Patents

Literature

190results about How to "Coloring firm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for uniform gradient-colour zirconium oxide porcelain blocks

ActiveCN104909745AContinuous uniform changeEasy to processImpression capsDentistry preparationsPolyethylene glycolMaterials science

The invention relates to zirconium oxide porcelain blocks for dental prosthesis, and aims at providing a preparation method for uniform gradient-colour zirconium oxide porcelain blocks. The preparation method comprises the following steps: (1) weighing the raw materials of CeO2, Fe2O3, ZrO2, Y2O3, Pr6O11 and Er2O3; (2) adding a polymer binder in the dried mixed powder, and granulating; (3) shaping the granulated material by a die by means of dry pressing to obtain porcelain block blanks; (4) carrying out isostatic cool pressing on the shaped porcelain block blanks; (5) pre-sintering the porcelain block blanks after the isostatic cool pressing; (6) flatly placing the pre-sintered porcelain block blanks in a dyeing container and dyeing, wherein the depth of soaking solution in the dyeing container is 0.1-5mm, the dyeing time is 1-3min, and the used dyeing solution comprises 1-5wt% of polyethylene glycol, 0.1-3wt% of erbium oxide, 0.5-10wt% of praseodymium oxide and the balance of ultrapure water; and (7) sintering the dyed porcelain blocks to obtain the uniform gradient-colour zirconium oxide porcelain blocks for dentistry. The porcelain blocks disclosed by the invention are stable and uniform in colouring, and continuous and uniform in colour changes.

Owner:CHENGDU BESMILE BIOTECH

Preparation method for smoky yellow crystal bead blanks

InactiveCN102503126AAchieve lead-freeHigh refractive indexGlass pressing apparatusPotassium carbonatePotassium permanganate

The invention discloses a preparation method for smoky yellow crystal bead blanks. The preparation method for smoky yellow crystal bead blanks aims to overcome shortcomings that existing preparation process for smoky yellow crystal bead blanks needs lead oxide as a raw material, coloring and optical properties of iron ions are poor, coloring property of manganese is unstable, and rhinestone bead blanks are poor in physical and chemical properties. Raw materials of the preparation method do not contain lead oxide, and the crystal bead blanks are good in physical and chemical properties, are proper in hardness and high in corrosion resistance. In the preparation method for the smoky yellow crystal bead blanks, raw materials of the smoky yellow crystal bead blanks include, by weight ratio, from 50 to 65 parts of quartz sand, from 2 to 20 parts of titanium dioxide, from 2 to 10 parts of sodium carbonate, from 7 to 20 parts of potassium carbonate, from 0.3 to 5 parts of potassium nitride, from 0.1 to 5 parts of cerium oxide, equal to or lower than 6 parts of boric acid, equal to or lower than 2 parts of aluminum hydroxide, equal to or lower than 8 parts of zinc oxide, equal to or lower than 10 parts of magnesium carbonate, equal to or lower than 15 parts of barium carbonate, equal to or lower than 2 parts of lithium carbonate, equal to or lower than 2 parts of potassium permanganate, equal to or lower than 4 parts of sodium nitrate and equal to or lower than 3 parts of iron oxide red.

Owner:ZHEJIANG WEIXING CRYSTAL

Method for preparing superconcentrate glass pigment and color crystal glass plate

The invention discloses a method for preparing a superconcentrate glass pigment and a color crystal glass plate. The glass pigment comprises the following raw materials of SiO2, Na2O, CaO, Al2O3, B2O3 and one of the color mixing raw materials of CoO, Cr2O3, CuO, MnO2, Se, CdS, TiO2 and CeO2 or mixture of two of the color mixing raw materials, wherein the adding proportion of the color mixing raw material accounts for 0.2-10% of the total weight percentage of the pigment raw material, and the adding amount of the color mixing raw material is 5-30 times more than the conventional adding amount. The melting point of the superconcentrate glass pigment is low, the coloring is carried out at moderate temperature, and the coloring process is easy to control and is stable. The invention has the advantages of simple method, convenient operation and convenient coloring, decreases the defective rate of colored product, and reduces the production cost. The prepared color crystal glass sheet has stable color and high transparency.

Owner:ANHUI SHENGSHI OPTICAL GLASS

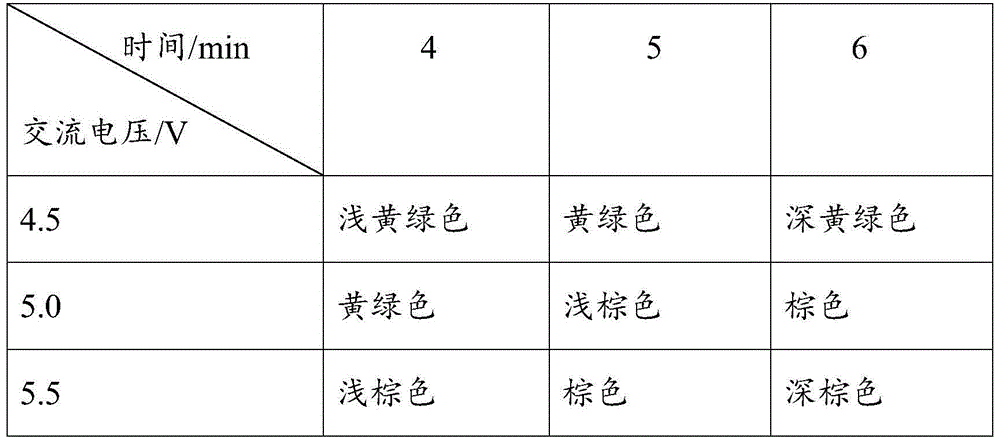

Coloring method adopting aluminium alloy alternate current electrolysis for precipitating silver and copper

The invention provides a coloring method adopting aluminium alloy alternate current electrolysis for precipitating silver and copper. The coloring method comprises the following steps: after pretreatment such as degreasing and oxidation film removing, an aluminium alloy piece is subjected to direct current electrolysis in the sulfuric acid medium to obtain the aluminium alloy piece provided with a porous oxide-film; then, the aluminium alloy piece provided with the porous oxide-film is subjected to alternate current electrolysis; a coloring liquid comprises 15-20 g / L of H2SO4, 4-7 g / L of AgNO3, 1.5-2.5 g / L of CuSO4.5H2O, 18-25 g / L of MgSO4.7H2O, 2-7 g / L of a complexing agent A or 5-10 g / L of a complexing agent B; the technological conditions of the coloring liquid are as follows: the temperature is 5-35 DEG C, the time is 3-7 min and the voltage is 4-7 V; lastly, the alternate current electrolyzed porous oxide-film aluminium alloy piece is subjected to hot water sealing treatment to obtain aluminium alloy materials. According to the coloring method, the technology is simple, the coloring is uniform and stable, the decay resistance of the aluminium alloy is improved, the antibacterial and sterilizing rate of the aluminium alloy reaches 99.0%, the duration of antibacterial and bactericidal action is long and the coloring treatment cost is low; no insoluble deposition is precipitated in the coloring liquid for long-term use and the coloring liquid is stable.

