Patents

Literature

34results about How to "Uniform coloring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

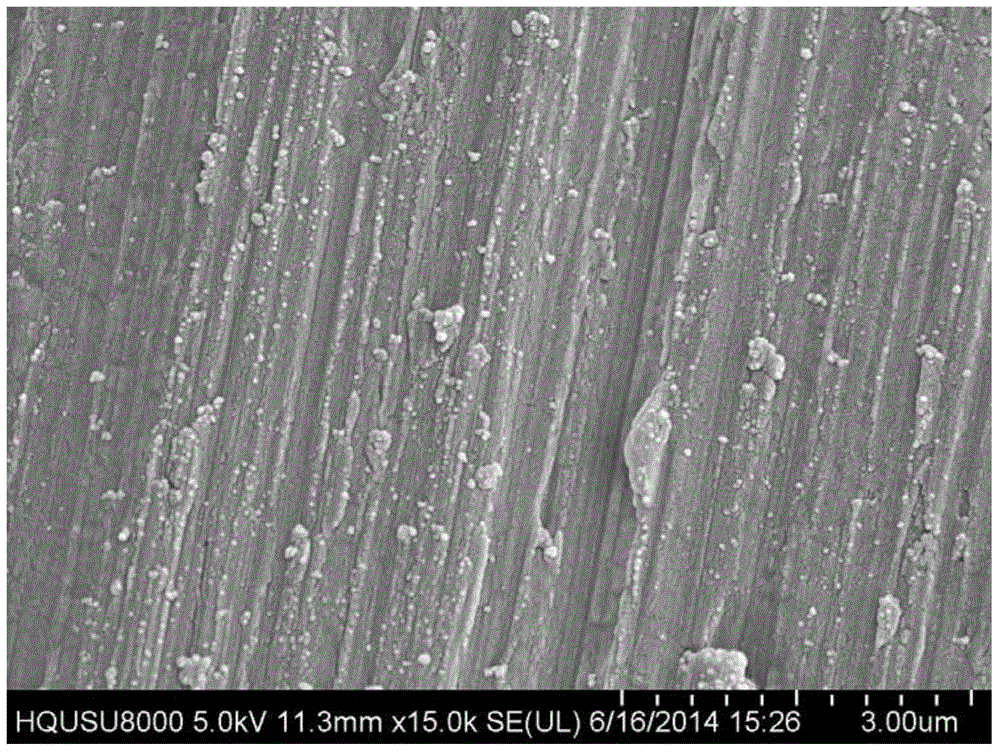

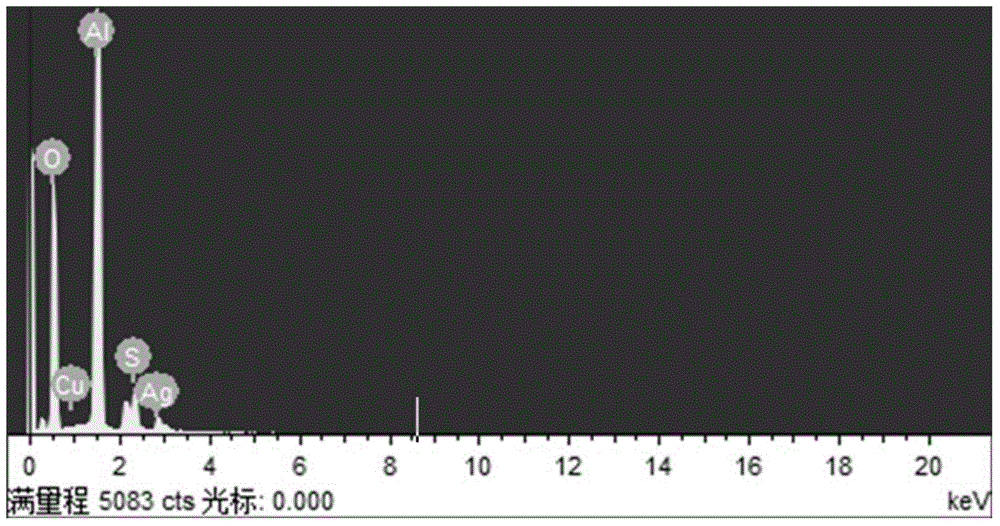

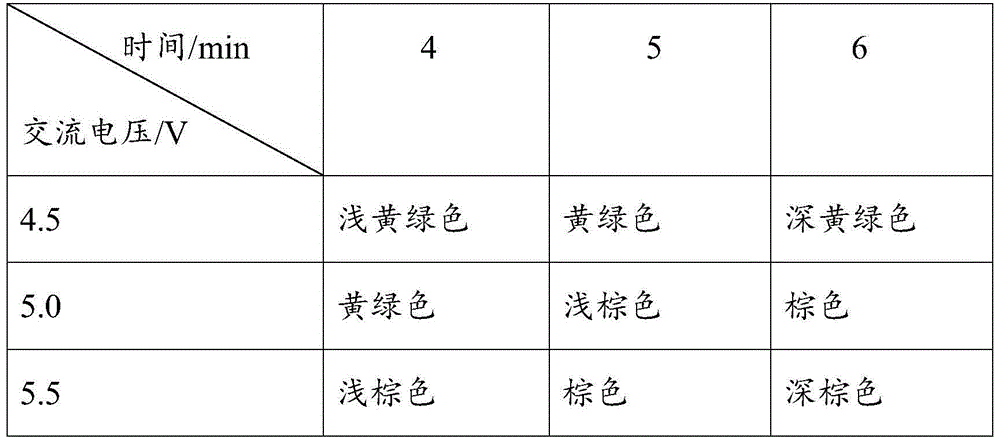

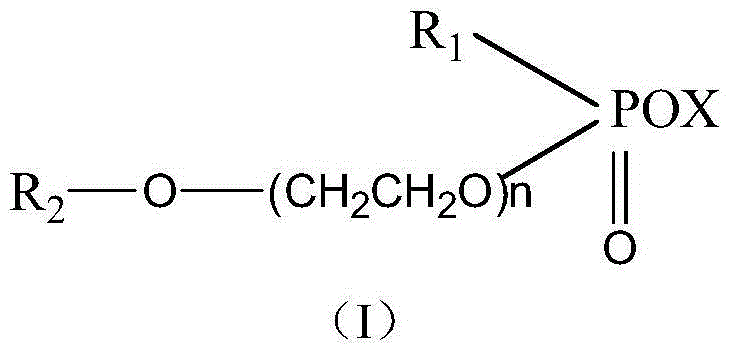

Coloring method adopting aluminium alloy alternate current electrolysis for precipitating silver and copper

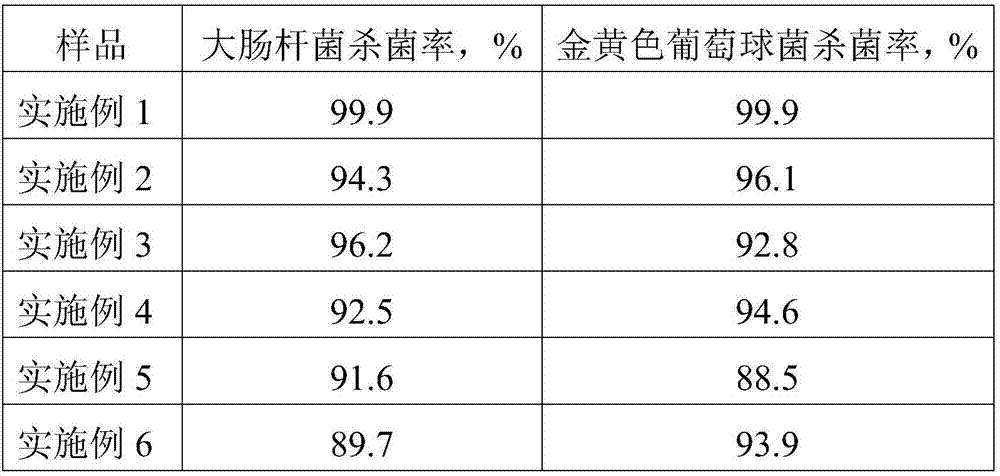

The invention provides a coloring method adopting aluminium alloy alternate current electrolysis for precipitating silver and copper. The coloring method comprises the following steps: after pretreatment such as degreasing and oxidation film removing, an aluminium alloy piece is subjected to direct current electrolysis in the sulfuric acid medium to obtain the aluminium alloy piece provided with a porous oxide-film; then, the aluminium alloy piece provided with the porous oxide-film is subjected to alternate current electrolysis; a coloring liquid comprises 15-20 g / L of H2SO4, 4-7 g / L of AgNO3, 1.5-2.5 g / L of CuSO4.5H2O, 18-25 g / L of MgSO4.7H2O, 2-7 g / L of a complexing agent A or 5-10 g / L of a complexing agent B; the technological conditions of the coloring liquid are as follows: the temperature is 5-35 DEG C, the time is 3-7 min and the voltage is 4-7 V; lastly, the alternate current electrolyzed porous oxide-film aluminium alloy piece is subjected to hot water sealing treatment to obtain aluminium alloy materials. According to the coloring method, the technology is simple, the coloring is uniform and stable, the decay resistance of the aluminium alloy is improved, the antibacterial and sterilizing rate of the aluminium alloy reaches 99.0%, the duration of antibacterial and bactericidal action is long and the coloring treatment cost is low; no insoluble deposition is precipitated in the coloring liquid for long-term use and the coloring liquid is stable.

Owner:SHISHI XINGHUO ALUMINUM PROD CO LTD +1

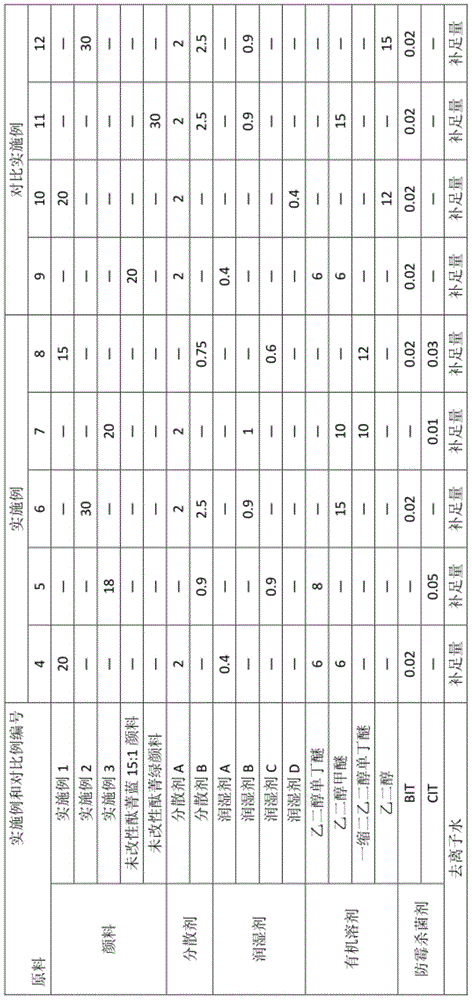

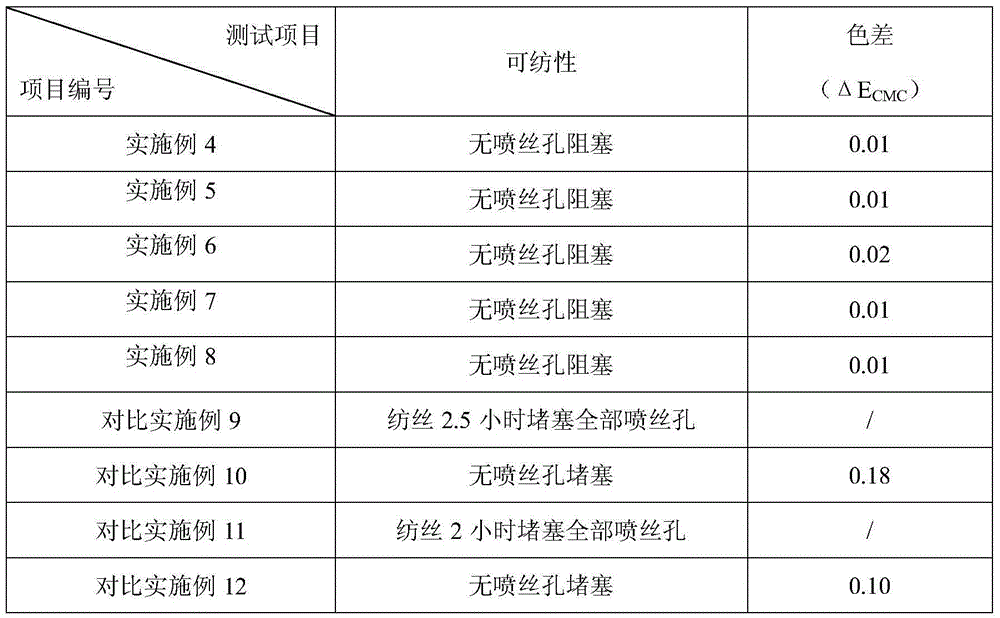

Phthalocyanine pigment water-based color paste for coloring viscose stock and preparation method thereof

ActiveCN103980766AUniform coloringGood coloring effect and spinnabilityArtificial filaments from viscosePigment pastesViscoseWetting

The invention relates to phthalocyanine pigment water-based color paste for coloring viscose stock. The color paste is prepared from a surface-modified phthalocyanine pigment, a dispersing agent, a wetting agent, an organic solvent, a mildew-proof bactericide and de-ionized water through such processes as dispersing, mixing, grinding, de-aerating and filtering. The color paste disclosed by the invention is used for coloring the viscose stock, and has such advantages as being uniform to color and capable of preventing a spinning jet from being blocked; and a coloring effect and a spinning property are excellent.

Owner:SUZHOU SUNMUN TECH CO LTD

Antiquing and colour-retouching decorative paint

The invention discloses antiquing and colour-retouching decorative paint. The antiquing and colour-retouching decorative paint comprises the following components in parts by weight: 50-60 parts of long oil alkyd resin, 22-30 parts of brown powder, 1.5-3 parts of dispersant, 1-2 parts of base material wetting agent, 15-16 parts of dimethylbenzene, 8-10 parts of tetramethylbenzene, 1-3 parts of anti-settling powder, 0.3-0.8 part of Co, 0.2-0.6 part of Mn and 0.1-0.3 part of anti-skinning auxiliary. The antiquing and colour-retouching decorative paint disclosed by the invention adopts long oil alkyd resin as a main ingredient, a special decorative effect can be produced, and transparent brown powder and Co and Mn used for paint are added, so that the decorative paint has extremely strong antiquing effect; and the antiquing and colour-retouching decorative paint disclosed by the invention can be solidified at normal temperature, has heat resisting and corrosion resisting performances and is also resistant to water, moisture, oil and salt mist. The colour-retouching decorative paint disclosed by the invention is good in colour forming, uniform in colouring and strong in line developing, has extremely strong decorative performance and can be widely applicable to individuation and top-grade interior decoration of a home, an apartment, a hotel, an office building and the like.

