation of alpha-ketoglutarate acid by adding alpha-ketoglutarate acid dehydrogenase inhibitor

InactiveCN101250563AImproved compared to the controlMicroorganism based processesFermentationTorulopsis glabrataCarbon metabolism

The invention relates to a method for adding alpha-ketoglutarate dehydrogenase inhibitor to realize excessive accumulation of alpha-ketoglutaric acid, which belongs to the technical field of the metabolic regulation optimized fermentation process of the protein level. The method of the invention comprises following steps: utilizing multi - vitamin - auxotrophic yeast of Torulopsis glabrata CCTCC M202019 as producing strains, regulating the activity of alpha-ketoglutarate dehydrogenase through adding the alpha-ketoglutarate dehydrogenase inhibitor: hydrogen peroxide, methotrexate, sodium hypochlorite or hydroxyamino in culture medium, purposively lowing the activity of the alpha-ketoglutarate dehydrogenase, reducing the degradation of the alpha-ketoglutaric acid in the metabolic process, and achieving the aim of the excessive accumulation of the alpha-ketoglutaric acid. The method of the invention cuts off carbon metabolism flow on a node of the alpha-ketoglutaric acid through regulating the stream distribution of carbon metabolism and the carbon metabolism flow, wherein the maximum output of the alpha-ketoglutaric acid reaches 23.2g / L, which is increased by 12.2% compared with the control. The invention provides a new thought for the fermentation research of TCA cycle intermediate metabolite.

Owner:GUANGDONG HUANXI BIOLOGICAL TECH

Dry chemical quick detecting reagent strip for glutamic-pyruvic transaminase and its producing method

ActiveCN1987461AThe process of detecting GPT is shortenedThe process of detecting GPT is simplifiedMicrobiological testing/measurementColor/spectral properties measurementsReagent stripHuman body

Purpose of the invention is to provide a reagent bar capable of half quantitative / quantitative detecting whether content of glutamic-pyruvic transaminase (GPT) inside human body is normal or not rapidly, and relevant fabricating method. The reagent bar includes PVC hard strip for supporting reaction. The hard strip possesses carrier film of adsorbing L-alanine, pyruvate oxidase, and alpha-ketoglutarate. Belonging to fast test in micro scale, the disclosed product is one-off consumption material for testing. Range for detecting GPT is 0-1000U / L.

Owner:WUXI SHENRUI BIO PHARMA

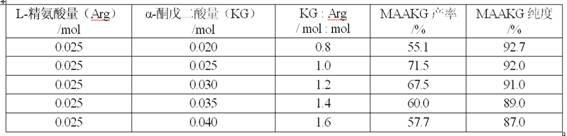

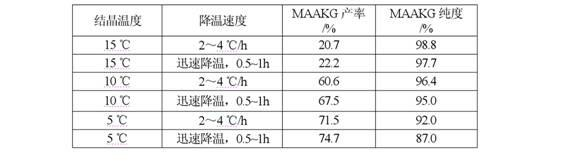

Process for preparing L-arginine-alpha-ketoglutarate (AAKG) from fermentation liquor through direct crystallization

ActiveCN102020593AHigh purityQuality improvementOrganic compound preparationCarboxylic acid salt preparationLiver functionsArginine

The invention belongs to the technical field of biopharmaceuticals and relates to a method for preparing L-arginine-alpha-ketoglutarate (AAKG) from raw materials comprising L-arginine and alpha-ketoglutarate obtained by fermentation. In the method, the L-arginine and alpha-ketoglutarate in the fermentation liquor are directly used as the raw materials for AAKG rather than being used for extracting the refined crystalline products. The process mainly comprises the following technical steps: fermentation liquor pretreatment, chelation, concentration, crystallization, dissolution for decolorization, recrystallization, drying and the like. The process is characterized by comprising the following steps: pretreating the fermentation liquor with L-arginine, adding a certain amount of fermentation filtrate with alpha-ketoglutarate to the pretreated fermentation liquor to be chelated, carrying out vacuum evaporation concentration and then cooling the crystal to obtain the coarse product; and recrystallizing the coarse product by utilizing an organic solvent to obtain the high-purity product. The process has the advantages of high product purity, short flow, obvious emission reduction effect and the like, and is easy for quality control. The AAKG is mainly used as a physique enhancer and has the functions of promoting the muscles to grow and recover rapidly, promoting liver cells to absorb the nutrients and energy, maintaining normal liver functions and the like.