Owner:SHISHI XINGHUO ALUMINUM PROD CO LTD +1

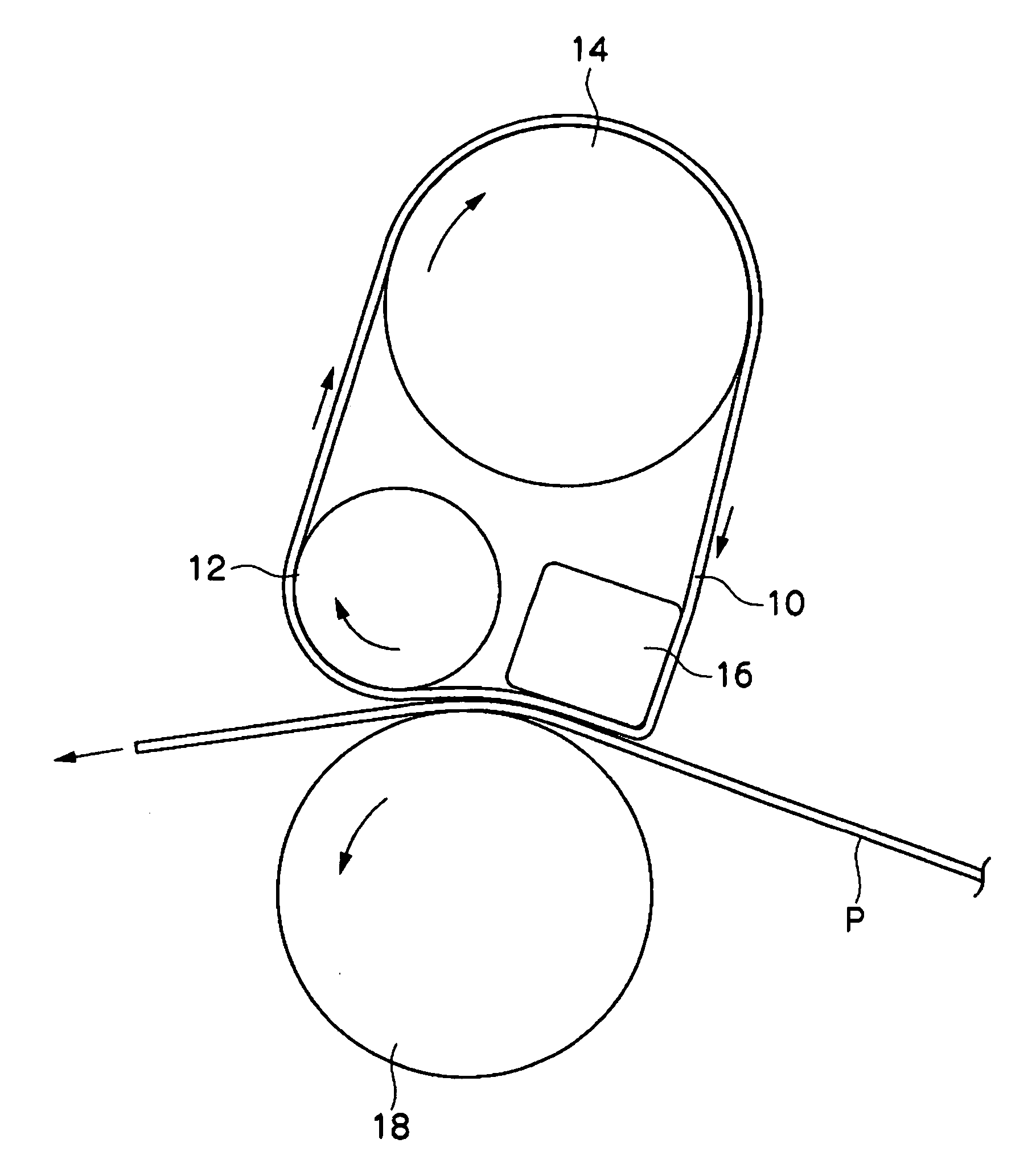

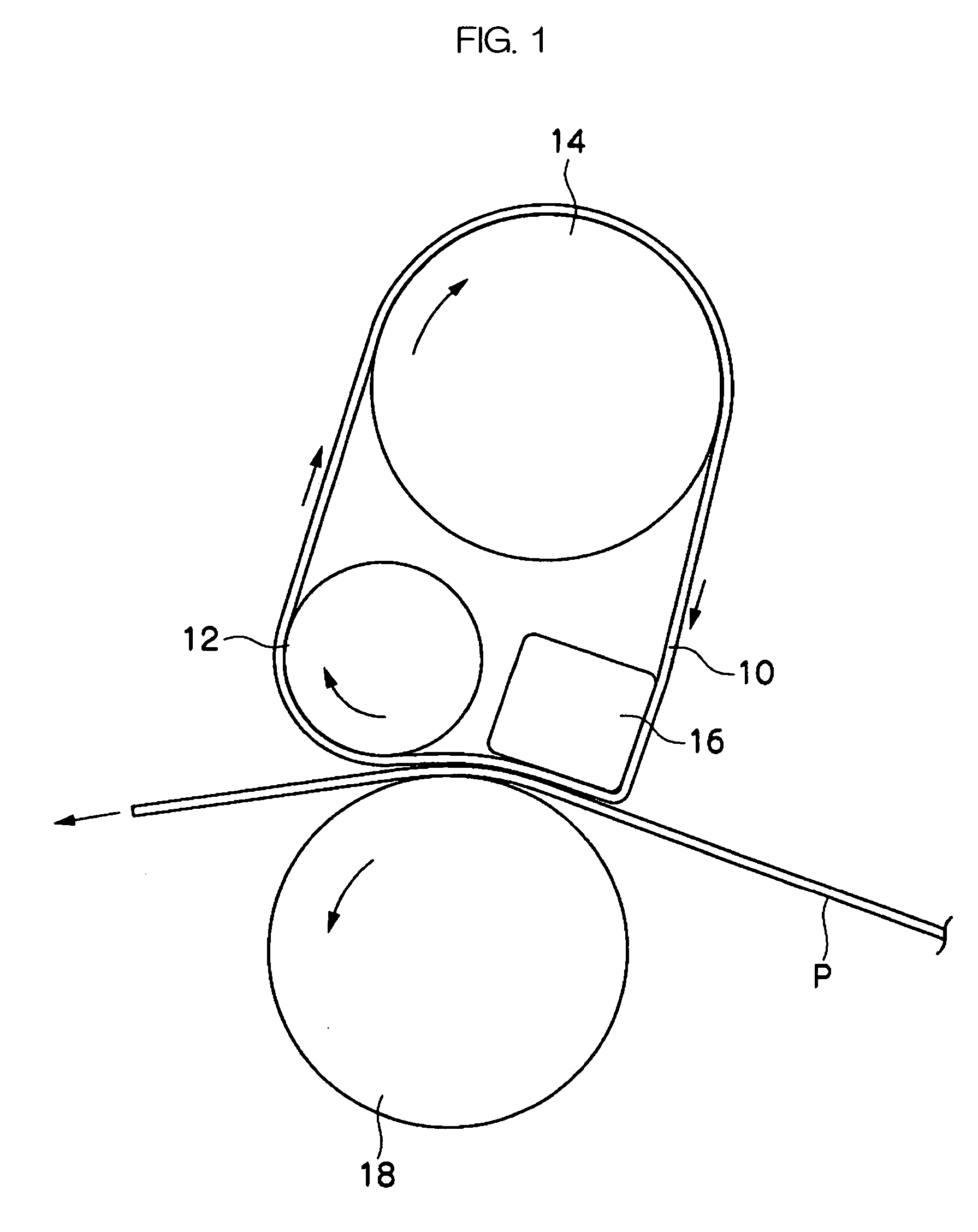

Color image forming method and color toner forming method

ActiveUS20060275679A1High glossStable high glossinessDevelopersElectrographic process apparatusColor imageDynamic viscoelasticity

The invention provides a color image forming method including charging, developing, transferring and fixing. The fixing includes thermally fixing a toner image to paper by using a heating body and a pressurizing member which is positioned opposite to the heating body via a film-like member. The color toner includes a toner particle containing a crystalline resin and a non-crystalline resin. When the color toner is subjected to dynamic viscoelasticity measurement employing a sine wave vibration method, a minimum value of the relaxation elasticity H in a relaxation spectrum obtained from frequency dispersion characteristics when a measurement frequency measured at 60 and 80° C. is 0.1 to 100 rad / sec and a measurement strain at a frequency of 6.28 rad / sec is 0.1 %, is in a range of about 10 to 900 Pa / cm2. A relaxation time λ corresponding to the minimum value is in a range of about 1 to 10,000 sec.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Anti-yellowing polychloroethylene

The invention relates to anti-yellowing PVC which belongs to the technical field of organic polymer compounds. The invention comprises the following components (weight percent): 41 to 50 percent of PVC, 24 to 30 percent of plasticizer, 1 to 3 percent of stabilizer, 0.1 to 0.2 percent of antioxidant, 1 to 4 percent of UV absorbent, 0.1 to 1 percent of lubricant, 0.03 to 0.1 percent of pigment, and 15 to 20 percent of filler. The invention can cause the PVC to achieve better anti-yellowing property, and the finished goods are white and have good weather and transfer resistance effects.

Owner:TAIZHOU FENGYUAN SANITARY CO LTD

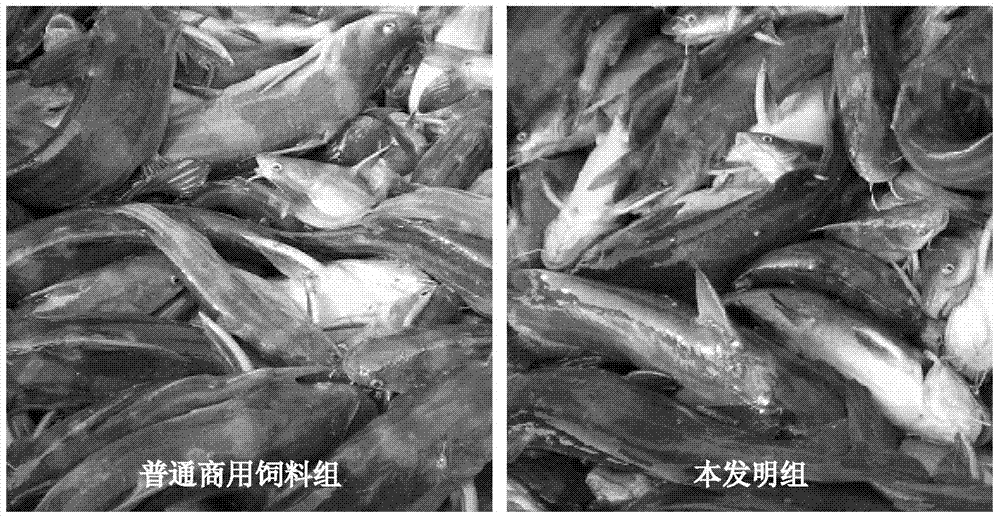

Feed with low fish meal content and application thereof

ActiveCN104286429AStable sourceDecreased feeding rateFood processingClimate change adaptationAnimal sciencePeanut meal

The invention discloses a feed with low fish meal content. The feed comprises the following components in parts by weight: 5-8 parts of import fish meal, 10-12 parts of chicken meal, 4-6 parts of meat and bone meal, 1-2 parts of spray drying blood powder, 4-6 parts of concentrated soybean protein, 8-12 parts of corn protein powder, 15-18 parts of peel-removing soybean meal, 7-10 parts of peanut meal, 2-3 parts of euphausia superba powder, 3-4 parts of Saccharomyces cerevisiae powder, 0.30-0.40 part of yeast extract, 0.20-0.30 part of mannan oligosaccharide, 0.01-0.02 part of Eucommia ulmoides leaf extract and 0.10-0.12 part of natural xanthophyll. The invention further discloses the application of the feed with low fish meal content. The feed with low fish meal content keeps the original effect in terms of growth performance and body color.

Owner:ZHUHAI RONGCHUAN FEED

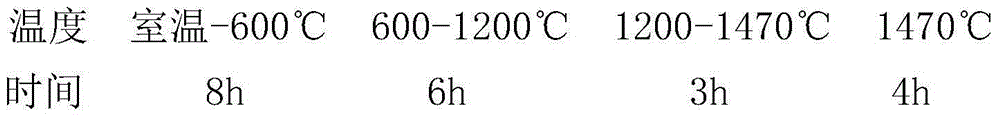

Preparation method of pink zirconia ceramic

The invention relates to a preparation method of pink zirconia ceramic. The preparation method comprises the following steps: with zirconia powder as a raw material of a ceramic matrix, adding erbium oxide powder to the zirconia powder to be used as a colorant and adding a binder to form a mixed material; preparing a ceramic body by using the mixed material; and carrying out multi-stage sintering treatment on the ceramic body to obtain a pink zirconia ceramic product, wherein the multi-stage sintering treatment at least comprises the following stages: firstly sintering for 7-9h at the temperature of room temperature to 600 DEG C, then sintering for 4-8h at the temperature of 600 DEG C-1200 DEG C, and then sintering for 6-8h at the temperature of 1200 DEG C-1500 DEG C. By utilizing the preparation method of the pink zirconia ceramic, zirconia can be stably colored to pink by pigment on premise of ensuring complete compactness of sintering of zirconia, and low manufacturing cost is maintained simultaneously.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

Inorganic colorful electrolysis coloring technology for aluminium profile anodic oxide film

ActiveCN102330137ASimple processEasy to achieve mass productionSurface reaction electrolytic coatingElectricityElectrolysis

The invention discloses an inorganic colorful electrolysis coloring technology for an aluminium profile anodic oxide film, which is characterized by comprising the following working procedures of: removing oil, etching by alkaline, oxidizing an anode, carrying out intermediate treatment and electrolysis coloring, and sealing holes, wherein the intermediate treatment working procedure is set between the working procedures of oxidizing an anode and electrolysis coloring and comprises three steps: a. DC (Direct Current) section: setting a supply voltage into a direct-current output mode, cleaning the micropores of the anodic oxide film, and reducing the thickness of a barrier layer, wherein a voltage value is 8-14V, and time is 20-50 seconds; b. AC (Alternating Current) section: setting the supply voltage into an alternating-current output mode, and generating a second layer of oxide film in the anodic oxide film; c. DC section: switching the supply voltage to the direct-current output mode, generating a third layer of film on the basis of the second layer of oxide film, wherein the voltage value is 10-20V, and operation time is controlled to 60-500s. According to the inorganic colorful electrolysis coloring technology, the existing electrolysis coloring equipment can be utilized to finish the full-color colorful electrolysis coloring aluminium or aluminium alloy in short time, and the inorganic colorful electrolysis coloring technology has the advantages of low production cost and good coloring quality.