Owner:晋江市家博圆新材料有限公司

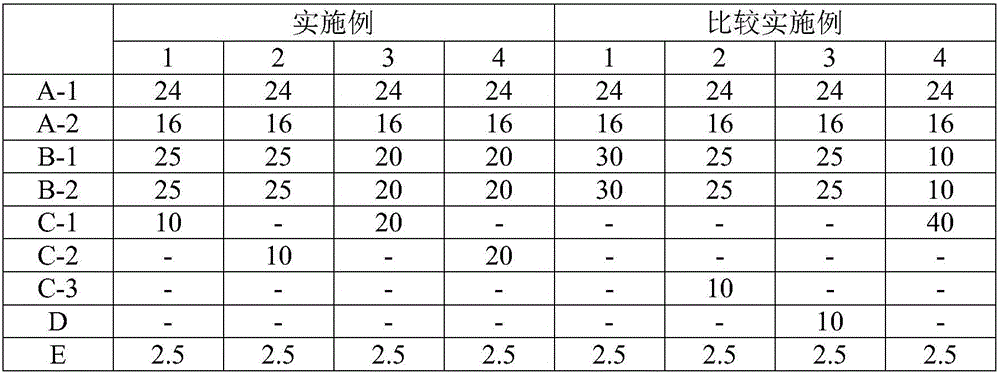

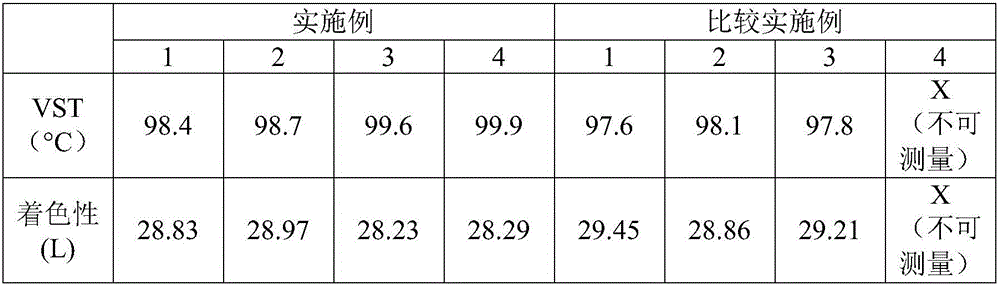

Thermoplastic resin composition with improved heat resistance and coloring property

The present invention relates to a thermoplastic resin composition and, more specifically, to an acrylic resin composition having improved coloring property and heat resistance by comprising an acrylic graft copolymer, an aromatic vinyl-cyano vinyl-based copolymer and an acrylic resin, and thus is suitable for an automotive exterior material.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Production process of filament-polyester-interwoven shading home textile fabric

ActiveCN103741336AGood effectUniform coloringDry-cleaning apparatus for textilesDyeing processPolyesterSizing

The invention relates to a production process of filament-polyester-interwoven shading home textile fabric. The fabric is formed by weaving polyester serving as a warp raw material and a group of black polyester elastic filaments and a group of mulberry silk which serve as a weft raw material. The production process includes the following steps of raw material section, raw material immersing, filament turning, doubling, weaving, desizing, degumming, dyeing and sizing. The production process is simple and reasonable, greatly reduces product production difficulty, reduces production cost under the premise that the high production rate is ensured, improves product light fastness, truly improves product yield and greatly reduces fabric cost price. The product shading rate achieves 99.99%.

Owner:如意屋家居有限公司

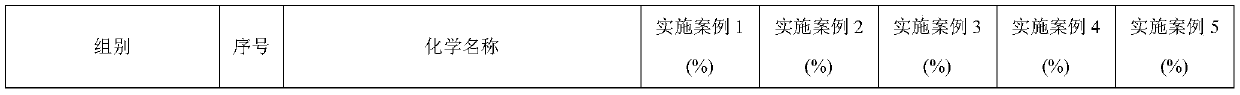

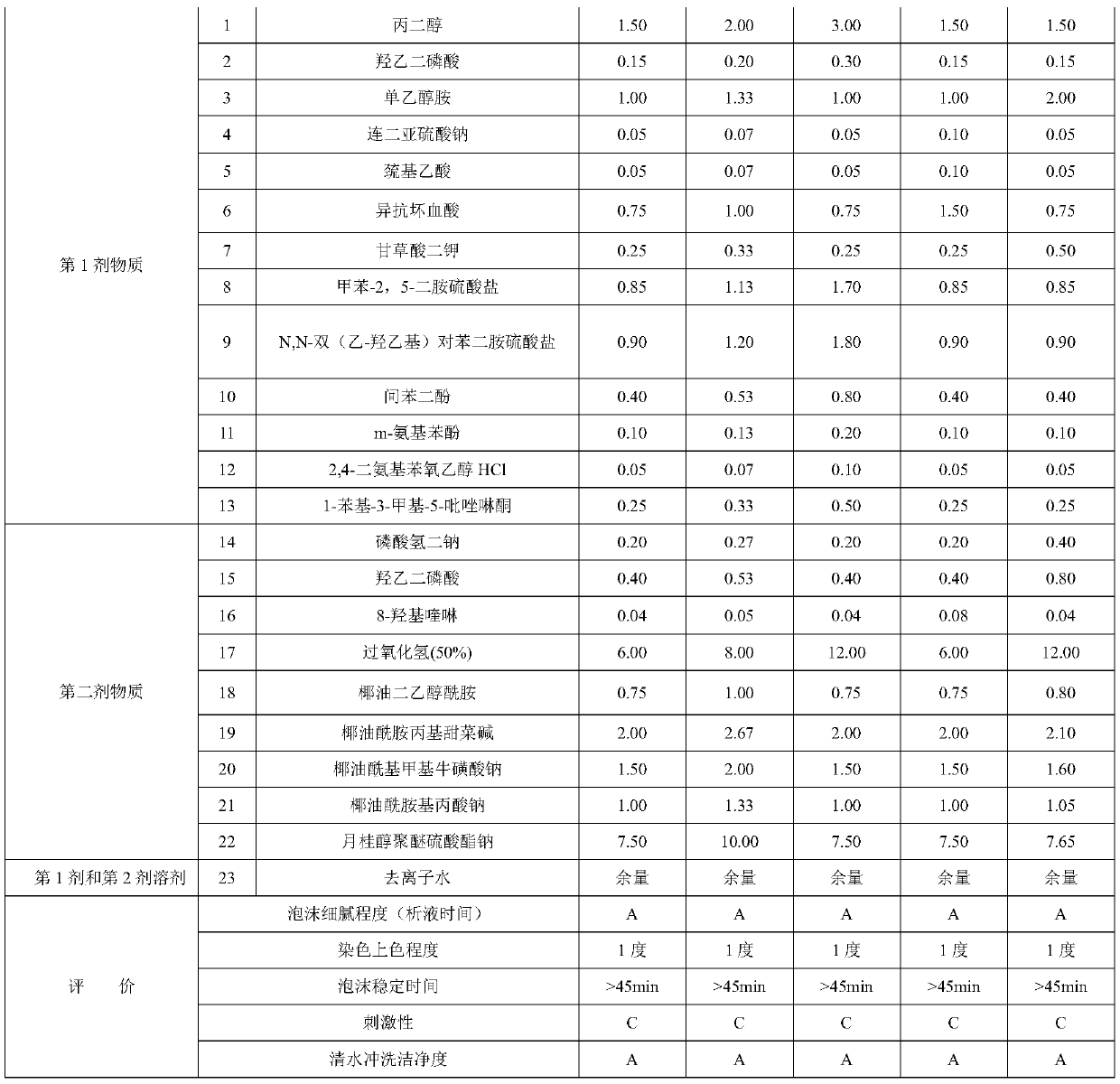

Dual agent type clear water physical hair dyeing foam

InactiveCN109718124ARich foamUniform coloringCosmetic preparationsHair cosmeticsHair dyesColoring agents

The invention discloses dual agent type clear water physical hair dyeing foam. The foam includes a first agent and a second agent; the first agent contains an anti-oxidant and a coloring agent; the second agent contains an oxidizing agent and a foaming agent; and after the first and second agents are mixed, the foam includes the following substances, by mass percentage: 0.6-1.2% of the anti-oxidant, 2.5-5.1% of the coloring agent, 6-12% of the oxidizing agent, and 12.5-25.5% of the foaming agent. The prepared foam is fine, stable and good in coloring effect, and has no stimulation.

Owner:黄茂仁

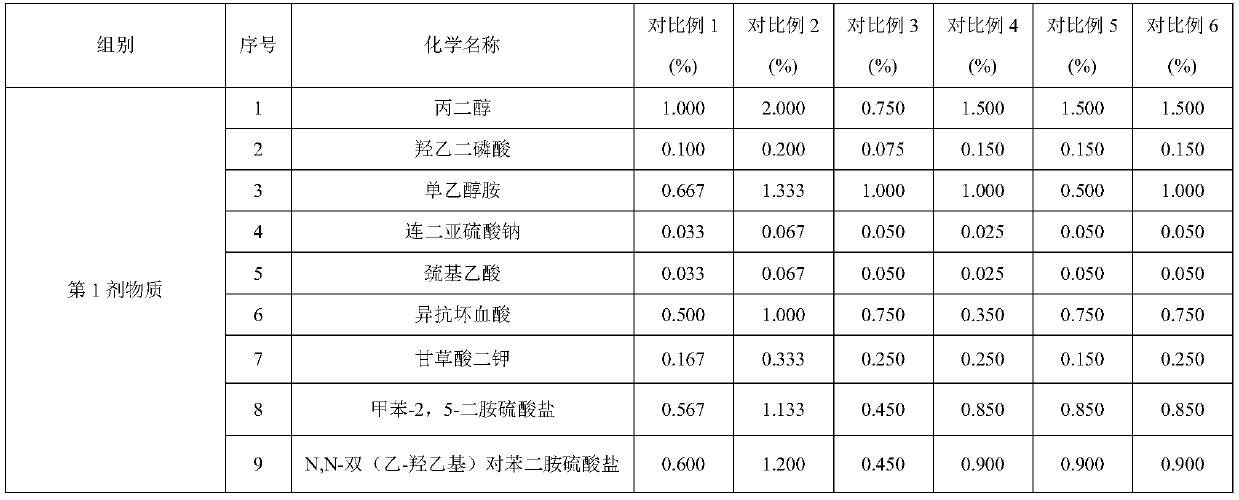

Polyester chiffon printing and dyeing process

The invention discloses a polyester chiffon printing and dyeing process. The polyester chiffon printing and dyeing process comprises pretreatment, dyeing treatment and posttreatment, wherein the dyeing treatment comprises the following steps: putting polyester chiffon into a low-concentration dying solution, performing dip dyeing, taking out the polyester chiffon, directly putting into a high-concentration dying solution, performing dip dyeing, and after naturally cooling the high-concentration dying solution, taking out the polyester chiffon to finish dyeing; the posttreatment comprises the following steps: drying the dyed polyester chiffon, putting into a mixed solution of a softening agent and a color fixing agent, soaking, drying, putting into a soaping box, cleaning, then drying and warehousing; the low-concentration dying solution comprises the following raw materials: dye, a cationic surfactant, a dispersant and cyclohexane; the high-concentration dying solution comprises the following raw materials: dye, a cationic surfactant, a dispersant, a color fixing agent and deionized water. The polyester chiffon printing and dyeing process is simple; by the polyester chiffon printing and dyeing process, the polyester chiffon is dyed under the conditions of room pressure and low temperature, is high in dyeing rate, is uniformly dyed, and is high in fastness, good in softness and antistatic.

Owner:泉州众科知识产权运营股份有限公司

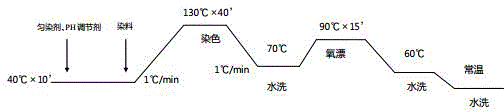

CVC knitted fabric dyeing and finishing method

InactiveCN104790225AUniform coloringFully dyedHeating/cooling textile fabricsDry-cleaning apparatus for textilesDyeingFiber

The invention belongs to the technical field of dyeing and finishing, and especially relates to a CVC knitted fabric dyeing and finishing method. The CVC knitted fabric dyeing and finishing method comprises following steps: dyeing, washing 1, oxygen bleaching, washing 2, washing 3, and setting; wherein in the step of dyeing, bath ratio ranges from 1:8 to 1:10, 0.5 to 1g of a leveling agent is added into each 1L of water, and 0.3 to 0.5g of a pH conditioning agent is added in each 1L of water. In the step of dyeing, a quantified dye is added at a uniform speed, temperature increasing speed is controlled to be 1 DEG C / min, and full level dyeing of two fibers is realized; at different stages, water at different temperature is used for washing, full washing is performed, so that cloth coloring uniformity is ensured; and setting temperature is determined to be 140 DEG C, and setting speed is determined to be 30m / min via repeated experiments, so that the best dyeing effect is obtained.