Owner:FUJIAN GUTIAN PHARMA

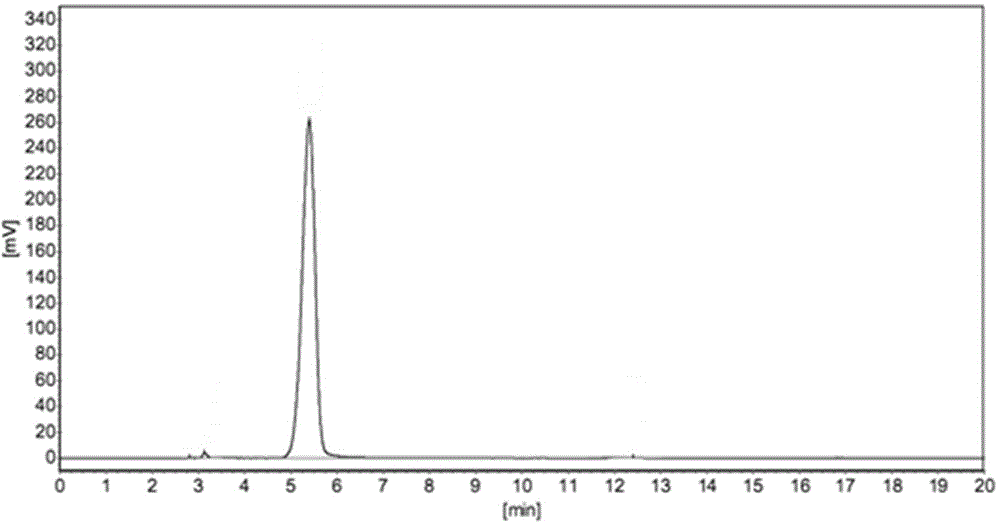

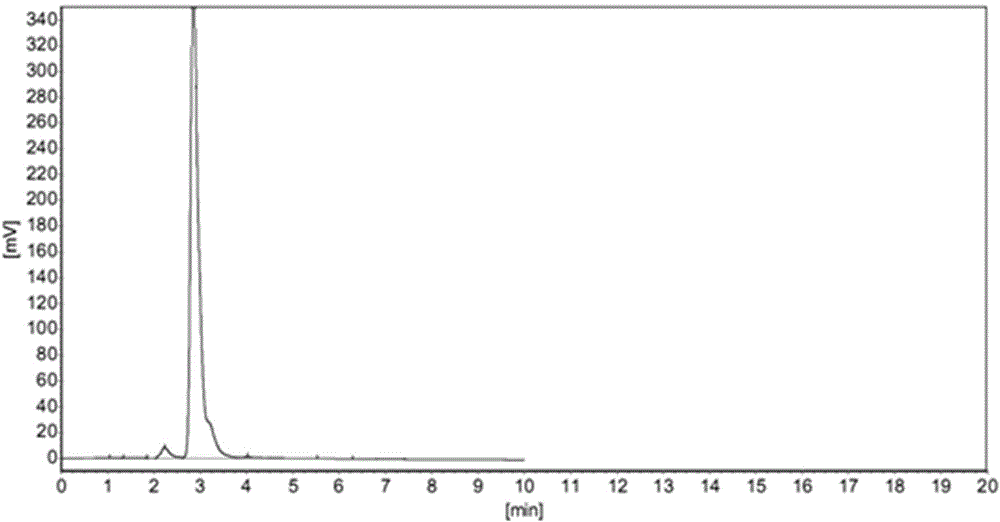

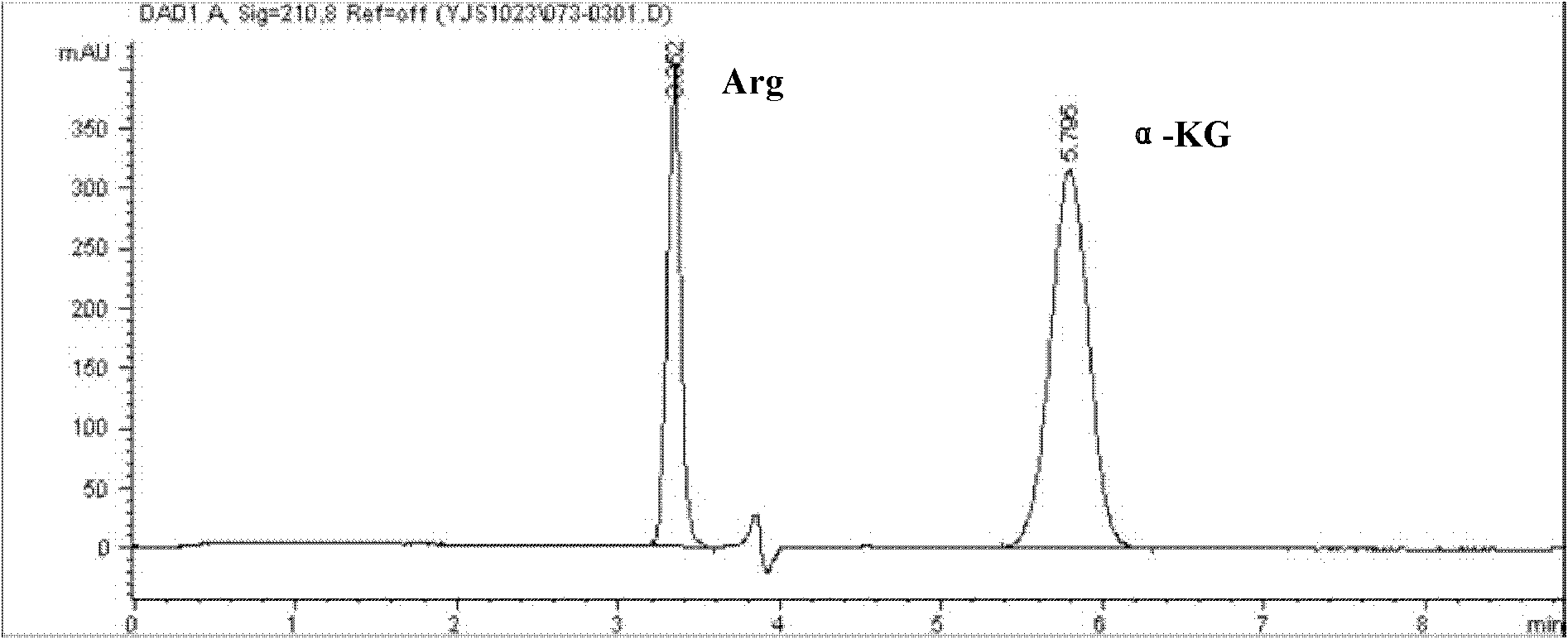

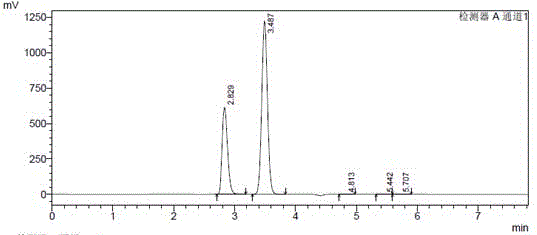

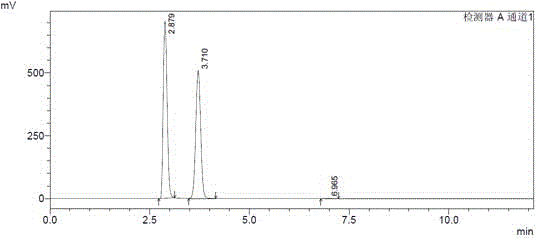

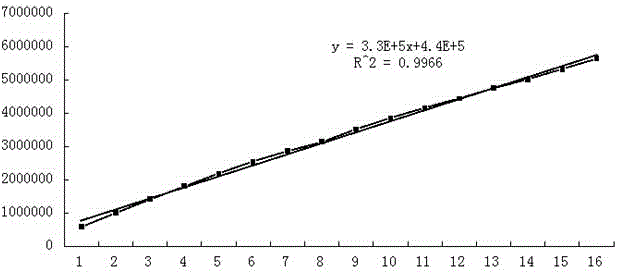

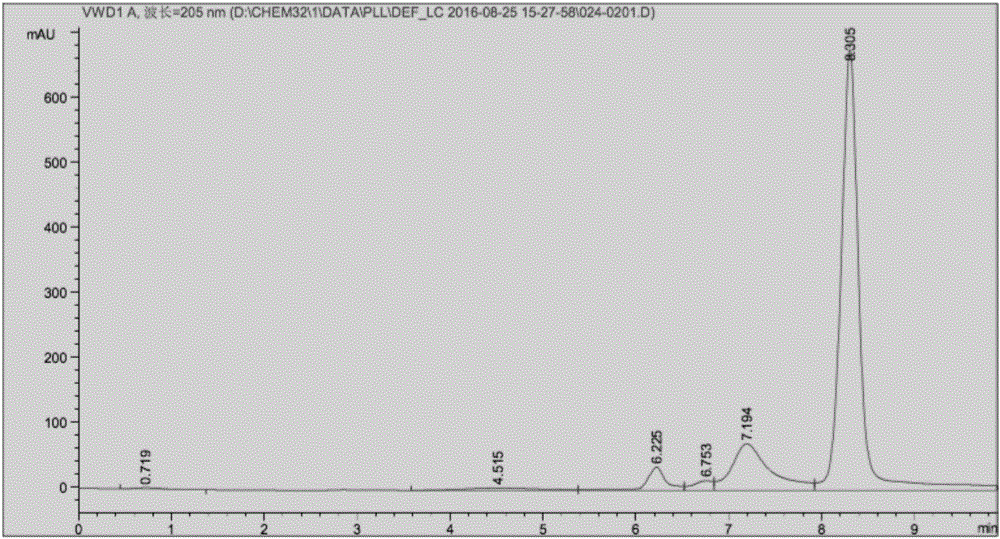

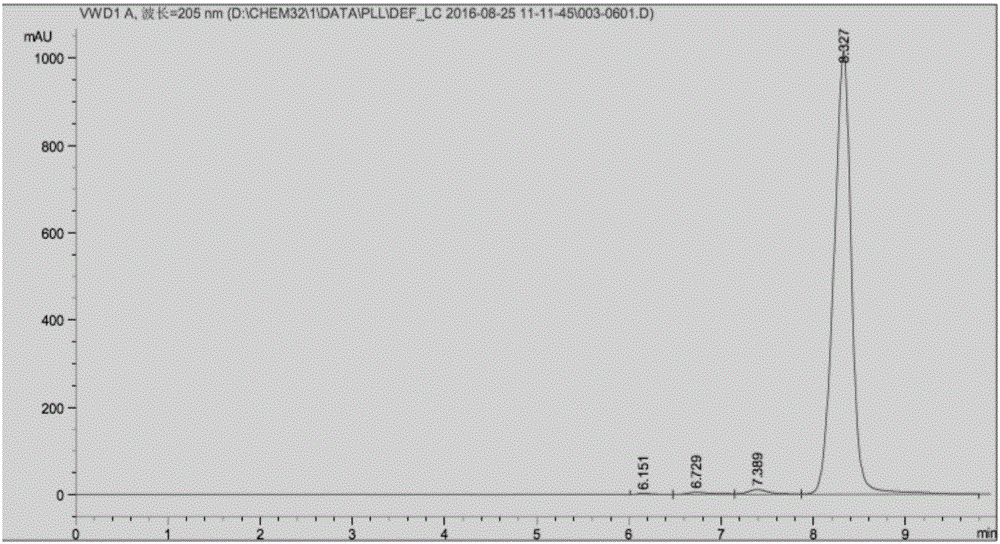

High-efficiency liquid-phase chromatography detection method of L-arginine-alpha-ketoglutarate

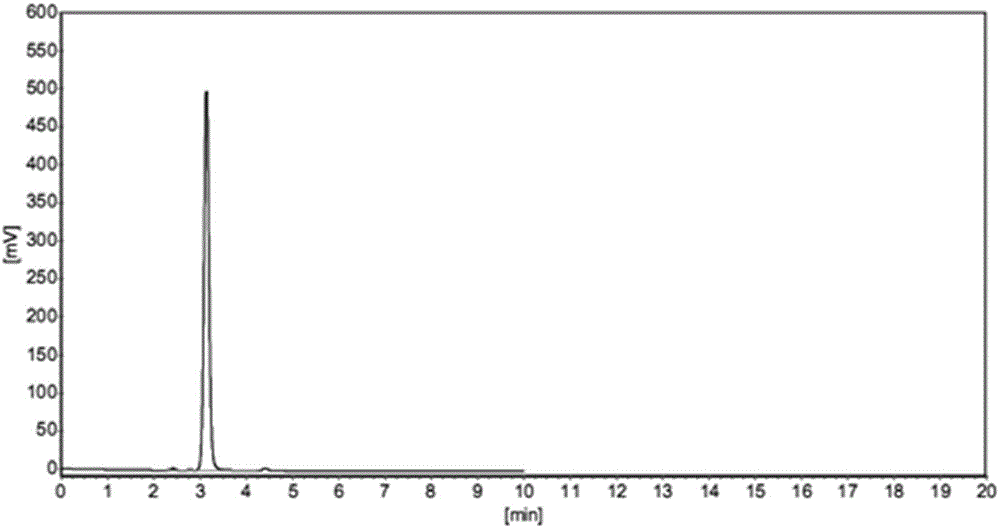

The invention discloses a high-efficiency liquid-phase chromatography detection method of L-arginine-alpha-ketoglutarate, and relates to the technical field of column chromatography. According to chromatographic condition, a chromatographic column adopts a C18 chromatographic column; a mobile phase adopts a 0.02mol / L to 0.08mol / L phosphate buffer solution with pH value of 3.0 to 4.0; the flow rate of the mobile phase is 0.5 to 1.3 ml / min; the detection wavelength is 200nm to 210nm; the temperature of the chromatographic column is 15 to 30 DEG C, and the content of L-arginine and the content of alpha-ketoglutarate in L-arginine-alpha-ketoglutarate or preparations of the L-arginine-alpha-ketoglutarate are determined by carrying out the high-efficiency liquid-phase chromatographic analysis. The content of L-arginine and the content of alpha-ketoglutarate in L-arginine-alpha-ketoglutarate or preparations of the L-arginine-alpha-ketoglutarate can be accurately determined by virtue of one-step high-efficiency liquid-phase chromatographic detection, and the two components can be well separated; moreover, the balance time of the C18 chromatographic column is short and is about 30 to 40 minutes, and the working efficiency can be improved.

