Colored bamboo fiber coal gangue brick

A bamboo fiber and coal gangue technology, which is applied in applications, household appliances, clay products, etc., can solve the problems that the strength index of coal gangue bricks needs to be improved, the thermal insulation performance of coal gangue bricks needs to be improved, and the impermeability of coal gangue bricks needs to be improved. , to achieve the effect of being conducive to sustainable development, good economy, saving resources and land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment 1, 35 parts of coal gangue, 15 parts of regenerated fine aggregate of construction waste, 10 parts of cement, and 8 parts of lime powder are put into a crushing and mixing crusher for crushing. 3 parts, 4 parts of activator, 3 parts of rubber powder, 2 parts of pigment, mixed with appropriate amount of water at the same time for mixing and stirring. It should be noted that wheel milling is required after stirring, which can ensure that the raw materials are fully mixed, and the mixture after wheel milling is sent to the aging warehouse for aging. After the aging is completed, the mixture is sent to a vacuum extruder to be extruded and then cut into codes. Then the cut body is dried and roasted to be processed into the required gangue bricks.

Embodiment 2-5

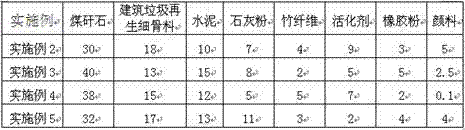

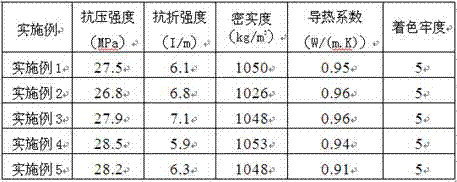

[0020] The preparation method of present embodiment 2-5 is identical with embodiment 1, and concrete component and content are as shown in table 1 below:

[0021] Table 1

[0022]

[0023] In embodiment 1-5, the bamboo fiber length can be any value between 5-15nm. The activator is a mixture of sodium sulfate and calcium sulfate, and the mass ratio of sodium sulfate and calcium sulfate is between 4-6:1. This activator can effectively accelerate the disintegration speed of coal gangue and significantly improve the reactivity of coal gangue. Reduce the sintering temperature of gangue bricks and save energy. The particle size of rubber powder is 0.3-2mm. The pigments are inorganic oxide pigments such as cobalt blue or iron red. Construction waste recycled fine aggregate is obtained by crushing and screening construction waste aggregate. Using construction waste recycled fine aggregate instead of traditional sand can effectively reuse construction waste and effectively save r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com