Owner:吴江新生针纺织有限责任公司

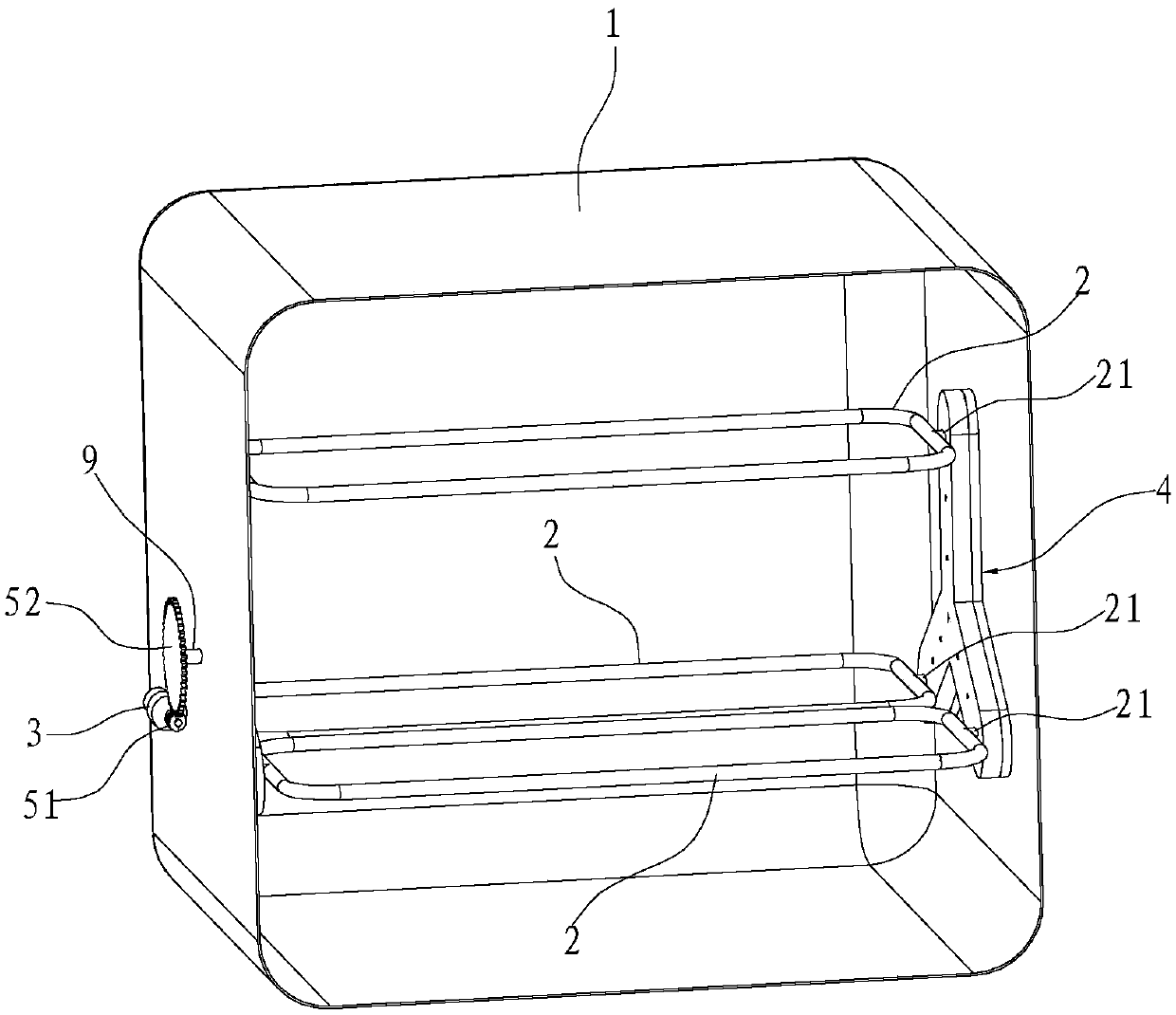

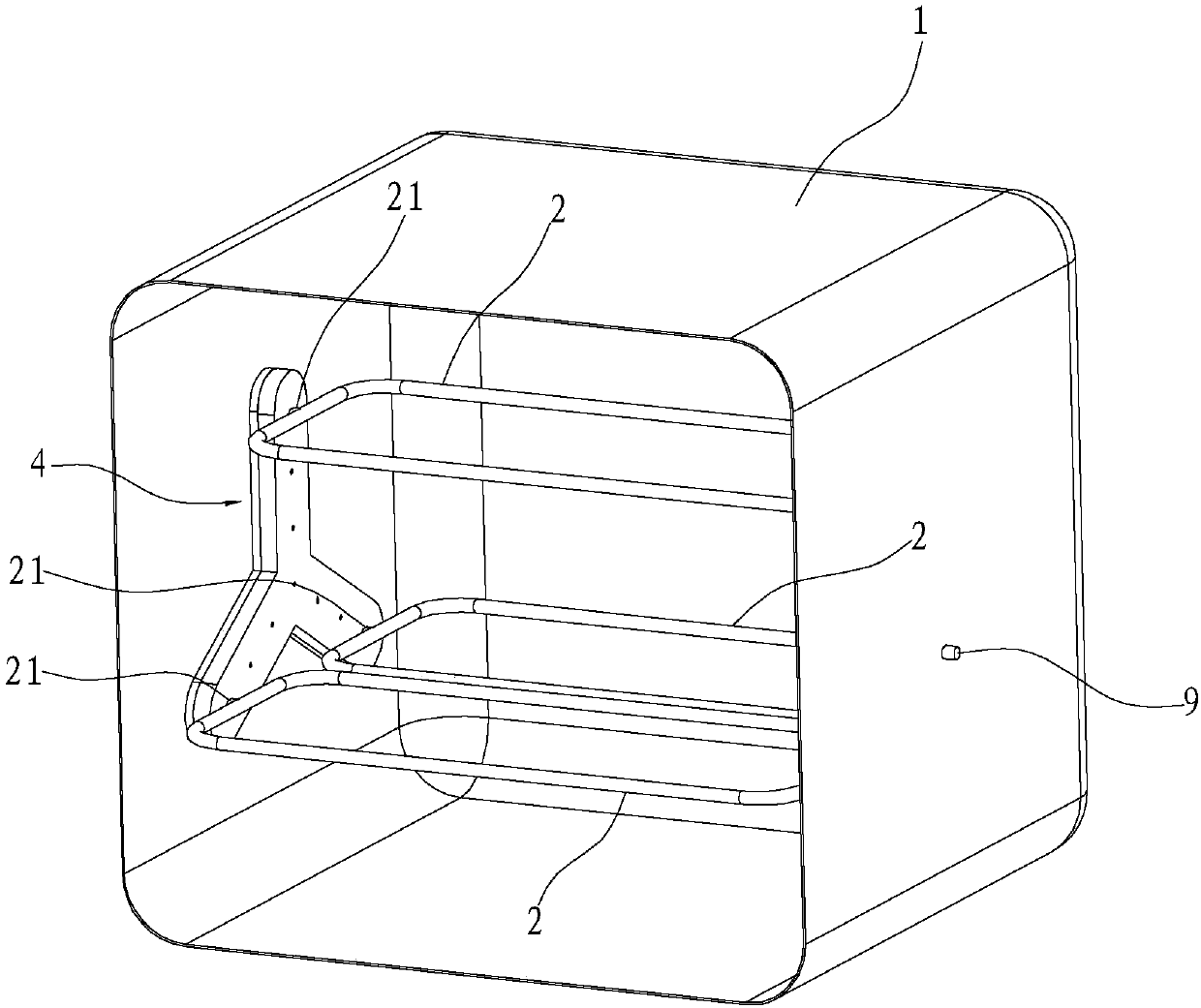

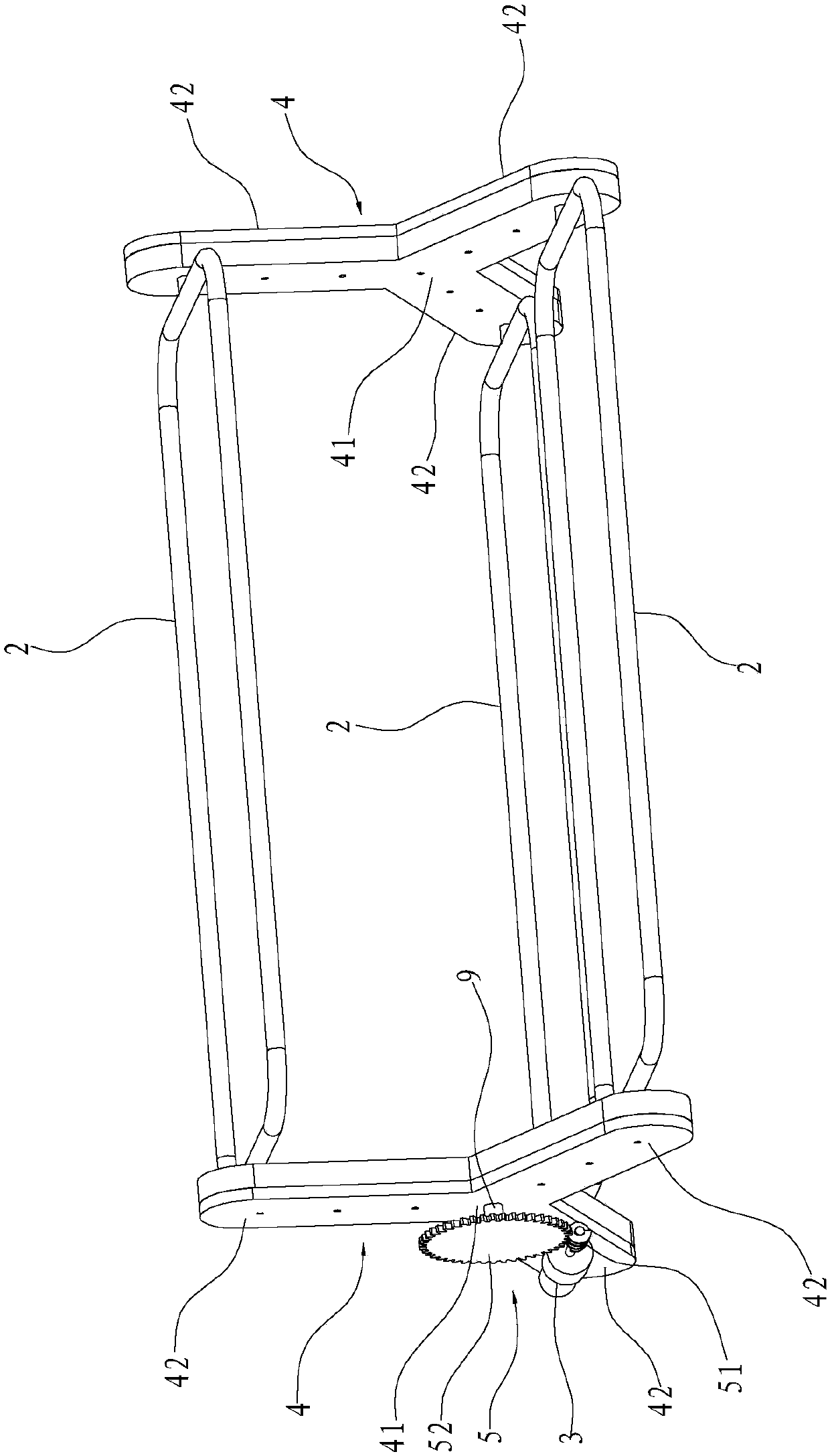

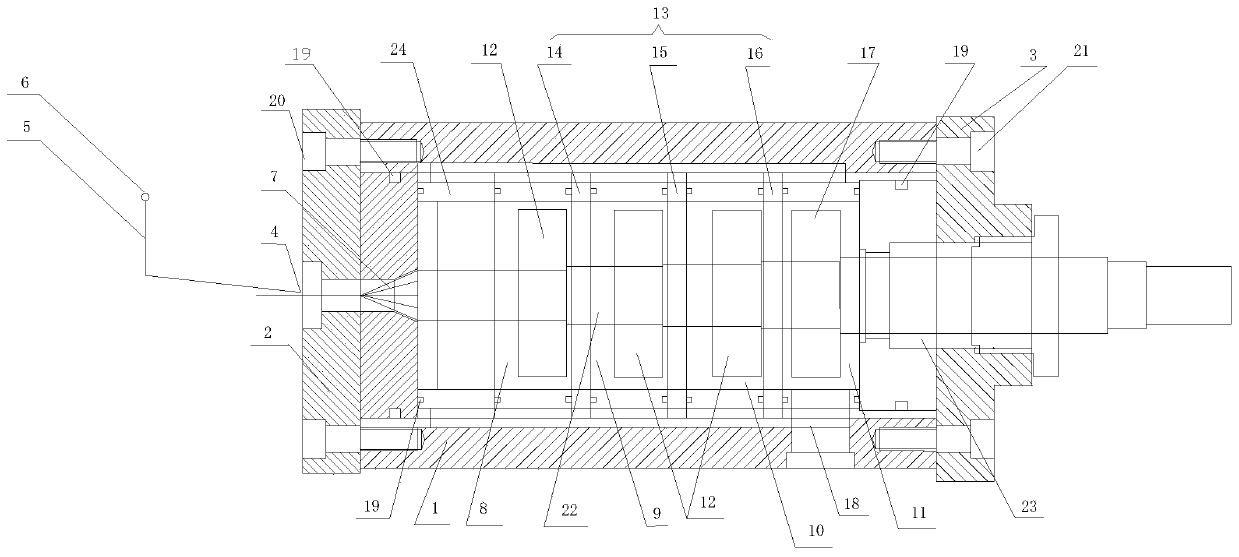

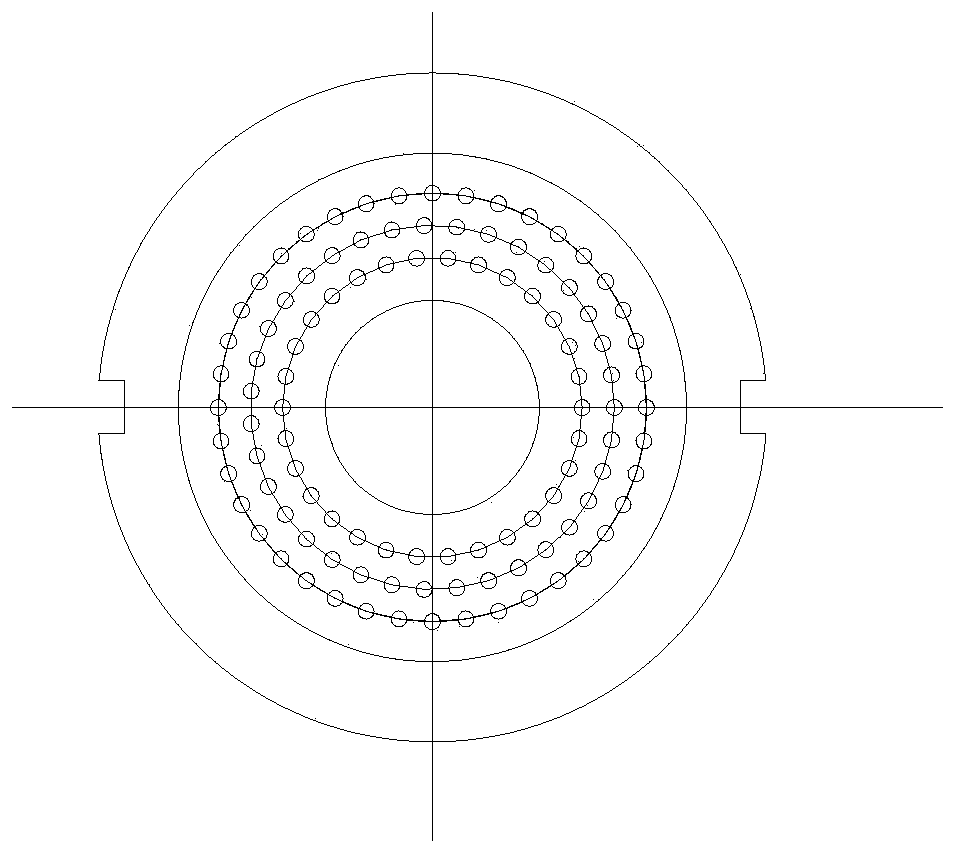

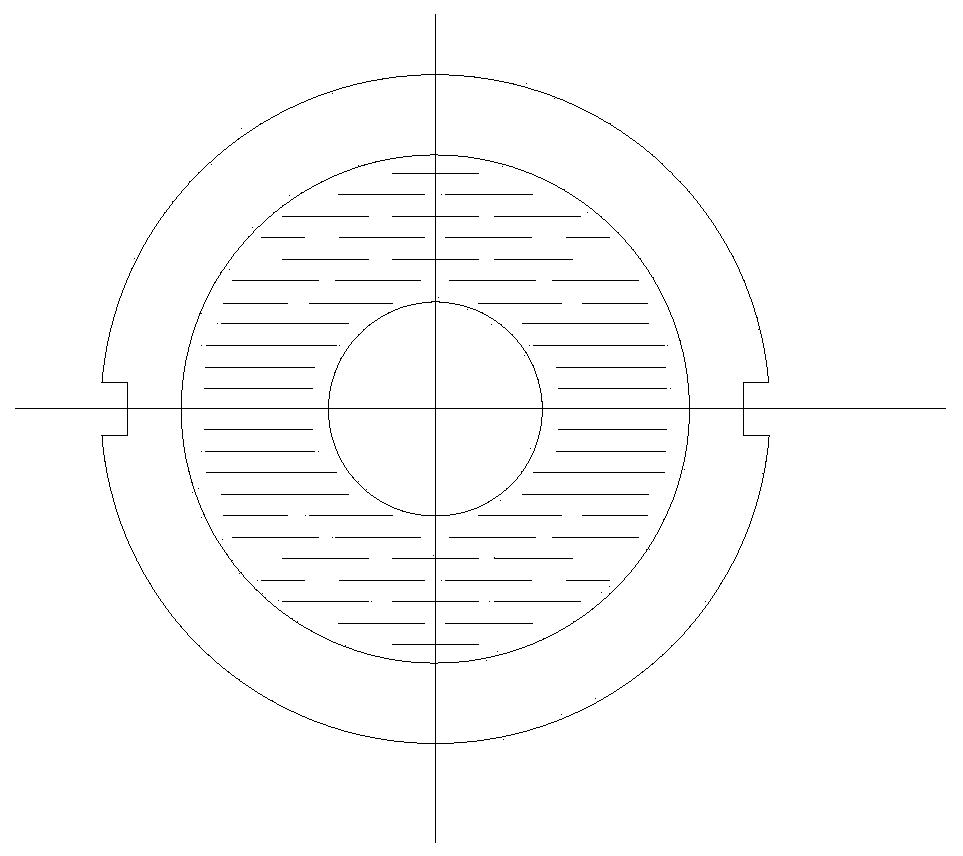

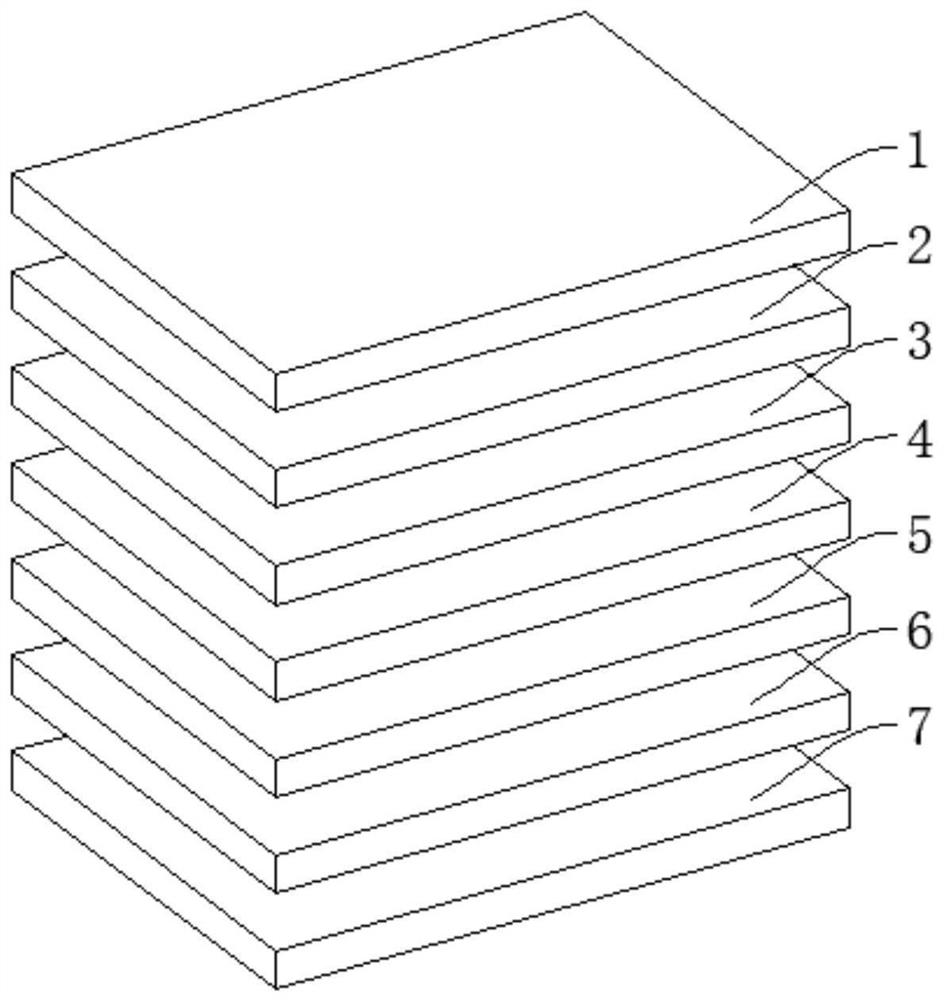

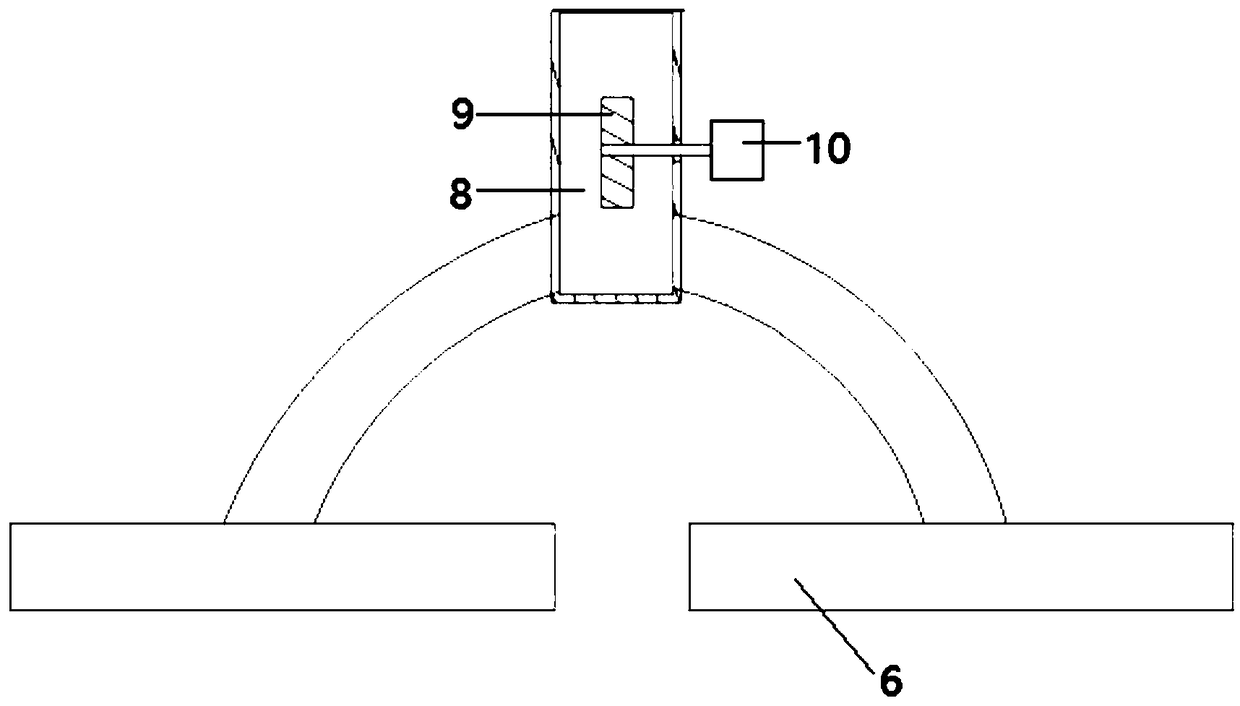

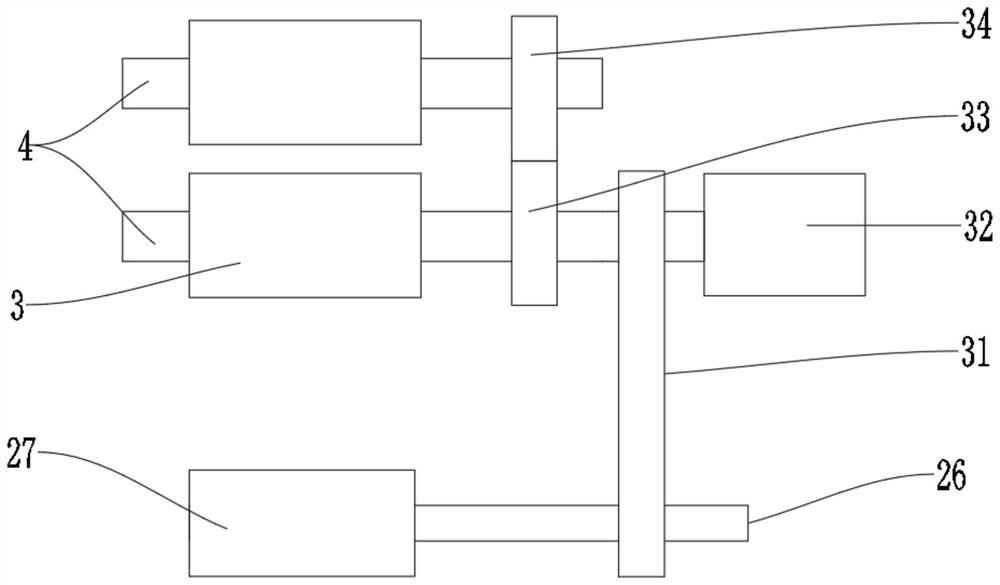

Self-balancing rotating grill structure and oven with same

PendingCN109984634AUniform coloringFood taste goodRoasting apparatusRoasters/grillsDrive motorEngineering

The invention relates to a self-balancing rotating grill structure. The structure comprises grills, rotating bases, a driving motor and gear sets; each gear set comprises a first gear, a second gear and an even number of transmission gears arranged between the first gear and the second gear, the rotating bases and the first gears can be driven by the driving motor to synchronously rotate, each first gear is in transmission with the corresponding second gear through the corresponding transmission gear, the grills are fixedly provided with rotating shafts, and the rotating shafts are connected with the rotating bases and penetrate through central holes of the second gears. According to the structure, the grills can automatically rotate and turn over, the distance and angle between food on the grills and a heat source can be changed accordingly, and therefore the food on the grills can be uniformly heated; the processed food is uniformly colored, grease and moisture are fully discharged,the taste of the food is good, and it can be ensured that the grills are kept in a horizontal state in the rotating state and prevented from rollover.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

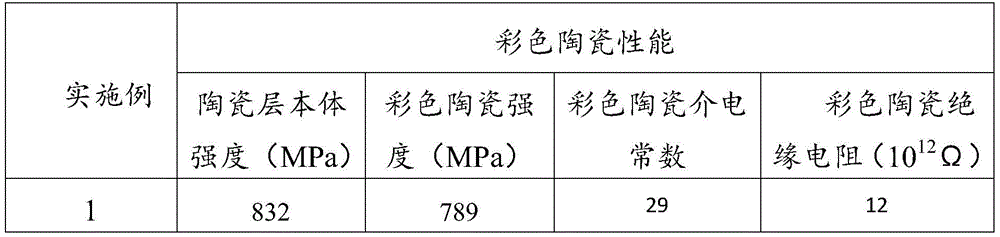

Dyeing slurry for preparing color ceramics

The invention discloses dyeing slurry for preparing color ceramics. The dyeing slurry is prepared from the following ingredients in parts by weight: 0.01 to 80 parts of pigments, 5 to 95 parts of glass powder, 1 to 30 parts of bonding agents, 0.1 to 5 parts of dispersing agents, 1 to 5 parts of plasticizers and 10 to 80 parts of organic solvents. The dyeing slurry for preparing color ceramics has the advantages that during the preparation of color ceramics, the dyeing slurry can be directly coated on a ceramic base plate; through sintering, polishing and the like, a dyeing layer with uniform and adjustable color is formed on the ceramic base plate, so that the color ceramics prepared from the dyeing slurry has the advantages that the color fading cannot easily occur; the coloring is uniform; the color precision is high; the color is adjustable; the surface mirror surface is smooth; the intensity of the ceramic body cannot be influenced, and the like.

Owner:CHAOZHOU THREE CIRCLE GRP

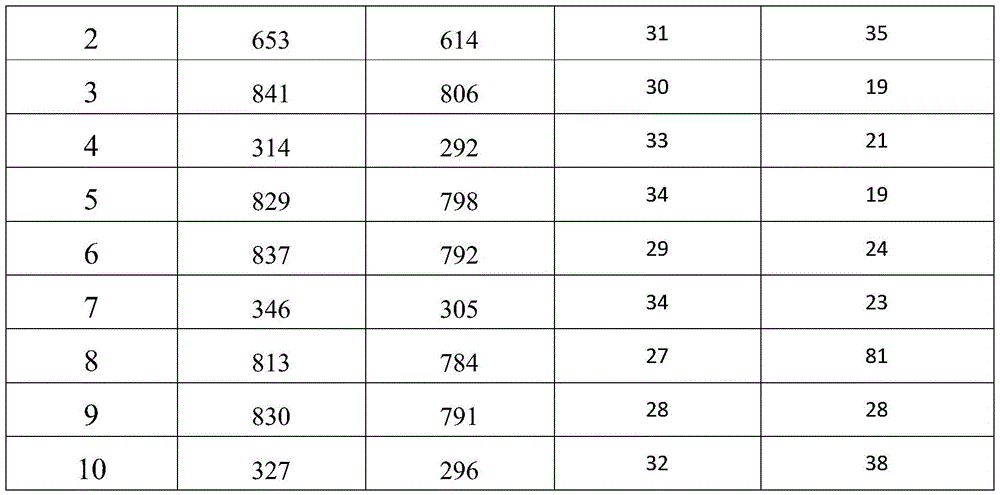

Painting agent for promoting grape ripening and color enhancing