Owner:GUANGYA ALUMINUM +1

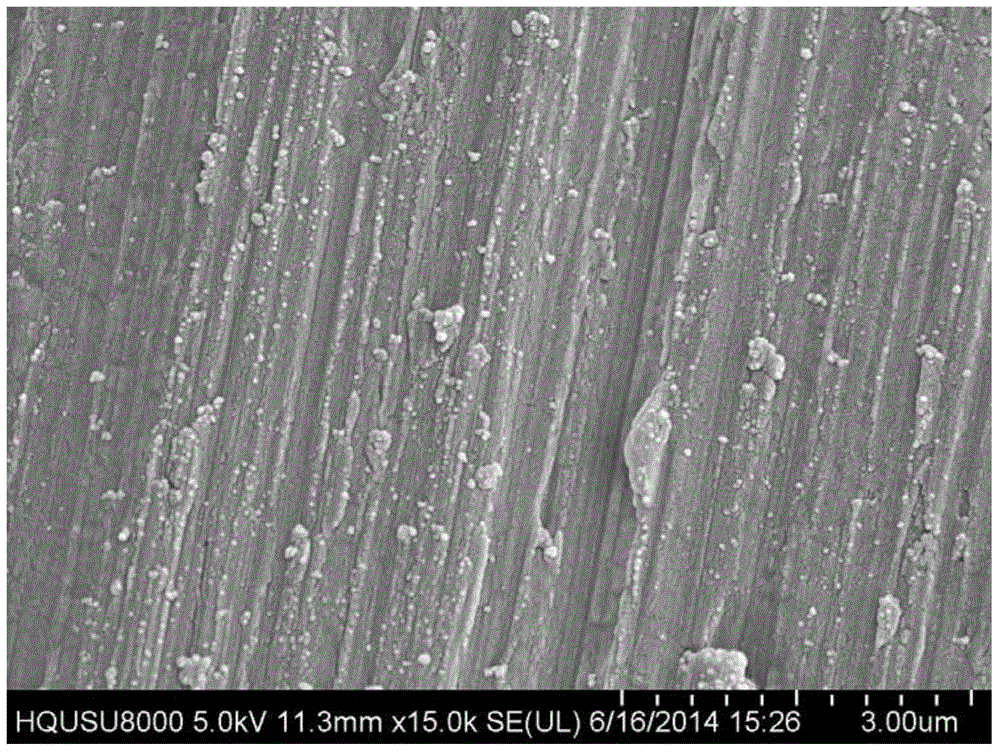

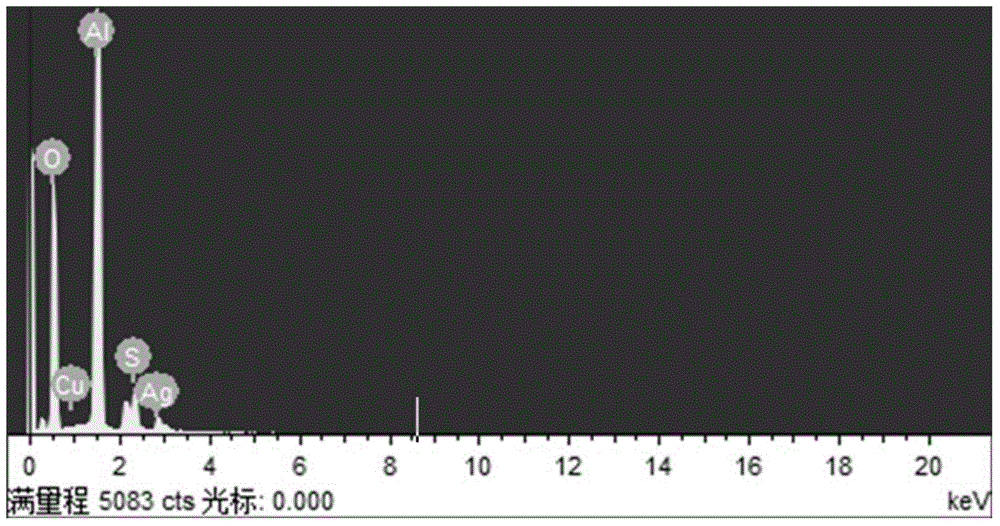

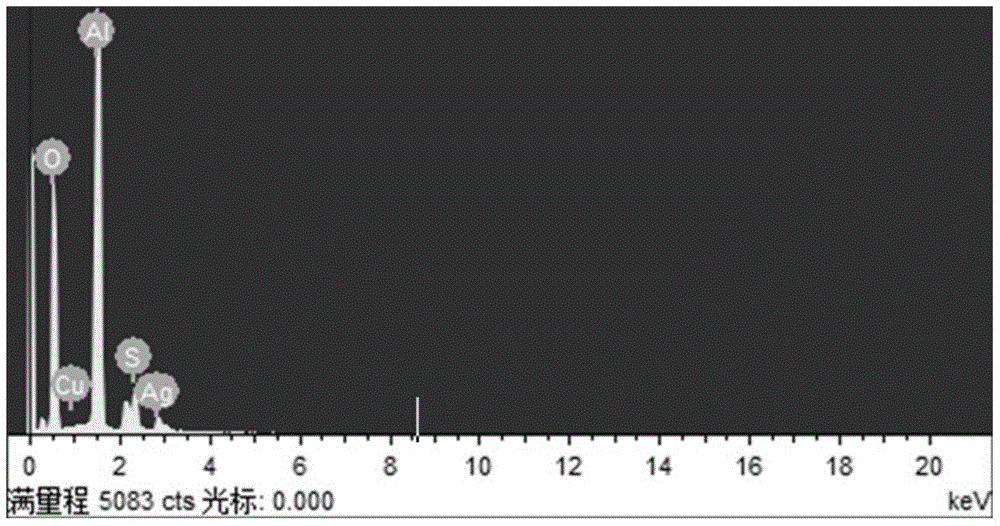

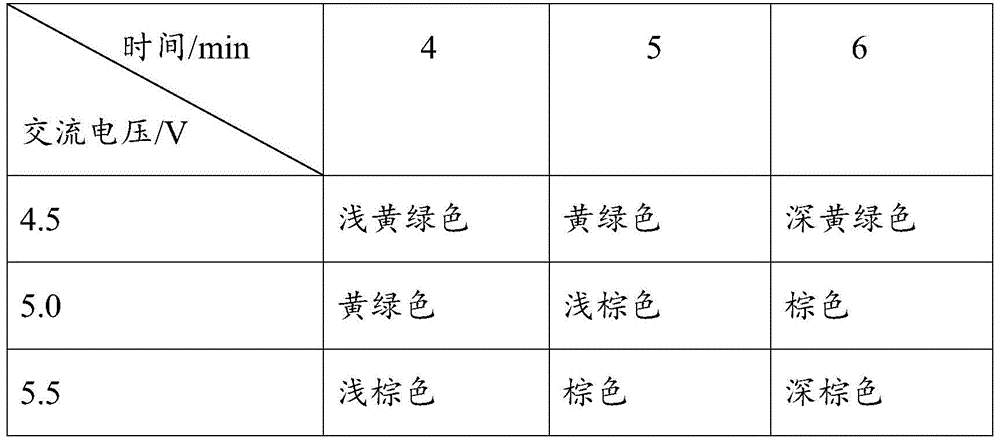

A kind of coloring method of aluminum alloy AC electrolytic deposition of silver and copper

The invention provides a method for coloring aluminum alloys by AC electrolytic deposition of silver and copper. The steps are as follows: the aluminum alloy parts after pretreatment such as degreasing and oxide film removal are subjected to direct current electrolysis in a sulfuric acid medium to obtain aluminum alloy parts with porous oxide films; The aluminum alloy parts with porous oxide film are subjected to alternating current electrolysis, and the coloring solution composition and process conditions are as follows: H 2 SO 4 15~20g / L, AgNO 3 4~7g / L, CuSO 4 ·5H 2 O 1.5~2.5g / L, MgSO 4 ·7H 2 O 18~25g / L, complexing agent A 2~7g / L or complexing agent B 5~10g / L; temperature 5~35℃, time 3~7min, voltage 4~7V; finally hot water sealing treatment to obtain aluminum alloy. The invention has simple process, not only uniform and stable coloring, but also improves the corrosion resistance of the aluminum alloy, and the antibacterial and sterilizing rate of the aluminum alloy reaches 99.0%, and the antibacterial and sterilizing effect lasts for a long time, and the coloring treatment cost is low. The coloring solution is very stable without insoluble precipitation after long-term use.

