A kind of disperse digital printing primer and preparation method thereof

A technology of digital printing and primer, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of single function of digital printing primer, high cost of sodium alginate, low starch price, etc., achieve bright color of printing and improve color fastness The effect of degree and pattern fullness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

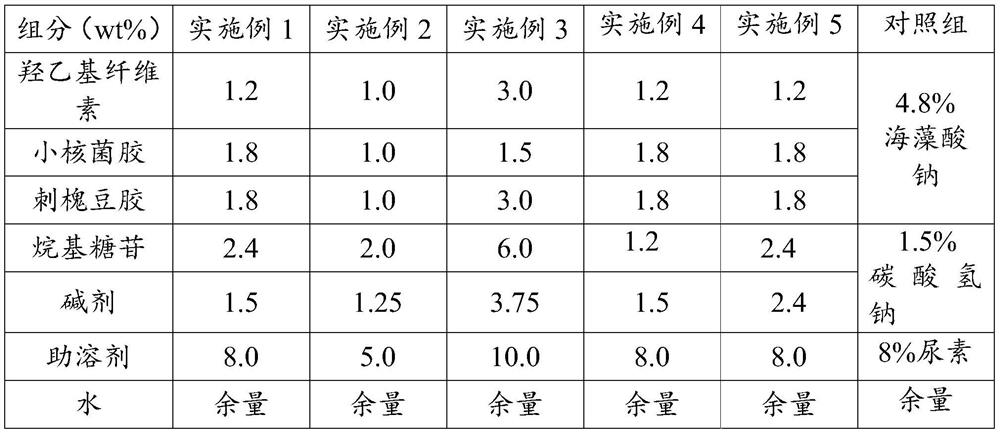

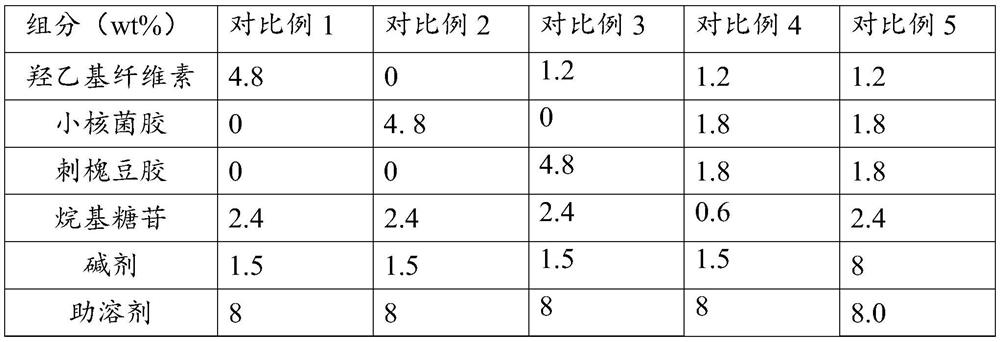

Examples

preparation example Construction

[0025] The preparation method of the reactive digital printing primer described in Embodiments 1-5 includes the following steps:

[0026] 1) Mix hydroxyethyl cellulose, sclerotiorum gum and locust bean gum evenly, add into 60°C water, stir evenly, and let stand to obtain a thickener solution;

[0027] 2) adding alkali agent, alkyl glycoside and cosolvent successively to the thickener to obtain the semi-finished product of printing primer;

[0028] 3) Add water again, stir evenly, and obtain the dispersed digital printing base slurry.

[0029] The alkaline agent of the embodiment of the present invention and the comparative example is composed of sodium carbonate and sodium trichloroacetate in a weight ratio of 1:0.8; the cosolvent is composed of diethylene glycol ether and thiodiglycol in a weight ratio of 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com