Owner:JING JING PHARMA

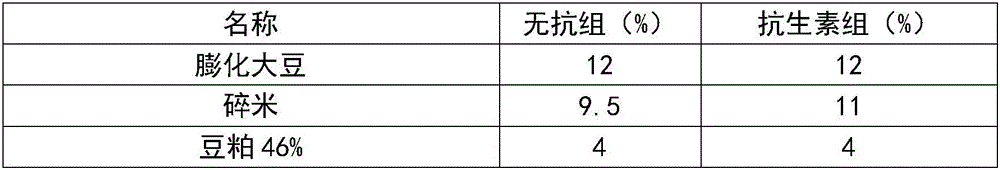

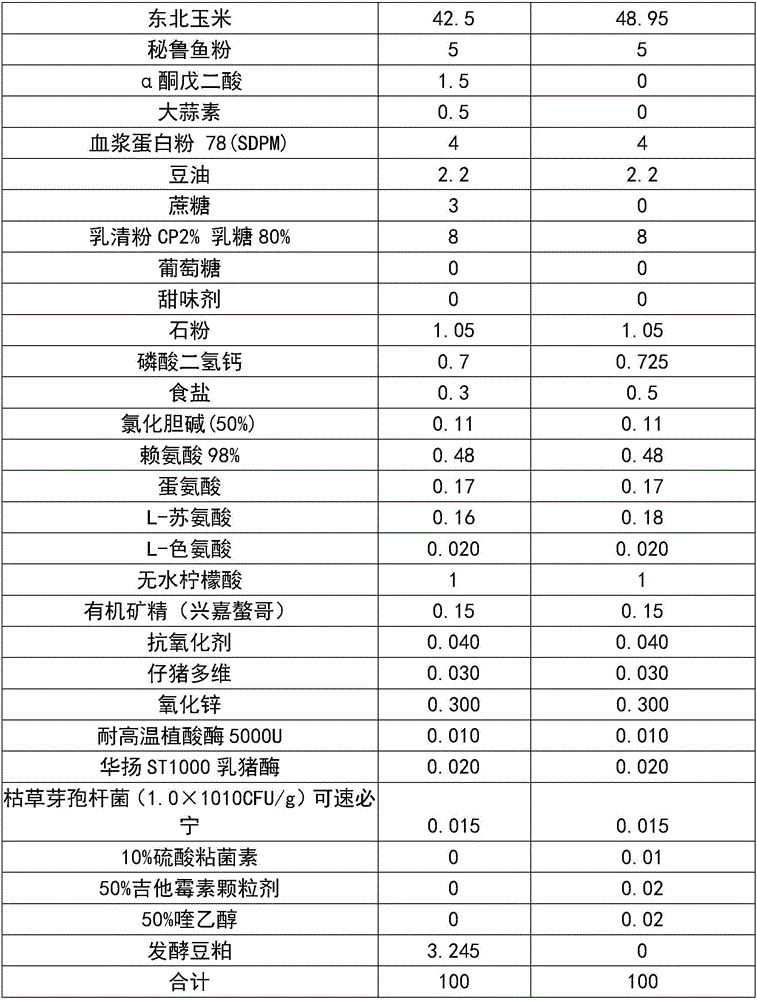

Pig feed free of antibiotic addition and preparation method thereof

InactiveCN105876195AIncreased metabolic mechanismsPromotes metabolic mechanismsFood processingAnimal feeding stuffBiotechnologyPhytase

The present invention discloses a pig feed free of antibiotic addition. The pig feed comprises the following components in parts by weight: 10-30 parts of extruded soybeans, 5-35 parts of crushed rice, 1-20 parts of soybean meal, 30-80 parts of Northeast corn, 1-10 parts of Peruvian fishmeal, 0-5 parts of alpha-ketoglutarate, 0-5 parts of allicin, 1-15 parts of plasma protein powder, 1-8 parts of soybean oil, 1-8 parts of sucrose, 1-20 parts of whey powder lactose, 0-5 parts of glucoses, 0-5 parts of a sweetener, 1-5 parts of stone powder, 0-2 parts of calcium dihydrogen phosphates, 0-2 parts of edible salt, 0-2 parts of choline chloride, 0-2 parts of lysine, 0-2 parts of methionine, 0-2 parts of L-threonine, 0-2 parts of L-tryptophan, 0-5 parts of anhydrous citric acids, 0-2 parts of organic mineral essences, 0-2 parts of antioxidants, 0-2 parts of piglet multi-vitamins, 0-2 parts of zinc oxide, 0-2 parts of 5000U high-temperature resistant phytase, 0-2 parts of piglet enzymes, 0-2 parts of bacillus subtilis Calsporin and 1-15 parts of fermented soybean meal. The pig feed can improve meat quality, and is safe, pollution-free, green and antibiotic-free.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI +1

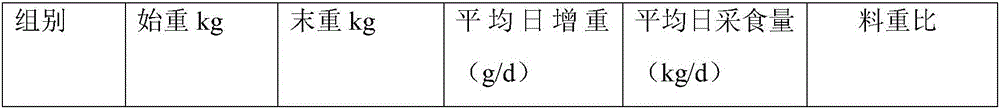

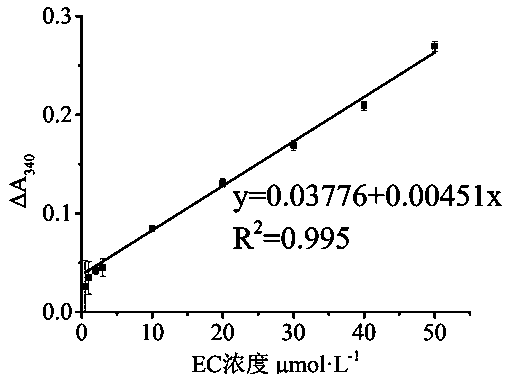

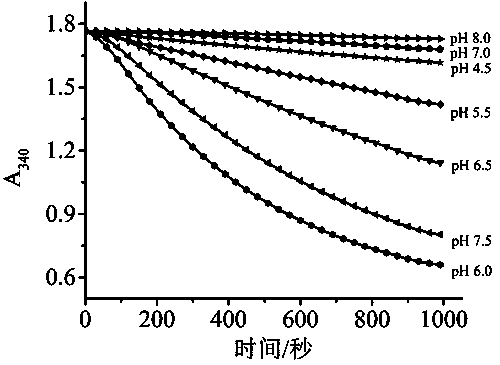

Spectrophotometric method for quickly detecting content of ethyl carbamate

ActiveCN104266984AColor/spectral properties measurementsPhotochemistryNicotinamide adenine dinucleotide

The invention discloses a spectrophotometric method for quickly detecting the content of ethyl carbamate, and belongs to the technical field of analytical chemistry and food safety inspection. Ethyl carbamate degrading enzyme and glutamate dehydrogenase construct a double-enzyme coupled system; the ethyl carbamate degrading enzyme hydrolyzes the ethyl carbamate to generate ethyl alcohol, water and ammonia, the ammonia reacts with a cosubstrate alpha-ketoglutarate under the catalysis of the glutamate dehydrogenase to generate glutamic acid, and reduced coenzyme namely NADH (Nicotinamide Adenine Dinucleotide Hydrogen) is oxidized concomitantly, so that the system changes the content of the ethyl carbamate into the content of the NADH, and the content of the ethyl carbamate in a liquid-state system can be detected by using the change of the light absorption value of the NADH at 340nm. By virtue of the method, the ethyl carbamate in a solution can be quickly detected, the ethyl carbamate in a yellow wine system can be simulated, the detection limit is as low as 0.1mu mol. L<-1>, and an effective way is provided for the detection of the ethyl carbamate in fermented food and beverages.

Owner:ANHUI HUATENG AGRI TECH CO LTD

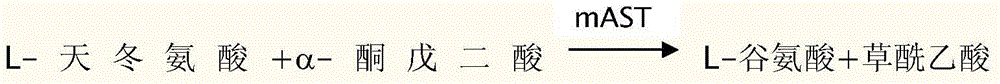

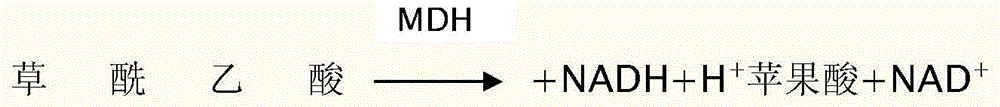

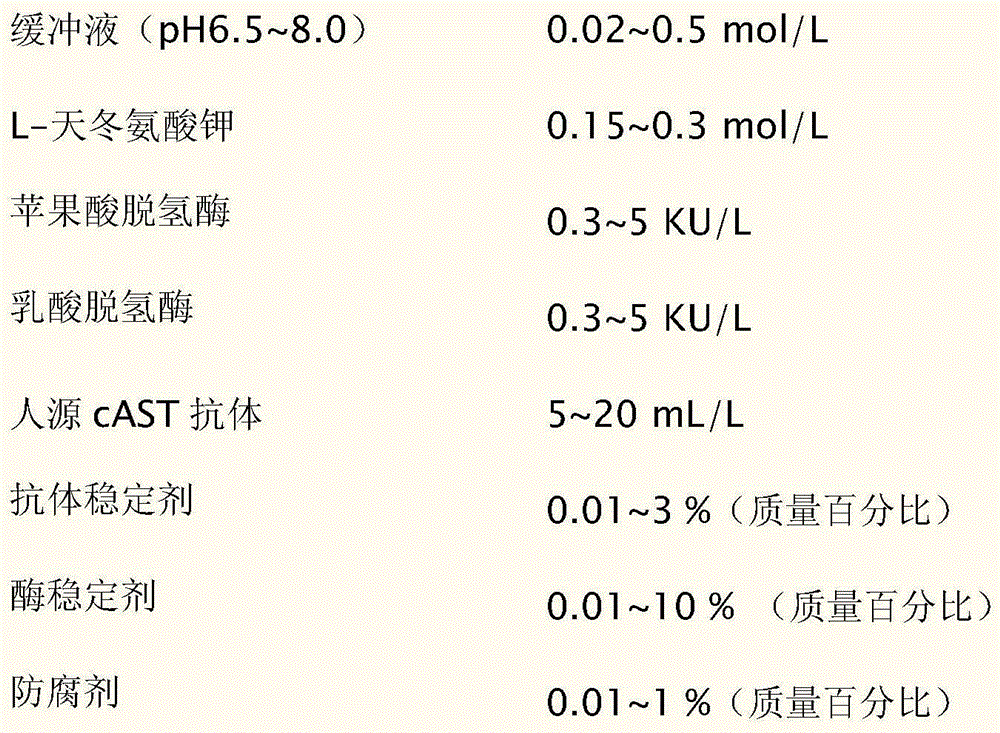

Aspartate transaminase mitochondrial isozyme detection kit

The invention discloses an aspartate transaminase mitochondrial isozyme detection kit, comprising: reagents 1: 0.02-0.5mol / L of buffer solution of which pH value is 6.5-8.0, 0.15-0.3mol / L of L-potassium aspartate, 0.3-5KU / L of malic dehydrogenase, 0.3-5KU / L of lactic dehydrogenase, 5-20mL / L of human cAST antibody, 0.01-3% of antibody stabilizer, 0.01-10% of enzyme stabilizer and 0.01-1% of preservative; and reagents 2: 0.02-0.5mol / L of buffer solution of which pH value is 7.0-9.0, 0.005-0.02mol / L of alpha-ketoglutarate, 0.1-0.5mmol / L of reduced coenzyme I, 0.01-1% of preservative and 0.01-10% of reduced coenzyme I stabilizer. The kit has the advantage of good stability.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

