Nano disperse black combined dye and preparation method thereof

A nano-dispersion and dye technology, applied in the direction of organic dyes, can solve the problems of not being able to meet the market demand, and achieve the effect of pure shade and good dyeing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

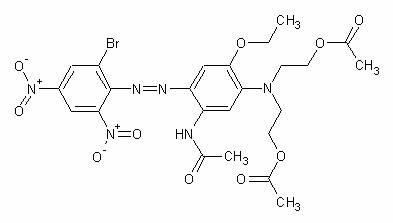

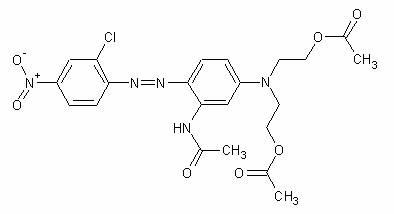

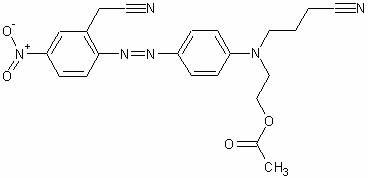

[0051] Add 37.5g of component A with structural formula (A-I), 10.5g of component B with structural formula (B-I), 2g of component C with structural formula (C-I), 90g of sodium lignosulfonate, and add water After mixing 260g, it was stirred to make a premixed solution, and then according to the preparation examples, a nano-dispersed black composite dye with excellent fastness and a particle size of 15nm-100nm was obtained.

Embodiment 2-16

[0053] According to the content ratio data of each component shown in Table 1, 50g of component A, component B, component C and 90g of additives were mixed with 260g of water and then stirred properly to make a premixed liquid, and then according to the preparation examples, the preparation A commercialized nano-disperse black combined dye with excellent fastness and a particle size of 15nm-100nm was obtained.

[0054] Table 1, each component composition of embodiment 2-16 combination dyestuff.

[0055]

[0056] .

Embodiment 17

[0058] 34g of component A with structural formula (A-I), 13g of component B with structural formula of (B-I), 3g of component C with structural formula of (C-I), 90g of sodium lignosulfonate and dispersant NNO The mixture was mixed with 260g of water and then stirred to make a premixed liquid. Then, according to the preparation examples, a nano-dispersed black combined dye with excellent fastness and a particle size of 15nm-100nm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com