Myceliophthora thermophila ferment as well as preparation method and application thereof

A technology of Myceliophthora thermophila and fermented products, which is applied in the field of fermented Myceliophthora thermophila and its preparation and application, and can solve the problems of easy inactivation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, the application of Myceliophthora thermophila in the production of cellulase

[0033] 1. Seed cultivation

[0034] Inoculate Myceliophthora thermophila on the PDA slant and culture at 45°C for 5 days.

[0035] 2. Fermentation

[0036] Adopt 250ml Erlenmeyer flask, and 50ml fermentation medium is housed in each Erlenmeyer flask.

[0037] Dig the seed slant (approximately 0.5×1 cm) into the fermentation medium, culture at 45°C, 180r / min shaking (radius 13mm) for 5 days, then centrifuge at 5000g for 20min, and collect the supernatant.

[0038] Fermentation medium (pH=5): take 50g of microcrystalline cellulose, 27g of corn steep liquor, 5g of ammonium sulfate, 6g of potassium dihydrogen phosphate, 2.5g of calcium carbonate, 1g of magnesium sulfate, 2.5g of glycerol and tween-802g, dissolve in water and make up to 1L with water.

[0039] 3. Determination of Enzyme Activity

[0040] Determination of enzyme activity (reaction temperature is 50°C, reaction pH...

