Thread dyeing device and method uniform in coloring

A technology for uniform color and thread dyeing, which is applied in the processing of textile materials, the configuration of equipment for processing textile materials, textiles and papermaking, etc. It can solve problems such as uneven dyeing, achieve uniform coloring, ensure the quality of dyeing threads, and is not easy to steam The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

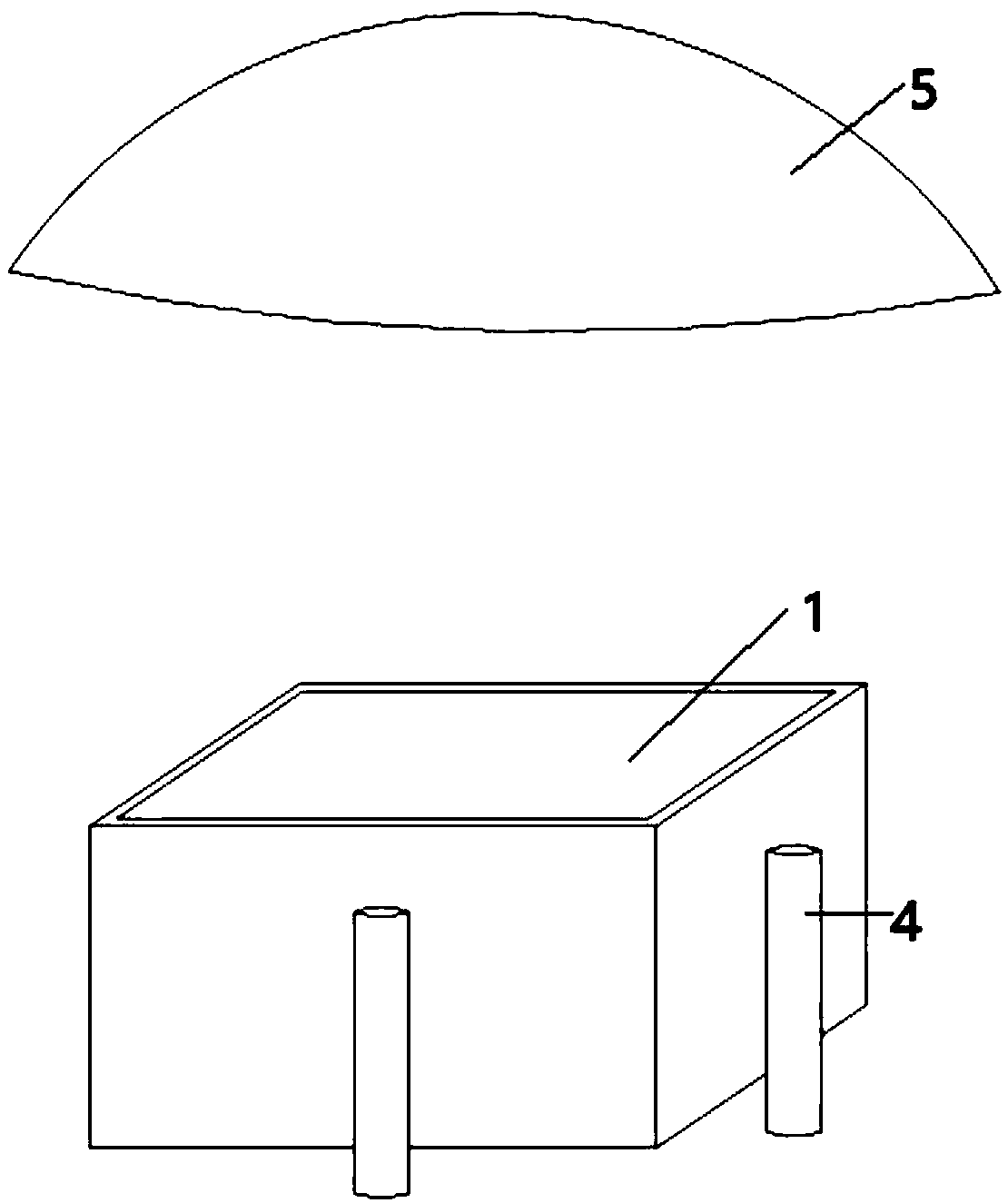

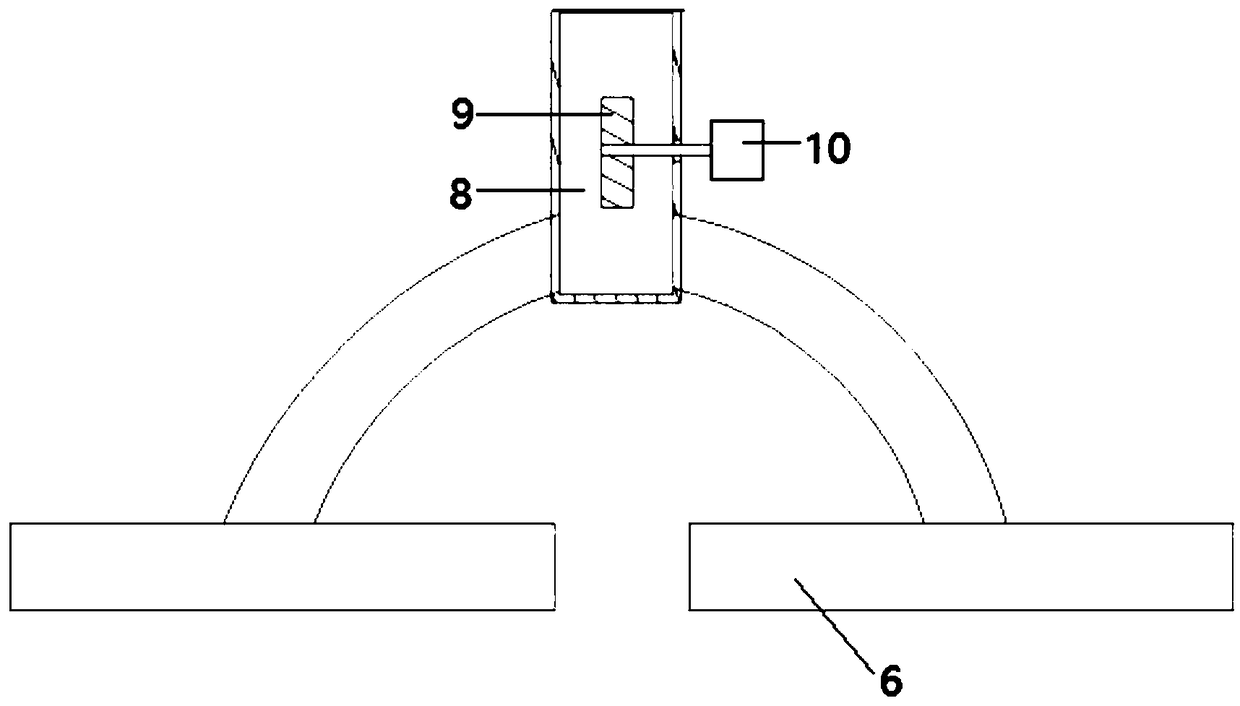

[0036] like figure 1 , Figure 5 The illustrated embodiment is a uniformly colored thread dyeing device, comprising a pool body 1 with an open upper end, such as Image 6 The shown conical groove 401, the elastic plate 402 at the bottom of the pool body, the vertically extendable air bag 403 in the conical groove, the heating device 3 on the pool body, and the outside of the pool body 4 illuminating lamps 4, the concave surface mirror 5 that arches upwards that is located at the top of pool body; Valve 405; also includes as figure 2 As shown in the two suction hoods 6, each suction hood is provided with a suction pump, and each suction hood is connected with an exhaust pipeline 8, and an impeller 9 is arranged in the exhaust pipeline, and the rotating shaft of the