L-ornithine-L-aspartate preparation method

ActiveCN102924311AHigh yieldSolve outputOrganic compound preparationAmino-carboxyl compound preparationCITRATE ESTEROrganic solvent

The invention relates to an L-ornithine-L-aspartate preparation method. The preparation method comprises the following steps: dissolving anyone or a mixture of L-ornithine-alpha-ketoglutarate, L-ornithine citrate and L-ornithine malate in water, adding L-aspartic acid, adjusting the pH value of the obtained solution to 7.0-8.0, adding active carbon for decoloring, filtering, adding a proper amount of an organic solvent miscible with water to the obtained filtrate, carrying out stirring crystallization, filtering, and drying. The L-ornithine-L-aspartate preparation method has the advantages of high yield, good product quality (high content, low impurity contents and the like), low cost and the like.

Owner:BEIJING SIHUAN PHARMA +2

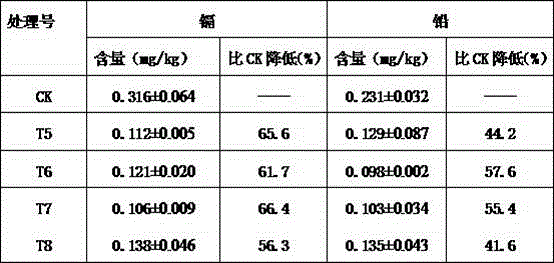

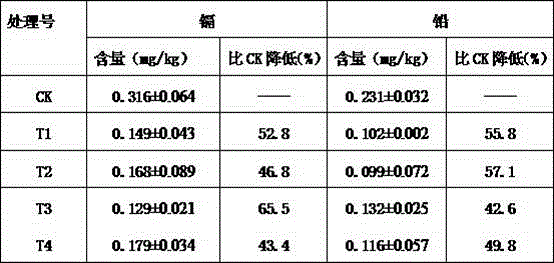

Rice heavy metal absorption blocking agent and use method thereof

ActiveCN105851002AImprove applicabilityRemove threatBiocidePlant growth regulatorsDiseaseFood safety

The invention discloses a rice heavy metal absorption blocking agent and a use method thereof. The blocking agent includes one or more effective components of alpha-ketoglutarate, glycerol and oxaloacetic acid. The aim of preventing heavy metal from being absorbed and transferred to rice can be achieved through leaf surface spraying in the rice tillering period, heading period and / or postulation period. The contents of lead, cadmium and other heavy metal polluting rice in rice fields can be remarkably reduced, and rice produced in rice fields slightly or intermediately polluted by heavy metal meets the food safety standard. The effective spraying concentration of the blocking agent is low, the blocking agent can be sprayed after being mixed with pesticides for preventing and treating rice diseases and pests, and cost is low.

Owner:SOUTH CHINA AGRI UNIV

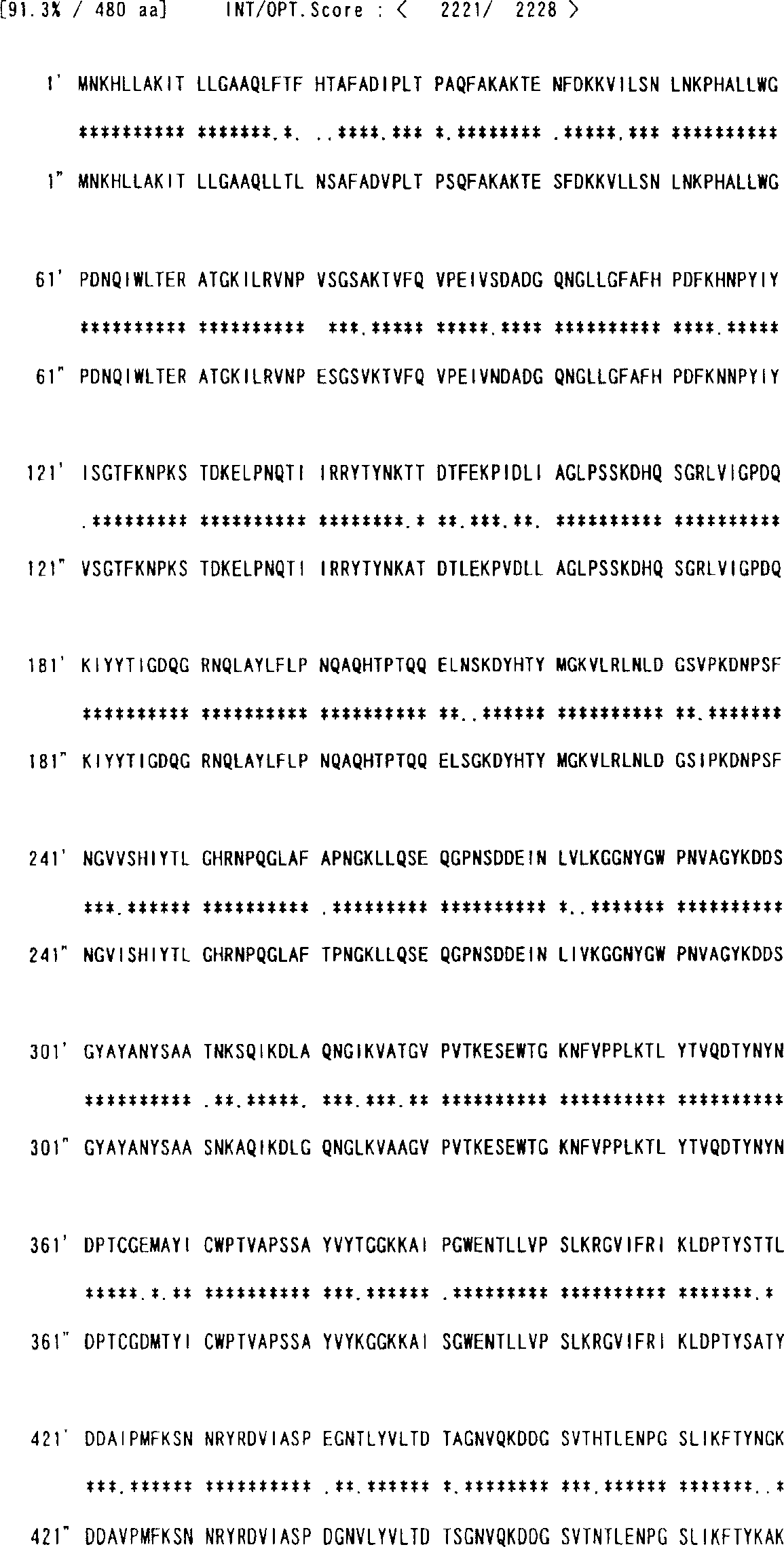

Composition for measuring glucose having improved substrate specificity

InactiveCN1912132AHigh precisionMicrobiological testing/measurementN-Butyric acid2-ketoglutaric acid

The present invention relates to a method for lowering activity with respect to maltose in glucose measurement comprising a step of reacting modified pyrroloquinoline quinone dependent glucose dehydrogenase subjected to amino acid sequence modification, wherein pyrroloquinoline quinone dependent glucose dehydrogenase is reacted in the presence of at least one type of substance selected from the group comprising succinic acid, malonic acid, glutaric acid, malic acid, phthalic acid, 2-ketoglutaric acid, 3,3-dimethylglutaric acid, pimeric acid, suberic acid, adipic acid, maleic acid, potassium chloride, ammonium chloride, diammonium hydrogen citrate, L-lysine, taurine, calcium glycerate, amino-n-butyric acid, sodium glycolate, sodium alpha-ketoglutarate, fumaric acid, glycine, glutamic acid, serine and citric acid.

Owner:TOYO TOYOBO CO LTD

Preparation method for L-ornithine-alpha-ketoglutarate

InactiveCN102373245AHigh purityIncrease productionOn/in organic carrierFermentationTransformation efficiencyL-Ornithine

The present invention relates to a preparation method for L-ornithine-alpha-ketoglutarate. The L-ornithine-alpha-ketoglutarate is produced by arginase transformation. The preparation method comprises the following steps: (1) preparation of immobilized enzyme; (2) optimization of transformation conditions; (3) product extraction and refining process. Compared to the prior art, the preparation method of the present invention has the following advantages that: the preparation method of the present invention has characteristics of low production cost, mild production conditions, less impurities in the transformation system, simple process steps, safe production operation and high purity; qualified products meeting the light transmission requirements can be synthesized; each liter of the reaction solution contains 300-320 g of the L-ornithine-alpha-ketoglutarate, and the transformation efficiency of the alpha-ketoglutaric acid is more than 90%; the preparation method further has other advantages.