Owner:SHISHI XINGHUO ALUMINUM PROD CO LTD +1

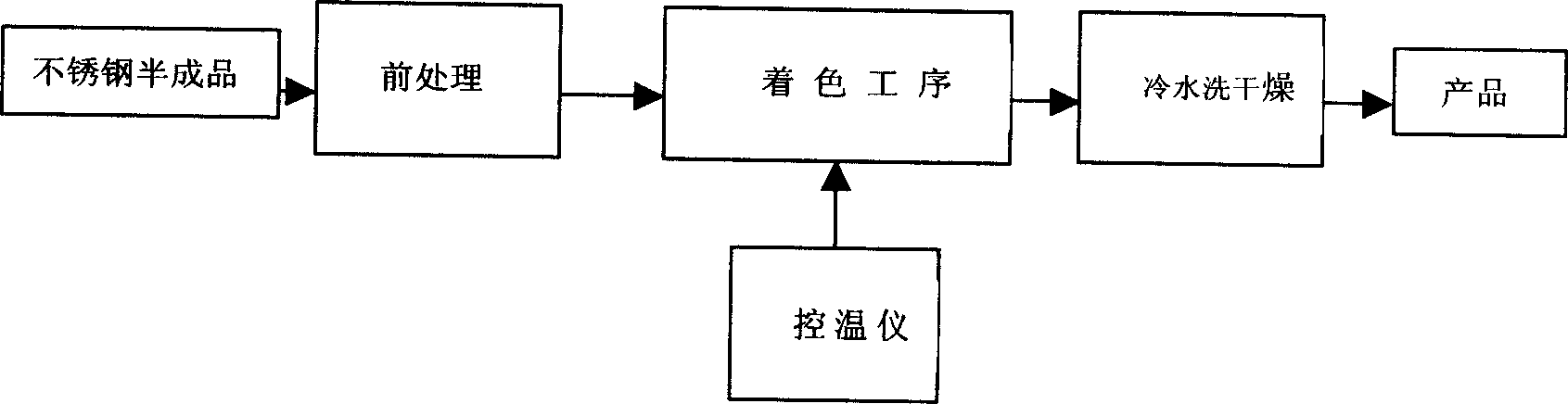

Stainless steel galvano-chemistry bepainting technique

The invention provides a stainless steel electrochemical coloring process, which adopts anodic electrolytic coloring for stainless steel workpieces at a relatively low concentration of coloring solution. The coloring solution used is mainly water as a solvent, and each liter of the solution includes: 30-100g of molybdate, 10-18g of boric acid, and 0.5-5g of manganese sulfate; and the basic process of the process is: first, the stainless steel workpiece Carry out pretreatment, and then immerse the stainless steel workpiece in the electrolytic cell filled with the above-mentioned coloring solution for coloring treatment. At the same time, pay attention to controlling the coloring current and coloring time. After the coloring is completed, wash and dry. The stainless steel electrochemical coloring process provided by the invention has simple required equipment and operation, does not contain toxic substances, is beneficial to environmental protection, and has stable coloring. High-quality stainless steel products can be produced through the process.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

Method for synthesizing high molecular retanning dyeing auxiliary agents through enzyme catalysis

InactiveCN101870990AImprove permeabilityImprove absorption rateTanning treatmentDyeing processSodium bicarbonateDye absorption

The invention relates to a method for synthesizing high molecular retanning dyeing auxiliary agents through enzyme catalysis, which comprises the following steps: dissolving p-aminobenzene sulfonic acid and 2, 3-dihydroxy naphthalene-6-sodium sulfonate into de-ionized water, using a sodium bicarbonate solution for regulating the pH value of the system, and finally, obtaining the retanning dyeing auxiliary agents through co-polymerization reaction carried out under the horse radish peroxidase (HRP) catalysis. The invention uses HRP as catalysts of the polymerization reaction, and the HRP has the advantages of high efficiency, high selectivity and environment protection when being used for catalyzing the polymerization. The invention has the advantages that phenols or arylamines can carry out polymerization in ortho positions or para positions of hydroxide groups and amino groups for forming a polymer with directly connected C-C structures and large pi conjugated systems, the formaldehyde pollution in the traditional synthesized retanning agents is avoided, and at the same time, the products with the conjugated systems contain a large number of auxochromic groups such as -NH2, -OH and -SO3H and the like. Retanning leather is full and soft, and the dye absorption rate is higher than 99 percent, and in addition, the retanning dyeing auxiliary agents have obvious dyeing aid effect.

Owner:SHAANXI UNIV OF SCI & TECH

ABS color master batch and preparation process thereof

The present invention discloses an ABS color master batch and a preparation process thereof. The ABS color master batch is prepared by adopting a carrier, a dispersing agent, toner, a polymer compatibilizing agent, an impact modifier, a heat stabilizer, a plastic additive and a filler as raw materials, wherein an air drying treatment is performed on the carrier, premixing is performed on the carrier resin, the toner and the dispersing agent, extrusion granulation is performed, sample plate and sample strip injection molding is performed, and finally a color performance, a tension performance and an impact performance are tested. According to the ABS master batch, characteristics of convenient use, no pollution on molded environment, high impact resistance, and uniform and stable coloring are provided; the resin carrier is subjected to the reasonable drying treatment so as to solve problems of easy flow mark production and non-uniform coloring of the traditional ABS master batch coloring; the pigment is added with the inorganic nanometer filler so as to improve dispersity of the pigment in the plastic product, coloring power of the pigment and covering power of the film product; and the production cost can be reduced, and the preparation method is simple, and is suitable for promotional use.

Owner:胡君

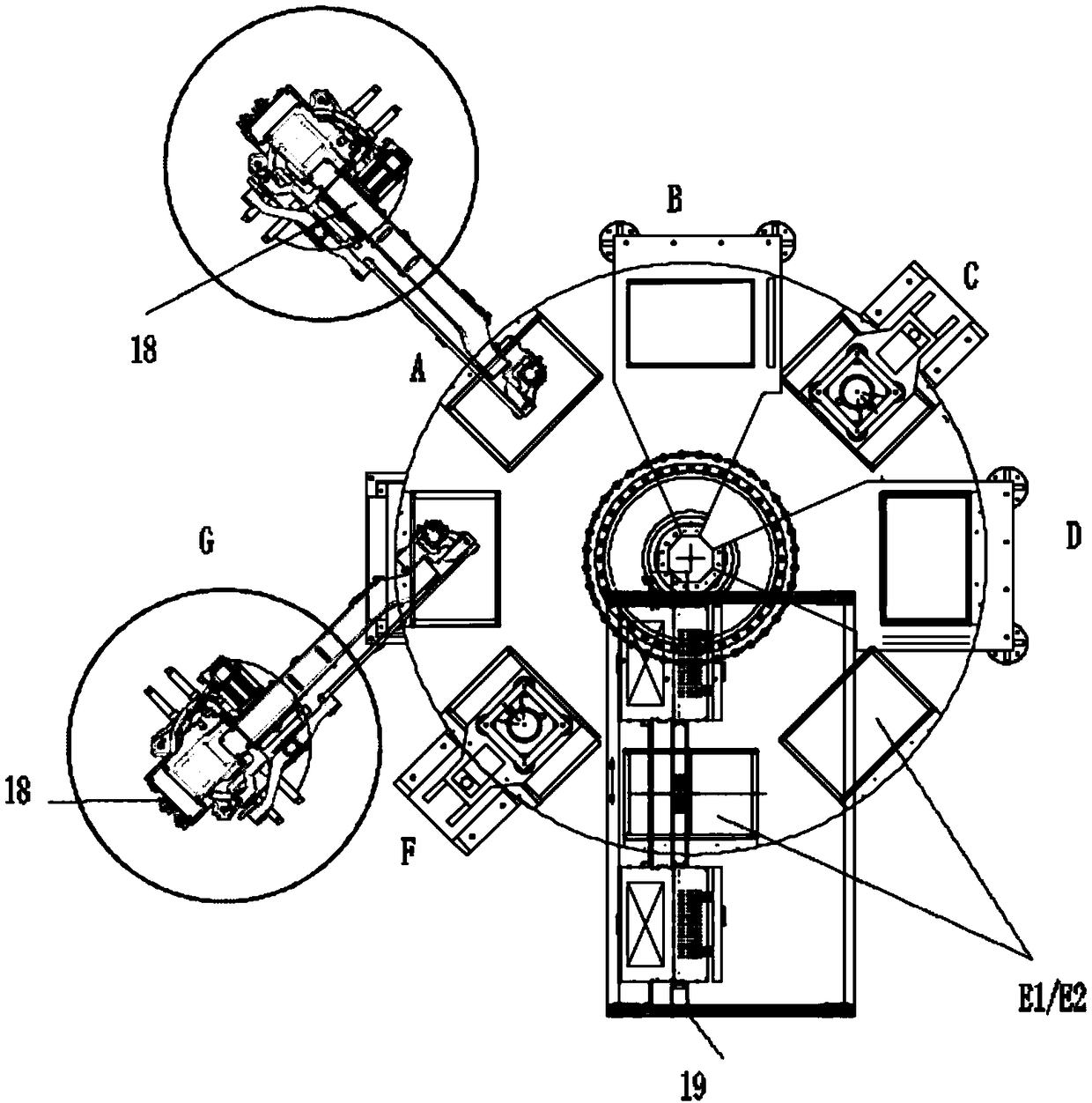

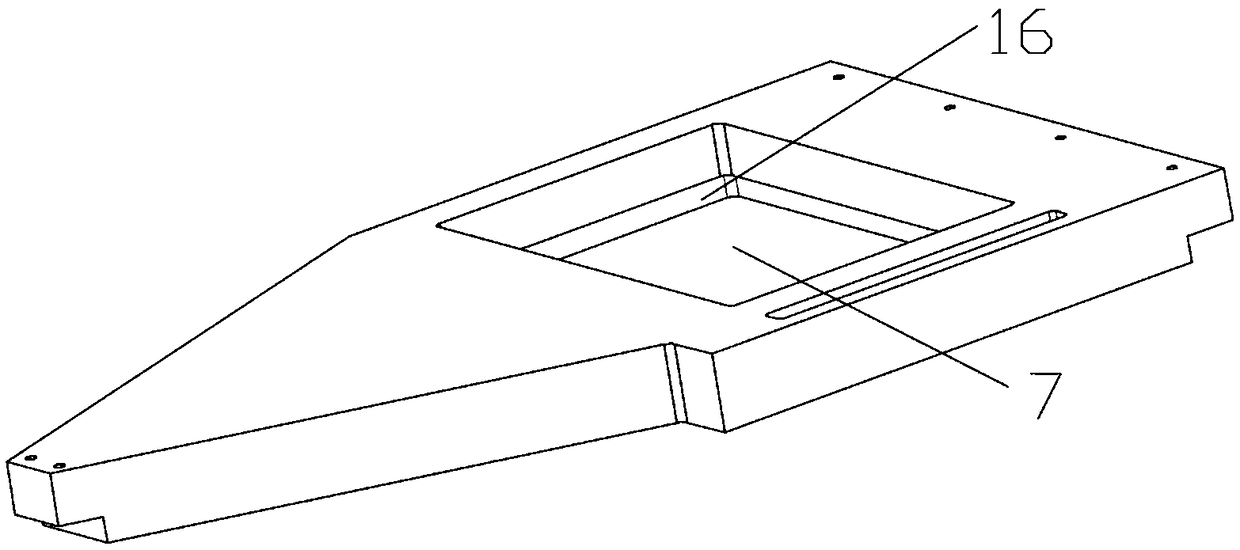

Production technology of lightweight heat-preserving artificial stone and multi-station turntable type production device