impeller and the worm gear and worm The structure 10 is connected, and the turbine of the worm gear structure is connected with the arc brush 104 through the flexible shaft 106, and the arc brush is arranged on t...

Embodiment 2

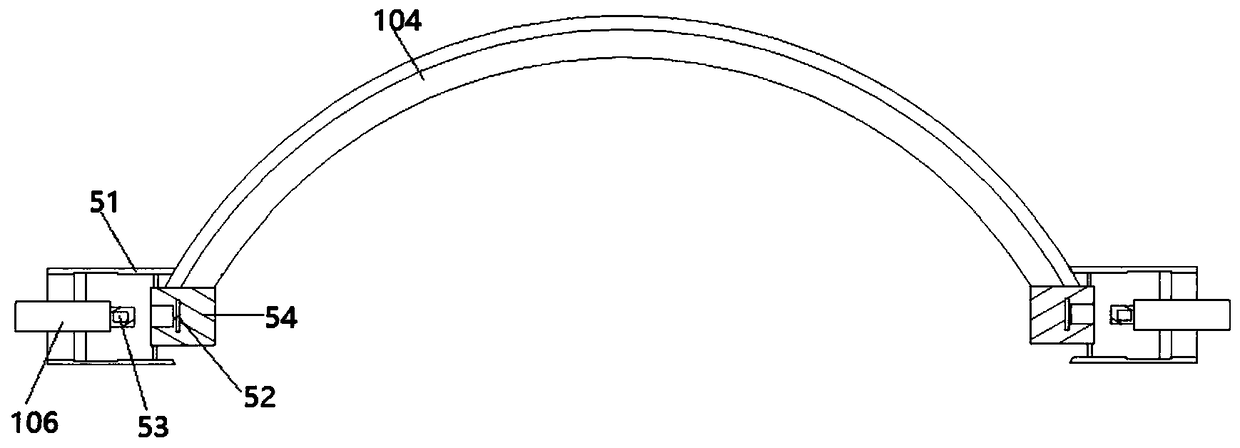

[0053] Embodiment 2 includes all structure and method parts of embodiment 1, such as image 3 As shown, the worm gear of embodiment 2 is meshed with the gear, and the rotating shaft of the gear is connected with another flexible shaft 106; the two ends of the arc brush are connected with the concave mirror through the fixed housing 51, and each fixed housing is provided with an arc brush. The fixed block 52 that is fixedly connected, the fixed block is rotatably connected with the fixed shell, and each flexible shaft is all rotatably connected with the corresponding fixed shell, and a permanent magnet 53 is arranged in each flexible shaft end, and a permanent magnet 53 is arranged in each fixed block. There are electromagnets 54, both of which are electrically connected to the controller.

[0054] The controller alternately controls the two electromagnets to be energized, so that the two flexible shafts are alternately connected and disconnected with the arc-shaped brush, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com