InactiveCN108522541AFast actingUniform coloringBiocidePlant growth regulatorsPhytosulfokineVitis vinifera

The invention relates to a painting agent for promoting grape ripening and color enhancing. The painting agent is prepared from the materials in weight percentage: 1% to 10% of ethephon, 0.001 to 0.5%of systemin, 0.1% to 2% of phytosulfokine, 0.1% to 0.5% of synergist, 15% to 25% of curing agent, 8% to 30% of thickening agent, 0.5 to 2% of wetting agent and the balance of filler. The painting agent disclosed by the invention can promote grape ripening and color enhancing through a mode of painting grape spike carpopodium, has an excellent color enhancing effect, reduces pesticide residues infruits, has no any effect on grape fruit powder and meanwhile can obviously increase yield.

Owner:SICHUAN LANYUE SCI & TECH

High-dispersity black polyethylene color master batch

The invention discloses a high-dispersity black polyethylene color master batch which is composed of the following components in parts by weight: 35 parts of carbon black, 43 parts of polyethylene, 20 parts of calcium carbonate, 1 part of zinc stearate and 1 part of stearic acid. The high-dispersity black polyethylene color master batch has favorable dispersity, can be applied to a flow casting or film spraying technique, and can also be applied to foamed products. When being applied to the flow casting or film spraying technique, the color master batch has the advantages of high dispersity and favorable color developing property, so that the film product is blacker and has favorable glossiness, thereby lowering the production of defectives. When the color master batch is applied to the foamed products, the foaming products have the advantages of no toner spot hole and uniform color darkness.

Owner:苏州清丰兴业塑胶有限公司

Novel double color offset printing machine

InactiveCN104401109ASmall misalignmentUniform coloringRotary lithographic machinesEngineeringCoating

The invention discloses a novel double color offset printing machine. The novel double color offset printing machine comprises a machine frame, a first offset printing wheel, a second offset printing wheel, a middle wheel, a coating wheel, a coloring device and a material box, wherein the middle wheel is arranged at one end of the machine frame, the first offset printing wheel is arranged right above the middle wheel, the second offset printing wheel is arranged right below the middle wheel, the coating wheel is tightly attached to the bottom of the second offset printing wheel, the material box is arranged below the coating wheel, and the coloring device is arranged above one side of the first offset printing wheel. By adopting the mode, the novel double color offset printing machine has the advantages of being high in reliability, accurate in positioning, compact in structure, high in printing speed, accurate in aligning, simple to operate, long in life, good in adaptability and the like, and simultaneously has a wide market prospect on the printing market.

