Color metallography coloring method of aluminum alloy

A color metallographic and aluminum alloy technology, applied in the preparation of test samples, etc., can solve problems such as poor effect, insufficient etching at grain boundaries, weak corrosion of sodium hydroxide, etc., and achieve simple steps and clear microstructure , good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Pre-etching: Immerse the A6N01 deformed aluminum alloy metallographic sample in an etching solution at 70°C for 1 to 2 minutes. After the etching is completed, rinse it with running water, clean it with anhydrous ethanol, and dry it with hot air; the etching solution is The solution obtained by dissolving potassium chloride in phosphoric acid and distilled water, the ratio is 1g potassium chloride: 21mL phosphoric acid: 29mL distilled water; the mass fraction of phosphoric acid is 85%;

[0038] (2) Coloring: Immerse the aluminum alloy metallographic sample after the pre-etching treatment in step (1) in Weck reagent for 10 to 20 seconds. After the surface is colored, rinse with running water, clean with absolute ethanol, and dry with hot air;

[0039] The ratio relationship of each substance in the Weck reagent is: 100 mL of distilled water: 4 g of potassium permanganate: 1 g of sodium hydroxide.

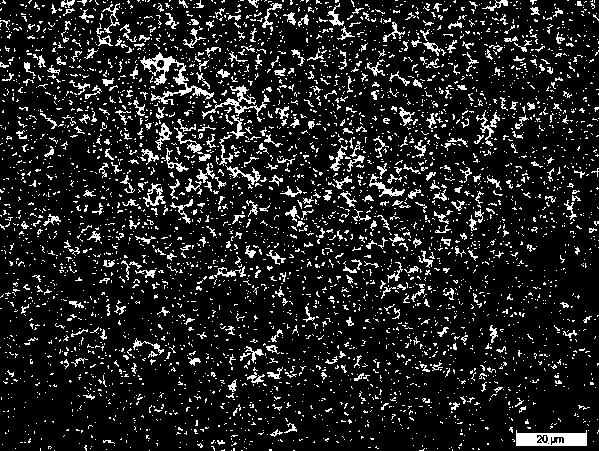

[0040] After coloring by the method of Example 1, a clear grain struc...

Embodiment 2

[0043] (1) Pre-etching: Immerse the A7N01 aluminum alloy metallographic sample in an etching solution at 70 °C for 1 to 2 minutes. After the etching is completed, rinse it with running water, clean it with anhydrous ethanol, and dry it with hot air; The volume ratio of the substance is: 20 phosphoric acid: 9 nitric acid: 40 distilled water; the mass fraction of phosphoric acid is 85%, and the mass fraction of nitric acid is 65%;

[0044] (2) Coloring: Immerse the aluminum alloy metallographic sample after the pre-etching treatment in step (1) in Weck reagent for 5-8 seconds. After the surface is colored, rinse with running water, rinse with absolute ethanol, and dry with hot air;

[0045] The ratio relationship of each substance in the Weck reagent is: 100 mL of distilled water: 4 g of potassium permanganate: 1 g of sodium hydroxide.

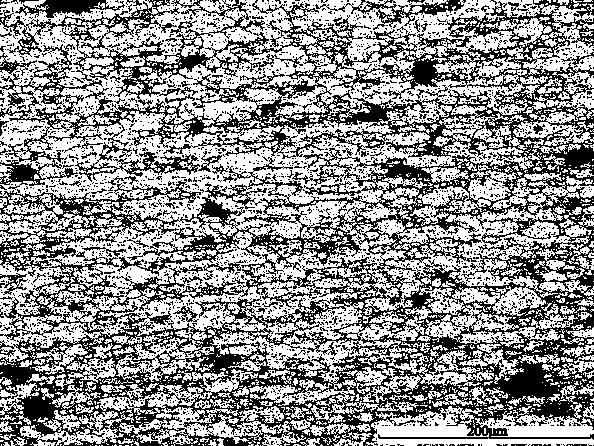

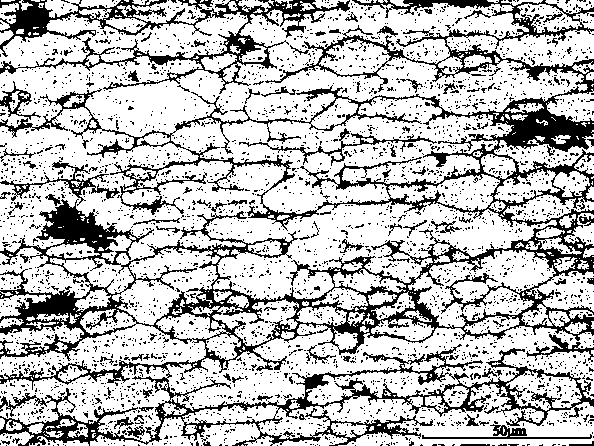

[0046] Depend on Figure 4 It can be seen that the grain boundary is partially corroded, but it is not clear enough, and from Figure 5 It ca...

Embodiment 3

[0048] (1) Pre-etching: Immerse the A6N01 deformed aluminum alloy metallographic sample in an etching solution at 73 °C for 1 to 2 minutes. After the etching is completed, rinse it with running water, clean it with anhydrous ethanol, and dry it with hot air; The ratio is 1g potassium chloride: 21mL phosphoric acid: 29mL distilled water; the mass fraction of phosphoric acid is 85%;

[0049] (2) Coloring: Immerse the aluminum alloy metallographic sample after the pre-etching treatment in step (1) in Weck reagent for 10 to 20 seconds. After the surface is colored, rinse with running water, clean with absolute ethanol, and dry with hot air;

[0050] The ratio relationship of each substance in the Weck reagent is: 100 mL of distilled water: 4 g of potassium permanganate: 1 g of sodium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com