Film-grade polypropylene coloring master batch and preparation method thereof

A technology of coloring masterbatch and polypropylene, which is applied in the field of film-grade polypropylene coloring masterbatch and its preparation, which can solve the problems of complex process, high cost, poor control of color difference, etc., and achieve simple process, low production cost, and coloring uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

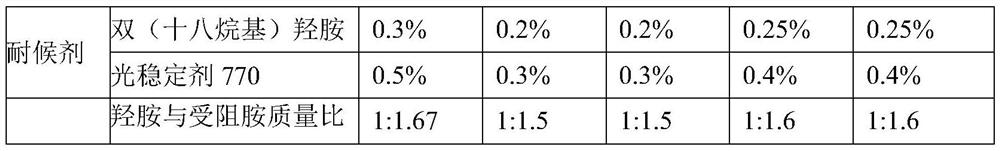

Embodiment 1-5

[0029] The preparation method of embodiment 1-5 film grade polypropylene coloring masterbatch is:

[0030] S1: Feed all the materials into the mixer through the intelligent weight loss weighing scale (1300Kg / h);

[0031] S2: The temperature of the feed port of the mixer is controlled at 110-115°C, the temperature of the mixing chamber area is controlled at 205-215°C, and the mixing is carried out at a speed of 600rpm through twin rotors to obtain a highly dispersed molten mixture;

[0032] S3: The molten mixture formed by kneading is extruded through a twin-screw extruder. The body temperature is kept at 225-227°C for extrusion;

[0033] S4: After passing the extruded highly dispersed molten mixture through the die, it is pelletized under water. The temperature of the water temperature process is controlled at 60-70°C. The colored masterbatch after pelletizing is dehydrated, dried, and screened in sequence to obtain round pellets. Sampling for testing.

Embodiment 6

[0035] S2 of Example 6: The temperature of the feed port of the kneader is controlled at 100-105°C, the temperature of the mixing chamber area is controlled at 190-195°C, and the double-rotor speed is 550rpm for kneading to obtain a highly dispersed molten mixture;

Embodiment 7

[0036] S2 of Example 7: The temperature of the feed port of the kneader is controlled at 115-120°C, the temperature of the mixing chamber area is controlled at 210-220°C, and the double-rotor speed is 500rpm for mixing to obtain a highly dispersed molten mixture;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com