CVC knitted fabric dyeing and finishing method

A knitted fabric, dyeing and finishing technology, applied in the field of dyeing and finishing technology, can solve the problems such as color difference and uneven staining of fabrics, and achieve the effect of balanced coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

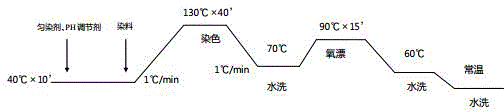

[0020] A kind of CVC knitted cloth dyeing and finishing technology is characterized in that, described CVC knitted cloth dyeing and finishing technology is carried out according to the following steps:

[0021] 1) Dyeing: Put the fabric in the dyeing machine, add leveling agent, pH regulator and disperse dye at a constant rate at a water temperature of 40°C, mix evenly and soak for 10 minutes, and heat up the water at a rate of 1°C per minute. Set the temperature rise to 130°C, boil the cloth for 50 minutes, then lower the water temperature to 70°C at a cooling rate of 1°C per minute;

[0022] 2) Washing 1: Change the water in the dyeing machine to clean water, keep the water temperature at 70°C, stir and wash;

[0023] 3) Oxygen bleaching: temperature rises to 90°C, oxygen bleaching for 15 minutes;

[0024] 4) Washing 2: Change the water in the dyeing machine to clean water, keep the water temperature at 60°C, stir and wash;

[0025] 5) Washing 3: After dehydrating the fabr...

Embodiment 2

[0030] A kind of CVC knitted cloth dyeing and finishing technology is characterized in that, described CVC knitted cloth dyeing and finishing technology is carried out according to the following steps:

[0031] 1) Dyeing: Put the fabric in the dyeing machine, add leveling agent, pH regulator and disperse dye at a constant rate at a water temperature of 40°C, mix evenly and soak for 10 minutes, and heat up the water at a rate of 1°C per minute. Set the temperature rise to 130°C, boil the cloth for 30 minutes, then lower the water temperature to 70°C at a cooling rate of 1°C per minute;

[0032] 2) Washing 1: Change the water in the dyeing machine to clean water, keep the water temperature at 70°C, stir and wash;

[0033] 3) Oxygen bleaching: temperature rises to 90°C, oxygen bleaching for 15 minutes;

[0034] 4) Washing 2: Change the water in the dyeing machine to clean water, keep the water temperature at 60°C, stir and wash;

[0035] 5) Washing 3: After dehydrating the fabr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com