Method for microbial fermentation synthesis of ª‡-ketoglutaric acid

A technology for microbial fermentation, ketoglutaric acid, used in microorganism-based methods, biochemical equipment and methods, microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

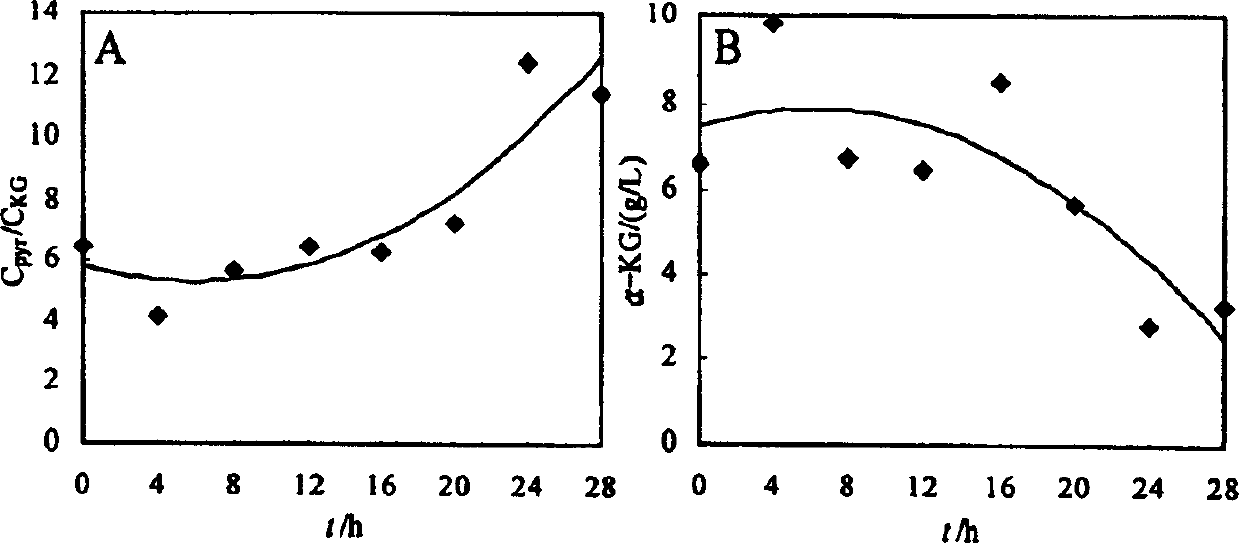

[0049] Sterilize the medium in a 7L fermenter, inoculate microbial seeds according to 10% (volume ratio), after inoculation and mixing, transfer 50mL of inoculated medium aseptically to a sterilized 500mL Erlenmeyer flask, and add 40g / L calcium carbonate was cultured in shake flasks, cultured at 30°C and 200rpm for 48h, and the concentration of α-ketoglutaric acid was measured to be 15.8g / L, C PYR / C KG is 3.1.

Embodiment 2

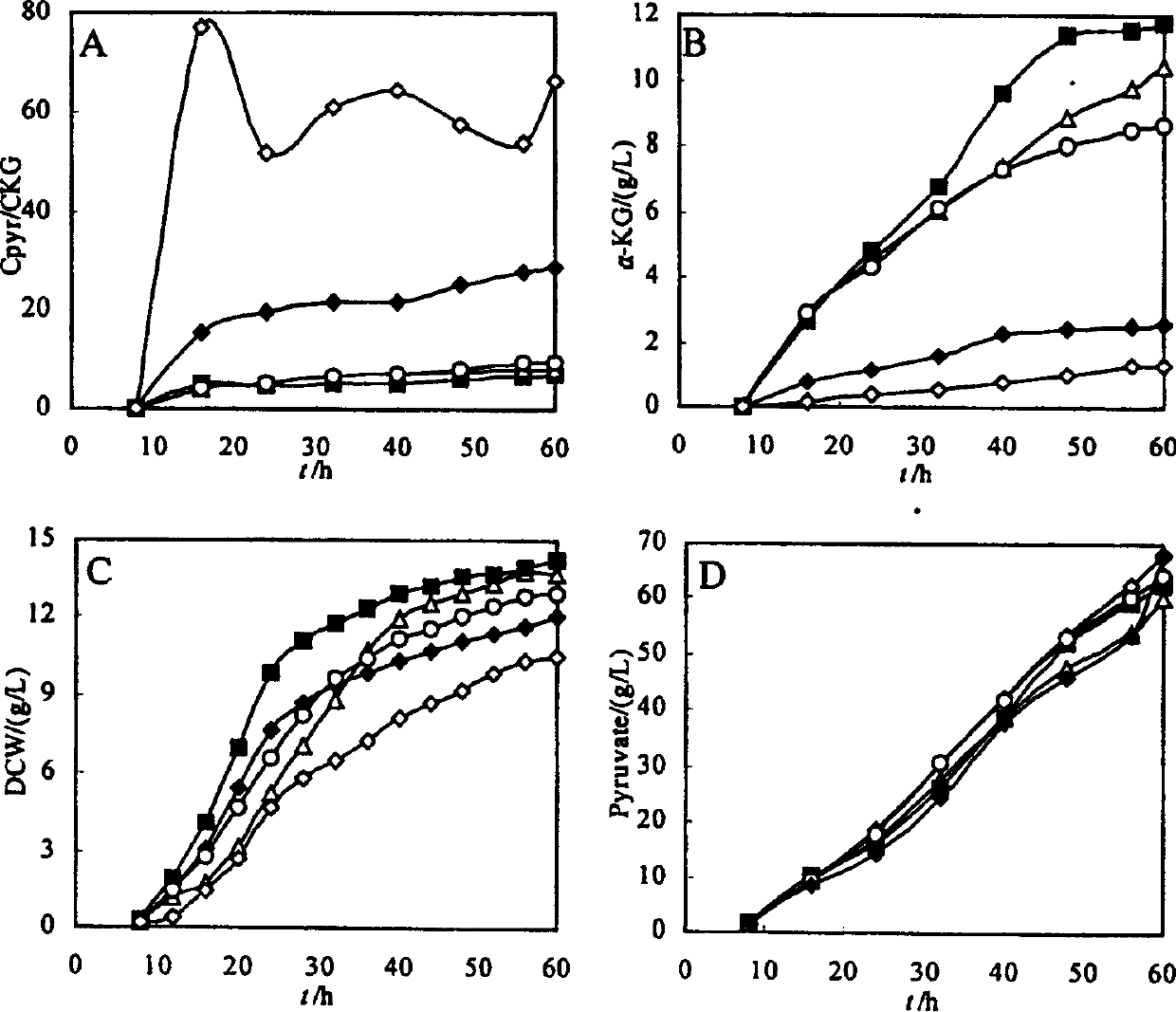

[0051] The inoculation and culture conditions were the same as in Example 1, and 20-40 μg / L of biotin was added. It was found that the concentration of α-ketoglutarate increased with the increase of biotin concentration, and C PYR / C KG slowing shrieking. When the total concentration of biotin in the medium reaches 60 μg / L, the concentration of α-ketoglutarate is 23.5 g / L, C PYR / C KG is 1.47.

Embodiment 3

[0053] Put 4L of fermentation medium in a 7L fermenter and then sterilize it, add Torulopsis glabrata according to 10% (volume ratio), add 40g / L calcium carbonate and 60μg / L biotin in the medium. After culturing at 30°C, ventilation rate 3L / (L·min), rotation speed 400rpm for 60h, the concentration of α-ketoglutaric acid was 38.4g / L, C PYR / C KG is 0.72.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com