InactiveCN109333750AFully automatedReasonable structure layoutDischarging arrangementFeeding arrangmentsColor textureArtificial stone

The invention provides a processing technology of a lightweight heat-preserving artificial stone. The lightweight heat-preserving artificial stone comprises a heat preserving layer and a surface decorating surface, wherein the surface decorating layer is formed by digitally coloring; a digital coloring production technology is carried out to color textures and reaches a 3D effect; powder is digitally colored, thus a stone board can be stably colored without being roasted in later processes, and the thickness of the stone board is decreased. Therefore, the lightweight stone with the heat preserving function can be obtained. The invention also aims at providing a multi-station turntable type production device. The device comprises a turntable assembly, a material distributing assembly, a pressing assembly, a discharging assembly, a digital coloring assembly and a manipulator assembly. The stone texture of the surface decorating layer subjected to the processing technology for digitally coloring the lightweight heat-preserving artificial stone and pressing molding is high in simulation degree, good in texture effect and stable to color.

Owner:湖南斯多孚节能科技有限公司

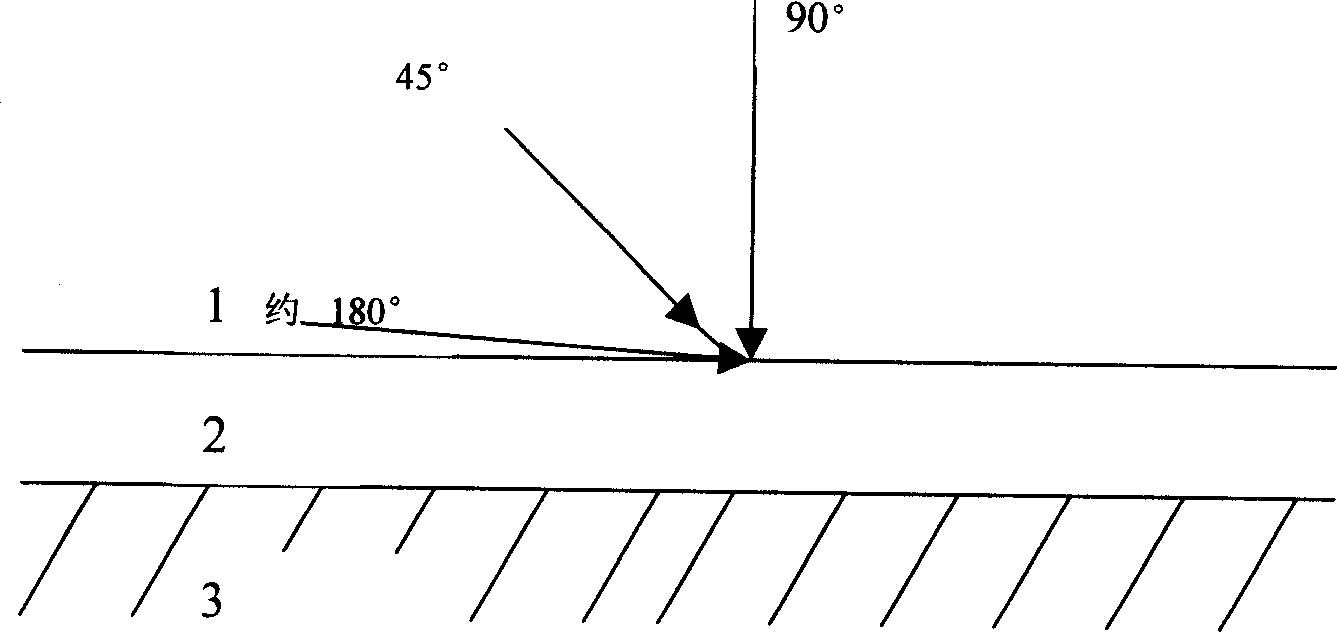

Processing method of surface-engraved multicolor aluminum profile

InactiveCN102358099AEnhance the three-dimensional senseColoring firmDecorative surface effectsMetallurgyMetal

The invention discloses a processing method of a surface-engraved multicolor aluminum profile, which can be used for engraving convex and concave floral designs on the surface of the aluminum profile and applying multiple colors of paint so as to achieve the advantages of strong third dimension and good decoration effect. The processing method comprises the following steps of: 1, engraving the surface of the aluminum profile; 2, primarily coloring; and 3, secondarily coloring comprising the procedures of (1), scribing engraving patterns on scribing paper, (2), adhering the scribing paper, (3), blending metal patient, (4), spraying the patient,(5), complementing color, and (6), washing.

Owner:张萌

Method for coloring surface of bamboo strip

InactiveCN101462291APromote safe productionEasy to produceWood treatment detailsVeneer manufactureSulfateEngineering

The invention discloses a bamboo strip surface coloration method, which is performed according to the steps of: production of bamboo strips, in which a bamboo material is cut into sections and hacked, and is scraped with bamboo green skin and bamboo yellow liner to be processed into the bamboo strips; cooking, in which dirt on the surfaces of the bamboo strips is removed, the bamboo strips are cooked in boiled water, and grease, sugar and bamboo pulp of the bamboo strips are removed; drying treatment, in which the bamboo strips are taken out and then are baked until the water content is between 8 and 12 percent; coloration, in which the bamboo strips are soaked into a boiled coloring liquid for 60 to 220 minutes, and the coloring liquid comprises the following components (according to weight percentage): 2 to 7 percent of ferrous sulfate, 0.1 to 0.25 percent of direct black, and the balance being water; and drying treatment, in which the bamboo strips are taken out and then are baked until the water content is between 8 and 12 percent. The method has the advantages of safe and simple production process, low production cost, and firm coloration.

Owner:朱文启

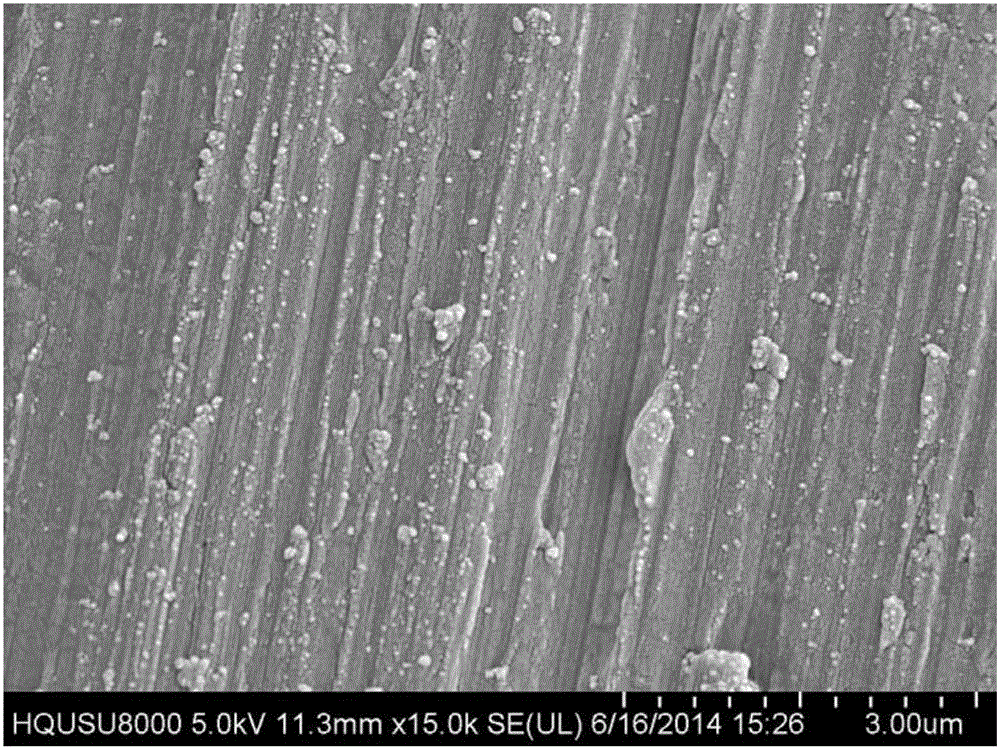

Zirconium oxide soaking coloration dyeing technique

The invention relates to dyeing of zirconium oxide, and particularly discloses a zirconium oxide soaking coloration dyeing technique. The technique comprises the following steps: presintering zirconium oxide; pulverizing the presintered zirconium oxide, and milling in a ball mill; soaking the zirconium oxide in a dyeing solution; drying with an ultraviolet lamp; and sintering at high temperature. The zirconium oxide dyeing technique has the advantages of short soaking dyeing time and higher production efficiency, can obtain the zirconium oxide with the color close to the teeth, and is suitable for industrial production.

Owner:珠海新茂义齿科技有限公司

Enteric coated type thin membrane coated premixed agent and preparation method thereof

InactiveCN1628641AHigh glossGood lookingPharmaceutical non-active ingredientsDrageesAcrylic resinThin membrane

Disclosed is an enteric coated type thin membrane coated premixed agent and preparation method, which comprises intestine dissoluble cellulose derivative, intestine dissoluble acrylic resin derivative, polyethylene glycol 6000. The intestine soluble type thin film coated premix has advantages of low cost, simple process for manufacturing, thus fitting for mass production.

