Yellow lyocell fabric prepared by dyeing with blakeslea trispora fermentation extract and preparation method thereof

The technology of Bollardella and Bollardi mold is applied in the field of fabric preparation to achieve the effects of less environmental pollution, mild dyeing conditions and strong reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

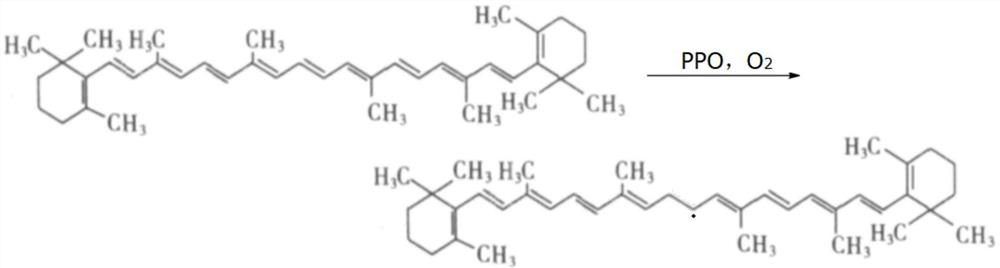

Method used

Image

Examples

Embodiment 1

[0042] The preparation method of the yellow lyocell fabric obtained by dyeing the fermented extract of B. trispora, the specific method comprises the following steps:

[0043] (1) Purification of B. trispora fermentation extract: the purification method comprises the steps:

[0044] S1: Preparation of slant medium: potato juice 20g / L, glucose 20g / L, potassium dihydrogen phosphate 3g / L, magnesium sulfate 1.5g / L agar 15g / L, vitamin B1 0.2mg / L;

[0045] S2: Pretreatment of B. trispora: activate B. trispora, and transfer B. trispora to the slant medium at an inoculum of 0.7%; culture at 29°C for 7 days, Among them, the mycelium of the positive bacteria is light yellow, and the mycelium of the negative bacteria is milky yellow;

[0046] S3: Preparation of seed medium: glucose 10g / L, corn starch 25g / L, potassium dihydrogen phosphate 0.6g / L, magnesium sulfate 0.3g / L, vitamin B1 0.6mg / L;

[0047] S4: Preparation of fermentation medium: cornstarch 35g / L, glucose 11g / L, soybean cake p...

Embodiment 2

[0056] The preparation method of the yellow lyocell fabric obtained by dyeing the fermented extract of B. trispora, the specific method comprises the following steps:

[0057] (1) Purification of B. trispora fermentation extract: the purification method comprises the steps:

[0058] S1: Preparation of slant medium: potato juice 18g / L, glucose 18g / L, potassium dihydrogen phosphate 2g / L, magnesium sulfate 1g / L agar 14g / L, vitamin B1 0.1mg / L;

[0059] S2: Pretreatment of B. trispora: activate B. trispora, and transfer B. trispora to the slant medium according to the inoculum amount of 0.6%; culture at 28°C for 6 days, Among them, the mycelium of the positive bacteria is light yellow, and the mycelium of the negative bacteria is milky yellow;

[0060] S3: Preparation of seed medium: glucose 8g / L, corn starch 20g / L, potassium dihydrogen phosphate 0.5g / L, magnesium sulfate 0.2g / L, vitamin B1 0.5mg / L;

[0061] S4: Preparation of fermentation medium: cornstarch 30g / L, glucose 10g / L,...

Embodiment 3

[0070]The preparation method of the yellow lyocell fabric obtained by dyeing the fermented extract of B. trispora, the specific method comprises the following steps:

[0071] (1) Purification of B. trispora fermentation extract: the purification method comprises the steps:

[0072] S1: Preparation of slant medium: potato juice 22g / L, glucose 22g / L, potassium dihydrogen phosphate 4g / L, magnesium sulfate 2g / L agar 16g / L, vitamin B1 0.3mg / L;

[0073] S2: Pretreatment of B. trispora: activate B. trispora, and transfer B. trispora to the slant medium at an inoculum of 0.8%; culture at 30°C for 8 days, Among them, the mycelium of the positive bacteria is light yellow, and the mycelium of the negative bacteria is milky yellow;

[0074] S3: Preparation of seed medium: glucose 12g / L, corn starch 30g / L, potassium dihydrogen phosphate 0.7g / L, magnesium sulfate 0.4g / L, vitamin B1 0.7mg / L;

[0075] S4: Preparation of fermentation medium: cornstarch 40g / L, glucose 12g / L, soybean meal powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com