Numerical control type dyeing and finishing equipment

A digitally controlled, dyeing and finishing technology, which is applied in the processing of textile materials equipment configuration, liquid/gas/steam treatment of indefinite length textile materials, spray/jet textile material treatment, etc., can solve the problems of easy color difference in fabrics and achieve coloring Uniformity, improve space utilization, and save the space occupied by equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The application will be described in further detail below in conjunction with the accompanying drawings.

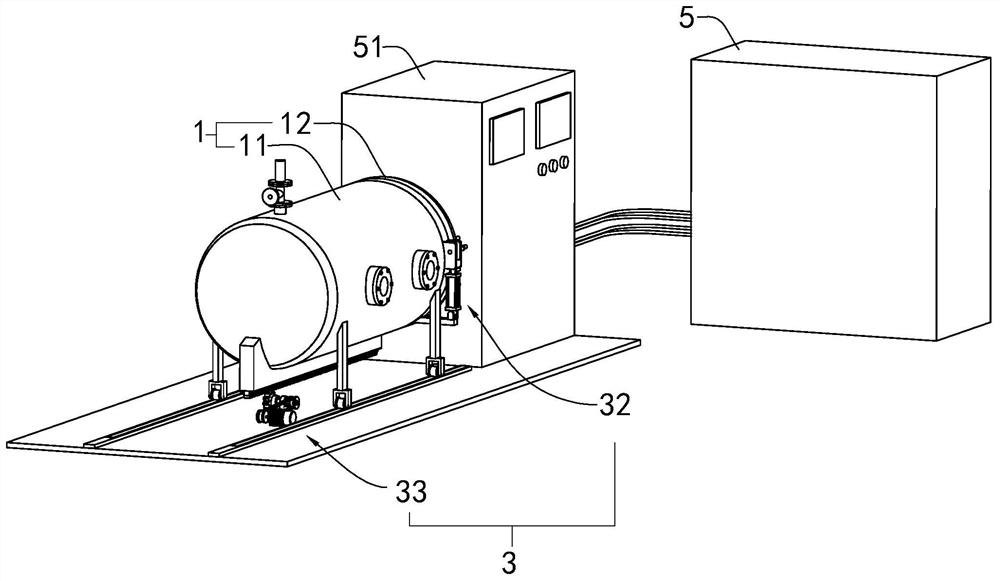

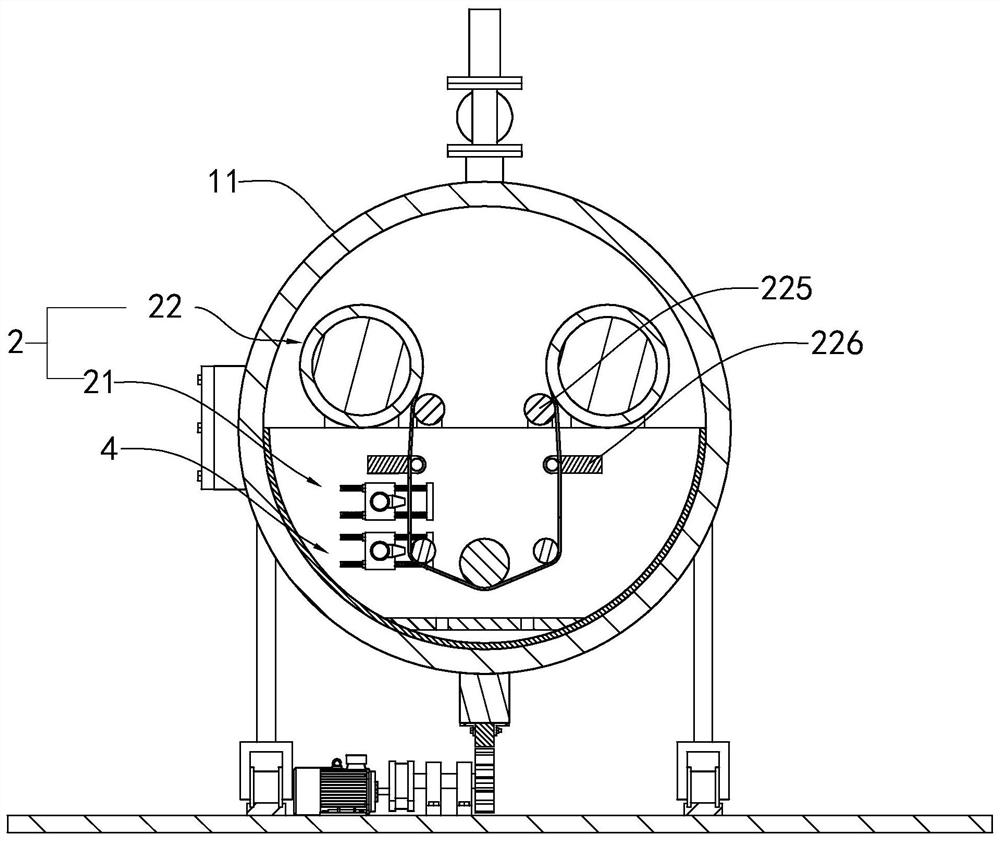

[0043] The embodiment of the present application discloses a numerically controlled dyeing and finishing equipment, referring to figure 