Method for producing multifunctional distiller's grain feed

A distiller's grains, multi-functional technology, applied in animal feed, animal feed, application, etc., can solve the problems of high fiber and single function, and achieve the goal of promoting animal growth, realizing rational utilization of resources, and enriching beneficial bacteria in the intestinal tract of animals Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Steam explosion pretreatment of raw distiller's grains:

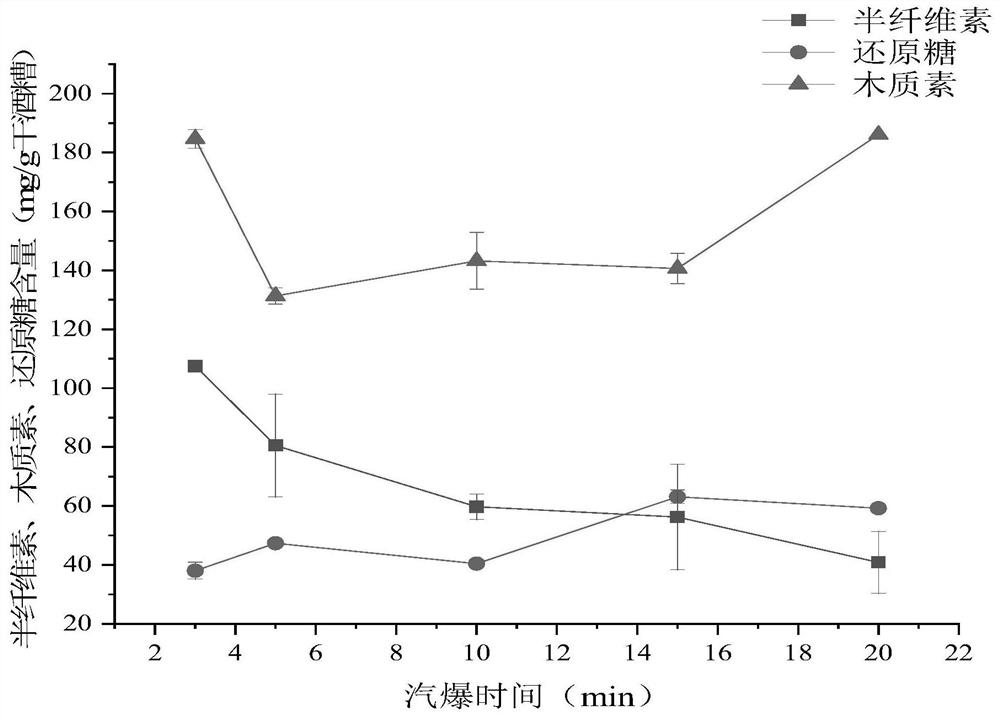

[0029] First, the fresh distiller's grains are placed on the material table of the steam explosion process test bench for steam explosion. The steam explosion pressure is 1.5MP, and the steam explosion time is controlled to 3 minutes, 5 minutes, 10 minutes, 15 minutes, and 20 minutes respectively. The reducing sugar, lignin and hemicellulose of the above-mentioned steam explosion products are determined, and the contents are shown in figure 1 .

Embodiment 2

[0031] Steam explosion pretreatment of raw distiller's grains:

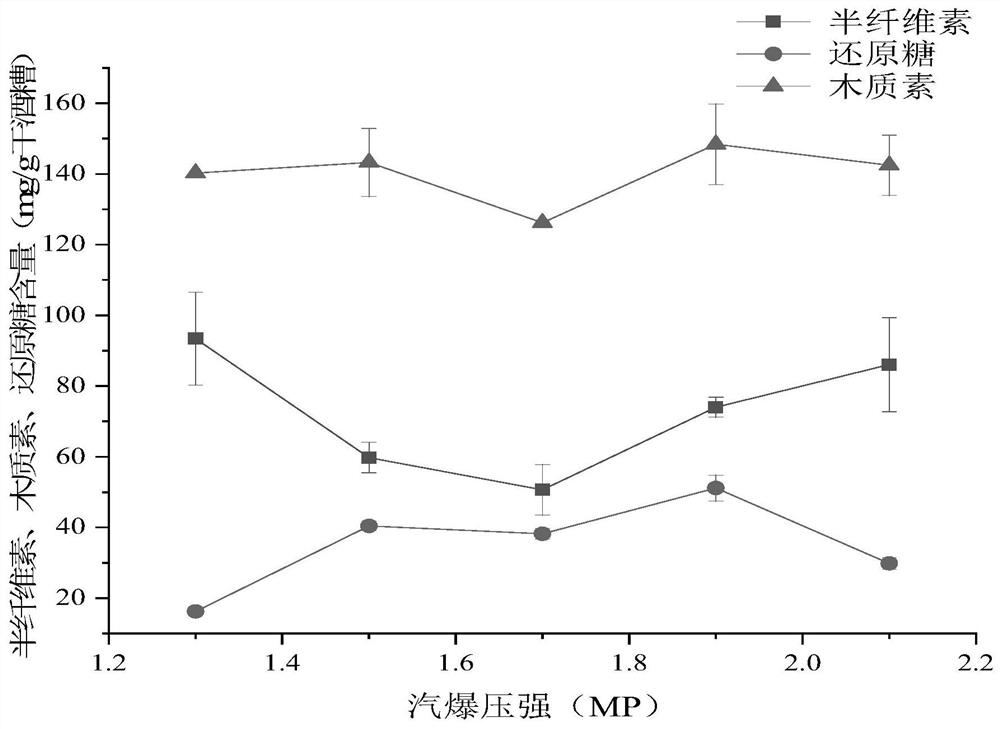

[0032] First, the fresh distiller's grains are placed on the material platform of the steam explosion process test bench for steam explosion. The steam explosion time is 10 minutes, and the steam explosion pressure is controlled to be 1.3MP, 1.5MP, 1.7MP, 1.9MP, and 2.1MP respectively. Determination of the reducing sugar, lignin and hemicellulose of the above-mentioned steam explosion products, see figure 2 .

Embodiment 3

[0034] Determination of lactic acid bacteria for distiller's grain feed production.

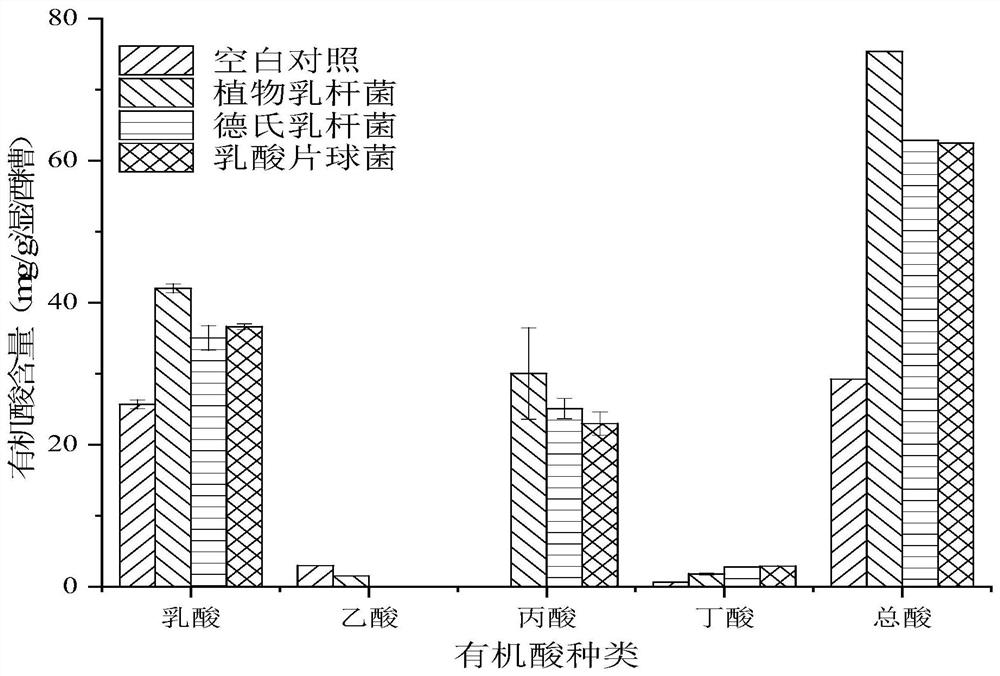

[0035] Combined embodiment 1 and 2 optimization steam explosion conditions, process the distiller's grains obtained under optimum steam explosion conditions (pressure 1.7MP, pretreatment time 15min) as fermentation substrate, it is packed in 250mL Erlenmeyer flask (90g per bottle) And sterilized at 121°C for 30 minutes. Fermentation experiments were carried out by combining the following three strains: ① Saccharomyces cerevisiae, Candida utilis, Bacillus subtilis, Trichoderma konningen, Lactobacillus germanica; ② Saccharomyces cerevisiae, Candida utilis, Bacillus subtilis, Konning wood Mold, Lactobacillus plantarum; ③ Saccharomyces cerevisiae, Candida utilis, Bacillus subtilis, Trichoderma korningii, Pediococcus lactis. Each combination was inoculated with various strains of bran koji in equal proportions, and the total inoculum amount was controlled at 10 g. After inoculation, it was placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com