Embodiment 2

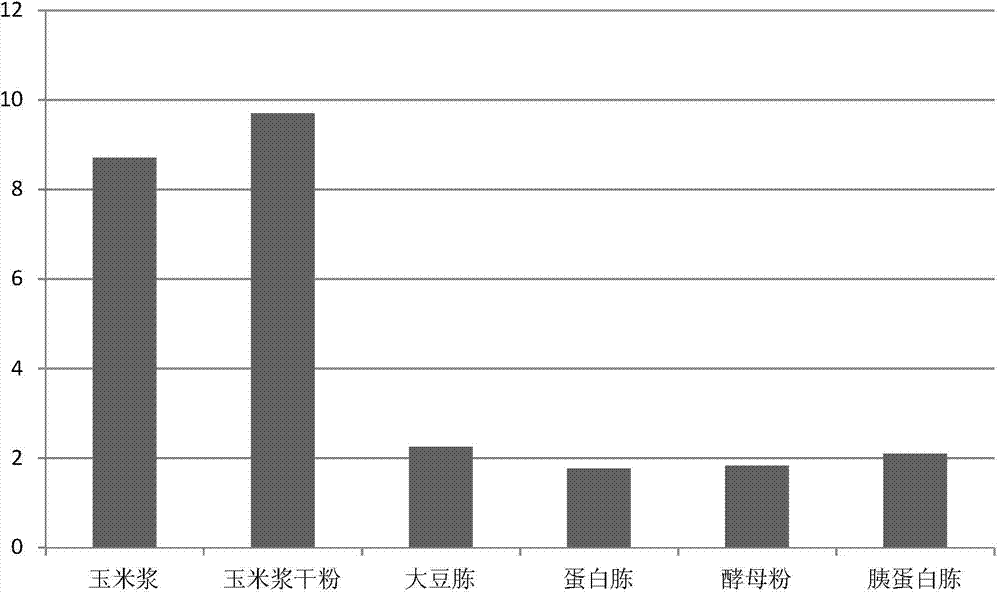

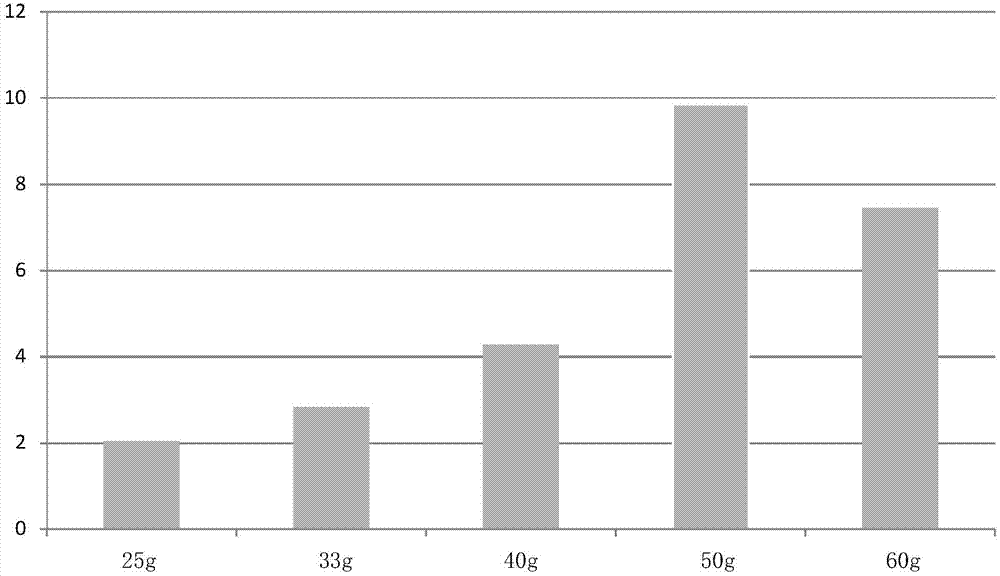

[0042] Embodiment 2, optimization of the fermentation conditions of Myceliophthora thermophila

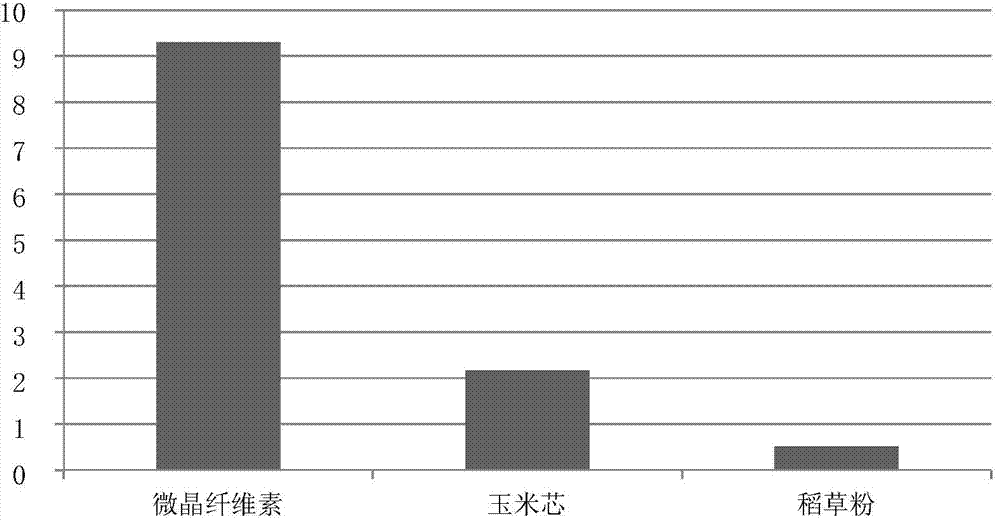

[0043] 1. The effect of different carbon sources on the production of cellulase

[0044] 1. Seed cultivation

[0045] Inoculate Myceliophthora thermophila on the PDA slant and culture at 45°C for 5 days.

[0046] 2. Fermentation

[0047] Adopt 250ml Erlenmeyer flask, and 50ml fermentation medium is housed in each Erlenmeyer flask.

[0048] Dig the seed slant (approximately 0.5×1 cm) into the fermentation medium, culture at 45°C, 180r / min shaking (radius 13mm) for 5 days, then centrifuge at 5000g for 20min, and collect the supernatant.

[0049] Fermentation medium (pH=5): 50g of carbon source (microcrystalline cellulose, corncob or rice straw powder), 27g of corn steep liquor, 5g of ammonium sulfate, 6g of potassium dihydrogen phosphate, 2.5g of calcium carbonate, 1g of magnesium sulfate, glycerin 2.5g and Tween-802g, dissolve in water and dilute to 1L with water.

[0050] 3. Det...

Embodiment 3

[0082] Embodiment 3, the enzymatic property of cellulase

[0083] 1. Optimum reaction temperature

[0084] Take step 2 of Example 1 to obtain the supernatant, and detect the enzyme activity with reference to the enzyme activity assay method of step 3 of Example 1. The only difference is that the following reaction temperatures are used respectively: 30°C, 40°C, 50°C, 60°C and 70°C ℃.

[0085] For supernatant results, see Figure 5 (The unit of the ordinate is U / mL). It has the highest enzyme activity at 60°C.

[0086] 2. Optimum reaction pH

[0087] Get the supernatant obtained in Step 2 of Example 1, and detect the enzyme activity with reference to the enzyme activity assay method in Step 3 of Example 1. The only difference is that the following buffer solution is used to replace "pH4.8, 0.05M disodium hydrogen phosphate-lemon Acid Buffer Buffer": 0.05M disodium phosphate-citrate buffer at pH 3.0, 4.0, 5.0 or 6.0.

[0088] For supernatant results, see Image 6 (The uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com