Method for coloring collagen

A collagen and pigment technology, applied in chemical instruments and methods, mixers with rotary stirring devices, dissolution, etc., can solve problems such as difficult cleaning of equipment and pipelines, large pollution of production equipment, cross-contamination of products, etc., to reduce cross-contamination. , low cost, and the effect of improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

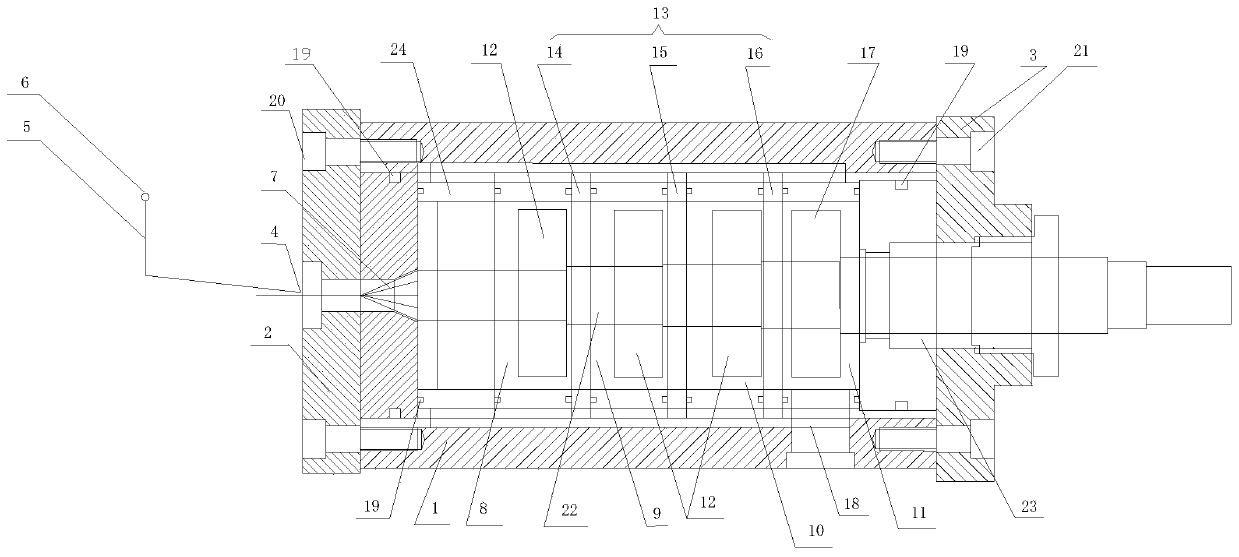

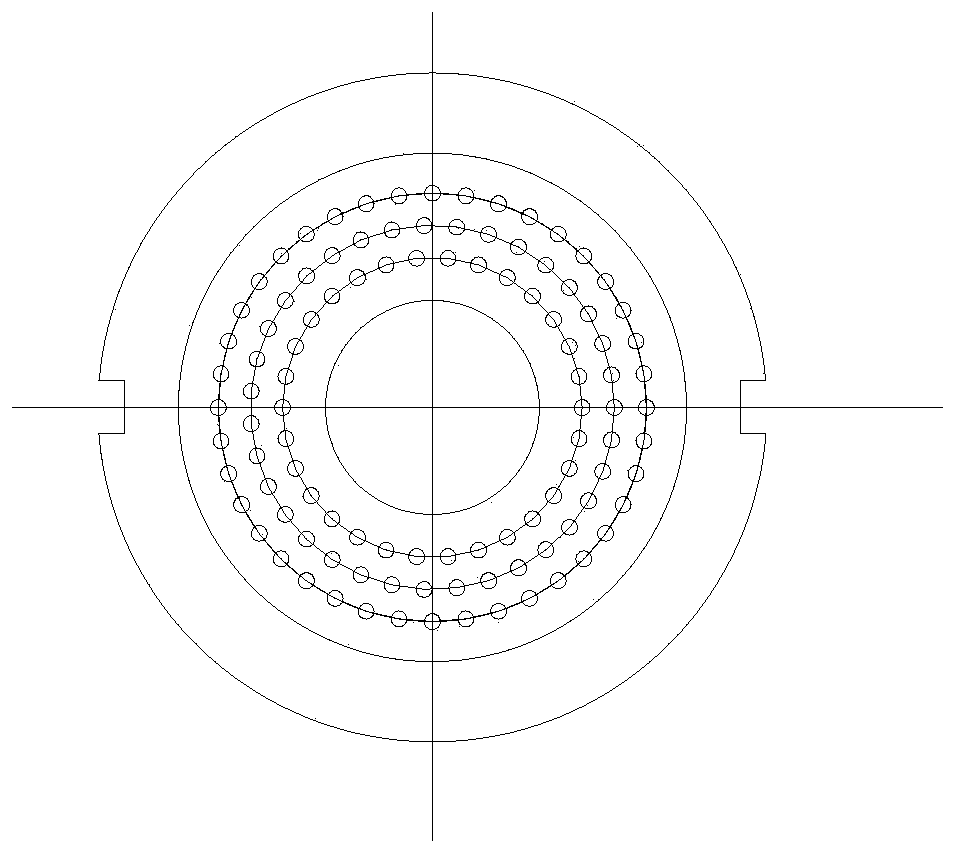

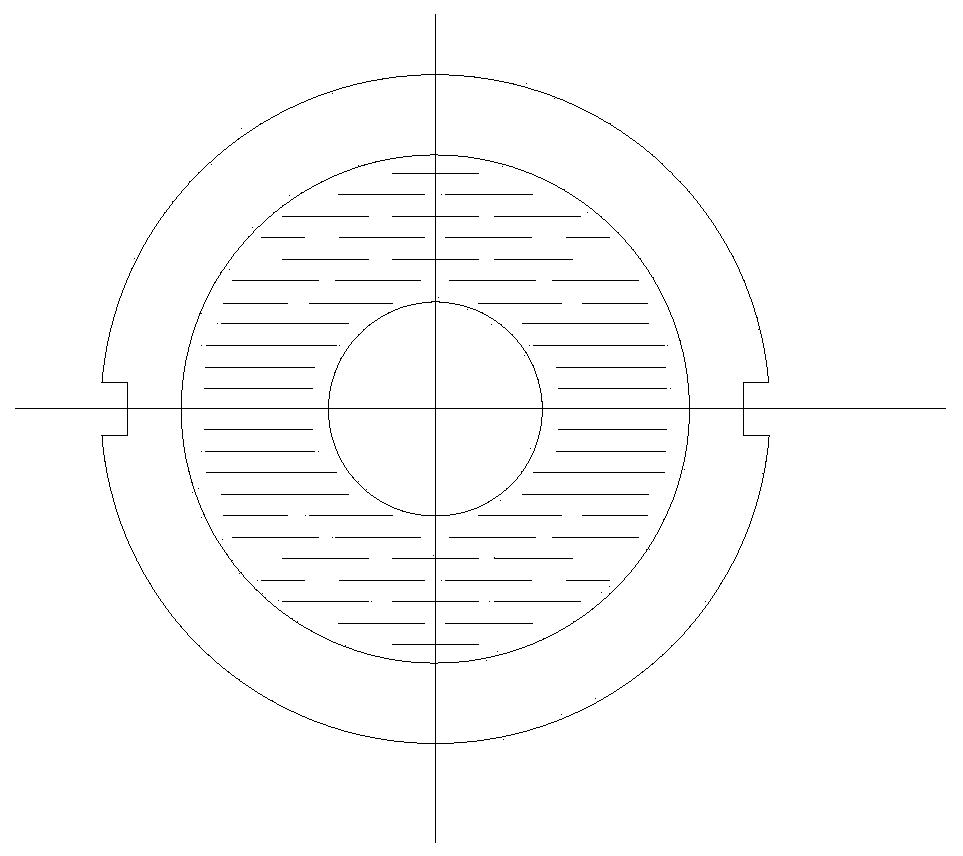

[0028] Attached below Figure 1-4 The present invention will be described in detail with specific embodiments.

[0029] An embodiment of the present invention provides a collagen coloring method, comprising the following steps:

[0030] (1) Combine collagen and pigment first;

[0031] (2) Then the collagen combined with the pigment is divided into pigment collagen small groups through the collagen dispersion disc;

[0032] (3) The above-mentioned pigmented collagen small group is stirred for the first time, and then combed for the first time through a first-level orifice plate;

[0033] (4) Then the pigment collagen is stirred for the second time, and then combed for the second time through the secondary orifice plate;

[0034] (5) The pigmented collagen is stirred for the third time, and then combed for the third time through a tertiary orifice plate to finally obtain evenly mixed pigmented collagen.

[0035] The above steps are all carried out in the dyed collagen stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com