Dyeing slurry for preparing color ceramics

A technology for dyeing slurry and ceramics, applied in the field of dyeing slurry, can solve the problems of low color accuracy, complex preparation process, uneven coloring, etc., and achieve the effects of high color accuracy, smooth surface mirror, and adjustable color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

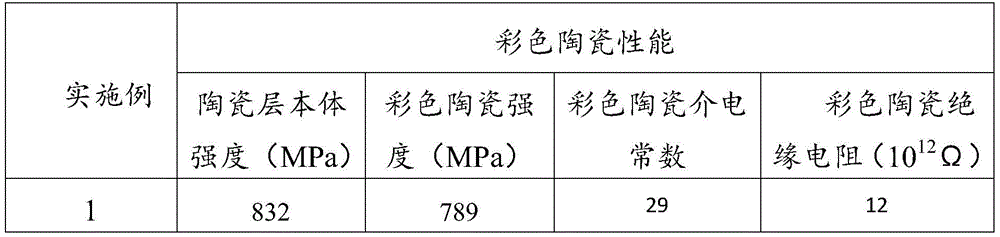

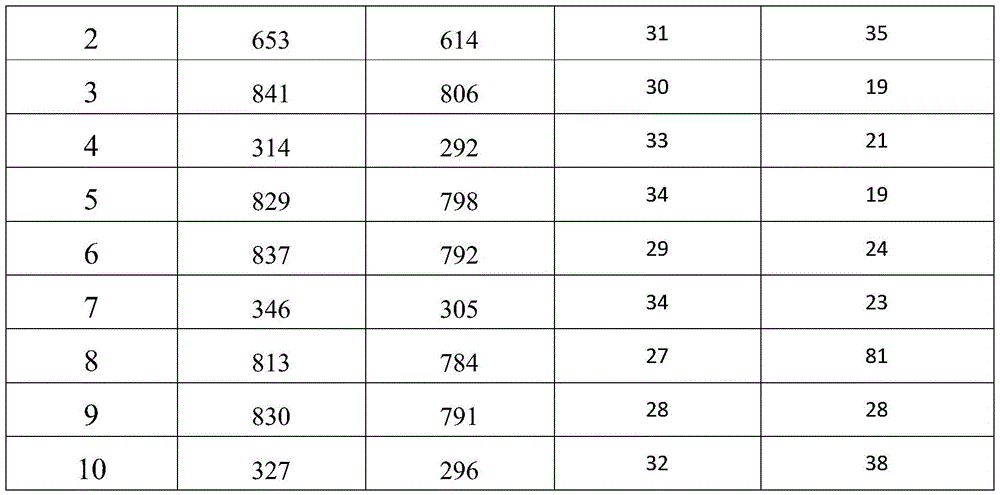

Examples

Embodiment 1

[0036] An embodiment of the dyeing slurry used to prepare colored ceramics according to the present invention, the dyeing slurry described in this embodiment comprises the following components by weight:

[0037]Pigment: 0.01 part of samarium oxide, glass powder: 5 parts of Na-B-Si glass powder, binder: 1 part of polyvinyl butyral, dispersant: 0.1 part of lecithin, plasticizer: 1 part of DOP, organic Solvent: 10 parts of ethanol.

[0038] Mix the above materials and ball mill for 5-24 hours to get uniformly dispersed dyeing slurry.

Embodiment 2

[0040] An embodiment of the dyeing slurry used to prepare colored ceramics according to the present invention, the dyeing slurry described in this embodiment comprises the following components by weight:

[0041] Pigment: 0.1 parts of chromium oxide, glass powder: 40 parts of Ba-B-Si glass powder, binder: 5 parts of acrylic resin, dispersant: TXA-11 parts, plasticizer: 5 parts of dioctyl ester, organic Solvent: 20 parts of toluene.

[0042] Mix the above materials and ball mill for 5-24 hours to get uniformly dispersed dyeing slurry.

Embodiment 3

[0044] An embodiment of the dyeing slurry used to prepare colored ceramics according to the present invention, the dyeing slurry described in this embodiment comprises the following components by weight:

[0045] Pigment: 80 parts of cuprous oxide, glass powder: 95 parts of Zn-Si glass powder, binder: 10 parts of ethyl cellulose, dispersant: 2 parts of PEG, plasticizer: 4 parts of the mixture of PEG and DOP ( The mass ratio of PEG and DOP is 1:1), organic solvent: 30 parts of ethyl acetate.

[0046] Mix the above materials and ball mill for 5-24 hours to get uniformly dispersed dyeing slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com