Owner:湖南天成生化科技有限公司

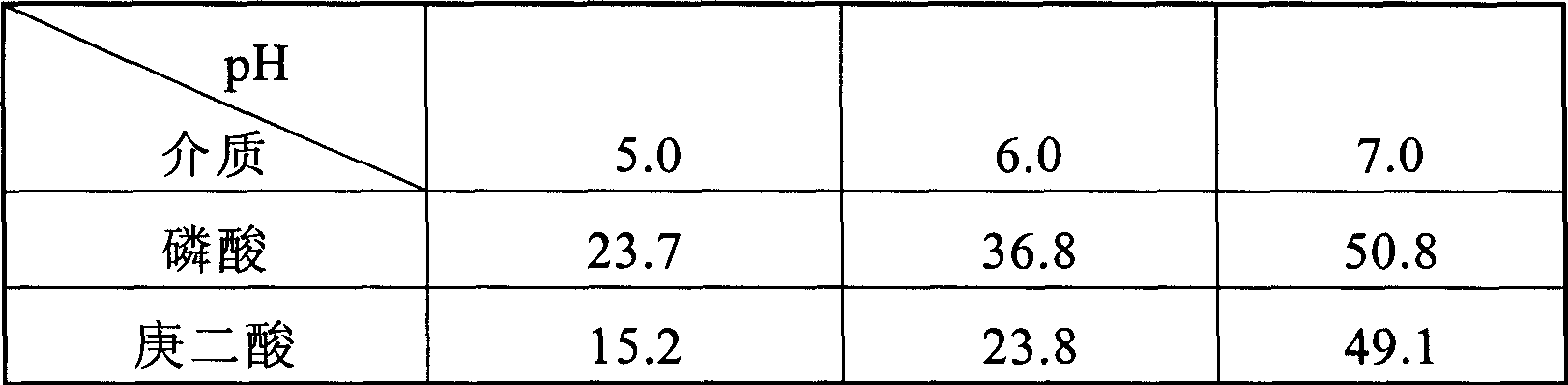

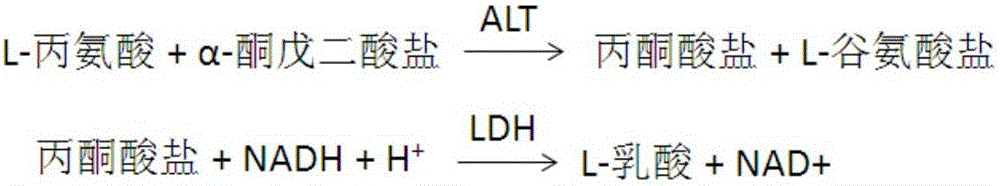

Multilayer-film dry chemical reagent strip for measuring glutamic-pyruvic transaminase by using enzyme coupled continuous monitoring assay

InactiveCN106323963AImprove stabilityEasy to operateMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsReagent stripBlood plasma

The invention discloses a multilayer-film dry chemical reagent strip for measuring glutamic-pyruvic transaminase by using enzyme coupled continuous monitoring assay. The reagent strip comprises four layers of film, namely diffusion film, blood filter film (in two layers) and bottom reaction film and is characterized in that corresponding enzyme reactants are adsorbed to the reaction film, pyruvic acid is generated from L-alanine and sodium Alpha-ketoglutarate under the catalysis of glutamic-pyruvic transaminase, the pyruvic acid acts with reduced coenzyme I(NADH) under the catalysis of lactic dehydrogenase (LDH) to generate NAD+, absorbance at 340 nm is decreased, and the amplitude of decrease is associated with the content of the glutamic-pyruvic transaminase. The reagent strip is applicable to the quick measurement of the activity of glutamic-pyruvic transaminase in human whole blood and serum or plasma, is simple and easy to operate, and is easy to clinically apply and popularize.

Owner:GETEIN BIOTECH

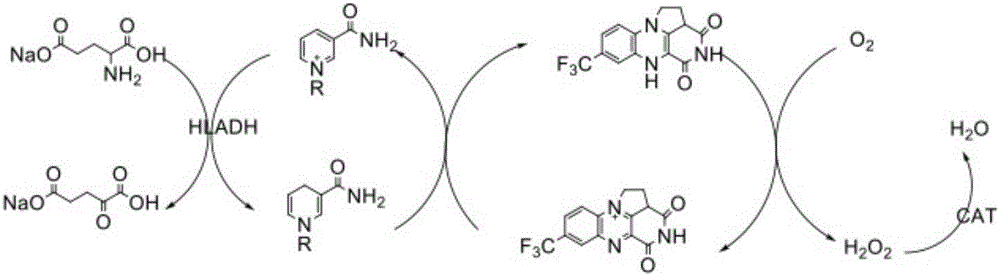

Method for alpha-ketoglutarate production by catalysis of L-glutamate dehydrogenase

ActiveCN106834366AGood reaction selectivityHigh yieldChemical recyclingFermentationL-glutamate dehydrogenaseBuffer solution

The invention discloses a method for alpha-ketoglutarate production by catalysis of L-glutamate dehydrogenase. Under conditions of existence of a hydrogen peroxide scavenging agent and in buffer solution, alpha-ketoglutarate is generated by oxidation reaction of L-glutamic acid or salts thereof under catalysis of L-glutamate dehydrogenase and cofactors. The L-glutamate dehydrogenase depending on the cofactors obtained by organic small-molecular catalytic regeneration is adopted for catalysis of L-glutamic acid or salts thereof to generate alpha-ketoglutarate through oxidation reaction, low cost of raw material and low production cost are realized, a production process is simple and easy to operate and free of environment pollution, resource recycling is realized, and a theoretical foundation is laid for industrial efficient production of alpha-ketoglutarate. The L-glutamic acid or salts thereof are directly used as raw materials to generate alpha-ketoglutarate through one-step reaction, and high reaction selectivity and high yield are realized.