Owner:成都市泰山药业有限公司

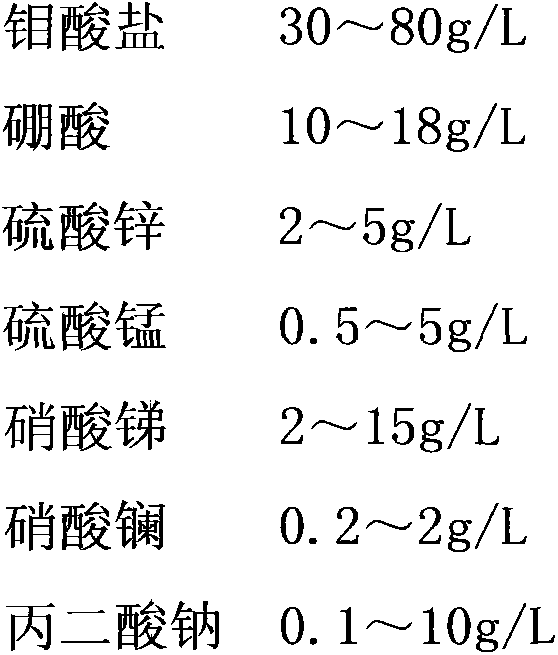

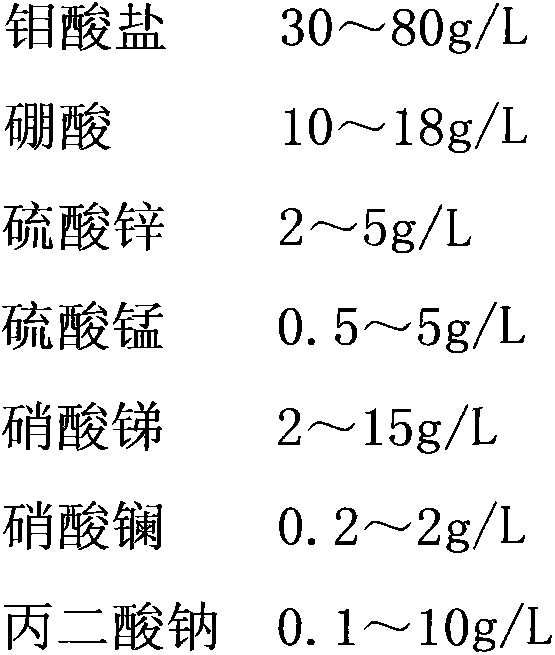

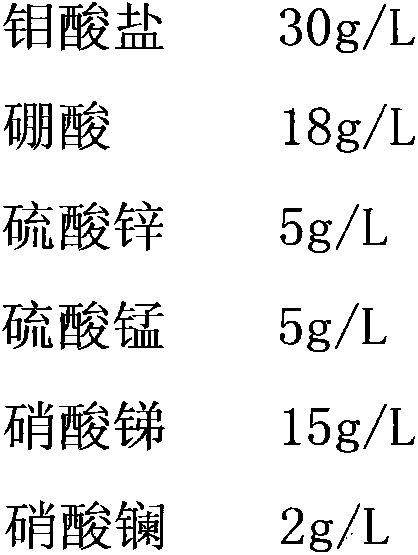

Colouring solution used for stainless steel electrochemical colouring and stainless steel electrochemical colouring method

ActiveCN103114320AChange the polarization processImprove performanceAnodisationToxic materialMalonate

The invention relates to a stainless steel surface treatment reagent, in particular to a stainless steel surface colouring method. According to the invention, with water as a solvent, each litre of solution contains 30-80g of molybdate, 10-18g of boric acid, 2-5g of zinc sulphate, 0.5-5g of manganese sulphate, 2-15g of antimony nitrite, 0.2-2g of lanthanum nitrite and 0.1-10g of sodium malonate. The stainless steel surface colouring method comprises the following basic flow: oil removing, electrolytic polishing, cleaning, colouring, cleaning and drying and obtaining the finished product, wherein an anode is a workpiece to be coloured, a cathode is a lead plate, a colouring current is controlled to be 0.1-5A / dm<2>, voltage is 1.5-2.5V, a colouring temperature is room temperature, colouring time is 0.1-30 minutes, cleaning and drying are carried out after colouring, and the surface of the obtained sample is uniform and bright. The stainless steel electrochemical colouring process provided by the invention needs simple equipment, is easy to operate, contains no toxic substance and is beneficial to environmental protection; and colouring is stable, and a high-quality colour stainless steel product can be produced by adopting the stainless steel electrochemical colouring process.

Owner:湖南中皖骏环保科技有限公司

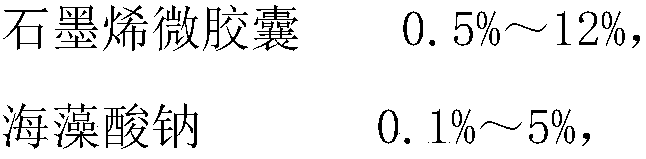

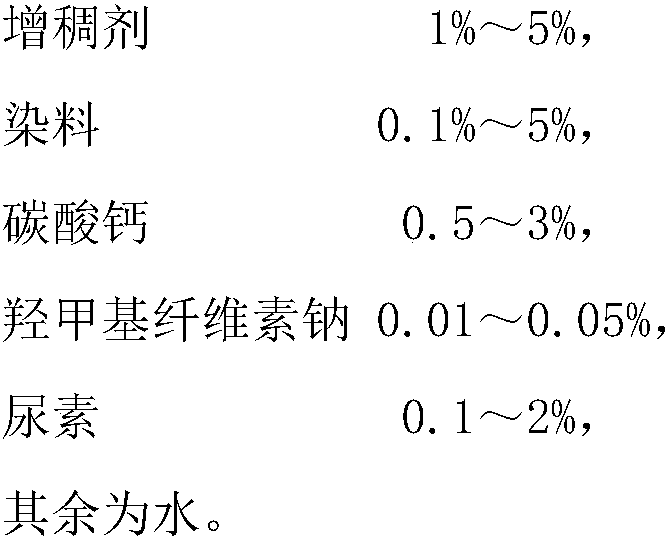

Graphene printing paste and preparation method thereof

InactiveCN108797152AImprove antibacterial propertiesExcellent far infrared heatingDyeing processGrapheneHydroxymethyl cellulose

The invention provides a graphene printing paste and a preparation method thereof. The graphene printing paste is prepared from the following components in percentage by mass: 0.5% to 12% of graphenemicrocapsule, 0.1% to 5% of sodium alginate, 1% to 5% of thickener, 0.1% to 5% of dye, 0.5% to 3% of calcium carbonate, 0.01 to 0.05% of sodium hydroxymethyl cellulose, 0.1 to 0.5% of urea, and the balance of water. The graphene printing paste has the advantages that by adding the graphene microcapsule into the printing paste, and optimally proportioning with other components, the printing fabricwith exquisite patterns can be produced by the traditional printing technology; the obtained printed fabric has good permeability and firm coloring property, and the water fastness can reach grade 4 or above; the antibacterial property, anti-ultrasonic property and the like are excellent, the number of bacteria on clothes is greatly reduced, the anti-ultraviolet property of the fabric is improved,and the health of a human body is protected.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

Stainless steel electrochemical colouring method

This invention is a kind of electro-chemstry staining method of non-corrosive steel. Firstly, pre-treatment for the semi-manufactured non-corrosive steel is essential. Molybdate water solution of 5.0-200 g / L is filled in the electrolytic bath as staining solution, and then the semi-manufactured non-corrosive steel is put into the solution to be stained. The staining electricity should be controlled between 0.02A / square decimeter and 0.6A / square decimeter, while the staining time is between 10 seconds and 60 minutes. At the same time, the temperature should be controlled between 15deg.C and 60 deg.C. After stained, the semi-manufactured non-corrosive steel is water-scrubbed. Then through desiccation, we can get stained non-corrosive steel. To sum up, the staining solution in this invention has no toxicity, has little pollution and power cost, so it does no harm to the workers' health. The technology is easy, and the stained color is stable and has high authenticity. What's more, the cost of the solution is low. You can get multi-colored, homogeneous and highly brightened product.

Owner:SOUTH CHINA UNIV OF TECH

Stably-colored silicon dioxide particles and preparation method thereof

ActiveCN107739035AEasy to prepareProcess stabilityInorganic/elemental detergent compounding agentsCosmetic preparationsSilicon dioxideSilicone oil

The invention belongs to the technical field of silicon dioxide, and particularly relates to stably-colored silicon dioxide particles and a preparation method thereof. The preparation method comprisesthe following steps: injecting sulfuric acid into a reaction kettle, then adding hydroxyl silicone oil, stirring and activating; adding water glass into the reaction kettle for reaction, adding pigments when the pH of a system is 3-4, stopping addition of the water glass when the pH of the system is 6-7, and continuing stirring until the material system is converted into gel; performing pressurefiltration on the formed silicon dioxide gel, washing, drying and crushing to obtain silicon dioxide particles; adding the silicon dioxide particles into the reaction kettle, adding allyl alcohol polyoxyalkyl ether and chloroplatinic acid-isopropanol, heating for reaction, separating solid particles from a solution after the reaction to obtain colored silicon dioxide particles. The preparation method is simple, and stable in technology; by the preparation method, various types of pigments can be effectively enwrapped, and the prepared colored silicon dioxide particles are very stably colored and are free of phenomena of color change, color fading or color bleeding in practical application.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

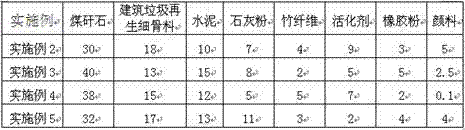

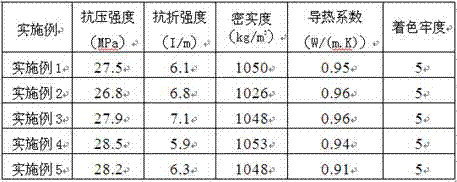

Colored bamboo fiber coal gangue brick

The invention relates to a colored bamboo fiber coal gangue brick. The colored bamboo fiber coal gangue brick comprises the following components in parts by weight: 30-40 parts of coal gangue, 13-18 parts of a construction waste regenerated fine aggregate, 10-15 parts of cement, 5-11 parts of lime powder, 2-5 parts of bamboo fibers, 2-9 parts of an activator, 2-5 parts of rubber powder and 0.1-5 parts of pigments. By making full use of waste rubber powder, industrial wastes and construction waste, resources and lands can be effectively saved, waste materials are consumed, and the colored bamboo fiber coal gangue brick has good economical benefit and sustained development is facilitated. By adding the bamboo fibers, the strength and density of the coal gangue brick can be obviously improved; by adding the waste rubber powder, the coal gangue brick has good waterproofness and insulating property; by adding an inorganic oxide into the coal gangue brick as the pigment of the coal gangue brick, the coal gangue brick is firmly colored and has very high practical value.

