ABS color master batch

A technology for color masterbatch and raw materials, applied in the field of color masterbatch, can solve the problems of dark color, agglomeration, dust flying, etc., and achieve the effects of improved service life and safety, uniform coloring and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

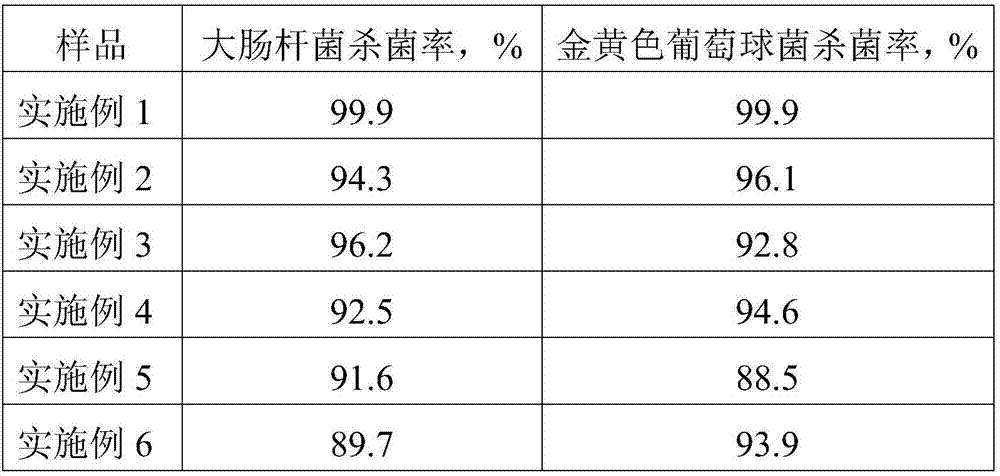

[0030] ABS masterbatch materials (parts by weight): 52 parts of ethylene-acrylic acid copolymer, 6 parts of sunset yellow, 8 parts of polyacrylamide, 0.6 parts of N-phenyl-N'-cyclohexyl-p-phenylenediamine, dimaleic acid 2 parts of octyl ester, 2.7 parts of antibacterial agent, 2.8 parts of ultraviolet absorber.

[0031] The ultraviolet absorber is composed of 2,4,6-tris(2'-hydroxy-4'-n-butoxyphenyl)-1,3,5-triazine, 2-(4,6-bis(2 ,4-Dimethylphenyl)-1,3,5-triazin-2-yl)-5-octyloxyphenol, 2-(4,6-diphenyl-1,3,5-triazine -2-yl)-5-hexyloxy-phenol according to the mass ratio of 1:1:1, stir and mix uniformly.

[0032] The antibacterial agent is obtained by stirring and mixing L-menthol, hinokitiol and phenoxyethanol at a mass ratio of 1:1:1.

[0033] The method for preparing the above-mentioned ABS masterbatch includes the following steps:

[0034] (1) Weigh all parts by weight of the raw materials in a mixing mixer for mixing, the mixing speed is 500 rpm, the mixing temperature is controlled...

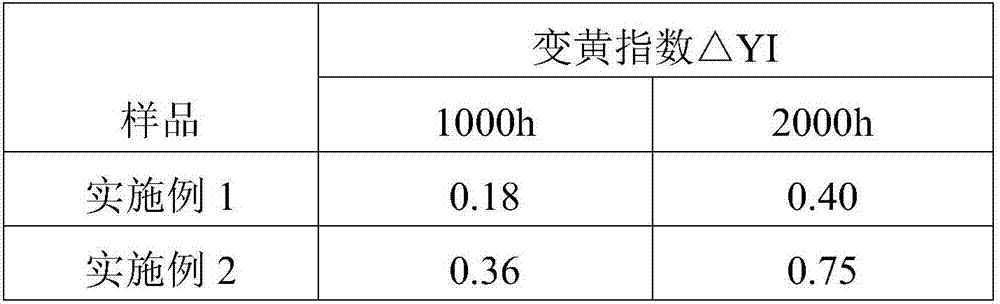

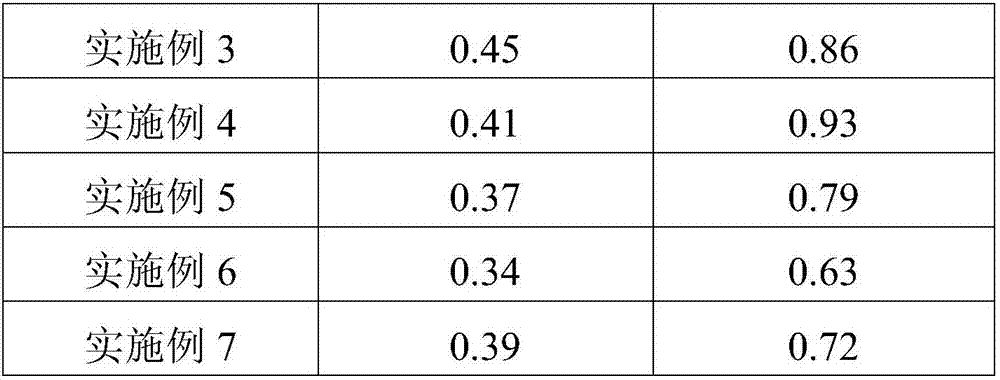

Embodiment 2

[0038] It is basically the same as Example 1, except that the ultraviolet absorber is composed of 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl )-5-octyloxyphenol, 2-(4,6-diphenyl-1,3,5-triazin-2-yl)-5-hexyloxy-phenol at a mass ratio of 1:1, stir and mix Get it evenly. The ABS masterbatch of Example 2 was obtained.

Embodiment 3

[0040] It is basically the same as Example 1, except that the ultraviolet absorber is composed of 2,4,6-tris(2'-hydroxy-4'-n-butoxyphenyl)-1,3,5-triazine , 2-(4,6-Diphenyl-1,3,5-triazin-2-yl)-5-hexyloxy-phenol is obtained by stirring and mixing uniformly at a mass ratio of 1:1. The ABS masterbatch of Example 3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com