Stripping agent for cationic dye dyed acrylic fabric and stripping method

A cationic dye and color stripping agent technology, which is applied in the field of color stripping agent for acrylic dyed fabrics, can solve the problems of poor reproducibility, unclean color stripping, and not deep dyeing, etc., to reduce consumption, improve environmental protection, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1: 32s pure acrylic yellow 1*1 rib fabric

[0017] The color stripping agent used in this embodiment comprises the following components in important percentages: 40% sodium stearate, 5% sodium alkylsulfonate, 10% fatty alcohol polyoxyethylene ether, and the balance is water. After each component is weighed according to the above weight percentage, the stripping agent is prepared.

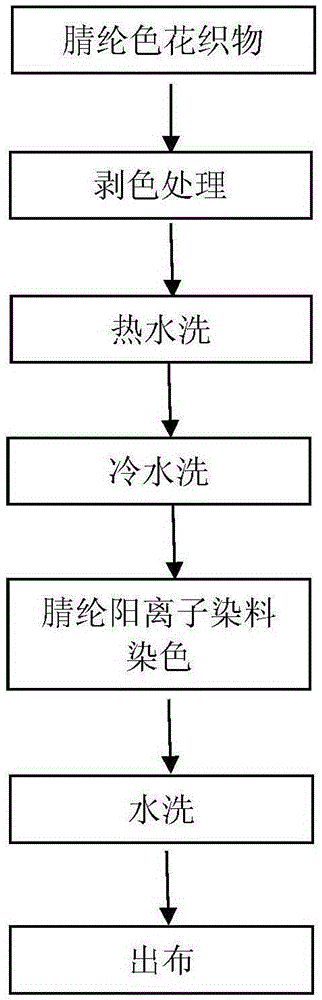

[0018] The stripping and re-staining process is as follows:

[0019] After dyeing with 0.3% Cationic Yellow X-8GL at 100°C and pH=4 for 40min, under the conditions of stripping agent 4g / L and bath ratio 1:20, the temperature was raised to 100°C at a rate of 2°C / min. ℃, stripping treatment for 20 minutes, draining, 60 ℃ hot water washing, cold water washing; then prepare 0.3% dye solution for counter-staining, 70 ℃ put dye, glacial acetic acid (adjust pH value = 4), at 1 ℃ / min Raise the temperature to 85°C at a rate of 10 minutes, heat it up to 95°C at a rate of 1°C / 2min, hold it for...

Embodiment 2

[0020] Example 2: 32s pure acrylic blue 1*1 rib fabric

[0021] The stripping agent used in this embodiment comprises the following components in important percentages: 45% sodium stearate, 10% sodium alkylsulfonate, 15% polyvinyl alcohol, and the balance is water. After each component is weighed according to the above weight percentage, the stripping agent is prepared.

[0022] The stripping and re-staining process is as follows:

[0023] After dyeing with 1.0% Cationic Blue X-GRRRL at 100°C and pH=4.5 for 50 minutes, under the conditions of stripping agent 6g / L and bath ratio 1:20, the temperature was raised to 100 at a rate of 2°C / min. ℃, stripping treatment for 25 minutes, draining, 60 ℃ hot water washing, cold water washing; then prepare 1.0% dye solution for counter-staining, 70 ℃ put dye, glacial acetic acid (adjust pH value = 4.5), at 1 ℃ / min Raise the temperature to 85°C at a rate of 10 minutes, heat it up to 95°C at a rate of 1°C / 2min, hold it at a temperature of 1...

Embodiment 3

[0024] Example 3: 32s pure acrylic black 1*1 rib fabric

[0025] The stripping agent used in this embodiment includes the following components in important percentages: 50% sodium stearate, 10% sodium lauryl sulfate, 15% fatty alcohol polyoxyethylene ether, and the balance is water. After each component is weighed according to the above weight percentage, the stripping agent is prepared.

[0026] The stripping and re-staining process is as follows:

[0027] After dyeing with 2% cationic black at 100°C and pH=5 for 60min, under the conditions of stripping agent 8g / L and bath ratio 1:20, raise the temperature to 100°C at a rate of 2°C / min, strip Color treatment for 30 minutes, draining, washing with hot water at 60°C, and washing with cold water; then prepare 2% dye solution for counterstaining, add dye and glacial acetic acid at 70°C (adjust pH = 5), and heat up at a rate of 1°C / min Heat to 85°C, keep warm for 10 minutes, heat up to 95°C at a rate of 1°C / 2min, hold for 10 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com