Biocatalysis method for preparing Alpha ketoglutarate from L-soda glutamate

A technology of ketoglutaric acid and sodium glutamate, applied in the biological field, can solve problems such as difficult expansion of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

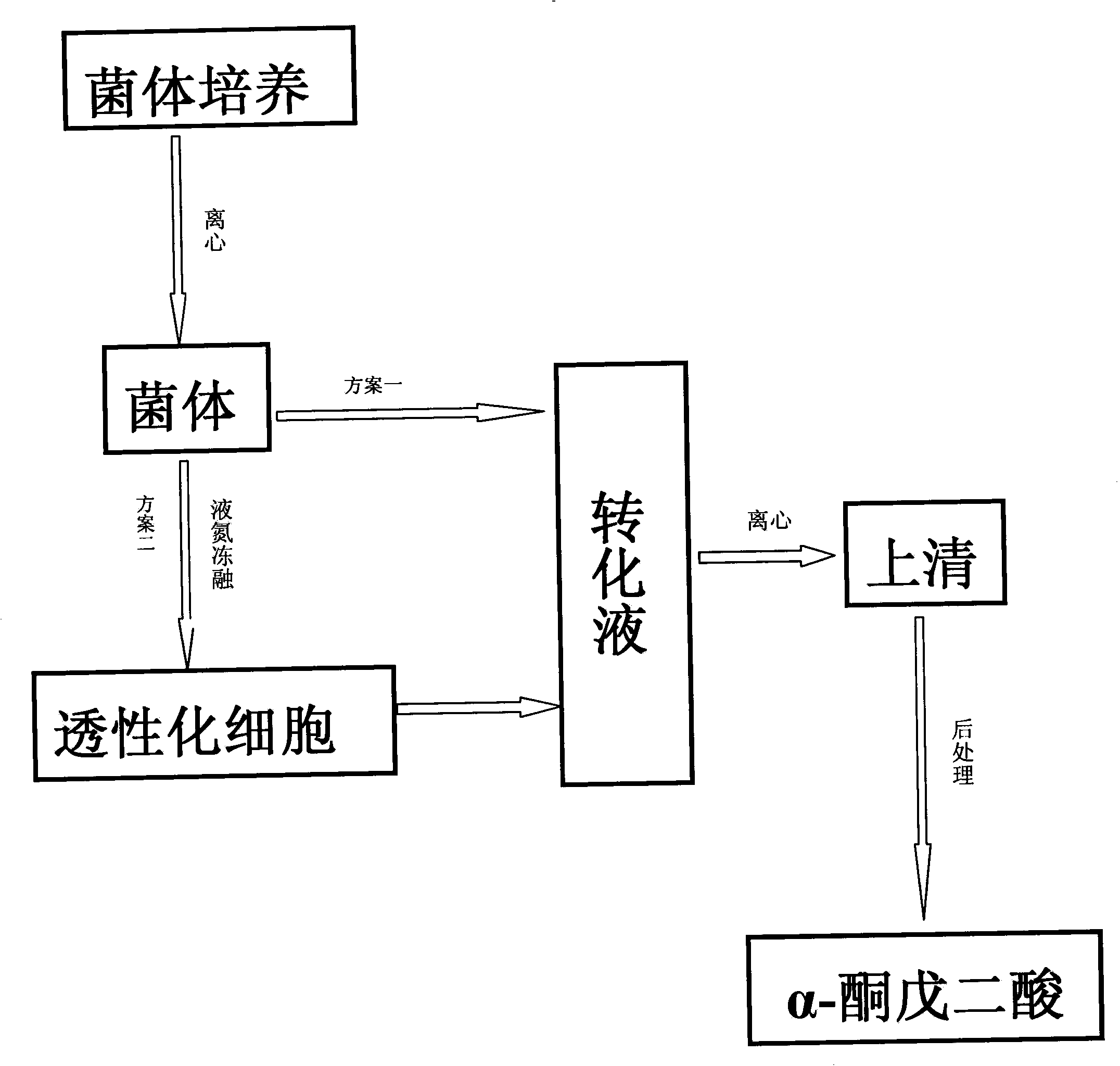

Method used

Image

Examples

Embodiment 1

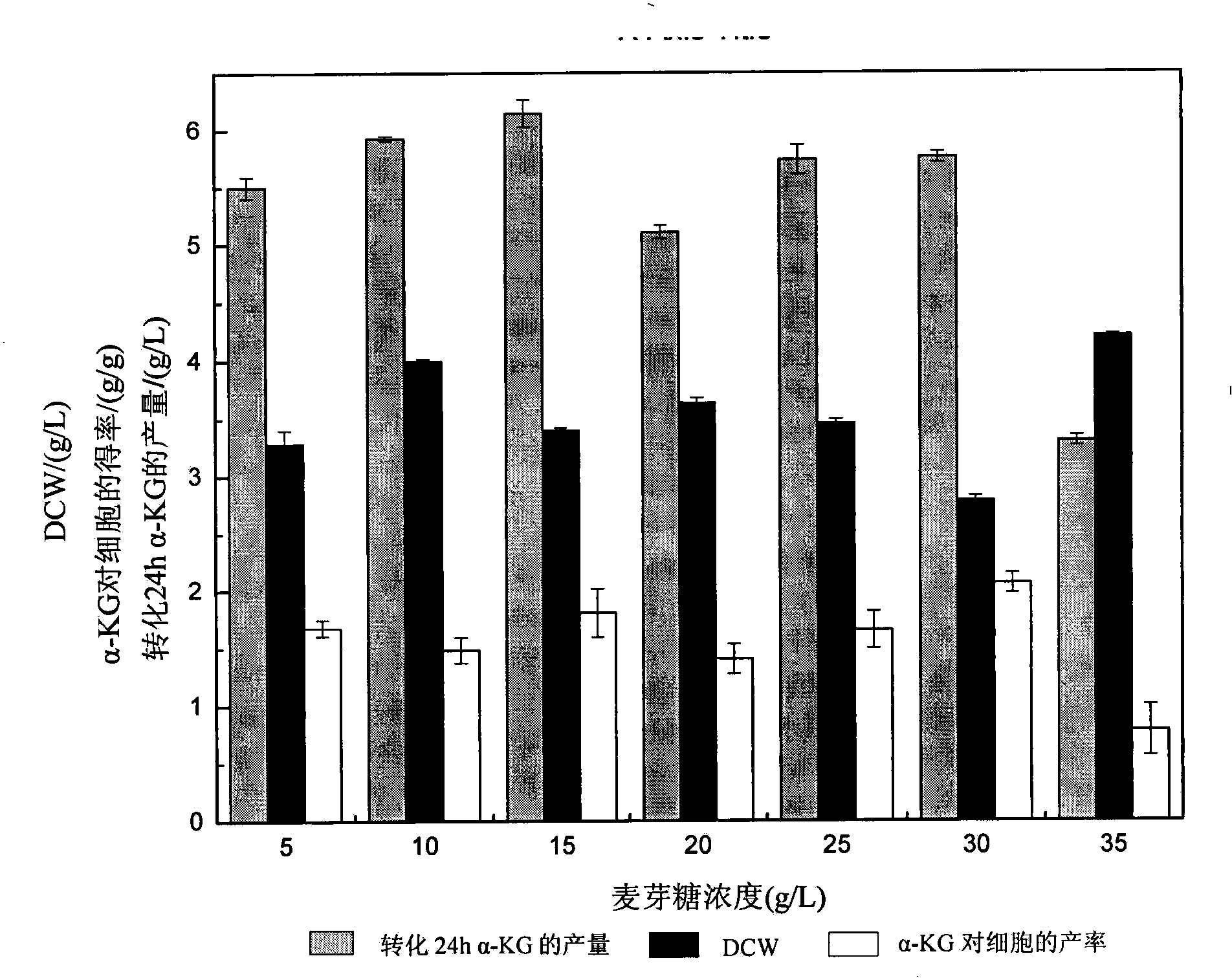

[0018] Embodiment 1, utilize single factor experiment to determine the optimal concentration of maltose.

[0019] After determining the optimum carbon source as maltose, the concentration gradient of 5g / L, 10g / L, 15g / L, 20g / L, 25g / L, 30g / L, 35g / L was selected, and the effect of maltose concentration on bacteria was studied. Effects on body growth and transformation ability. After 48 hours of culture in shake flasks, take 30ml of fermentation broth in a 50ml centrifuge tube and centrifuge at 8000rpm for 5min, discard the supernatant, resuspend the bacteria with 30ml of transformation solution and pour them into shake flasks. After 24 hours of down-conversion, samples were taken every 6 hours to determine the production of α-KG by HPLC.

Embodiment 2

[0020] Embodiment 2, under optimal culture medium and culture condition, measure the growth of bacterium and the situation of enzyme production.

[0021] In order to further improve the transformation ability of the bacteria, the growth characteristics and enzyme production characteristics of the bacteria under the optimal nutritional conditions and culture conditions were studied. Selected 9 shake flasks (500L in size) and divided them into three groups. The volume of each shake flask was 50ml, and 5ml of seed liquid was inserted into them. They were cultivated at 200r / m and 30°C for 48h, and samples were taken every few hours and collected. Measurement data.

Embodiment 3

[0022] Embodiment 3, the impact of different bacterial cell concentrations on transformation

[0023] Due to the relatively stable transformation performance of the bacteria, the bacteria concentration (dry weight) of 2g / L, 4g / L, 6g / L, 8g / L, and 12g / L was set to study the effect of the bacteria concentration on the conversion rate and α-KG output Impact. Measure 15ml, 30ml, 45ml, 60ml, 90ml of fermentation broth after 48 hours of fermentation (cell concentration is 4g / L), centrifuge at 8000rpm for 5min, resuspend cells with 30ml of transformation solution and pour into shake flask at 30℃, 200rpm The transformation was carried out for 6 hours under the conditions, and after 6 hours, a sample was taken to measure the yield of α-KG by HPLC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| affinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com