Net cover structure of engineering air bag

A technology of airbags and nets, which is applied in the direction of special-purpose ships, warships, ship salvage, etc., to achieve the effects of reasonable force, saving economic cost investment, reasonable axial force and lateral force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

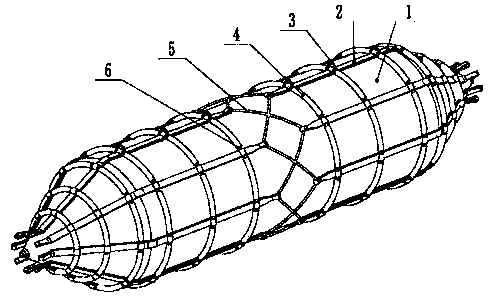

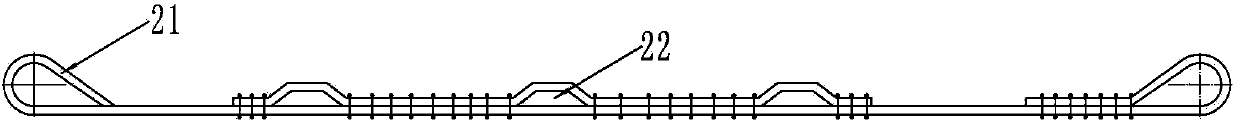

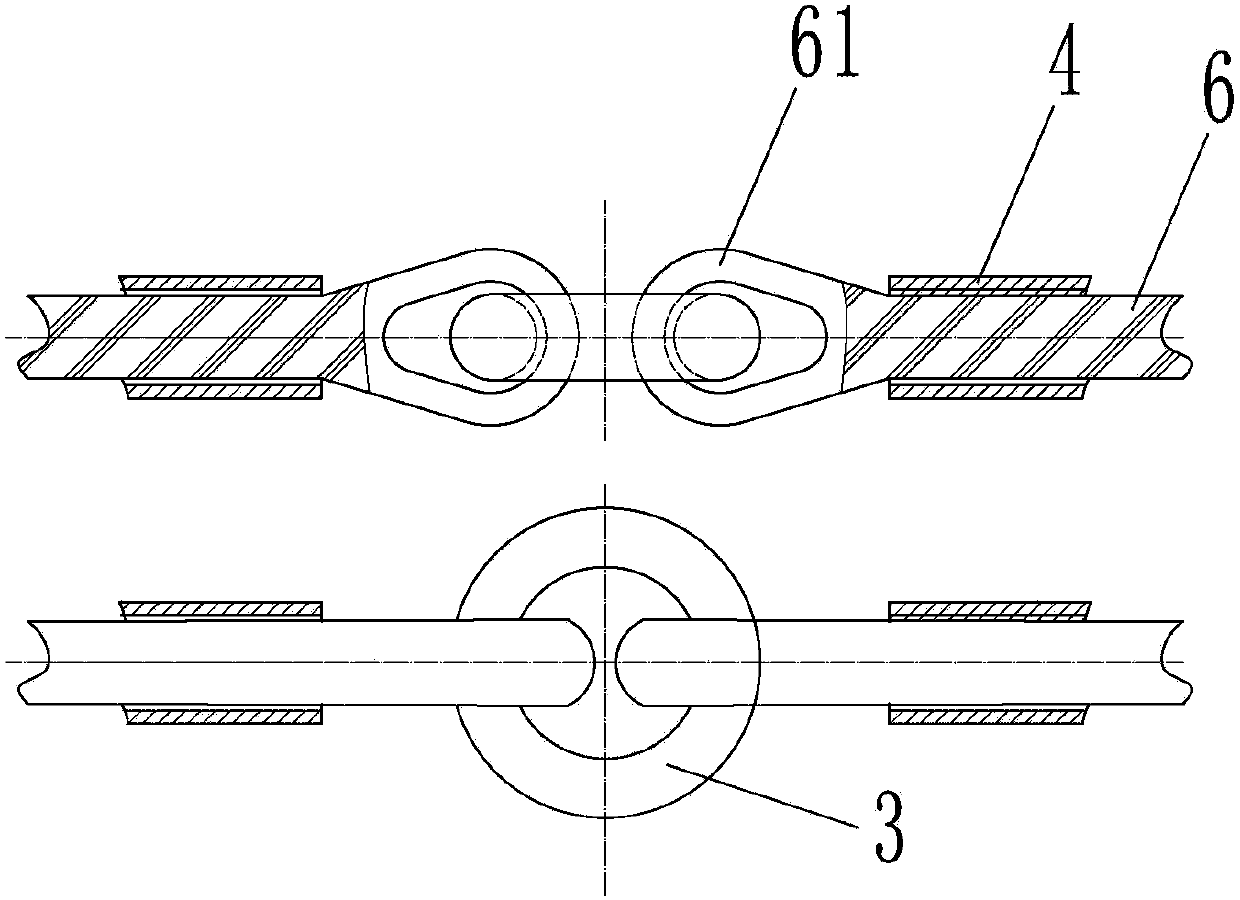

[0020] The present invention will be further described below in conjunction with the accompanying drawings. In this example, outside the capsule body of the airbag 1, a net structure composed of 8 longitudinal suspenders 2 and 12 transverse suspenders 5 is installed, and the 8 longitudinal suspenders 2 are evenly distributed on the circumference of the capsule body, and the positioning is realized by the rubber tube 4; The 12 horizontal slings 5 pass through the inner hole of the rubber tube 4 and the fixing holes on the longitudinal sling 2 to realize the connection limit between the 8 longitudinal slings 2 in the circumferential direction to ensure a uniform spacing. The longitudinal sling 2 is at both ends of the airbag 1 There are lugs, the other end of which is located in the middle of the capsule body, and the longitudinal tension of the eight longitudinal slings 1 is realized by cross-winding the ropes 5 .

[0021] In this example, the optimal scheme of the underwater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com