Red lyocell fabric obtained through animal dye cochineal dyeing and preparation method of red lyocell fabric

An animal dye, cochineal technology, applied in the direction of dyeing, textile and paper making, etc., to achieve the effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the red lyocell fabric obtained by dyeing with animal dye cochineal, the specific method comprises the following steps:

[0035] (1) Preparation of cochineal red pigment solution: select the dried cochineal body, wash with clean water to remove impurities; boil and reflux with petroleum ether for 7h, the ratio of material to liquid is 1:5 (g / mL); then boil and reflux with ethanol 7h, the ratio of material to liquid is 1:5 (g / mL), and after drying, it is used as a raw material for subsequent use; 10 g of raw material is weighed and put into a conical flask, and distilled water extractant is added, and the ratio of material to liquid is 1:6 (g / mL); Extract at 85°C for 4 hours, and filter after extraction to obtain cochineal red pigment solution for later use.

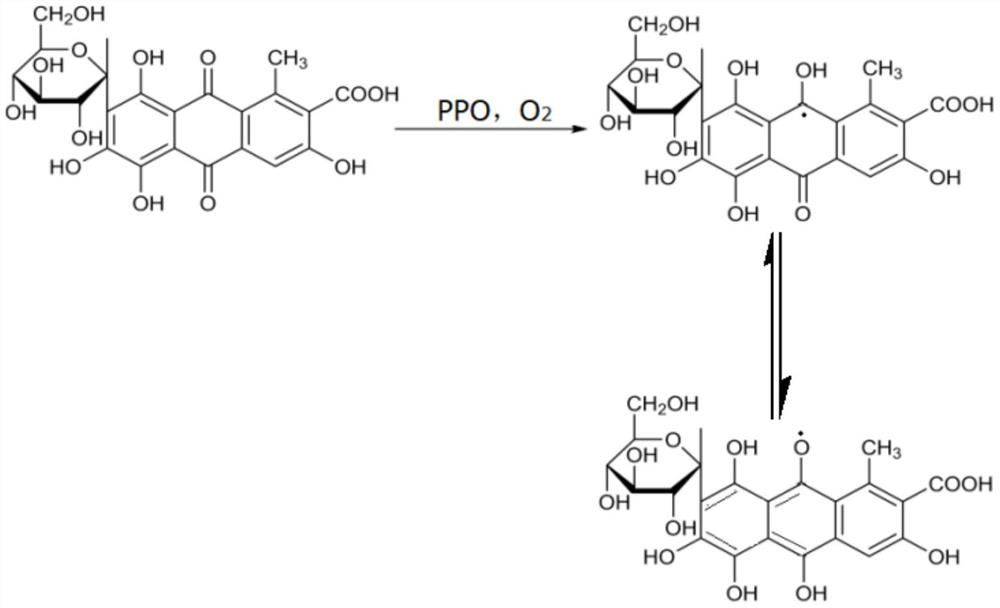

[0036](2) Preparation of enzyme solution: Preparation of polyphenol oxidase solution: Dissolve polyphenol oxidase in phosphate buffer solution with a pH of 6.5 to prepare 25 mg / mL polyphen...

Embodiment 2

[0041] The preparation method of the red lyocell fabric obtained by dyeing with animal dye cochineal, the specific method comprises the following steps:

[0042] (1) Preparation of cochineal red pigment solution: choose the dried body of cochineal worm, wash with clean water to remove impurities; boil and reflux with petroleum ether for 6h, and the ratio of material to liquid is 1:4 (g / mL); then boil and reflux with ethanol 6h, the ratio of material to liquid is 1:4 (g / mL), and after drying, it is used as a raw material for subsequent use; 10g of raw material is weighed and put into a conical flask, and distilled water extractant is added, and the ratio of material to liquid is 1:5 (g / mL); Extract at 85°C for 3 hours, and filter after extraction to obtain cochineal red pigment solution for later use.

[0043] (2) Preparation of enzyme solution: Preparation of polyphenol oxidase solution: Dissolve polyphenol oxidase in phosphate buffer solution with a pH of 6.5 to prepare 20 mg...

Embodiment 3

[0048] The preparation method of the red lyocell fabric obtained by dyeing with animal dye cochineal, the specific method comprises the following steps:

[0049] (1) Preparation of cochineal red pigment solution: choose the dried body of cochineal worm, wash with clean water to remove impurities; boil and reflux with petroleum ether for 8h, and the ratio of material to liquid is 1:6 (g / mL); then boil and reflux with ethanol 8h, the ratio of material to liquid is 1:6 (g / mL), after drying, it is used as a raw material for subsequent use; 10g of raw material is weighed and put into a conical flask, and distilled water extractant is added, and the ratio of material to liquid is 1:7 (g / mL); Extracted at 90°C for 5h, and filtered after the extraction to obtain cochineal red pigment solution for later use.

[0050] (2) Preparation of enzyme solution: Preparation of polyphenol oxidase solution: Dissolve polyphenol oxidase in phosphate buffer solution with a pH of 6.5 to prepare 30 mg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com