Owner:常熟印刷厂有限公司

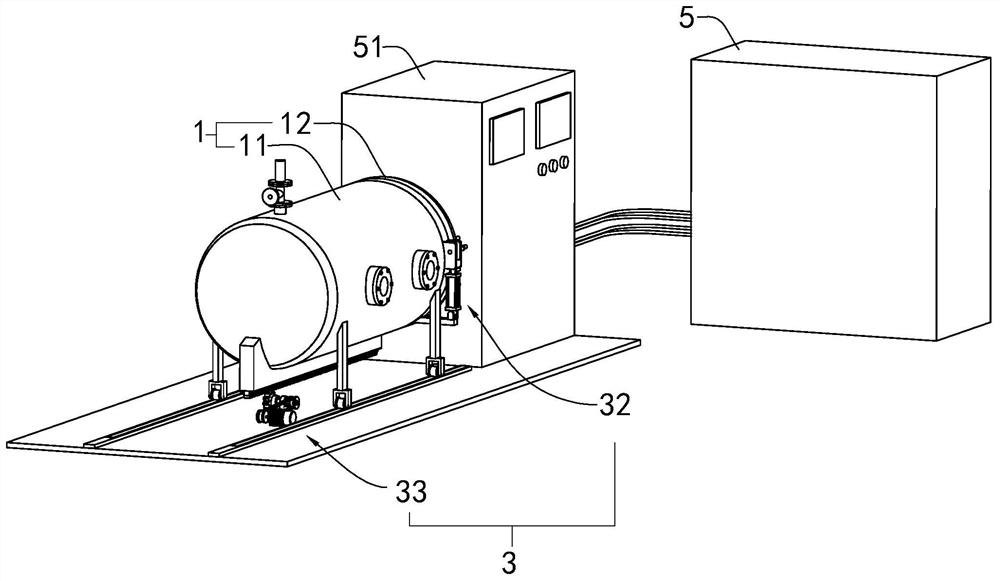

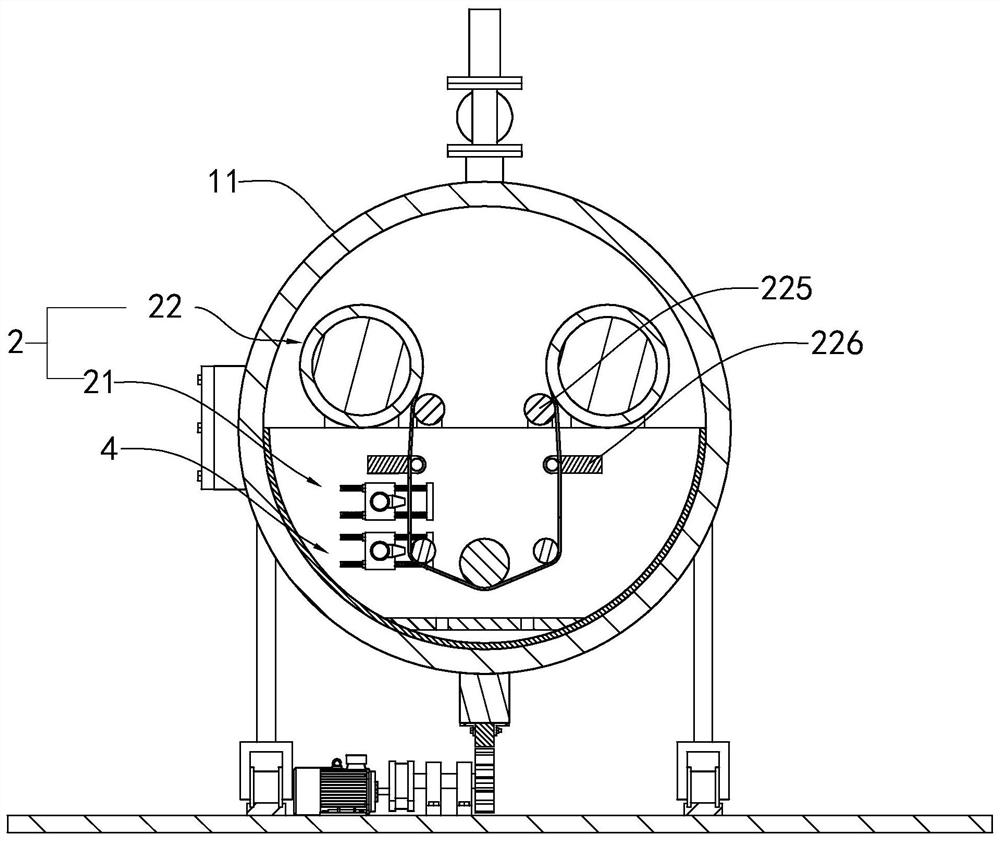

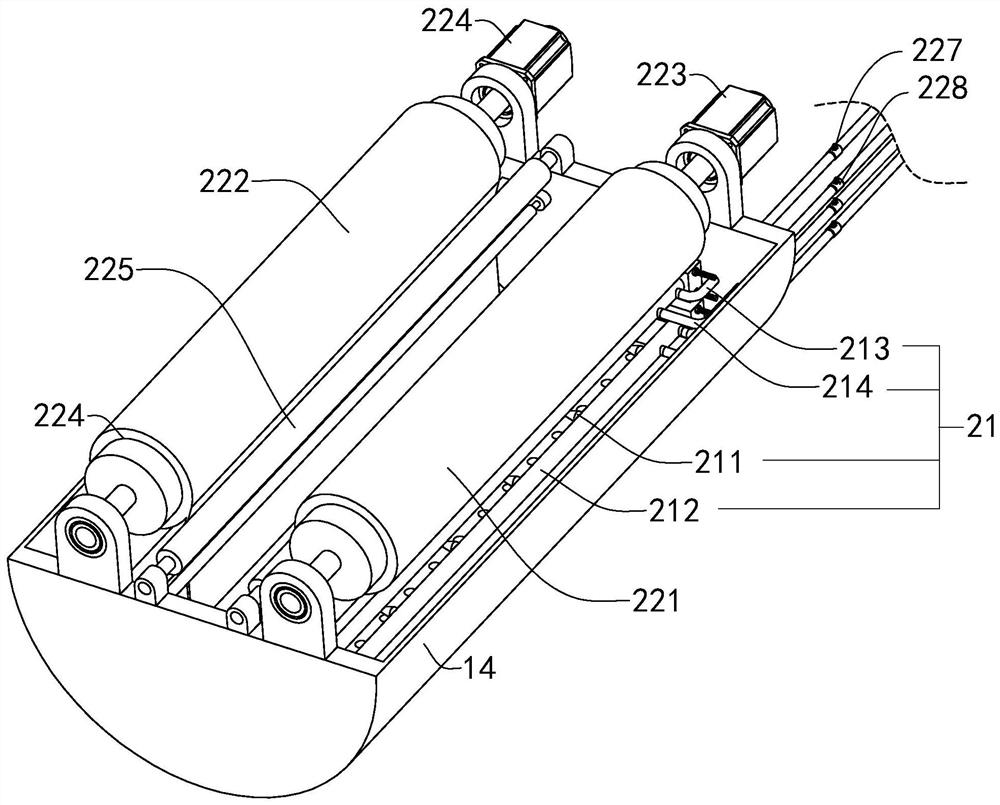

Numerical control type dyeing and finishing equipment

PendingCN113914039AUniform coloringShorten dyeing timeLiquid/gas/vapor open-width material treatmentTextile treatment containersProcess engineeringDyeing

The invention discloses numerical control type dyeing and finishing equipment. The numerical control type dyeing and finishing equipment comprises a dyeing vat, the dyeing vat comprises a vat body and a vat cover, a dyeing device used for dyeing cloth is arranged in the dyeing vat, a numerical control device is arranged on one side of the dyeing vat, and the dyeing device comprises a steam medium dyeing mechanism and a conveying mechanism used for conveying the cloth. The steam medium dyeing mechanism comprises a plurality of digital sprayers and a dyeing pipe arranged below a feeding roller, the multiple digital sprayers are arranged on the dyeing pipe at intervals, and the numerical control device controls the steam medium dyeing mechanism. The multiple digital sprayers are arranged on the steam medium dyeing mechanism, the digital sprayers are controlled by the numerical control device to discharge liquid, the cloth is dyed in a vapor-liquid spraying mode, the problem that the dyed cloth has various color differences can be solved as much as possible, the effect of uniformly dyeing the cloth is achieved, and compared with a traditional dyeing mode, water, electricity and steam resources can be effectively saved.

Owner:刘政

COLOUR ISTGURU glamor gloss lipstick and production method thereof

InactiveCN109908012ASilky touchUniform coloringCosmetic preparationsMake-upOCTYLDODECANOLShea butter

The invention relates to COLOUR ISTGURU glamor gloss lipstick, prepared from, by weight, a component A, a component B and a component C, a component D and a component E, wherein the component A includes 2-6 parts of dibutyl lauroyl glutamide, 2-6 parts of dibutyl ethylhexanoyl glutamide, 10-22 parts of tridecyl trimellitate, 4-10 parts of diisostearyl malate, 10-20 parts of isooctyl palmitate, 5-20 parts of hydrogenated C6-C20 polyolefin, and 5-12 parts of octyldodecanol; the component B includes 20-40 parts of alkyl benzoate and 0.05-0.15 part of variable color powder; the component C includes 0.5-4.5 parts of hydrogenated castor oil; the component D includes 0.05-0.15 part of hydrogenated shea butter, 0.05-0.15 part of olive oil, and 0.05-0.15 part of meadowfoam seed oil; the component Eincludes 1-1.5 parts of a pigment. The invention also discloses a production method of the COLOUR ISTGURU glamor gloss lipstick. The COLOUR ISTGURU glamor gloss lipstick is made with unique color combination according to the principle of human body PH-responding color variation, has black appearance but displays red after being applied, and provides lasting full coat; with the shea butter, oliveoil and meadowfoam seed oil, the COLOUR ISTGURU glamor gloss lipstick enables the lips to be nourished and protected for long time.

Owner:广州尚庄化妆品有限公司

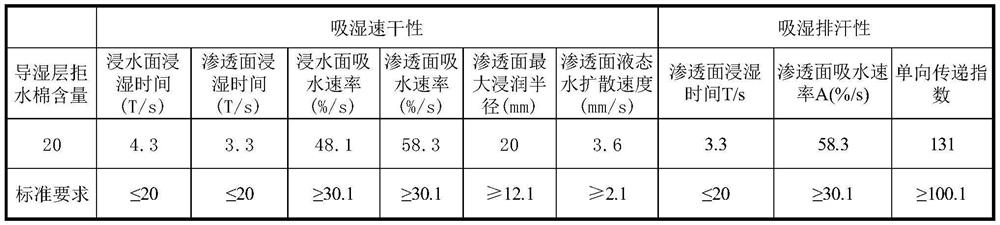

One-way moisture-conducting blank-dyed fabric

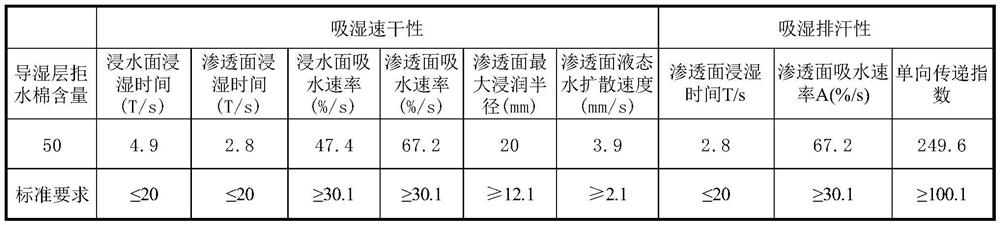

PendingCN113215714ALow costUniform coloringWeft knittingLiquid repellent fibresWoven fabricMoisture transfer

The invention provides a one-way moisture-conducting blank-dyed fabric. The one-way moisture-conducting blank-dyed fabric is of a double-layer structure; an inner layer and an outer layer have the difference of hydrophilicity and hydrophobicity; the outer layer is a hydrophilic layer formed by hydrophilic yarn; the inner layer is a moisture conducting layer formed by hydrophobic yarn; and the outer layer and the inner layer are connected through fabric weave points. The one-way moisture-conducting blank-dyed fabric is obvious in moisture-absorbing and sweat-releasing effects, soft and comfortable in hand feeling and skin-friendly and breathable to wear, still has relatively good one-way moisture-conducting performance after being washed for multiple times, and meets the moisture-absorbing and sweat-releasing requirements of a dynamic moisture transfer method in a second part of GB / T21655.2-2019 evaluation of moisture absorption and quick drying of textiles.

Owner:ZHEJIANG HUAFU COLOR TEXTILE

Strawberry planting method

The invention relates to a strawberry planting method. The strawberry planting method is characterized in that 1 strong seedlings are cultured, wherein culture is generated performed at the end of March and at the beginning of the April; 2, soil testing and fertilization are performed, deep ploughing and flat raking are performed, and even stirring is performed; 3, rectangular pieces are finely made, and water absorption is performed for saturation; 4, detoxified strawberry seedlings are tissue-cultured; 5, transplantation is performed at the end of August and at the beginning of September; 6, dripping pipes are laid on October, a mulching film and a greenhouse film are put on, and greenhouse temperature is controlled, wherein the temperature in a squaring period is 25-28 DEG C, the temperature in a flowering and fruiting period is 24-26 DEG C, and the temperature at night is no lower than 5 DEG C; 7, reasonable topdressing is performed, and bees are put at the beginning of initial flowering for pollen spreading; 8, rice chaff is put in soil for fermentation, and diseases and insect pests are prevented and controlled; 9, 80-90% of strawberry fruits are picked when being red. The strawberry planting method is reasonable and scientific, a prevention and control effect during strawberry planting is remarkable, and the strawberry yield is increased.

Owner:罗田县万家丰农机专业合作社

Green under-liquid special anti-quenching quartz glass tube

A green under-liquid special anti-quenching quartz glass tube is disclosed. In production of high purity quartz sands of a quartz glass tube, with the weight of the high purity quartz sands as basic parts by weight, raw materials are added in parts by weight as follows: 0.1-0.8 / 1000 of cupric oxide, 0.001-0.01 / 1000 of sodium chloride, 0.001-0.03 / 1000 of ferric oxide, 0.001-0.03 / 1000 of potassium nitrate, 0.01-0.05 / 1000 of europium oxide, 0.001-0.05 / 1000 of aluminum oxide and 0.1-0.8 / 1000 of chromic oxide or potassium dichromate. The raw materials adequately mixed with the high purity quartz sands enter into a furnace to smelt and then are drawn to required quartz glass tubes. The green under-liquid special anti-quenching quartz glass tube drawn and molded by the preparation process of integrally coloring the tube wall is uniform in integral coloring of the tube wall, is free from explosion and has high strength. The green under-liquid special anti-quenching quartz glass tube is a super strength anti-quenching quartz glass tube special for underwater or under-liquid lighting appliances.

Owner:JIANGSU SHENGDA QUARTZ PROD CO LTD

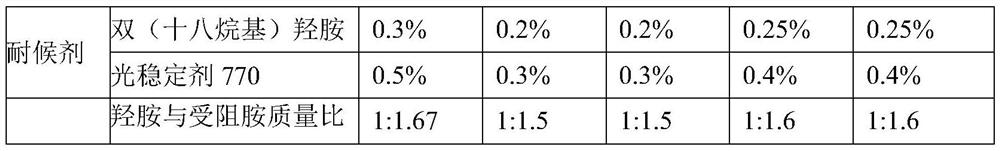

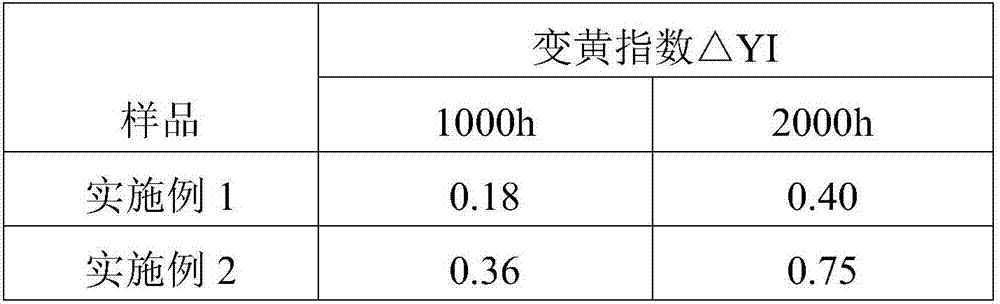

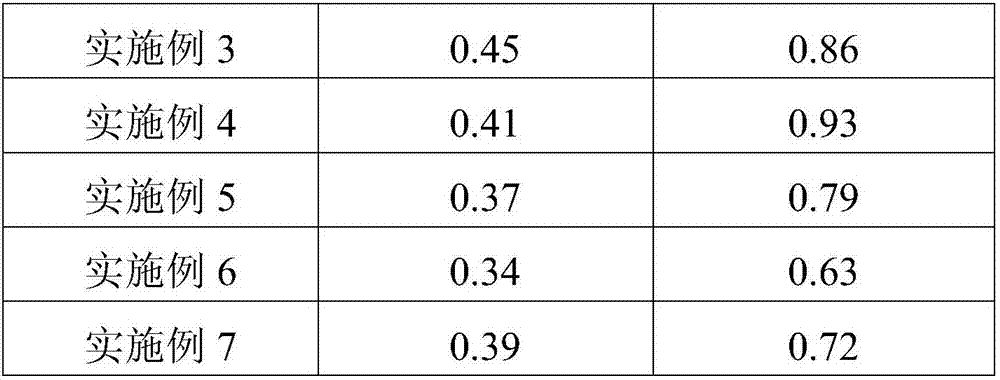

Film-grade polypropylene coloring master batch and preparation method thereof

The invention discloses a film-grade polypropylene coloring master batch, which is prepared from the following main raw material components in percentage by mass: 28 to 43 percent of isotactic homo-polypropylene, 55 to 70 percent of inorganic pigment, 0.2 to 1.05 percent of dispersing agent and 0.5 to 1.8 percent of weather-resistant agent. The content of the coloring pigment in the formula system of the film-grade polypropylene coloring master batch is high, but the coloring pigment is well dispersed in the film-grade polypropylene coloring master batch, the coloring is uniform, and the color difference is low; the whiteness, the color difference value, the weather resistance and the moisture content of the film-grade polypropylene coloring master batch all meet the product standards of the film-grade polypropylene coloring master batch. The invention further discloses a preparation method of the film-grade polypropylene coloring master batch, continuous mixing and extrusion operation of a double-rotor continuous mixing mill is adopted, the technological process is simple, the production cost is low, and the preparation method is suitable for batch production.