Owner:NANJING UNIV OF TECH

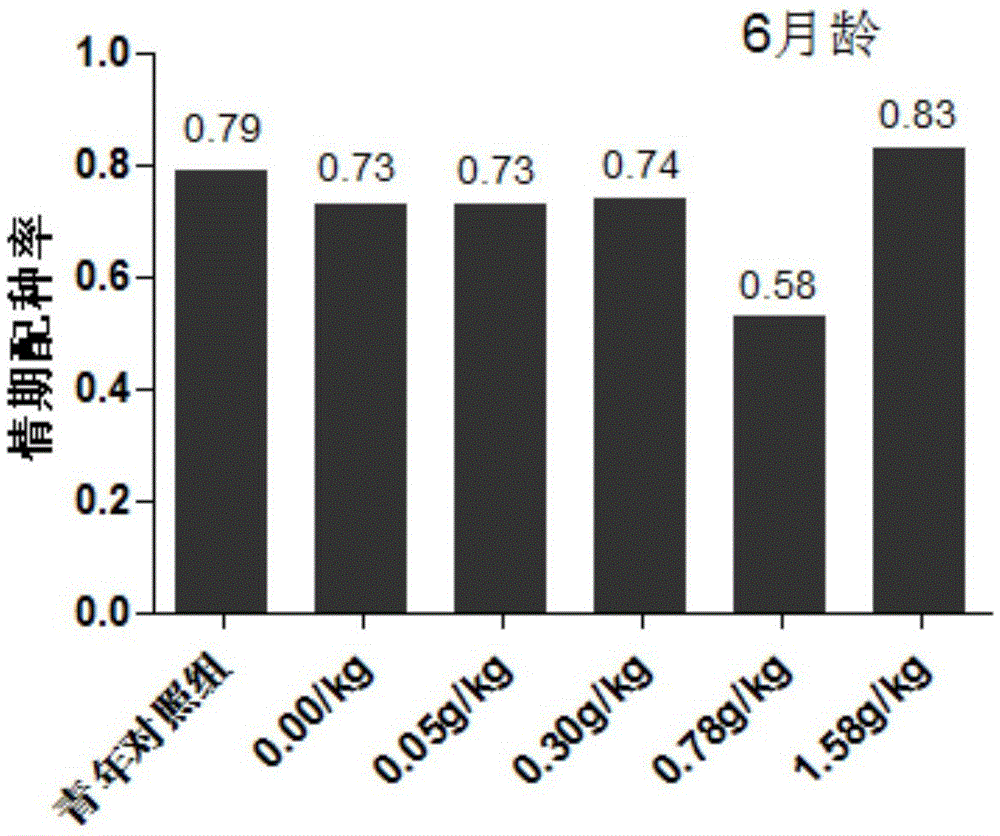

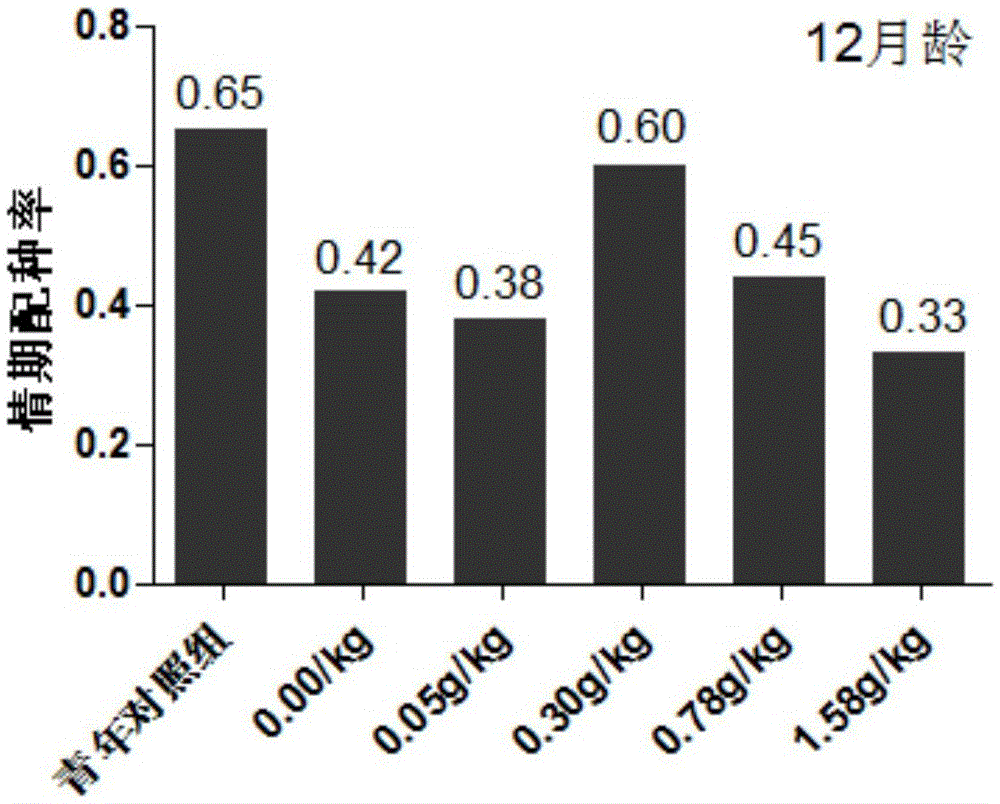

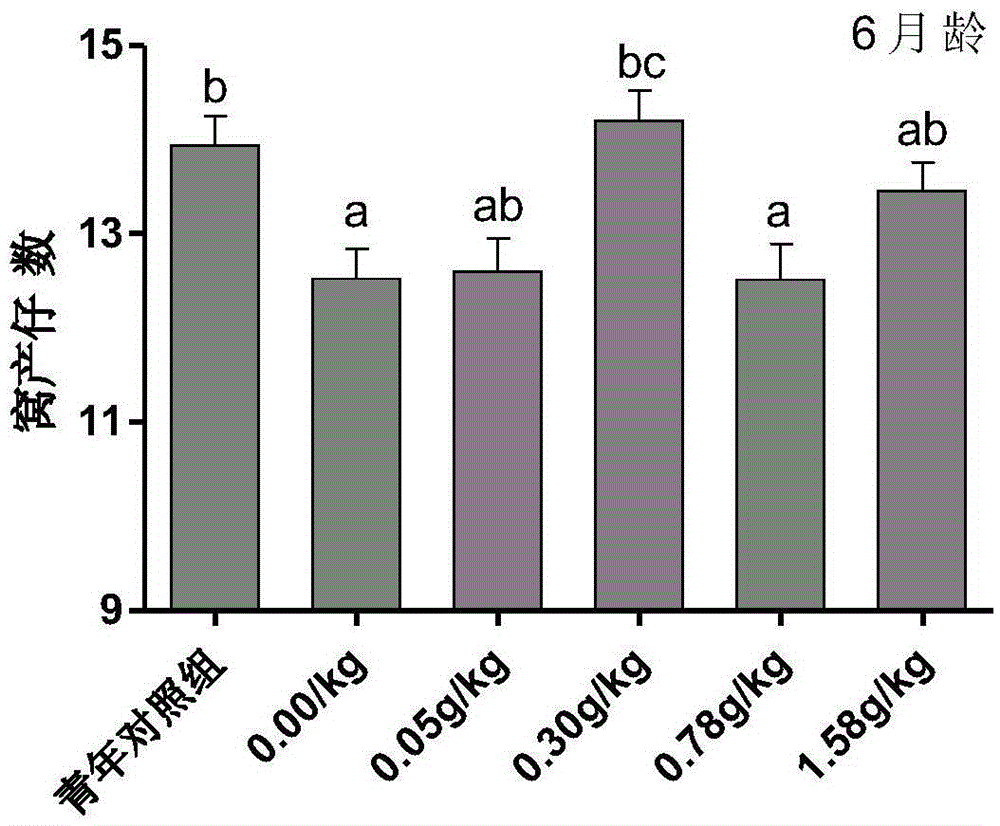

Method for improving fertility of older animals

ActiveCN105475230AIncrease litter sizeImprove reproductive efficiencyOrganic active ingredientsSexual disorderAnimal scienceLitter

The invention relates to the field of animal husbandry and animal reproduction and particularly discloses a method for improving the fertility including the litter size and the sexual period breeding rate of older animals. It is found for the first time that the sexual period breeding rate and the litter size of multiparous animals can be remarkably increased by enabling the older animals to orally take a proper dose (the daily dose ranges from 0.05 g / kg to 1.58 g / kg) of alpha-ketoglutarate for a long time. The multiparous animals take alpha-ketoglutarate by adding alpha-ketoglutarate to drinking water or feed of the animals, adding according to requirements can be conveniently achieved, the dose can be changed in time, and the method can be widely used under an automatic feeding and water feeding system. The method is applied to livestock breeding, the edible safety of meat can be guaranteed, and meanwhile development of the breeding industry is also promoted.

Owner:CHINA AGRI UNIV

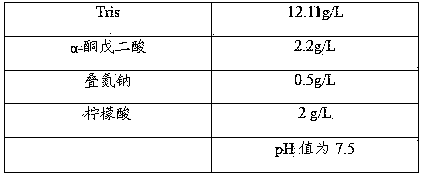

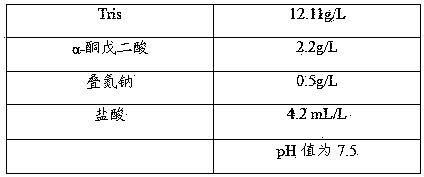

Buffer solution for human serum alanine aminotransferase measurement

The invention discloses a buffer solution for human serum alanine aminotransferase measurement, is used in a kit by using Tris-citric acid as a buffer system. The kit comprises a first reagent and a second reagent, wherein the first reagent is composed of Tris, alanine, NADH (nicotinamide adenine dinucleotide), lactate dehydrogenase, sodium azide and citric acid; and the second reagent is composed of Tris, alpha-ketoglutarate, sodium azide and citric acid. The buffer solution for human serum alanine aminotransferase measurement adopts the Tris-citric acid as the buffer system. The buffer solution can provide benign conditions for enzymatic reaction of alanine aminotransferase in human serum; and the matched kit has higher accuracy and stability of measurement data than the existing reported buffer solutions, and thus, is worthy of popularization and application.

Owner:SUZHOU COMING CHENGYE MEDICAL TECH

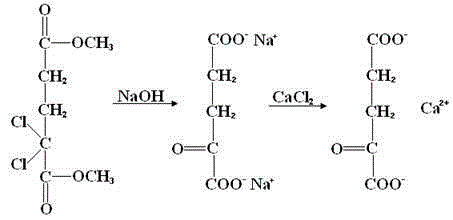

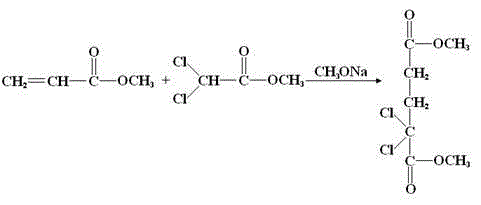

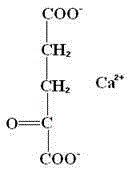

Preparation method of calcium alpha-ketoglutarate

InactiveCN102976927AEvenly distributedHigh yieldCarboxylic acid salt preparationSodium methoxideHydrolysis

The invention provides a preparation method of calcium alpha-ketoglutarate, which comprises the following steps: a) adding sodium methoxide into methyl dichloroacetate, and dropwisely adding methyl acrylate to carry out reaction; b) washing the mixed solution in the step a) with water, separating the water phase from the organic phase, and carrying out vacuum distillation on the organic phase to obtain dimethyl 2,2-dichloroglutarate; c) adding NaOH into the dimethyl 2,2-dichloroglutarate, and reacting at 60 DEG C to generate sodium alpha-ketoglutarate; and d) adding calcium chloride into the product in the step c), and stirring to obtain the calcium alpha-ketoglutarate. By changing the addition mode of the catalyst, the catalyst is uniformly distributed in the reaction system; and as the other product is added gradually, the concentration of the catalyst becomes lower, thereby effectively controlling the reaction process between the methyl dichloroacetate and methyl acrylate and enhancing the product yield. The intermediate product can be prepared into the sodium alpha-ketoglutarate by hydrolysis once, thereby shortening the procedure and enhancing the yield.

