Method for preparing anti-wrinkle real silk fabric

A technology for silk fabrics and wrinkled silk is applied in the field of preparation of functional textiles, which can solve the problems affecting the consumption of silk fabrics, low elasticity of silk fibers, low elastic recovery rate, etc. /S value increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

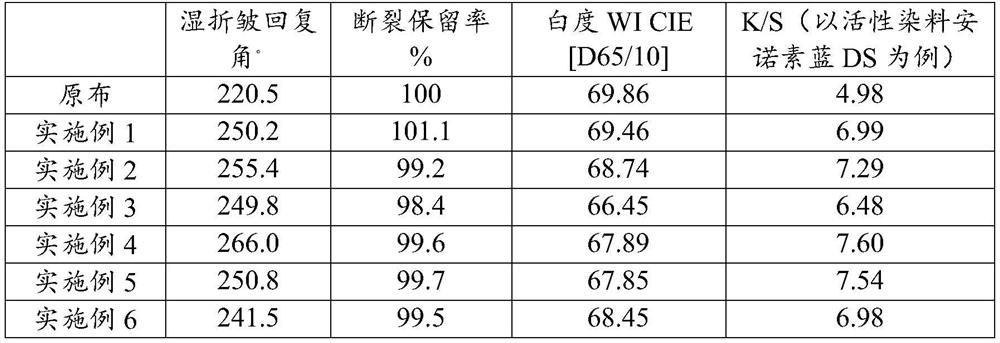

Examples

Embodiment 1

[0025] Step 1: Silk fabric pretreatment, experimental plan: silk fabric 10cm×10cm, 60°C, soap flakes 2g / L, NaHCO 3 5g / L, liquor ratio 1:50, boiled in water for 30min, and dried in vacuum at 60°C. Then use acetone, ethanol, and deionized water to wash with ultrasonic vibration, and ultrasonically wash each solution for 20 minutes. After washing, take out the cloth sample and dry it in vacuum at 60°C.

[0026] Step 2: Preparation of pyrimidine derivative dispersion emulsion method, experimental scheme: Add Span 20 (20% o.w.t) and Tween 80 (30% o.w.t) into 100 mL of water, and emulsify at a speed of 10000 rpm for 30 min. During this process, 10% (o.w.f) 2,4,6-trichloropyrimidine compound was slowly added to the solution. Water was then added to dilute the emulsion to obtain a 3 g / L solution. Finally, silicone defoamer, 2 g / L sodium sulfate (catalyst) and 6 g / L sodium bicarbonate were added to each diluent and stirred uniformly to prepare a uniform dispersion of the pyrimidine c...

Embodiment 2

[0029] Step 1: Silk fabric pretreatment, experimental plan: silk fabric 10cm×10cm, 60°C, soap flakes 2g / L, NaHCO 3 5g / L, liquor ratio 1:50, boiled in water for 30min, and dried in vacuum at 60°C. Then use acetone, ethanol, and deionized water to wash with ultrasonic vibration, and ultrasonically wash each solution for 20 minutes. After washing, take out the cloth sample and dry it in vacuum at 60°C.

[0030] Step 2: Preparation of pyrimidine derivative dispersion emulsion method, experimental scheme: Add Span 20 (20% o.w.t) and Tween 80 (30% o.w.t) into 100 mL of water, and emulsify at a speed of 10000 rpm for 30 min. During this process, 10% (o.w.f) 2,4,6-trichloropyrimidine compound was slowly added to the solution. Water was then added to dilute the emulsion to obtain a 3 g / L solution. Finally, silicone defoamer, 2 g / L sodium sulfate (catalyst) and 6 g / L sodium bicarbonate were added to each diluent and stirred uniformly to prepare a uniform dispersion of the pyrimidine c...

Embodiment 3

[0033] Step 1: Silk fabric pretreatment, experimental plan: silk fabric 10cm×10cm, 60°C, soap flakes 2g / L, NaHCO 3 5g / L, liquor ratio 1:50, boiled in water for 30min, and dried in vacuum at 60°C. Then use acetone, ethanol, and deionized water to wash with ultrasonic vibration, and ultrasonically wash each solution for 20 minutes. After washing, take out the cloth sample and dry it in vacuum at 60°C.

[0034] Step 2: Preparation of pyrimidine derivative dispersion emulsion method, experimental scheme: add Span 20 (20% o.w.t) and Tween 80 (30% o.w.t) into 100-150 mL of water, and emulsify at a speed of 10000 rpm for 30 minutes. During this process, 10% (o.w.f) 2,4,6-trichloropyrimidine was slowly added to the solution. Water was then added to dilute the emulsion to obtain a 3 g / L solution. Finally, silicone defoamer, 2 g / L sodium sulfate (catalyst) and 6 g / L sodium bicarbonate were added to each diluent and stirred uniformly to prepare a uniform dispersion of the pyrimidine co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com