Preparation method of calcium alpha-ketoglutarate

A technology of calcium ketoglutarate and dimethyl dichloroglutarate, applied in the preparation of carboxylate, organic chemistry, etc., can solve the problem of difficult to control the progress of the reaction, high concentration of sodium methoxide, more and more violent reaction, etc. problems, to achieve the effect of improving yield, shortening process and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

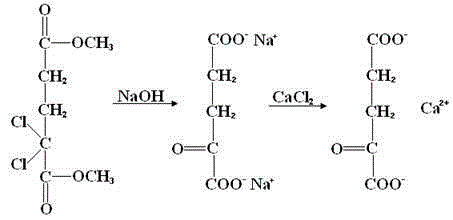

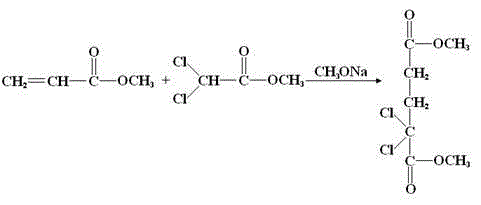

[0017] Below, the preparation method of α-ketoglutarate calcium of the present invention is further described in conjunction with chemical equation and specific examples:

[0018] The chemical reaction involved in the preparation method of α-ketoglutarate calcium of the present invention is:

[0019]

[0020]

[0021] a) Add sodium methoxide solution with a concentration of 30% (mass percentage) into methyl dichloroacetate, stir evenly, control the temperature of the system at 40°C to 50°C, keep it warm for 30 minutes, and then add methyl acrylate dropwise for reaction , after reacting for 4 hours, stop stirring, and maintain the reaction temperature for 10 minutes; wherein, the ratio of the amount of methyl dichloroacetate and methyl acrylate added is 1:1.1, and the amount of sodium methoxide is the amount of the two reactants 1%~2% of the sum;

[0022] b) Add water to the mixed solution after step a), wash it, let it stand, separate the water phase and the organic pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com