Owner:江阴市得宝新材料科技有限公司

ABS color master batch

The invention discloses ABS color master batch. The ABS color master batch is prepared from the following raw materials in parts by weight: 48 to 52 parts of an ethylene-acrylic acid copolymer, 6 to 12 parts of pigment, 6 to 12 parts of polyacrylamide, 0.2 to 0.8 part of N-phenyl-N'-cyclohexyl-p-phenylenediamine, 1 to 3 parts of di-2-ethylhexyl maleate, 2 to 4 parts of antibacterial agent and 2 to 4 parts of ultraviolet absorbent. The ABS color master batch provided by the invention has good dispersity in an ABS product and uniform coloring, solves the problems that the cost of common color master batch in market for realizing weather resistance, acid resistance, hot resistance, cold resistance is high. In addition, the ultraviolet absorbent and the antibacterial agent are added simultaneously, so that the service life of the ABS product is prolonged and the safety of the ABS product is greatly improved.

Owner:雄子(上海)新材料科技有限公司

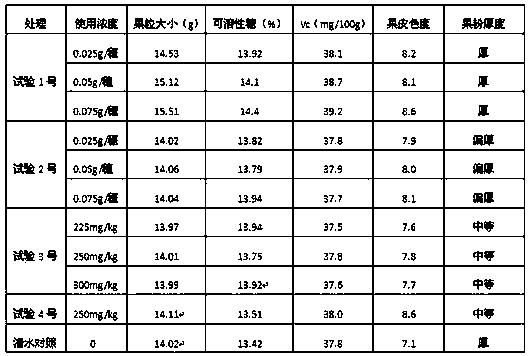

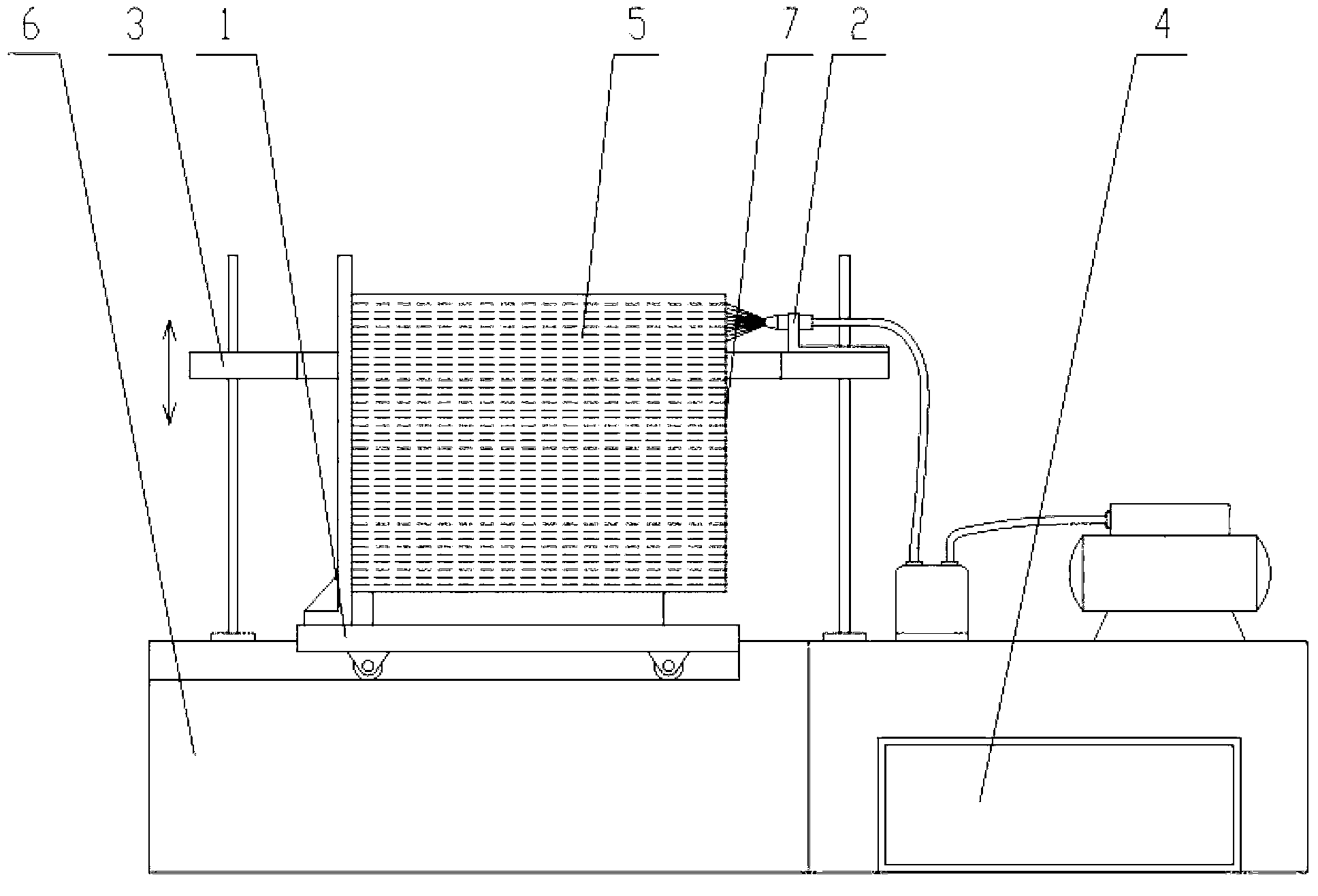

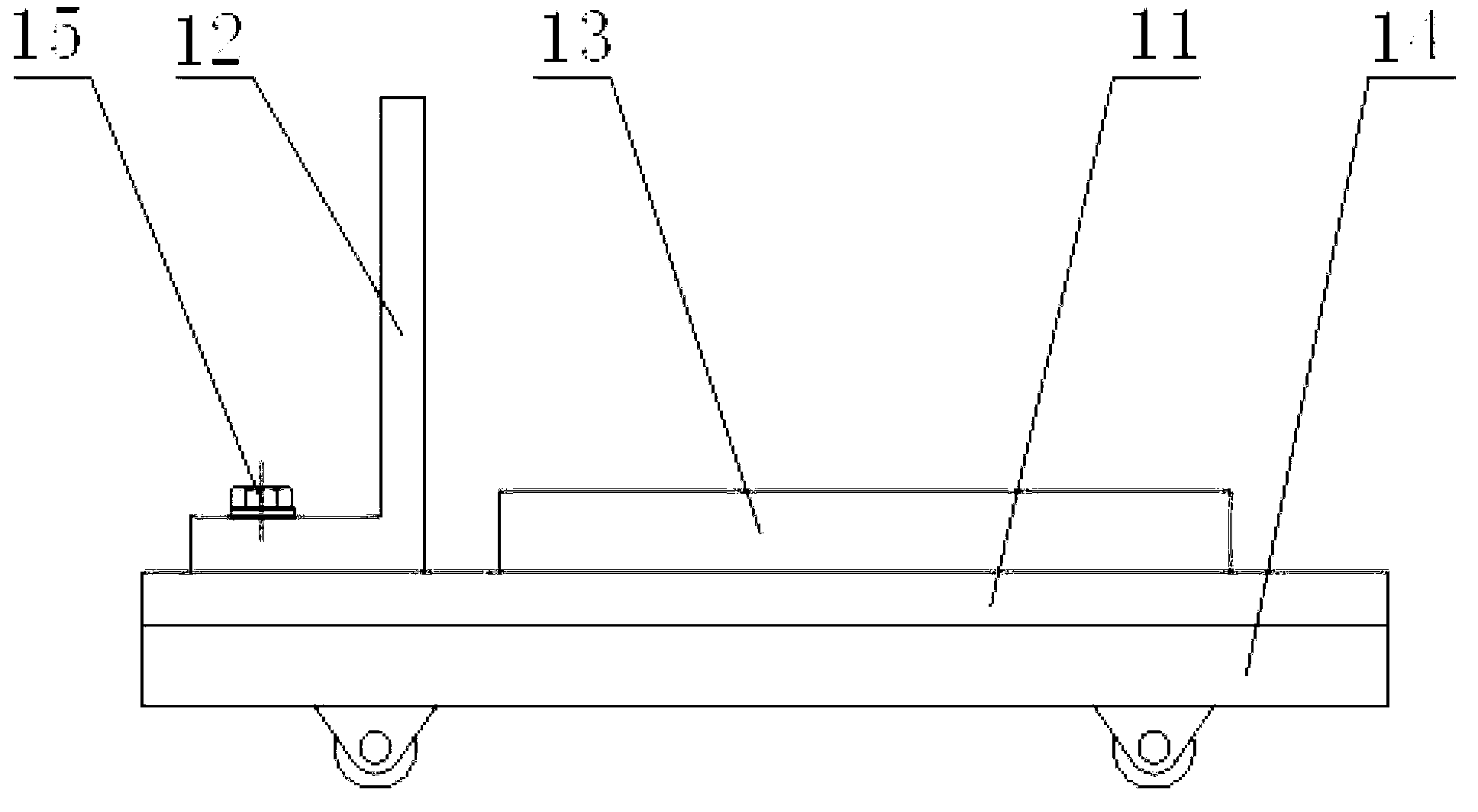

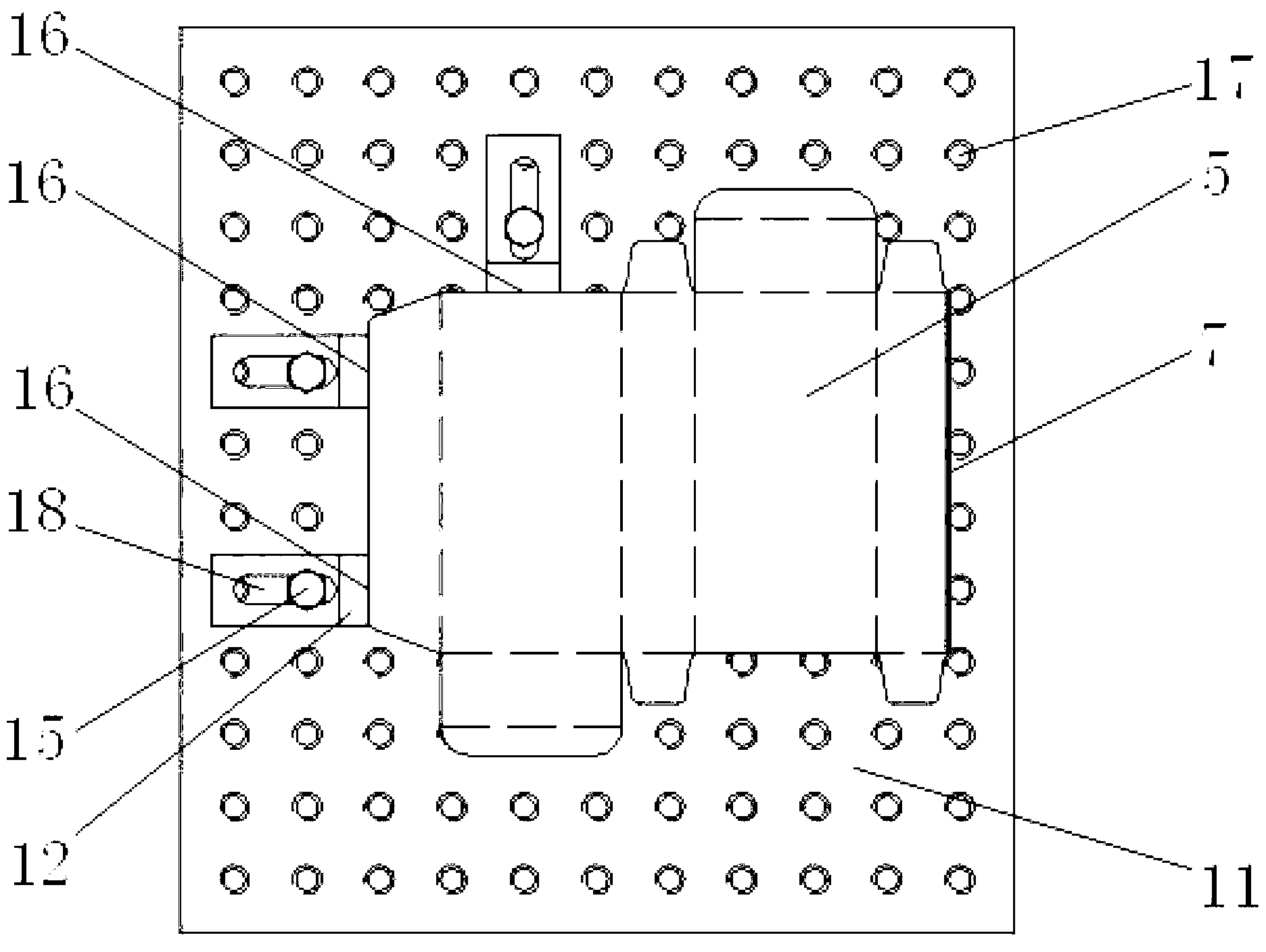

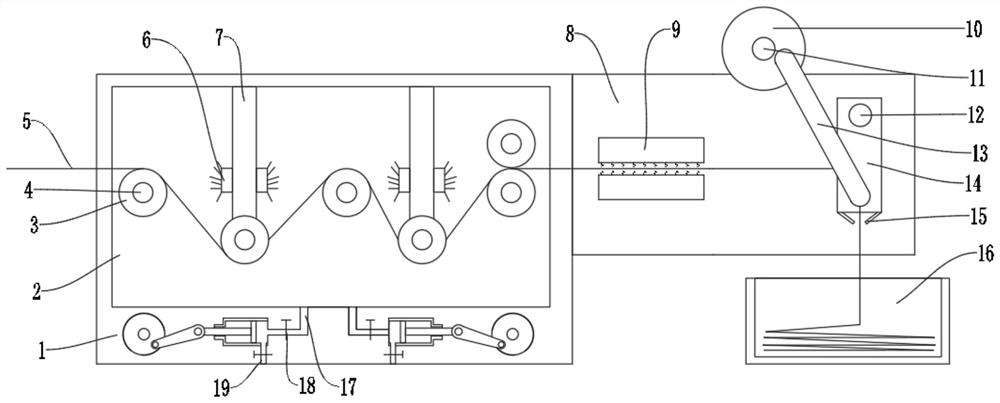

Trimming and coloring device of paper box piece die

InactiveCN103252922ASimple structureUniform coloringContainer making machineryDriven elementPrinting ink

