Super-bright polyester drawn yarn and preparation method thereof

A polyester drawn yarn, bright technology, applied in filament/thread forming, textile and papermaking, fiber processing, etc., can solve the problems of increasing process complexity, high production cost, increasing the difficulty of dyeing polyester fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation method of super bright polyester drawing yarn, the steps are as follows:

[0063] (1) prepare modified polyester;

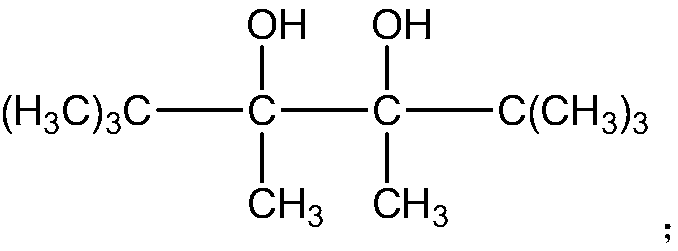

[0064] (1.1) Preparation of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol;

[0065] After mixing palladium acetate and dimethyl di-tert-butylethylene evenly, add a hydrogen peroxide solution with a mass concentration of 10%, react at a temperature of 72°C for 3 hours, and obtain 2,2,3, 4,5,5-hexamethyl-3,4-hexanediol, wherein the mass ratio of dimethyl di-tert-butylethylene, hydrogen peroxide solution and palladium acetate is 1:2.0:0.015, 2,2,3,4 , the structural formula of 5,5-hexamethyl-3,4-hexanediol is shown in formula (I);

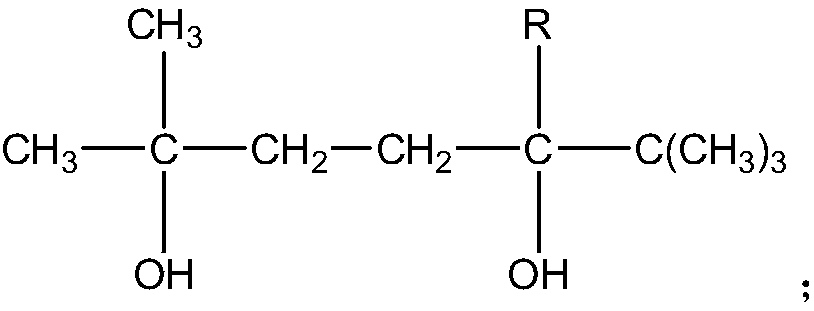

[0066] (1.2) Preparation of 2,6,6-trimethyl-2,5 heptanediol;

[0067] (a) Mix potassium hydroxide aqueous solution and isobutanol at a ratio of 5:1 in a molar ratio of isobutanol to potassium hydroxide, and react for 4 hours at a temperature of 100° C. to obtain potassium isobutoxide. During the reaction, With stirring...

Embodiment 2

[0085] The preparation method of super bright polyester drawing yarn, the steps are as follows:

[0086] (1) prepare modified polyester;

[0087] (1.1) Preparation of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol;

[0088] After mixing palladium acetate and dimethyl di-tert-butylethylene evenly, add hydrogen peroxide solution with a mass concentration of 11%, react at a temperature of 70°C for 4 hours, and obtain 2,2,3, 4,5,5-hexamethyl-3,4-hexanediol, wherein the mass ratio of dimethyl di-tert-butylethylene, hydrogen peroxide solution and palladium acetate is 1:1.8:0.015, 2,2,3,4 , the structural formula of 5,5-hexamethyl-3,4-hexanediol is shown in formula (I);

[0089] (1.2) Preparation of 2,6,6-trimethyl-2,5 heptanediol;

[0090] (a) Mix potassium hydroxide aqueous solution and isobutanol at a ratio of 5.5:1 in a molar ratio of isobutanol to potassium hydroxide, and react for 5 hours at a temperature of 100° C. to prepare potassium isobutoxide. During the reaction, With stirrin...

Embodiment 3

[0105] The preparation method of super bright polyester drawing yarn, the steps are as follows:

[0106] (1) prepare modified polyester;

[0107] (1.1) Preparation of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol;

[0108] After mixing palladium acetate and dimethyl di-tert-butylethylene evenly, add a hydrogen peroxide solution with a mass concentration of 12%, react at a temperature of 74°C for 4 hours, and obtain 2,2,3, 4,5,5-hexamethyl-3,4-hexanediol, wherein the mass ratio of dimethyl di-tert-butylethylene, hydrogen peroxide solution and palladium acetate is 1:1.6:0.015, 2,2,3,4 , the structural formula of 5,5-hexamethyl-3,4-hexanediol is shown in formula (I);

[0109] (1.2) Preparation of 2,6,6-trimethyl-5-ethyl-2,5-heptanediol;

[0110] (a) Mix potassium hydroxide aqueous solution and isobutanol according to the ratio of isobutanol to potassium hydroxide molar ratio of 5:1, and react at a temperature of 105°C for 4.5h to obtain potassium isobutoxide. During the reaction Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com