Coloring method adopting aluminium alloy alternate current electrolysis for precipitating silver and copper

A technology of electrolytic deposition and electrolytic coloring, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problems of poor stability of coloring liquids, achieve long-lasting antibacterial and bactericidal effects, convenient operation, and low cost of coloring treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

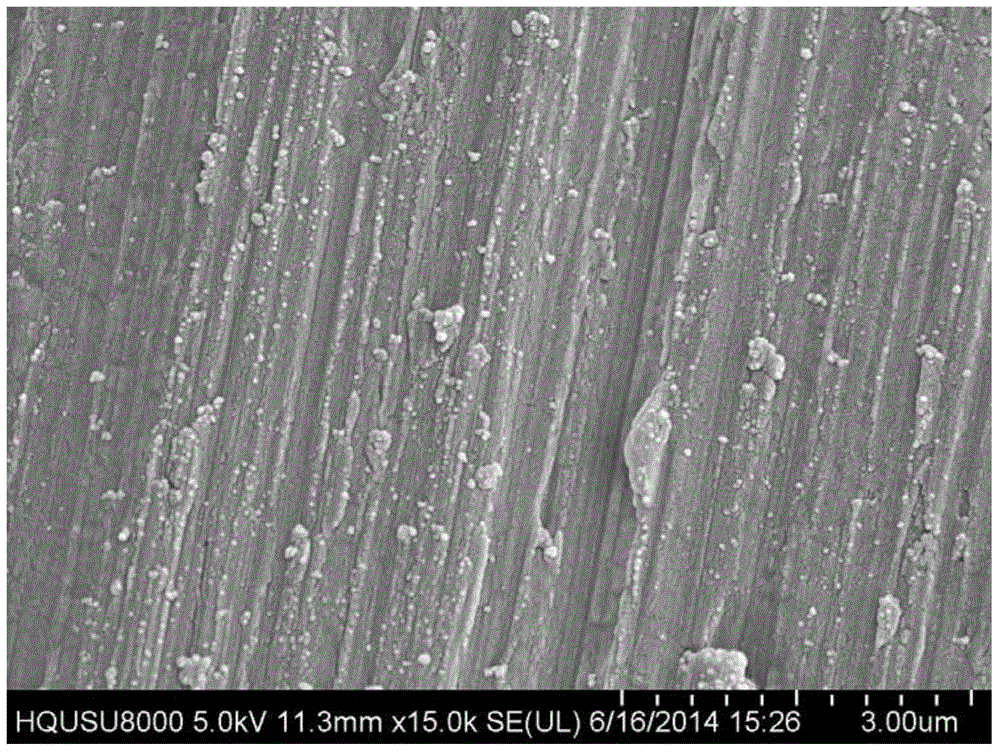

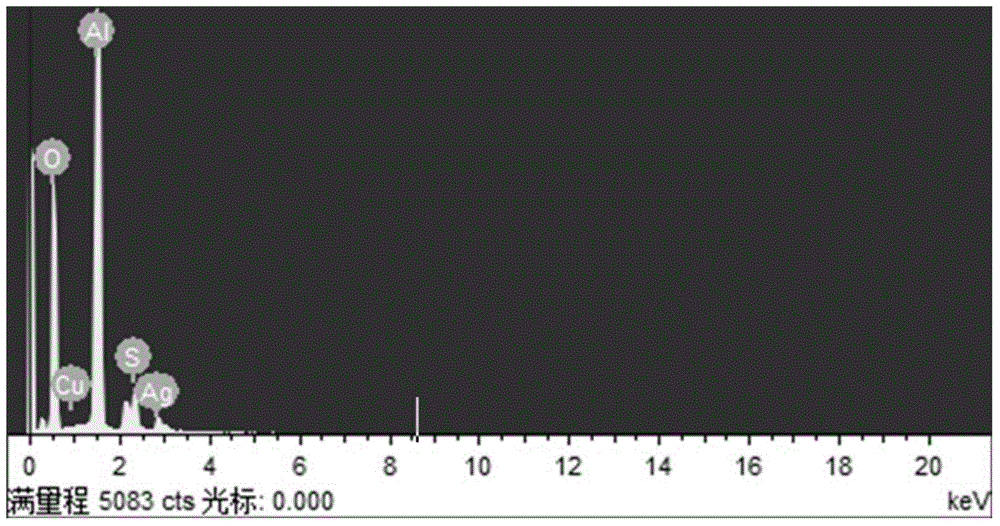

[0037] After pretreatment such as degreasing, oxide film removal, ash removal, and water washing, the aluminum alloy sheet contains 5g / LAl 2 (SO 4 ) 3 18H 2 O and 170g / LH 2 SO 4 Concentrated solution, electrolysis at 19-21 DEG C and 14V DC voltage for 30 minutes, washing and immersing to remove the surface electrolyte, to obtain an aluminum alloy sheet with a porous oxide film with a thickness of about 15-20 microns.

