Method for microbial fermentation synthesis of ª‡- ketoglutaric acid

A microbial fermentation, ketoglutaric acid technology, applied in the direction of fermentation

Inactive Publication Date: 2004-11-10

JIANGNAN UNIV

View PDF1 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, microbial fermentation and synthesis of α-ketoglutarate has not been reported in the literature.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Login to View More

Abstract

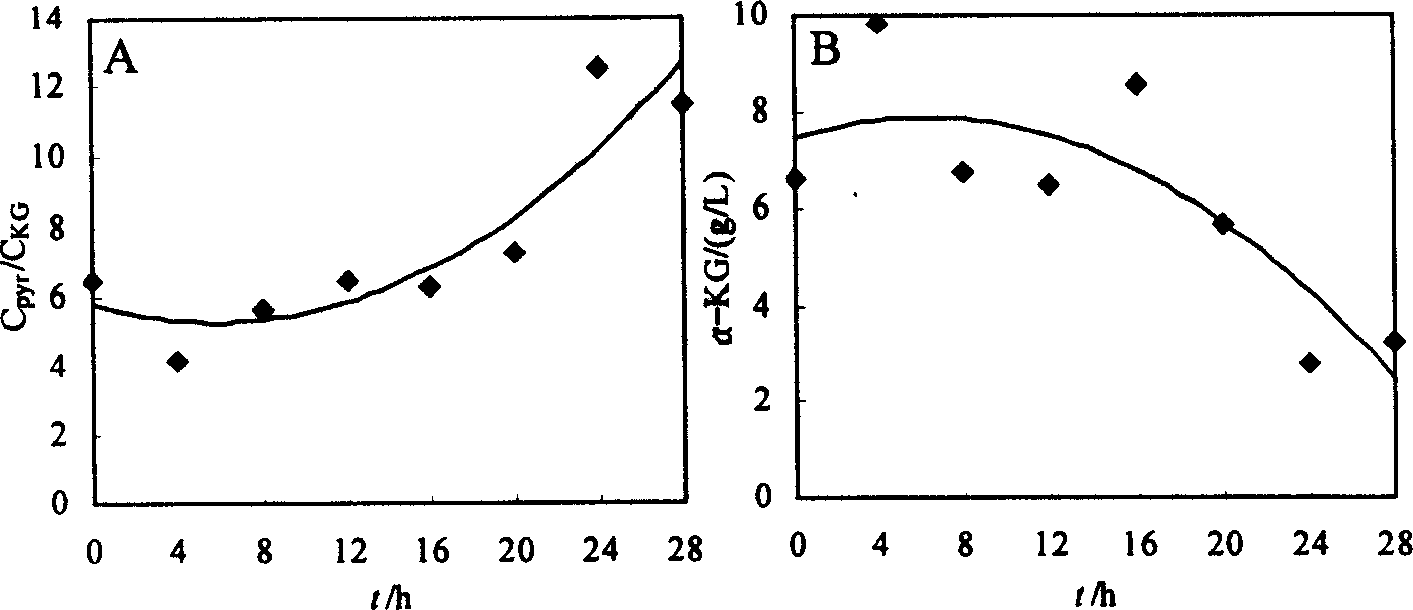

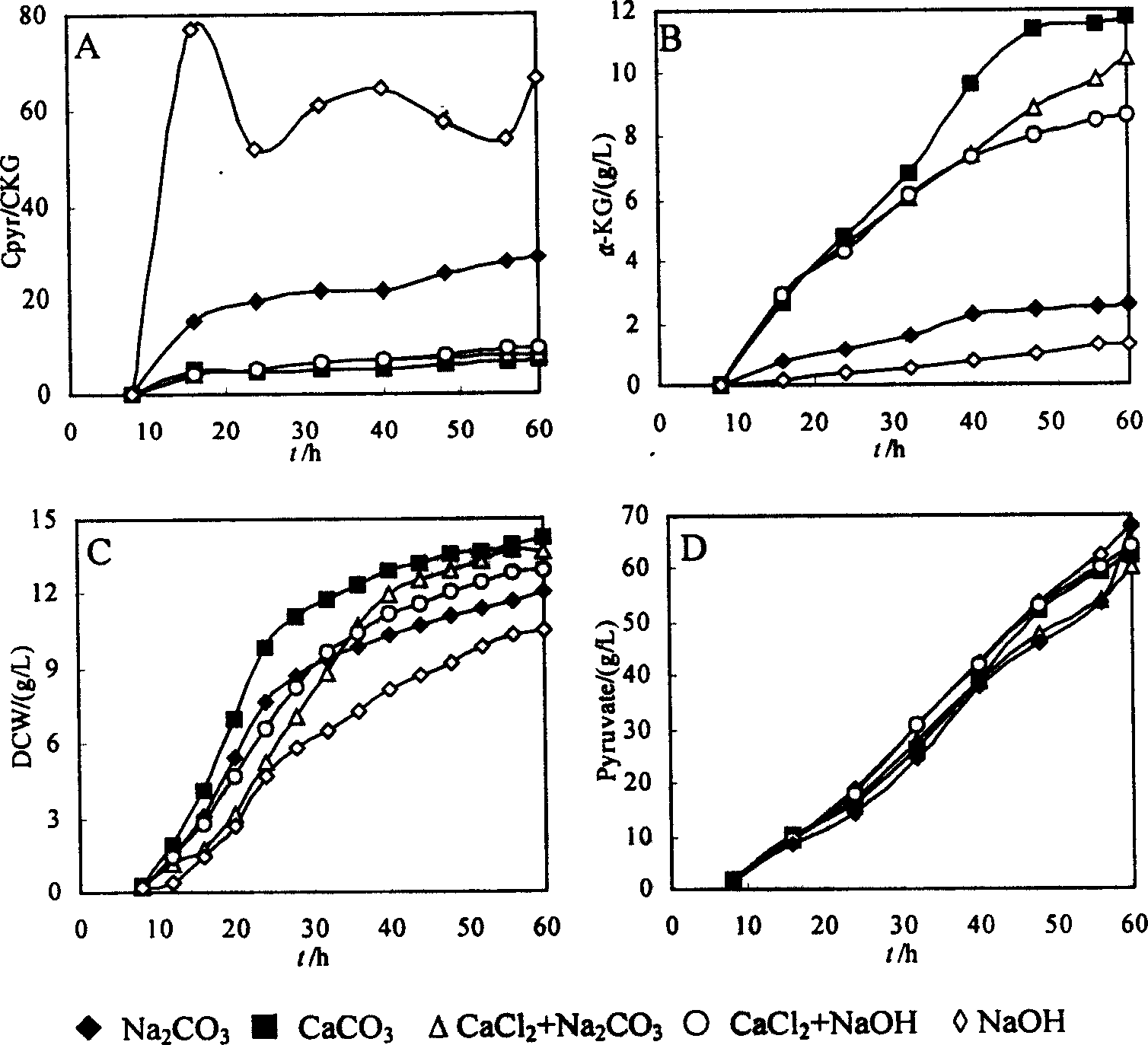

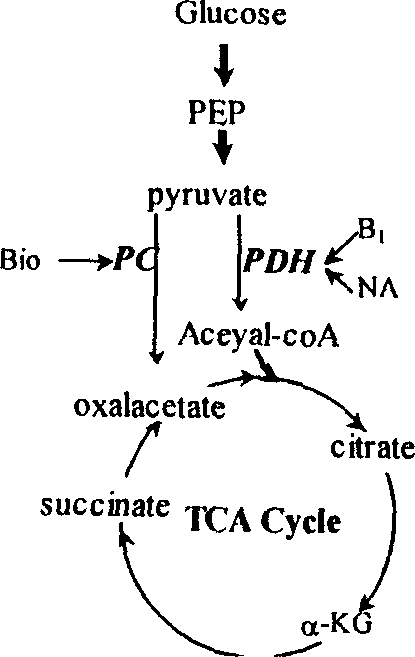

The invention is a method of synthesizing alpha-ketoglutarate by fermenting microbes, promoting to produce a large amount of alpha-ketoglutarate in fermenting course by adding CaCO3 to the culture medium and increasing biotin concentration. in the course of fermenting candida glabrata CCTCC M202019 to producing pyruvic acid, the delay of time of adding CaCO3 will inhibit the generation of alpha-ketoglutarate and increase the carbon mole ratio of pyruvic acid to alpha-ketoglutarate (CPYR / CKG), and increase of CaCO3 concentration in the culture medium will promote accumulation of a large amount of alpha-ketoglutarate, when the CaCO3 concentration is 40g / L, it is most beneficial to alpha-ketoglutarate generation. Keeping the CaCO3 concentration in the culture medium but increasing biotin concentration in the culture medium so as to promote the continuous increase of the alpha-ketoglutarate concentration but continuous decrease of CPYR / CKG value, and when biotin concentration is 60mum g / L, accumulated