Owner:绍兴职业技术学院

Method of Supplementing Animals with Carotenoids by Drinking Water

InactiveUS20090220640A1Short timeReduce usageAnimal feeding stuffAccessory food factorsPotable waterCarotenoid

The present invention provides a method of supplementing animals with carotenoids by drinking water, comprising the following steps of: (1) making yellow and / or red pigments into the microencapsulated dry powders or beadlets; (2) mixing the aforementioned microencapsulated dry powders or beadlets in a certain proportion and dissolving them in water to prepare for a pigment solution; (3) administering the prepared pigment solution to animals by drinking. The method of supplementing the carotenoids according to the present invention has the advantages of easy absorption, economical dosages of pigments, high efficiency of coloration, stable coloration and small effects on the process of pigments in comparison with conventional methods currently.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

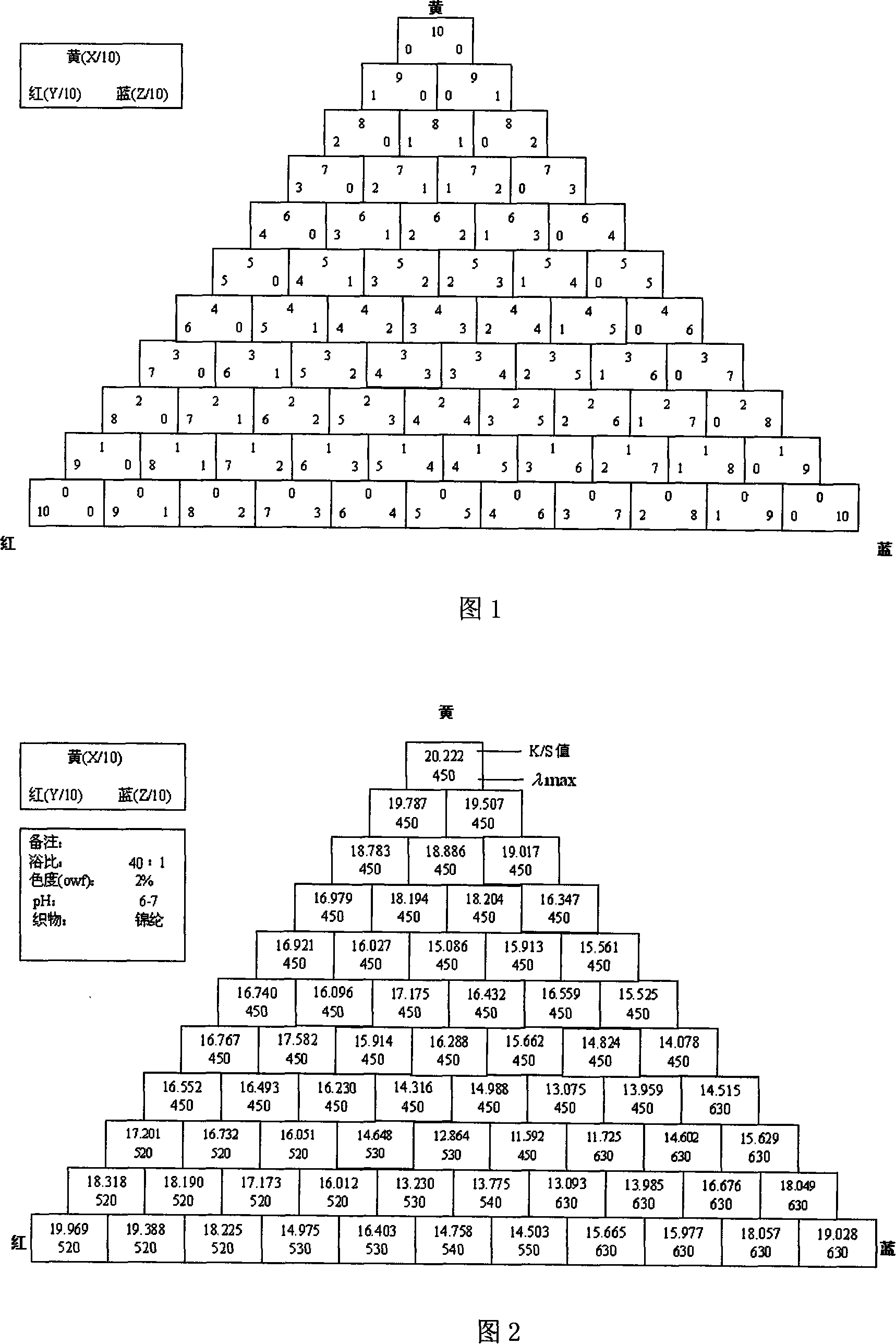

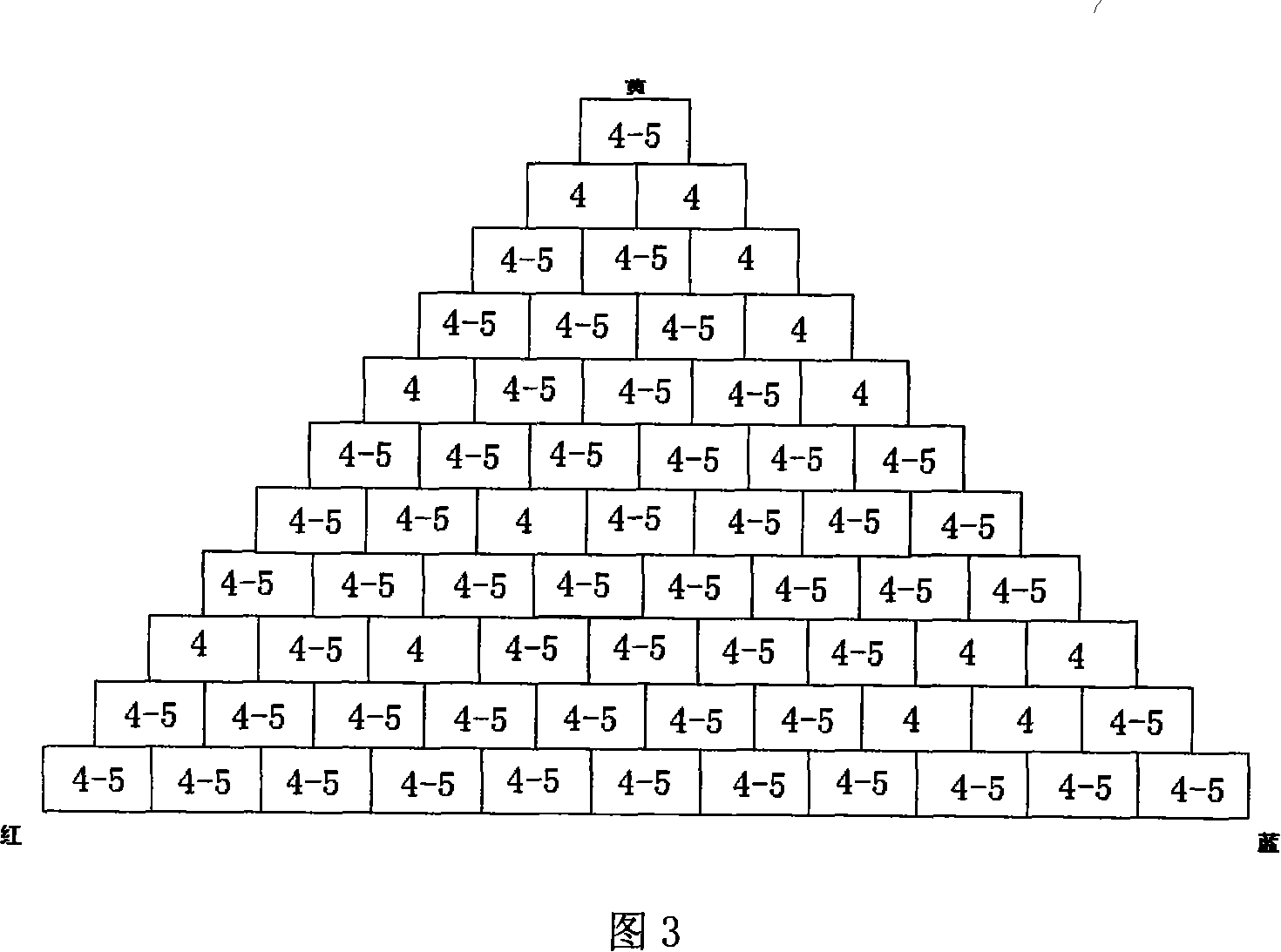

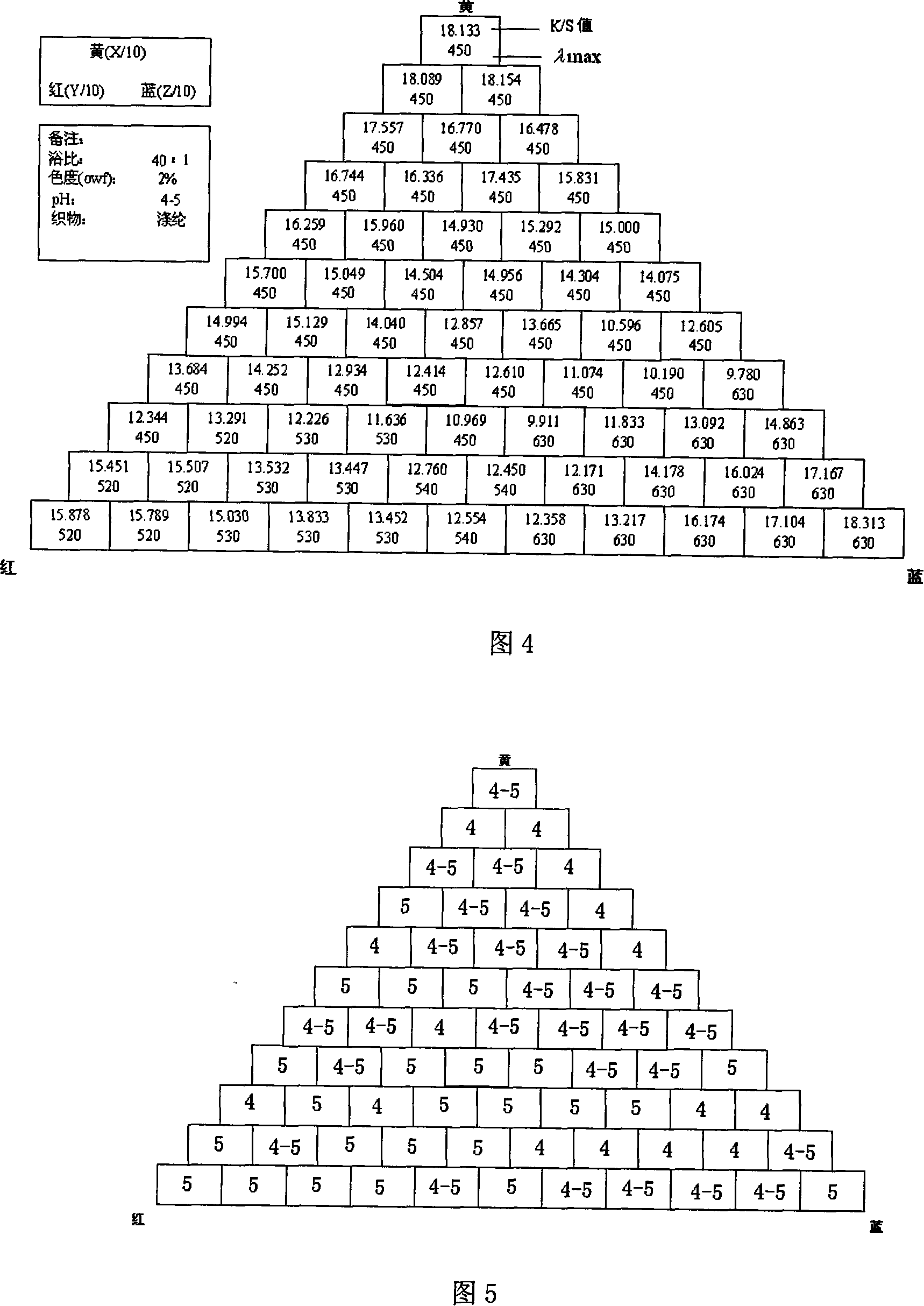

Color matching method of micro-encapsulation disperse dyes

InactiveCN101117774AReduce consumptionColoring firmDyeing processMicroballoon preparationDisperse dyeMicro-encapsulation

The present invention discloses a method with dispersed paint micro-capsule dyeing textile for micro-capsule dispersion and color matching, including melamine resin pre-polymer or polyurethane as wall material to make the dispersed pain micro-capsule, which is used to carry out rope dyeing on polyester or nylon textiles, without leveling agent, dispersant, penetrating agent and etc. The method is characterized in that: the dispersed paint micro-capsule employs three primary colors dispersed paint capsule, namely, the red dispersed paint micro-capsule, yellow dispersed paint micro-capsule and blue dispersed paint micro-capsule, which can perform color matching on polyester or nylon textiles. Through the dosage control of the red, yellow and blue paint micro-capsules, varieties of colors can be painted on textiles, with firm color fixation; the technology is simple and meets the requirements of even dyeing, dispersion and dyeing transfer; the dyeing temperature is low, so energy consumption during dyeing is saved.

Owner:常州汉诺斯生物科技有限公司 +1

Dyeing process of color knitted denim coating

ActiveCN105484073ASolve the problem that the knitted fabric cannot be dyed by the rope dyeing machineSolve the problem of dyeing one sideDyeing processThermal energyStaining

The present invention relates to a dyeing process of a color knitted denim coating. The process includes coloring and fixation. The coloring is as below: beating a coloring agent into coloring foam by a foam generator, applying the coloring foam onto a staining surface of a full width traveling fabric, controlling the amount of foam and fabric speed to reach liquid amount of the fabric at 8-15%, and progressively drying by seven groups of cloth drying cylinders at different temperatures at a drying temperature with constant temperature increment of 70 DEG C-120 DEG C. The fixation is as below: beating a coloring agent into coloring foam by a foam generator, applying the coloring foam onto a staining surface of a full width traveling fabric in the step B, controlling the amount of foam and fabric speed to reach liquid amount of the fabric at 8-15%, and progressively drying by seven groups of cloth drying cylinders at different temperatures at a drying temperature with constant temperature increment of 70 DEG C-120 DEG C. The coloring and fixation both use a foam coating manner, and the liquid amount of the fabric is controlled at a low range of 8%-15%, so as to realize the dyeing process of knitted denim. The process has the advantages of uniform coloring, firm staining, and reduction of heat and water consumption.

Owner:JIANGYIN FUBO TEXTILE CO LTD

Horse bean root tip cell microkernel flaking method

InactiveCN101246098AGreat Coloring ContrastReduce consumptionPreparing sample for investigationLima beansBiology

The present invention discloses a method for preparing the piece of root apiex microkernel of lima beans, the method comprises the steps of soaking seed to hasten germination to the seed of the lima beans, fixed-isolating the root tip, dyeing and performing and the like. The method integrates the fixing and the isolating to one step with a fixed-isolating liquid, lead to that the experiment which needs about 25 hours for completion formerly can be completed in about 30 minutes, the experiment time is greatly saved and the chemical consumption is reduced; and through the using of the cell nucleus dye liquor with simple operation and good dyeing effect the optimum microkernel piece-making effects of evident cell nucleus dyeing, large nuclearsubstance contrast ratio and definite cell profile are obtained thereby ensuring the feasibility for monitoring the environment with the microkernel technique of the lima beans root tip and the accuracy.