1 , the numerically controlled dyeing and finishing equipment includes a dyeing vat 1, the dyeing vat 1 includes a cylinder body 11 and a cylinder cover 12, the dyeing vat 1 is provided with a dyeing device 2, a color fixing device 3 and a cleaning device 4, and the outside of the dyeing vat 1 is provided with a numerical control device 5 and a transmission device 51, the color fixing device 3 includes a locking mechanism 32 for sealing the dyeing vat 1.

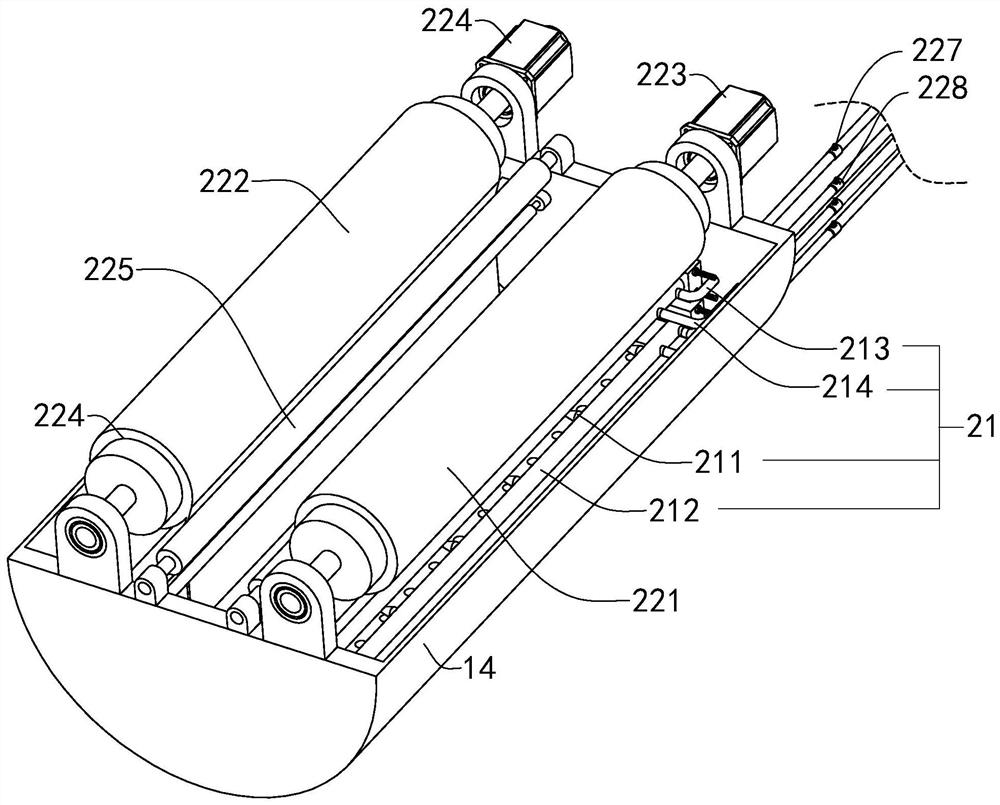

[0044] refer to figure 2 and image 3 , the dyeing device 2 includes a steam-mediated dyeing mechanism 21 and a transmission mechanism 22, the transmission mechanism 22 includes a feeding roller 221 and a receiving roller 222, the feeding roller 221 side is provided with a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com