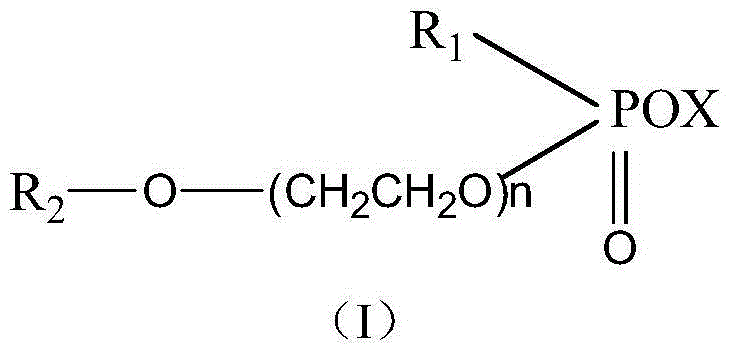

Phthalocyanine pigment water-based color paste for coloring viscose stock and preparation method thereof

A technology of phthalocyanine pigment and viscose collagen solution, which is applied in the direction of pigment slurry and artificial filament made of viscose, which can solve the problem of poor adsorption and matching between dispersion aid and pigment surface, easy clogging of spinneret, coloring Inhomogeneity and other problems, to achieve the effect of uniform coloring, good coloring effect and spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 300 grams of 20% formaldehyde solution and add an appropriate amount of ammonia water to adjust the pH value of the solution to 8.5 to obtain an alkaline formaldehyde solution; immediately mix the formaldehyde solution with 1 kg of phthalocyanine blue 15:1 pigment, and then mix the mixture 1. The ball mill was ground for 1 hour, and 122 grams of urea was added 10 minutes after the ball mill started to grind, and the grinding was continued to obtain the ground product; the above-mentioned ground product and 2.9 kilograms of aqueous solution were mixed and stirred for 40 minutes, then separated by filtration, rinsed with clear water and dried to obtain Surface modified phthalocyanine blue 15:1 pigment.

Embodiment 2

[0025]Add 400 grams of 10% formaldehyde solution and add an appropriate amount of triethanolamine to adjust the pH value of the solution to 8.0 to obtain an alkaline formaldehyde solution; immediately mix the formaldehyde solution with 1 kg of phthalocyanine green pigment, and then mix the mixture with a ball mill Grind for 1 hour, and add 95 grams of urea 10 minutes after the start of ball mill grinding, and continue grinding to obtain a grinding product; mix and stir the above-mentioned grinding product and 7.3 kg of aqueous solution for 40 minutes, then filter and separate, rinse with water and dry to obtain a surface modification. Phthalocyanine green pigment.

Embodiment 3

[0027] Add 400 grams of 20% formaldehyde solution and add an appropriate amount of triethanolamine to adjust the pH value of the solution to 9.0 to obtain an alkaline formaldehyde solution; immediately mix the formaldehyde solution with 1 kg of phthalocyanine blue 15:3 pigment, and then pass the mixture through Mix and grind in a ball mill for 1 hour, and add 175 grams of urea 10 minutes after the start of the ball mill grinding, and continue grinding to obtain a grinding product; mix and stir the above grinding product and 5.5 kg of aqueous solution for 50 minutes, then separate by filtration, rinse with water and dry A surface-modified phthalocyanine blue 15:3 pigment was obtained.

[0028] Preparation Example of Phthalocyanine Pigment Water-based Color Paste for Viscose Glue Coloring

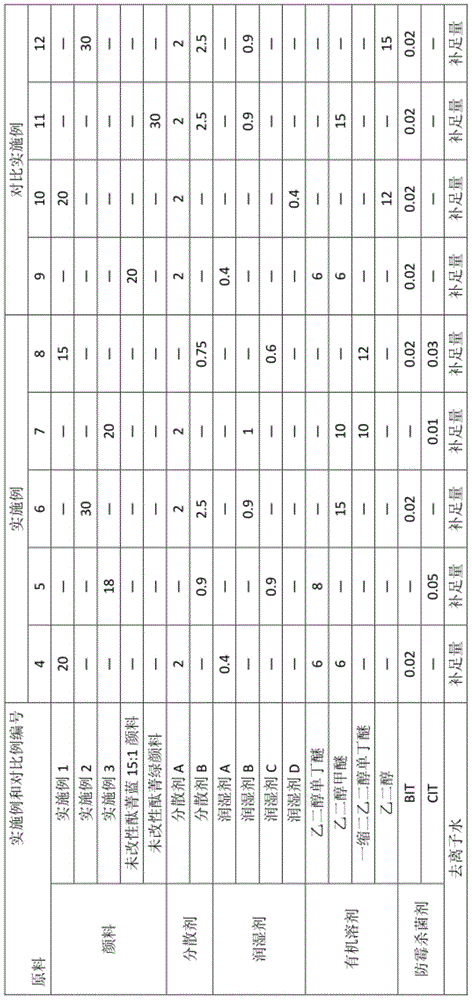

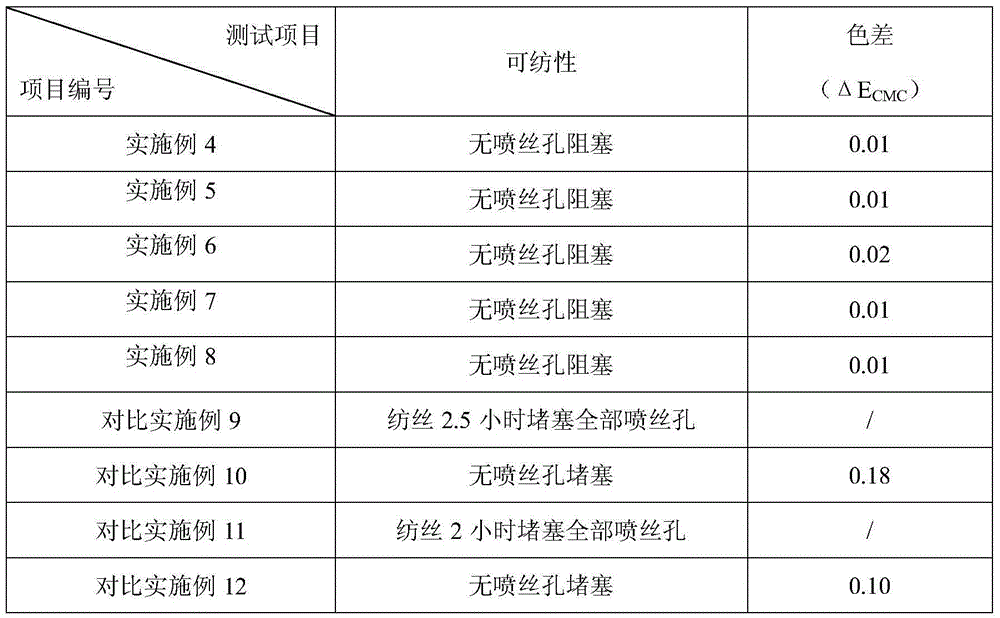

[0029] Embodiment 4~8 and comparative example 9~12 all produce according to following processing steps:

[0030] 1) Reserve 15% of the total mass of deionized water, and disperse the remai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com