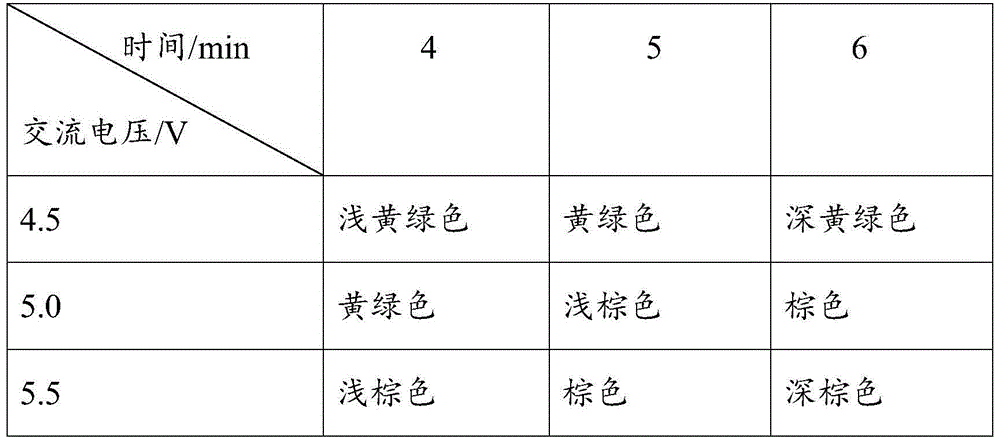

[0038] with H 2 SO 4 17g / L, AgNO 3 5g / L, CuSO 4 ·5H 2 O 1.5g / L, MgSO 4 ·7H 2 O 20g / L, glycine 3.2g / L to prepare coloring electrolyte, carry out AC electrolytic coloring on the aluminum alloy sheet at a temperature of 25°C, then wash and soak in water to remove the surface electrolyte, and finally seal with hot water. Table 1 below shows the colors attached to AC electrolytic aluminum alloys at different times and AC voltages.

[0039] Table 1 When CuSO 4 ·5H 2 Influence of AC electrolysis voltage and time on the coloring of aluminum alloy at O 1....

Embodiment 2

[0042] After pretreatment such as degreasing, oxide film removal, ash removal, and water washing, the aluminum alloy sheet contains 5g / LAl 2 (SO 4 ) 3 18H 2 O and 170gLH 2 SO 4 Concentrated solution, electrolysis at 19-21 DEG C and 14V DC voltage for 30 minutes, washing and immersing to remove the surface electrolyte, to obtain an aluminum alloy sheet with a porous oxide film with a thickness of about 15-20 microns.

[0043] with H 2 SO 4 17g / L, AgNO 3 5g / L, CuSO 4 ·5H 2 O 2.0g / L, MgSO 4 ·7H 2 O 20g / L, glycine 3.2g / L to prepare colored electrolyte. Perform AC electrolytic coloring on the aluminum alloy sheet at a temperature of 25°C, then wash and soak to remove the surface electrolyte, and finally seal with hot water. Table 2 below shows the colors attached to AC electrolytic aluminum alloys at different times and voltages.

[0044] Table 2 When CuSO 4 ·5H 2 Influence of AC electrolysis voltage and time on the coloring of aluminum alloy at O 2.0g / L

[0045] ...

Embodiment 3

[0047] Degreasing, removing oxide film and other pre-treated aluminum alloy sheets containing 5g / L Al 2 (SO 4 ) 3 18H 2 O and 170gLH 2 SO 4 In a solution with a high concentration, use DC electrolysis at 19-21°C and 14V for 30 minutes, wash and soak to remove the surface electrolyte, and obtain a porous oxide film with a thickness of about 15-20 microns.

[0048] with H 2 SO 4 17g / L, AgNO 3 5g / L, CuSO 4 ·5H 2 O 2.5g / L, MgSO 4 ·7H 2 O 20g / L, glycine 3.2g / L to prepare colored electrolyte. Perform AC electrolytic coloring on the aluminum alloy sheet at a temperature of 25°C, then wash and soak to remove the surface electrolyte, and finally seal with hot water. Table 3 below shows the colors attached to AC electrolytic aluminum alloys at different times and voltages.

[0049] Table 3 When CuSO 4 ·5H 2 Influence of AC electrolysis voltage and time on the coloring of aluminum alloy at O 2.5g / L

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com