Blue lyocell fabric prepared by dyeing escherichia coli fermentation extract and preparation method of blue lyocell fabric

A technology of Escherichia coli and extract, applied in the field of blue lyocell fabric and its preparation, to achieve the effect of mild dyeing conditions, less environmental pollution and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

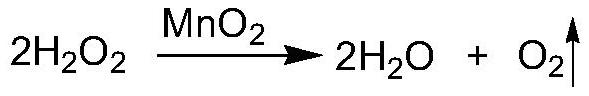

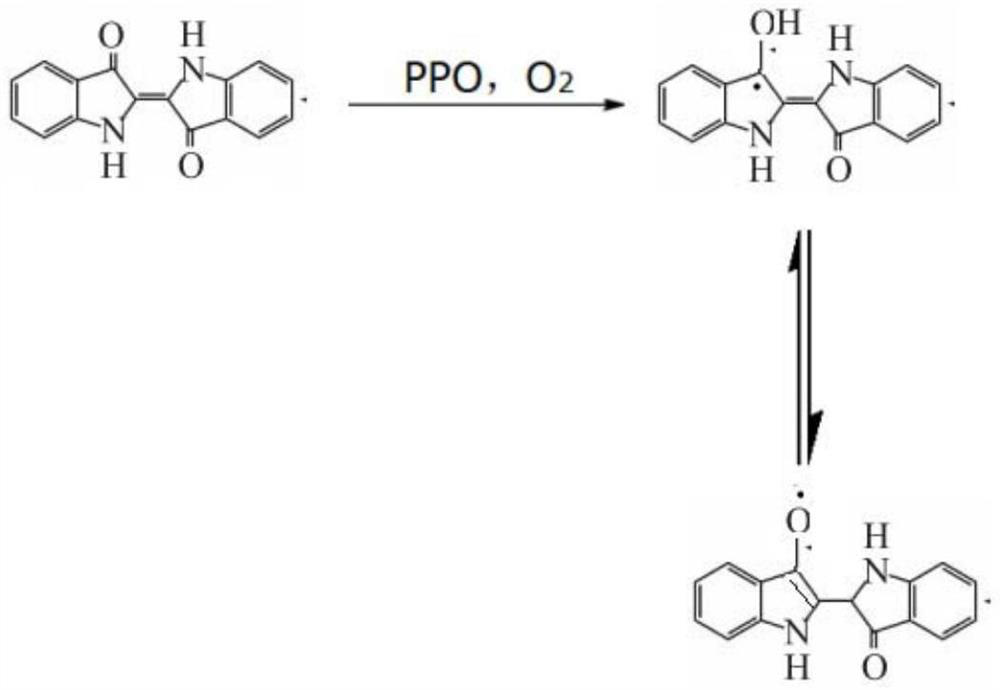

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the blue lyocell fabric obtained by dyeing the Escherichia coli fermented extract, the specific method comprises the following steps:

[0040] (1) purification of escherichia coli fermentation extract: described purification method comprises the steps:

[0041] S1: The configuration of the seed medium: glucose 1.1g / L, potassium dihydrogen phosphate 0.6g / L, magnesium sulfate 0.25g / L;

[0042] S2: Configuration of fermentation medium: indole 0.15g / L, agar 1.1g / L, potassium dihydrogen phosphate 1.1g / L, magnesium sulfate 0.25g / L, calcium chloride 0.25g / L;

[0043] S3: Seed cultivation: under sterile conditions, insert Escherichia coli into the seed medium according to the inoculation amount of 1.1%, and cultivate for 54 hours at the temperature of 29°C and the rotation speed of 180r / min;

[0044] S4: Fermentation culture: under sterile conditions, insert the cultivated seed culture solution into the sterilized fermentation medium with an inoculati...

Embodiment 2

[0051] The preparation method of the blue lyocell fabric obtained by dyeing the Escherichia coli fermented extract, the specific method comprises the following steps:

[0052] (1) purification of escherichia coli fermentation extract: described purification method comprises the steps:

[0053] S1: The configuration of the seed medium: glucose 1.0g / L, potassium dihydrogen phosphate 0.5g / L, magnesium sulfate 0.2g / L;

[0054] S2: Configuration of fermentation medium: indole 0.1g / L, agar 1.0g / L, potassium dihydrogen phosphate 1.0g / L, magnesium sulfate 0.2g / L, calcium chloride 0.2g / L;

[0055] S3: Seed cultivation: under sterile conditions, insert Escherichia coli into the seed medium according to the inoculum amount of 1%, and cultivate for 48 hours at a temperature of 28°C and a rotational speed of 150r / min;

[0056] S4: Fermentation culture: under sterile conditions, insert the cultivated seed culture solution into the sterilized fermentation medium with an inoculation amount o...

Embodiment 3

[0063] The preparation method of the blue lyocell fabric obtained by dyeing the Escherichia coli fermented extract, the specific method comprises the following steps:

[0064] (1) purification of escherichia coli fermentation extract: described purification method comprises the steps:

[0065] S1: The configuration of the seed medium: glucose 1.2g / L, potassium dihydrogen phosphate 0.7g / L, magnesium sulfate 0.3g / L;

[0066] S2: Configuration of fermentation medium: indole 0.2g / L, agar 1.2g / L, potassium dihydrogen phosphate 1.2g / L, magnesium sulfate 0.3g / L, calcium chloride 0.3g / L;

[0067] S3: Seed cultivation: under sterile conditions, insert Escherichia coli into the seed culture medium according to the inoculation amount of 1.2%, and cultivate for 60 hours at the temperature of 30°C and the rotation speed of 200r / min;

[0068] S4: Fermentation culture: under sterile conditions, insert the cultivated seed culture solution into the sterilized fermentation medium with an inocu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com