Cationic binder for denim paint dyeing

A cationic adhesive and paint dyeing technology, which is applied in the field of textile printing and dyeing, can solve the problems of high local concentration and paint stains, and achieve the effects of increased color yield, excellent hand feeling, and improved anti-yellowing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

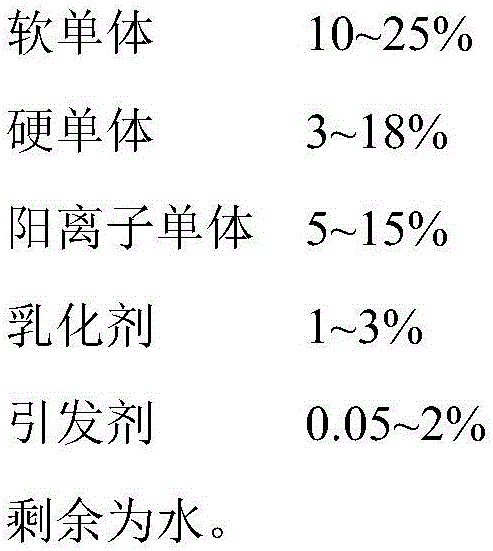

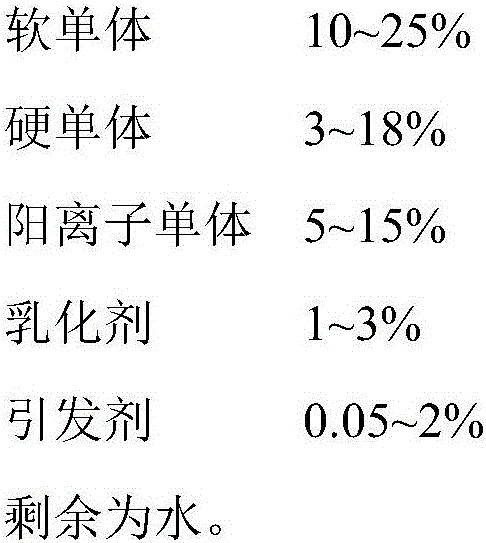

Method used

Image

Examples

Embodiment 1

[0030] Place the four-necked flask equipped with a reflux condenser, a stirrer, and a dropping funnel in a constant temperature water bath, add 2.5 g of emulsifier benzyltriethylammonium chloride, 3 g of PVP-K30 and 200 g of distilled water, stir evenly, and heat up to 40°C, add 0.15g of 2,2'-azobisisopropylamidine hydrochloride (V-50), dropwise add 30g of butyl acrylate, 9g of ethyl methacrylate, 15g of DAC, 3g of 1,6-hexyl Diol diacrylate and other mixtures, use acetic acid to adjust the pH value of the emulsion to 4-5, control the dropping speed, the dropping time is 3 hours, add 0.18g V-50 after the dropping, keep it warm for 1 hour, and raise the temperature to 65°C. Keep warm for 1 hour, cool to 30°C and filter out.

Embodiment 2

[0032] Place the four-necked flask equipped with a reflux condenser, agitator, and dropping funnel in a constant temperature water bath, add emulsifying agent dodecyltrimethylammonium chloride 3g, PVP-K30 6g and distilled water 200g, stir evenly, Raise the temperature to 45°C, add 3.6g of 2,2'-azobisisopropylamidine hydrochloride (V-50), dropwise add 60g of isooctyl acrylate, 20g of styrene, 15g of DMC, 4.5g of acrylamide and other mixtures , use citric acid to adjust the pH value of the emulsion to 5-6, control the dropping speed, the dropping time is 2.5 hours, add 0.3g V-50 after dropping, keep warm for 1 hour, heat up to 70°C, keep warm for 1 hour, and cool to Filter and discharge at 30°C.

Embodiment 3

[0034] Place the four-necked flask equipped with a reflux condenser, a stirrer, and a dropping funnel in a constant temperature water bath, add emulsifiers dioctadecyldimethylammonium chloride 2g, PEG-800 0.6g, T-07 0.4 g and 200g of distilled water, stir evenly, heat up to 50°C, add 4.4g of 2,2'-azobisisopropylamidine hydrochloride (V-50), dropwise add 75g of hexyl acrylate, 30g of methyl methacrylate , 45g DAC, 30g hydroxypropyl acrylate and other mixtures, use acetic acid to adjust the pH value of the emulsion to 4-5, control the dropping speed, the dropping time is 4 hours, add 1.6g V-50 after the dropping, keep warm for 1 hour, and heat up Heat to 75°C, keep warm for 1 hour, cool to 20°C and filter out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com