quantity of alpha- ketoglutarate is 23.5g / L. when Ca2+ exists, in-cell phosphoenolpyruvate carboxylase activity can be increased by 40%, and the activity of pyruvic acid dehydrogenase system does not change obviously. The increase of the Ca2+ and biotin concentration can remarkably the activity of enhance pyruvic acid dehydrogenase, thus making T.glabrata transfer from production of pyruvic acid by fermenting to synthesis of high-concentration alpha-ketoglutarate.

Description

technical field The invention relates to a method for synthesizing α-ketoglutaric acid by microbial fermentation. Background technique α-ketoglutaric acid (α-ketoglutaric acid, referred to as α-KG), chemical name: 2-oxo-1,5 glutaric acid, structural formula is It is a white or off-white powdery substance, easily soluble in water, widely used as an organic intermediate in the production of organic synthesis; it is an important biochemical reagent, and can be used as a supporting reagent to measure liver function, as a nutritional Strengthening agents are widely used in: improving the body's immune ability; reducing the body loss of postoperative patients and long-term patients; serving as precursors for the synthesis of aminobutyric acid and glutamic acid in the brain; related to energy production in the body. As a component of sports nutrition drinks, it can promote aerobic energy supply; increase athletes' insulin levels, promote the absorption of amino acids, blood su...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12P7/50

Inventor 陈坚李寅刘立明伦世仪

Owner JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com