Owner:CHENGDU UNIV

Preparation method of shallow crystal and yellow crystal bead blank

ActiveCN102320747AHigh refractive indexAchieve lead-freeGlass pressing apparatusManganesePotassium carbonate

The invention discloses a preparation method of a shallow crystal and yellow crystal bead blank. For overcoming the defects that lead oxide is needed in the raw materials, iron ions have poor coloring and optical properties, the coloring of manganese is instable and the crystal bead blank is poor on the aspects of physical and chemical properties and the like in the conventional process for preparing the shallow crystal and yellow crystal bead blank, the invention provides the preparation method of the shallow crystal and yellow crystal bead blank, wherein in the method, the lead oxide is notneeded in the raw materials, and the crystal bead blank has good physical and chemical properties, proper hardness and strong corrosion resistance. The method is technically characterized in that: the shallow crystal and yellow crystal bead blank comprises the following raw materials in part by weight: 50 to 65 parts of quartz sand, 2 to 20 parts of titanium white powder, 2 to 10 parts of sodium carbonate, 1.6 to 13 parts of potassium carbonate, 0.3 to 3 parts of potassium nitrate, 0.1 to 5 parts of cerium oxide, less than or equal to 6 parts of boric acid, less than or equal to 2 parts of aluminum hydroxide, less than or equal to 8 parts of zinc oxide, less than or equal to 10 parts of strontium carbonate, less than or equal to 15 parts of barium carbonate, less than or equal to 2 parts of lithium carbonate, and less than or equal to 2 parts of potassium permanganate.

Owner:浙江鑫伟兴水晶有限公司

Efficient gravure and film covering process of corrugated board

InactiveCN109177337AIncrease surface areaThick coloringMechanical working/deformationDuplicating/marking methodsCardboardAdhesive

The invention provides an efficient gravure and film covering process of a corrugated board. The efficient gravure and film covering process comprises the following steps that a corrugated molding machine is adopted to corrugate the corrugated board, and a lining is attached onto the corrugated board; an adhesive is applied to a web paperboard; nanometer silicon dioxide is applied to the positionof the adhesive; a pattern is pressed onto the web by a platen roller and a rubber roller, and a film is covered; composite corrugated board and pre-printed paper are synthesized by a surface attaching machine; mold cutting and creasing are conducted by a mold cutting and creasing machine; corrugated boards after mold cutting and creasing are positioned in an automatic folding machine in batch; and each creasing is folded, and sealing part is glued. The adhesive is applied to the corrugated board firstly, and then the nanometer silicon dioxide is applied to the adhesive, and therefore the nanometer silicon dioxide is attached to the adhesive. The pattern is pressed onto the web by the platen roller and the rubber roller, and therefore large area being shaded without white is achieved. Small figures and texts are shaded thickly and clearly and with continuous lines. The printing rage is wide, and efficiency is high.

Owner:扬中市惠丰包装有限公司

Papanicolaou staining fluid and using method thereof

InactiveCN103571909ALow costColorfulMicrobiological testing/measurementPreparing sample for investigationStainingPotassium

The invention relates to Papanicolaou staining fluid and a using method thereof. The Papanicolaou staining fluid consists of fluid A, fluid B and 95 percent ethanol, wherein the fluid A is improved hematoxylin staining fluid; the fluid B is prepared from a phosphotungstic acid, eostm and light green. A method for preparing the improved hematoxylin staining fluid comprises the following steps of dissolving hematoxylin into the 95 percent ethanol, dissolving potassium alum into 100 DEG C boiling water, mixing two mixed solutions, adding an oxidant, stirring for at least 50 minutes, adding a glacial acetic acid, and stirring for at least 50 minutes. A method for preparing the fluid B comprises the following steps of mixing 95 to 97 mass percent of 0.2 to 0.6 percent phosphotungstic acid solution, 1.5 to 2.5 mass percent of eostm solution and 1.5 to 2.5 mass percent of light green solution. When the Papanicolaou staining fluid is used, a smear is fixed in the 95 percent ethanol, and is flushed in a specific environment by adding a corresponding amount of fluid A and a corresponding amount of fluid B. The Papanicolaou staining fluid has the advantages of low cost, bright color, clear contrast, coloring stability, is simple to prepare and convenient to operate, is easily popularized and used in various medical units and the like, and is applied to the display and diagnosis of the estrogen level of a vaginal smear and the poorly-differentiated small-angle cell carcinoma of a cervical smear and a sputum smear.

Owner:WENZHOU KONT BIOLOGY & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com