Dyeing process of cotton/aloe fiber blended yarns

A technology of aloe vera fiber and blended yarn, which is applied in the directions of dyeing method, fiber treatment, plant fiber, etc., can solve the problems of high dyeing temperature and color fixing temperature, difficult to blend yarn, long time used, etc. The effect of high /S value, lowering dyeing temperature and fixing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

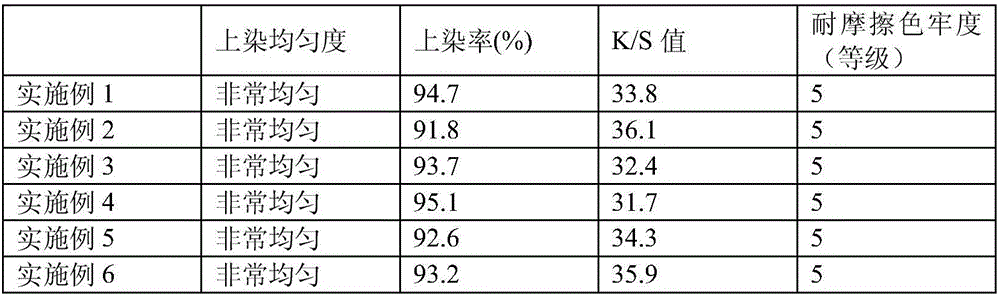

Examples

Embodiment 1

[0033] A kind of dyeing process of cotton / aloe fiber blended yarn, its step is as follows:

[0034] (1) Preprocessing:

[0035] Selected raw materials: 28tex, blended yarn with cotton / aloe fiber of 65 / 35;

[0036] Equipped with pretreatment solution: polyphenol oxidase 0.8g / L, phytase 0.8g / L, cellulase 1g / L, silk fibroin 2g / L, trimethylglycine 2.3g / L;

[0037] The enzyme activity of the polyphenol oxidase is 350u / g, and the enzyme activity of phytase and cellulase is 500u / g;

[0038] The processing parameters are: 5% (owf), time 35min, temperature 40°C;

[0039] (2) Dyeing treatment:

[0040] Rinse the pretreated cotton / aloe fiber blended yarn, dry it, and then use reactive dyes to dye the aloe fiber knitted fabric in one bath and one step by exhaust dyeing method. The specific dyeing process is: wetting, dyeing and soaping Dehydration drying:

[0041] Reactive Brilliant Red KD-8B 2%

[0042] Sodium carbonate 15g / L

[0043] Yuanmingfen 26g / L

[0044] Dyeing temperature...

Embodiment 2

[0048] A kind of dyeing process of cotton / aloe fiber blended yarn, its step is as follows:

[0049] (1) Preprocessing:

[0050] Selected raw materials: 28tex, blended yarn with cotton / aloe fiber of 65 / 35;

[0051] Equipped with pretreatment solution: polyphenol oxidase 1.1g / L, phytase 0.5g / L, cellulase 1g / L, silk fibroin 2g / L, trimethylglycine 2.8g / L;

[0052] The enzyme activity of the polyphenol oxidase is 350u / g, and the enzyme activity of phytase and cellulase is 500u / g;

[0053] The processing parameters are: 3% (owf), time 45min, temperature 35°C;

[0054] (2) Dyeing treatment:

[0055] Rinse the pretreated cotton / aloe fiber blended yarn, dry it, and then use reactive dyes to dye the aloe fiber knitted fabric in one bath and one step by exhaust dyeing method. The specific dyeing process is: wetting, dyeing and soaping Dehydration drying:

[0056] Reactive Brilliant Red KD-8B 2%

[0057] Sodium carbonate 15g / L

[0058] Yuanmingfen 26g / L

[0059] Dyeing temperature...

Embodiment 3

[0063] A kind of dyeing process of cotton / aloe fiber blended yarn, its step is as follows:

[0064] (1) Preprocessing:

[0065] Selected raw materials: 28tex, blended yarn with cotton / aloe fiber of 65 / 35;

[0066] Equipped with pretreatment solution: polyphenol oxidase 0.9g / L, phytase 0.7g / L, cellulase 1g / L, silk fibroin 2g / L, trimethylglycine 2.4g / L;

[0067] The enzyme activity of the polyphenol oxidase is 350u / g, and the enzyme activity of phytase and cellulase is 500u / g;

[0068] The processing parameters are: 4% (owf), time 36min, temperature 39°C;

[0069] (2) Dyeing treatment:

[0070] Rinse the pretreated cotton / aloe fiber blended yarn, dry it, and then use reactive dyes to dye the aloe fiber knitted fabric in one bath and one step by exhaust dyeing method. The specific dyeing process is: wetting, dyeing and soaping Dehydration drying:

[0071] Reactive Brilliant Red KD-8B 2%

[0072] Sodium carbonate 15g / L

[0073] Yuanmingfen 26g / L

[0074] Dyeing temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com