Owner:TIANJIN TIANCHENG PHARMA

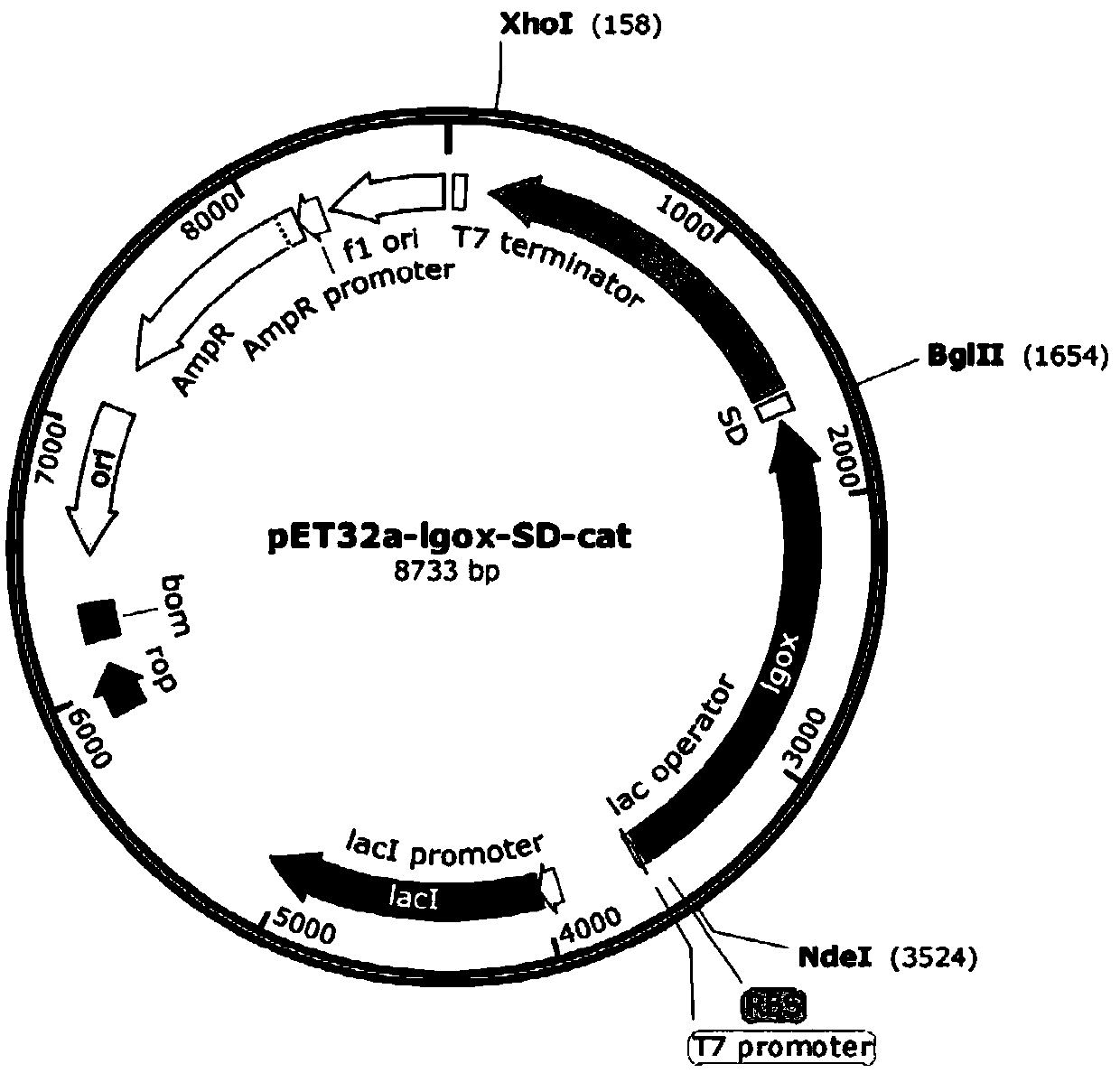

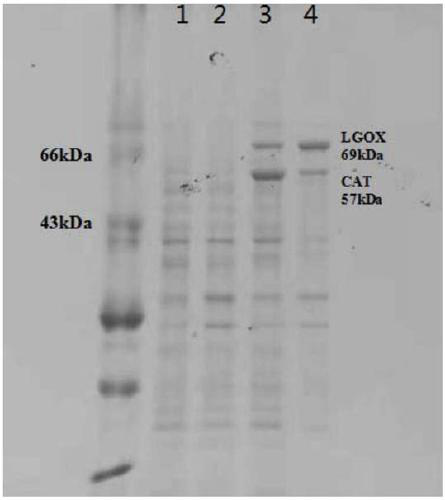

Recombinant vector for expressing L-glutamic oxidase and catalase, engineering bacteria, applications thereof and method for producing Alpha-ketoglutarate

ActiveCN109679979AIncreased ability to produce alpha-ketoglutarateImprove use valueOxidoreductasesFermentationAlpha ketoglutarateGene

The invention provides a recombinant vector for expressing L-glutamic oxidase and catalase, engineering bacteria, applications thereof and a method for producing Alpha-ketoglutarate and belongs to thefield of molecular biological technique and enzyme engineering. The recombinant vector for expressing L-glutamic oxidase and catalase provided by the invention is capable of promoting capacity of converted substrates of L-glutamic oxidase and catalase to generate Alpha-ketoglutarate by inserting a regulating sequence SD for regulating expressions of L-glutamic oxidase gene LGOX and catalase geneCAT into a vector and has a higher practical use value.

Owner:SICHUAN JISHENG BIOPHARM CO LTD

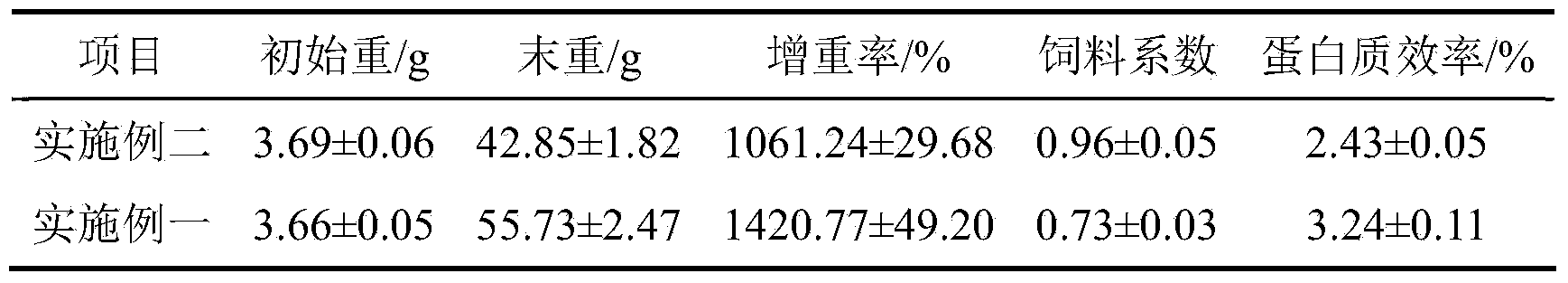

Compound bait for promoting growth of sturgeons

InactiveCN106360135AIncrease profitImprove conversion rateFood processingClimate change adaptationCarbamylglutamic acidVitamin C

The invention relates to compound bait for promoting growth of sturgeons. Every 1000 parts by weight of the compound bait for promoting growth of sturgeons contains 200 parts of soybean meal, 200 parts of flour, 100 parts of meat powder, 100 parts of fish oil, 80 parts of shrimp powder, 0.5-1 part of composite vitamins, 300-310 parts of fish meal, 2-4 parts of composite trace elements, 2-4 parts of table salt, 2-4 parts of choline, 1-2 parts of alpha-ketoglutarate, 1-2 parts of arginine and 1.5-3 parts of N-carbamylglutamic acid, wherein the composite vitamins contain at least two kinds of vitamin A, vitamin B, vitamin C, vitamin D and vitamin E, and the meat powder is lean chicken meat powder. The compound bait disclosed by the invention is convenient to use, high in protein utilization rate, high in feed conversion rate and low in bait coefficient, the sturgeons can grow quickly, the immunity of the sturgeons can be enhanced, and besides, water bodies cannot be influenced.

Owner:TIANJIN MODERN TIANJIAO AQUATIC FEED CO LTD

Feed additive for increasing protein utilization rate of sturgeon feed and addition method of feed additive

InactiveCN104304685AImprove protein utilizationPromote growthClimate change adaptationAnimal feeding stuffAnimal scienceSturgeon

The invention relates to a feed additive and an addition method thereof, in particular to a feed additive for increasing a protein utilization rate of sturgeon feed and an addition method of the feed additive. The additive aims at solving the problems of low protein utilization rate, low conversion rate, poor use effect and high feed coefficient of the existing sturgeon feed. The feed additive is prepared by mixing alpha-ketoglutarate, arginine, N-carbamylglutamate and cellulose. The addition method comprises the step of mixing 2-4 parts of feed additive for increasing the protein utilization rate of the sturgeon feed with 96-98 parts of sturgeon feed. The invention provides a feed additive for increasing the protein utilization rate of the sturgeon feed and the addition method of the feed additive.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