The invention discloses a trimming and coloring device of a paper box piece die. The trimming and coloring device of the paper box piece die comprises a machine base, a stacking device, an ink-jetting device, a lifting device and a control system. The ink-jetting device comprises a nozzle, a nozzle support, a printing ink delivery pipe, a printing ink storage and an air compressor. The lifting device comprises a lifting table, a turn-screw, a lifting guide rail and a driving element. The nozzle is installed on the lifting table. The stacking device comprises a stacking pallet, a locating pallet, a locating support and a backing plate. Box pieces are stacked on the backing plate, the nozzle is directed at a box piece die to be colored of the box pieces for trimming, and the lifting device and the ink-jetting device are controlled by the control system. The trimming and coloring device of the paper box piece die has the advantages of being simple in structure, even in coloring, convenient to use, high in efficiency, and capable of achieving automatic production of trimming and coloring of the paper box piece die.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

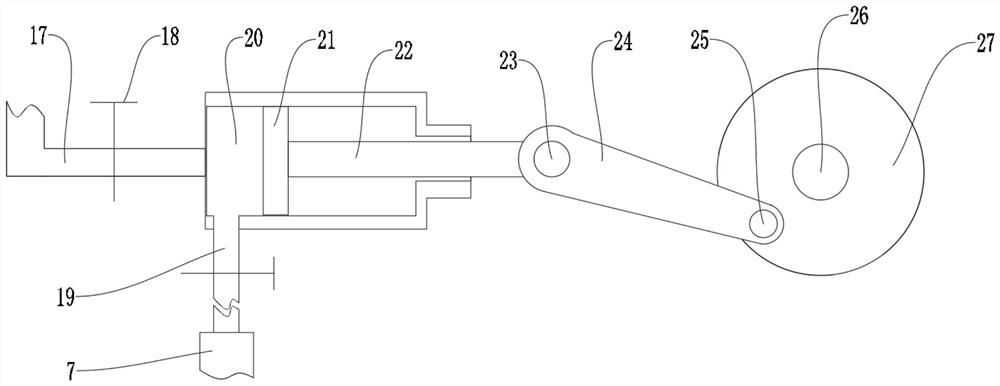

Method for coloring collagen

InactiveCN110354743AUniform coloringImprove quality and stabilityRotary stirring mixersTransportation and packagingCombingContamination

The invention discloses a method for coloring collagen. The method comprises the following steps of: (1) combining collagen with a pigment at first; (2) then dispersing the collagen bonded with the pigment into pigment-collagen pellets via a collagen dispersion disc; (3) subjecting the pigment-collagen pellets to primary stirring and then to primary combing with a first-stage orifice plate; (4) subjecting the pigment-collagen pellets to secondary stirring and then to secondary combing with a second-stage orifice plate; and (5) subjecting the pigment-collagen pellets to tertiary stirring and then to tertiary combing with a third-stage orifice plate so as to obtain uniformly mixed pigment collagen. The method of the invention can ensure uniform coloration of collagen and reduce cross-contamination of the product.

Owner:GUANGXI SHENGUAN COLLAGEN BIOLOGICAL GRP CO LTD

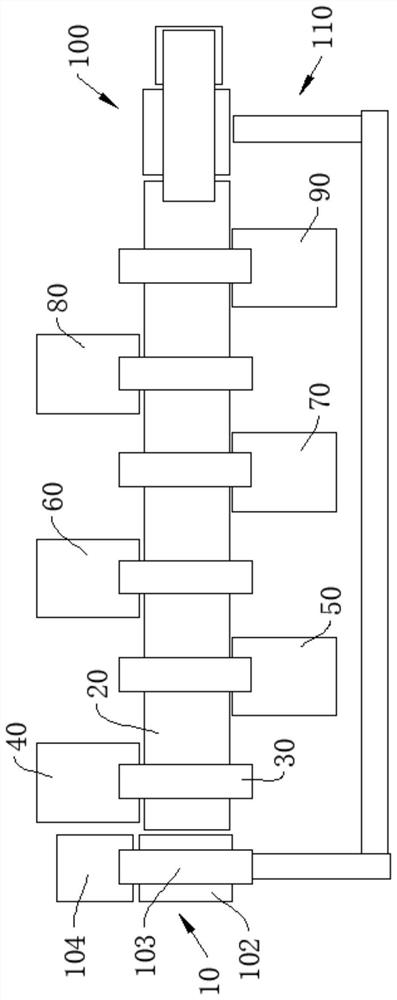

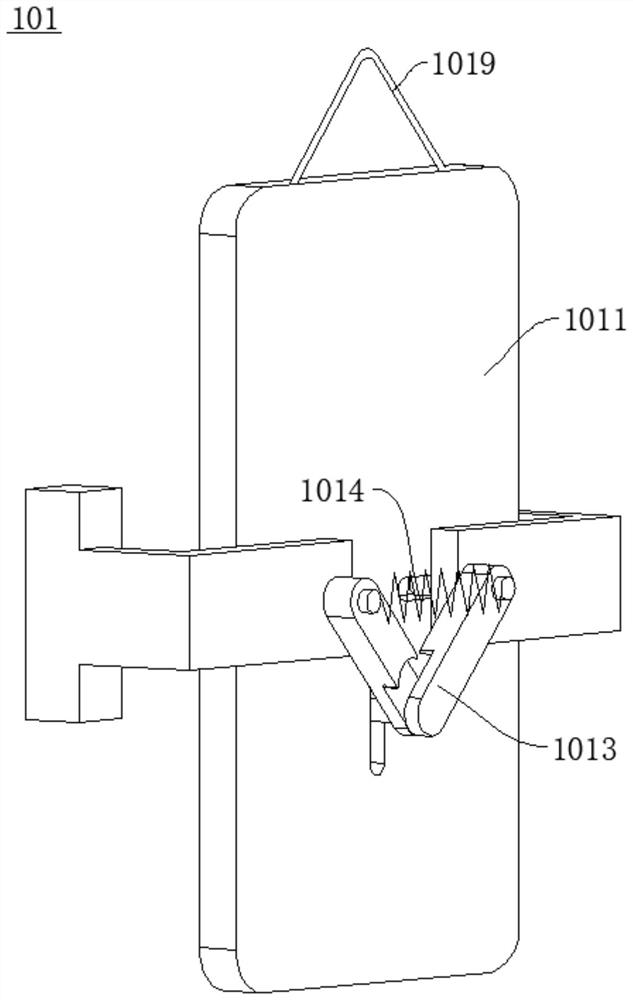

Noctilucent mobile phone backboard production line equipment

PendingCN113746964AIncrease productivityUniform coloringRotary pressesCoatingsManufacturing engineeringElectrical and Electronics engineering

The invention relates to noctilucent mobile phone backboard production line equipment which comprises a clamp assembly machine, a clamp transporter, a clamp taking and placing machine, a Logo printing machine, a plane transfer printing machine, a vacuum coating machine, an ink printing machine, a vacuum high-pressure machine, a clamp disassembling machine, a clamp recycling machine and a cover plate strengthening device. A clamp is arranged in the clamp assembly machine; the clamp assembly machine is used for loading the plate into a clamp; the clamp transporter transports the clamp to pass through the Logo printing machine, the plane transfer printing machine, the vacuum coating machine and the ink printing machine in sequence to form a semi-finished backboard product; the semi-finished backboard product is separated from the clamp through a clamp disassembling machine; and the clamp recycling machine transports the clamp back to the clamp assembly machine. According to the noctilucent mobile phone backboard production line equipment, full-automatic production of the mobile phone backboard can be achieved, the production efficiency can be improved, the mobile phone backboard produced through the noctilucent mobile phone backboard production line equipment can emit noctilucent light in the dark or in the dark, and the mobile phone backboard is provided with a gradient color layer through the process that gradient color is achieved through dip dyeing.

Owner:SHENZHEN ATES SCI & TECH CO LTD

Method for preparing forest tree seed pelleting coatings

InactiveCN105409386AFlat surfaceUniform coloringSeed coating/dressingSodium carboxymethylcelluloseAmygdalus persica

The invention relates to the field of forest tree seed culturing, in particular to a method for preparing forest tree seed pelleting coatings. An adhesive directly serves as liquid, and the amount and the concentration of the added liquid, the liquid-powder ratio, the liquid-powder adding interval, the amount of the liquid added during last-time curing and curing time are controlled. The method has the advantages that in a traditional method, an adhesive is only added once and is added in the beginning, and liquid added in several times of following pelleting is water; in the method, the adhesive serves as the liquid and is used all the time in the whole process; compared with the traditional coating method, the liquid with the adhesive (a peach gum and sodium carboxymethylcellulose solution) and powder are added at the same time, and the liquid-powder ratio, the concentration of the liquid, the once adding amount, the interval, the rotating speed of a pelleting coating device and the like are strictly controlled; by means of the preparing method, the pelleting coatings can be smooth in surface, even in coloring and not prone to breakage.

Owner:HEBEI ACAD OF FORESTRY SCI

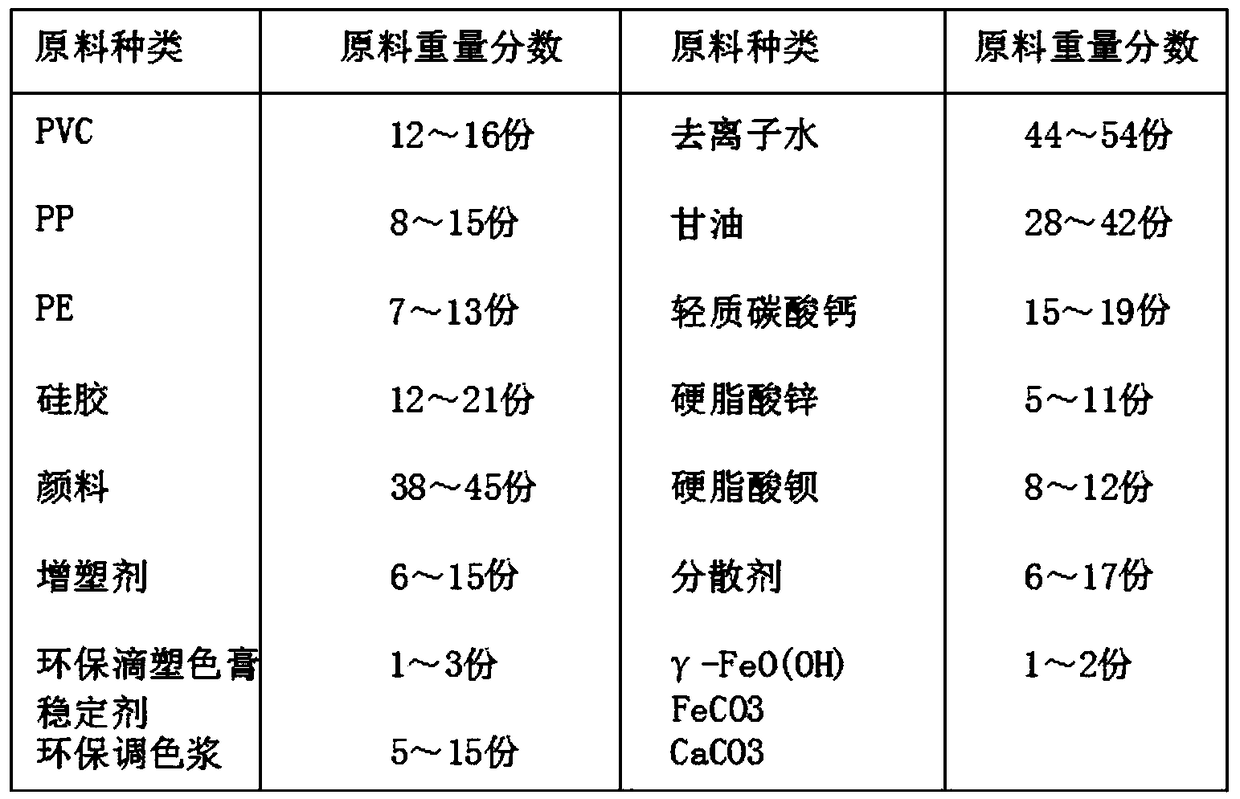

Environmental protection micro injection color paste

The invention relates to an environmental protection micro injection color paste. The environmental protection micro injection color paste comprises 12 to 16 parts of PVC, 8 to 15 parts of PP, 7 to 13parts of PE, 12 to 21 parts of silica gel, 38 to 45 parts of a pigment, 6 to 15 parts of a plasticizer, 44 to 54 parts of deionized water, 28 to 42 parts of glycerin, 15 to 19 parts of light calciumcarbonate, 5 to 11 parts of zinc stearate, 8 to 12 parts of barium stearate, and 6 to 17 parts of a dispersant. Novel materials are added into an obtained base material, and dispersion grinding is carried out so as to obtain the environmental protection micro injection color paste. The environmental protection micro injection color paste is prepared from the novel environment-friendly materials ata scientific and reasonable ratio, the common environment-friendly safe raw materials are adopted in the formula, so that the obtained environmental protection micro injection color paste is high insafety, uniform in coloring, low in manufacturing cost, and excellent in application potential, is convenient to use, is economical, is green, is friendly to the environment; pollution is low; polycyclic aromatic hydrocarbon detection standards are achieved; no polycyclic aromatic hydrocarbon is detected; and environment protection safety requirements are satisfied.

