Graphene printing paste and preparation method thereof

A technology of printing paste and graphene, which is applied in dyeing, textiles and papermaking, etc., can solve the problems of poor permeability, poor antibacterial performance, poor color fastness and washing fastness, etc., and achieve bacteria reduction and excellent antibacterial properties , coloring firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

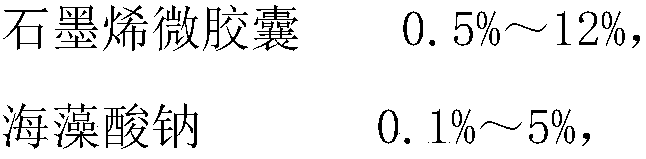

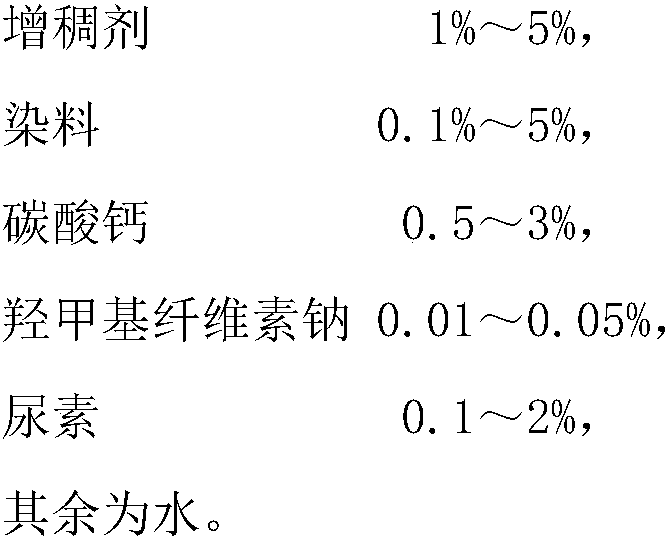

[0027] This embodiment provides a graphene printing paste and a preparation method thereof. The components and mass percentages of the graphene printing paste are shown in Table 1.

[0028] The preparation method of described graphene printing slurry is as follows:

[0029] Step 1: Disperse the prepared graphene powder in deionized water, prepare an aqueous solution with a concentration of 0.1-5 mg / ml, and add a dispersant in proportion. Then ultrasonicate it for 30min~60min to make it disperse evenly;

[0030] The graphene powder is prepared by one of a mechanical exfoliation method, a liquid phase exfoliation method, a chemical vapor deposition method, and a redox method;

[0031] The addition of the dispersant is 1% to 5% of the graphene powder; the dispersant is selected from polyvinyl alcohol, polyethylene glycol, sodium lignosulfonate, polyvinylpyrrolidone, hexadecane One or more of Trimethylammonium Bromide, Sodium Lauryl Sulfonate, Sodium Lauryl Sulfate.

[0032] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com