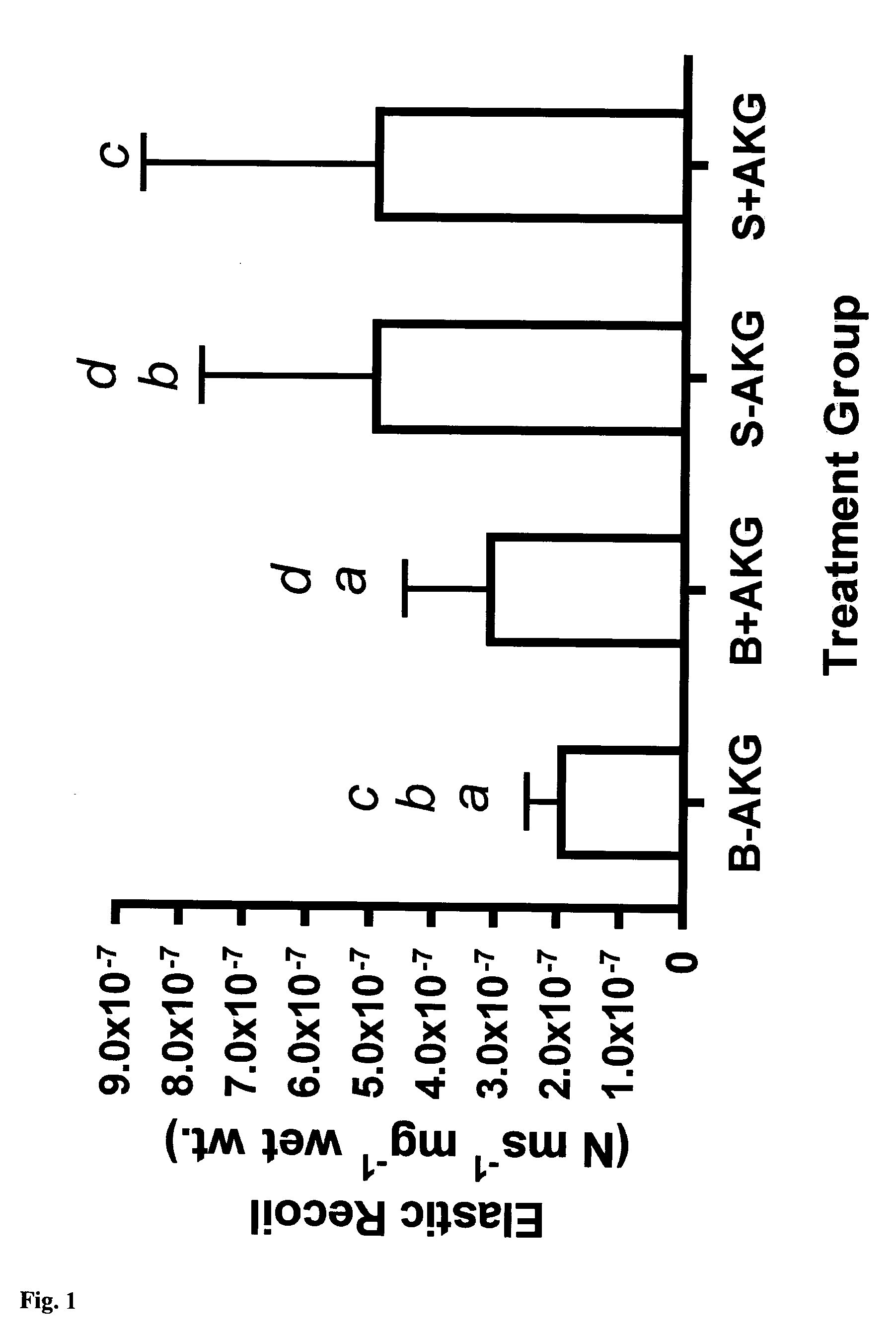

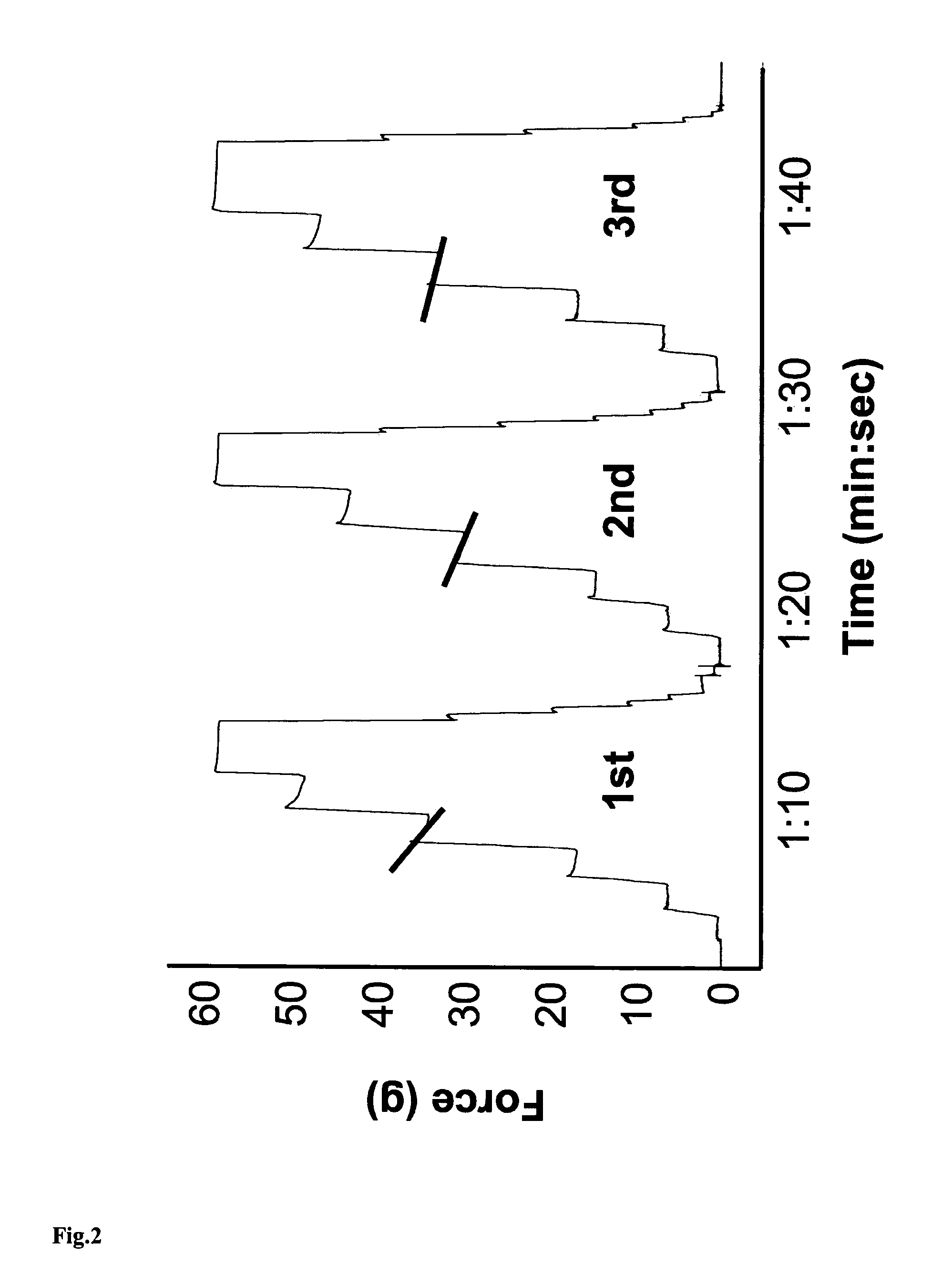

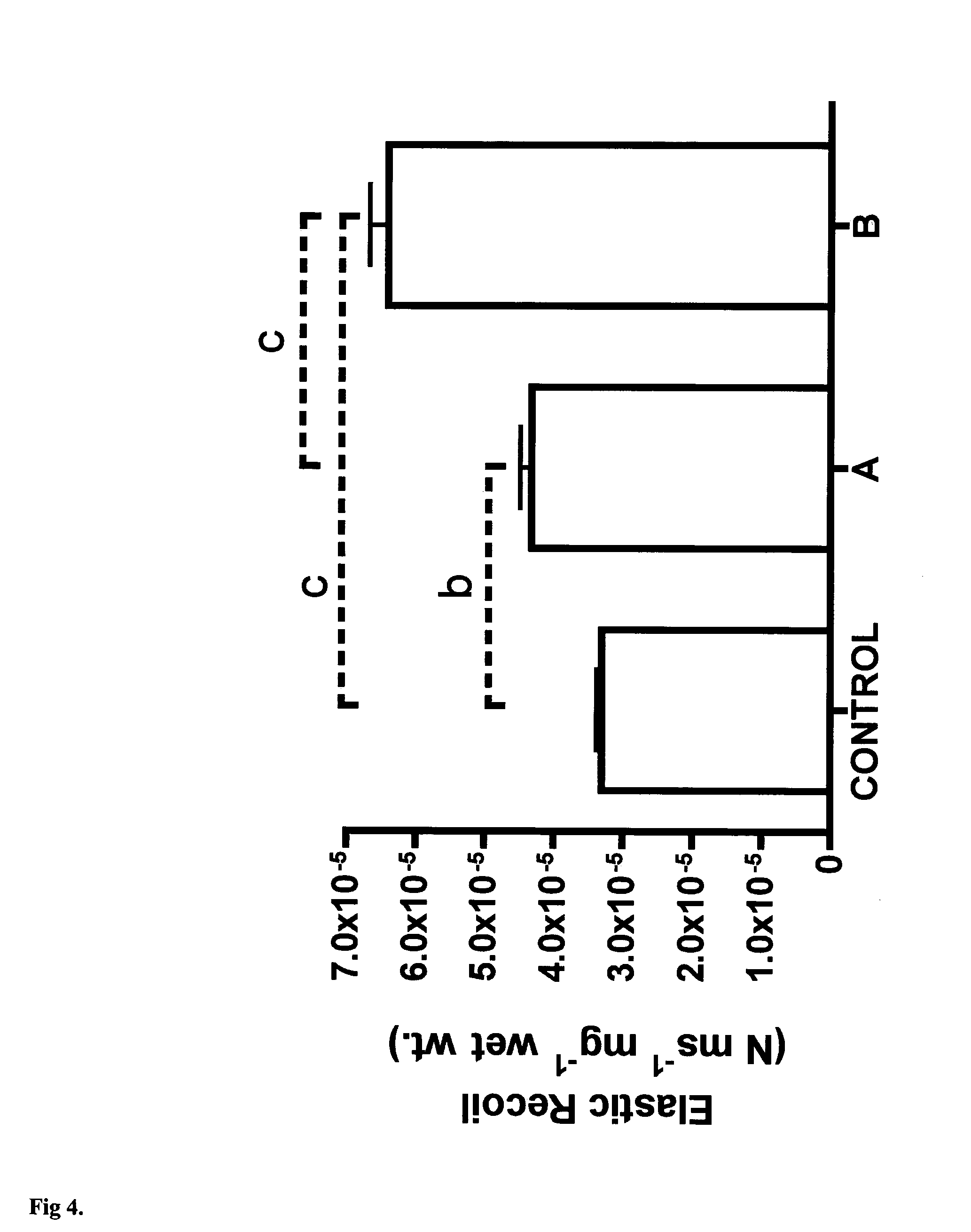

Use of pharmacologically active chemical compounds

The present invention relates to the new use of alpha-ketoglutarate, amides, and salts and mixtures thereof for the manufacture of a pharmaceutical preparation or a food or feed supplement for the in vivo therapeutic improvement of blood vessel elasticity, in particular arterial elasticity in a subject in need thereof. Improving the blood vessel elasticity may be used in the for the treatment and / or prophylaxis of hypertension, pulmonary arterial hypertension, cardiovascular disease, retinal vascular disease, heart failure, atherosclerosis, ventricular hypertrophy, stroke, arterial aneurysm, kidney failure, nephrosclerosis and diseases related to hypertension.

Owner:EHNTRESS AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com