Owner:广德粤华塑业制品有限公司

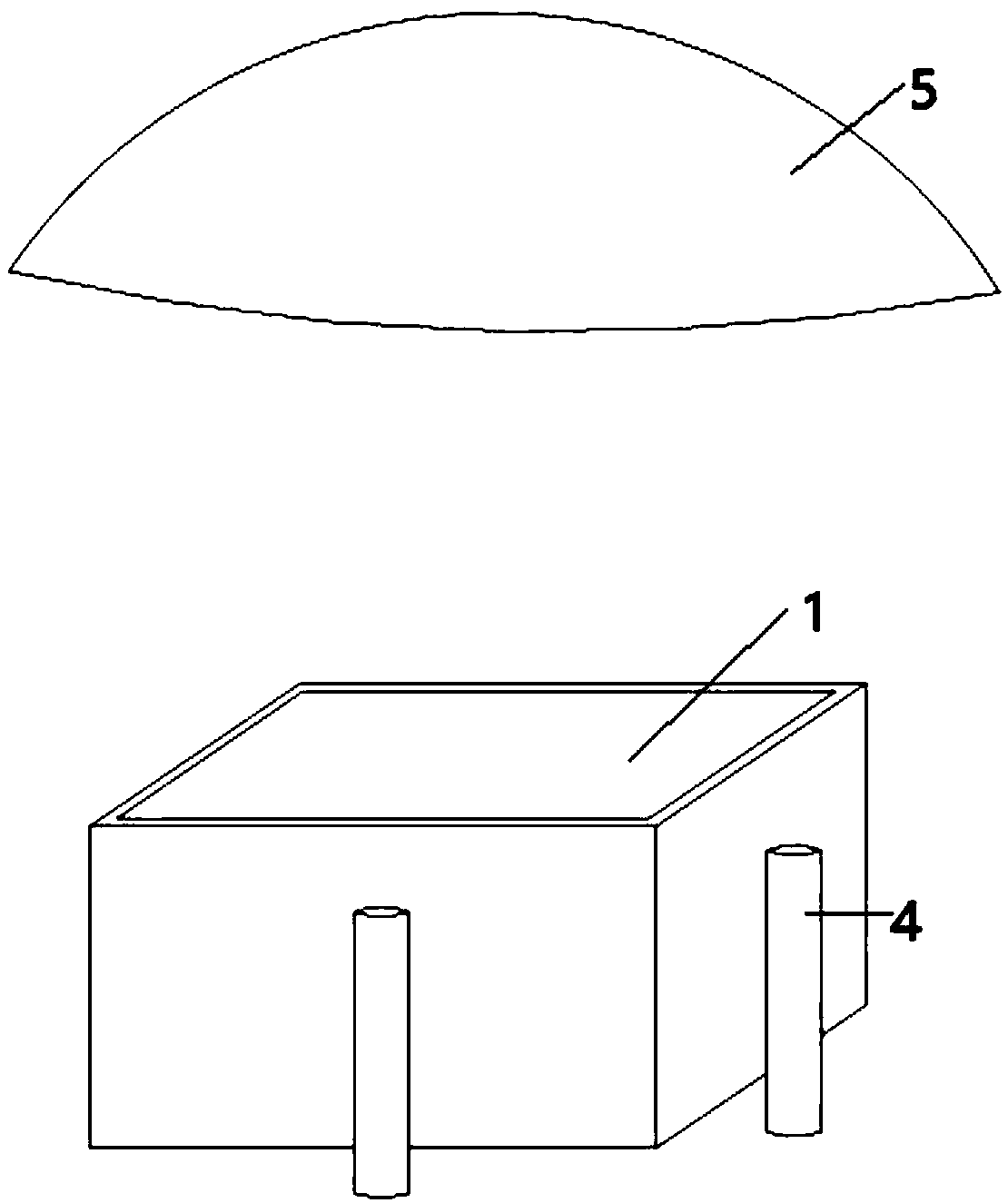

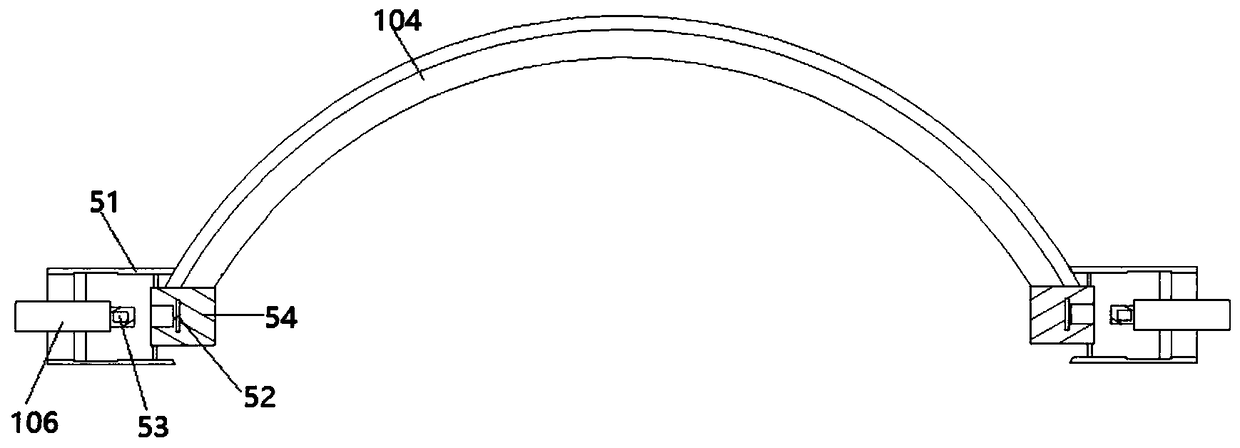

Thread dyeing device and method uniform in coloring

ActiveCN109371617AAvoid corrosionUniform coloringTextile treatment containersTextile treatment machine arrangementsElectromagnetic valveMarine engineering

The invention discloses a thread dyeing device and method uniform in coloring. The device comprises a pool body with an opening in the upper end, a conical groove in the lower portion of the center ofthe pool body, an elastic plate arranged at the bottom of the pool body, an air bag, a heating device on the pool body, a plurality of illuminating lamps on the outer side of the pool body, and an upward-arched concave mirror above the pool body, wherein the air bag is arranged in the conical groove and can vertically stretch; the cross section of the conical groove is gradually reduced from topto bottom, and the air bag is connected with an inflation pump; a first electromagnetic valve is arranged on the air bag. The device has the advantages that coloring is uniform, and the lamps are notlikely to be corroded by steam.

Owner:安徽省脉思图内衣科技有限公司

Method for shortening dyeing time during application of lanasol dye to cashmere non-red dyeing

The invention discloses a method for shortening dyeing time during application of lanasol dye to cashmere non-red dyeing, and relates to a dyeing method. The method comprises 6-10 steps according to different dye materials. Compared with the prior art, the method has the advantages that novel fatty amine modified polyoxyethylene ether anionic and nonionic surfactant dyeing auxiliaries are adopted, so that the operation time when the dye auxiliaries are added is shortened, the heat preservation time during dyeing post-treatment and the hot washing frequency during post-treatment are shortened and reduced, the production efficiency is greatly improved, the cost is saved, the production concept of energy conservation, emission reduction, quality improvement and efficiency improvement is met, and the product quality and the production delivery time are guaranteed.

Owner:宁波康赛妮新纤维科技有限公司

Textile fabric dyeing equipment

InactiveCN112281342AUniform coloringOptimize the overall structureHeating/cooling textile fabricsTextile treatment by spraying/projectingElectric machineryWoven fabric

The invention discloses textile fabric dyeing equipment, and relates to the relatively large-range field. The equipment comprises a dyeing pool; a plurality of conveying mechanisms are arranged in thedyeing pool in an up-down staggered mode; each conveying mechanism comprises a transmission connecting rod and a conveying hub; the conveying hubs are used for conveying a fabric body and are connected with the output end of a motor through the transmission connecting rods; the transmission connecting rod located at the lowest position is rotationally connected with a connecting plate; a water spraying pipe is installed on the connecting plate; a plurality of water spraying heads are arranged on the two sides of the water spraying pipe; the water spraying pipe is connected with the dyeing pool through a backflow mechanism; the water inlet end and the water outlet end of a piston chamber in the backflow mechanism are connected with a water inlet pipe and a water outlet pipe respectively; the water inlet pipe is connected with the dyeing pool; and the water outlet pipe is connected with the water spraying pipe. A linkage mode is adopted; and compared with a traditional textile mode of spraying dye to a fabric and conveying the fabric, the linkage mode has the advantages that the extra power expenditure is reduced, the overall structure is optimized, and the dyeing effect is improved.

Owner:熊东梅

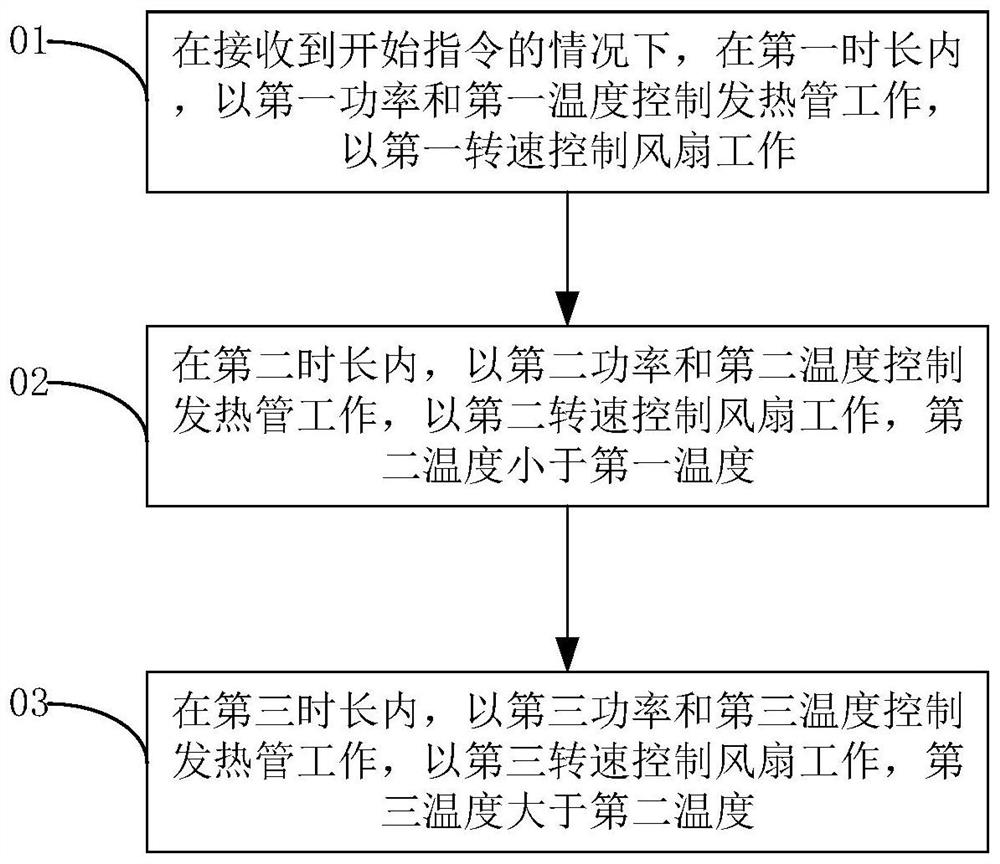

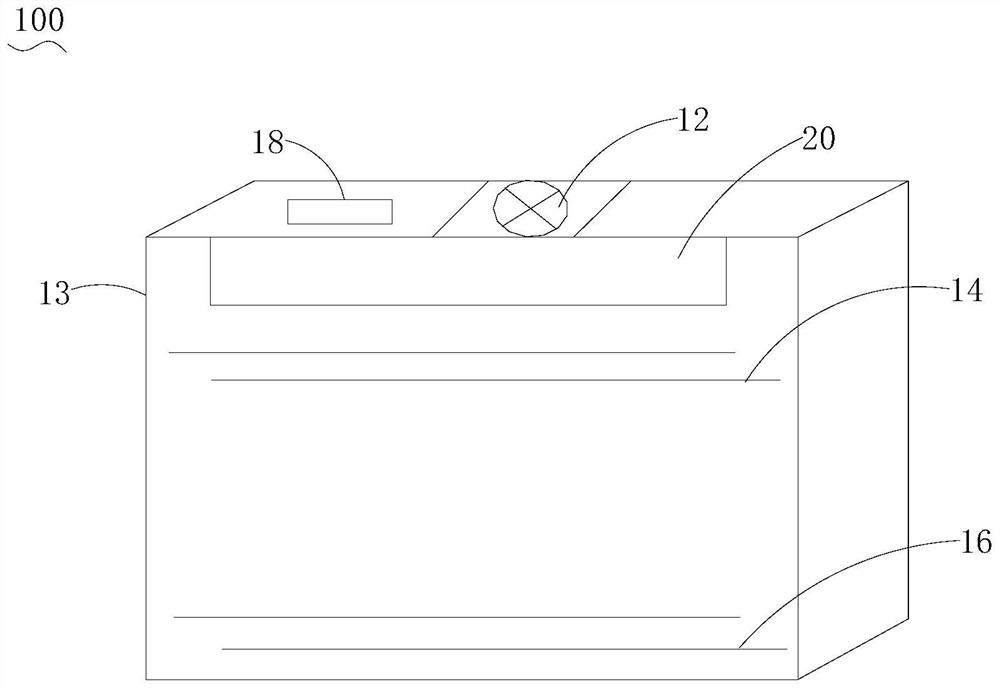

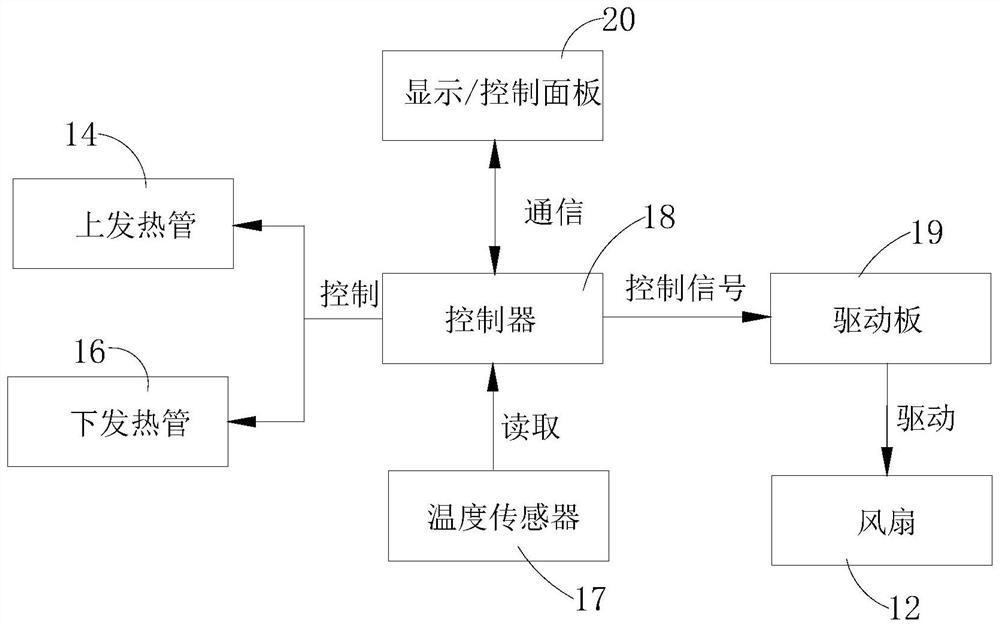

Control method, cooking electric appliance and storage medium

PendingCN113907620AUniform coloringIncrease cooking speedRoasters/grillsProcess engineeringTemperature control

The invention discloses a control method, a cooking electric appliance and a storage medium. The control method comprises the steps that under the condition that a starting instruction is received, a heating pipe is controlled to work at first power and first temperature within first duration, and a fan is controlled to work at first rotating speed; within a second duration, the heating pipe is controlled to work at a second power and a second temperature, the fan is controlled to work at a second rotating speed, and the second temperature is lower than the first temperature; and within a third duration, the heating pipe is controlled to work at a third power and a third temperature, the fan is controlled to work at a third rotating speed, and the third temperature is higher than the second temperature. According to the control method, fries and other special dishes can be fried in a one-key process, the fries are crispy and colored more uniformly, the cooking speed can be increased, the cooking time can be shortened, the effect that the generated harmful substances such as acrylamide of food materials are minimum can be achieved, and the cooked dishes are healthier.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +2

Jade green optical glass composition

InactiveCN106986535AImprove chemical stabilityUniform coloringGlass shaping apparatusRefractive indexColoring agents

The invention provides a jade green optical glass composition which is composed of a basic glass component and a jade green coloring agent, wherein the basic glass comprises the following components in parts by weight: 65-75 parts of SiO2, 4-7 parts of Al2O3, 2-5 parts of CaO, 2-5 parts of PbO, 4-7 parts of BaO and 2-5 parts of ZnO; the jade green coloring agent comprises the following component: Na2SiF6; and the content of the jade green coloring agent in the composition is 3-6 parts by weight. The glass formula is reasonably adjusted, so that the chemical stability of the glass is improved, and the optical glass composition is uniform in coloring, high in devitrification capacity and high in refractive index.

Owner:NANTONG XIANGYANG OPTICAL ELEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com