Polyester chiffon printing and dyeing process

A printing and dyeing process and chiffon technology, which is applied in the field of general printing and dyeing of textiles, can solve the problems of high color yield and complex process, and achieve the effects of good softness, improved dyeing rate and high color fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

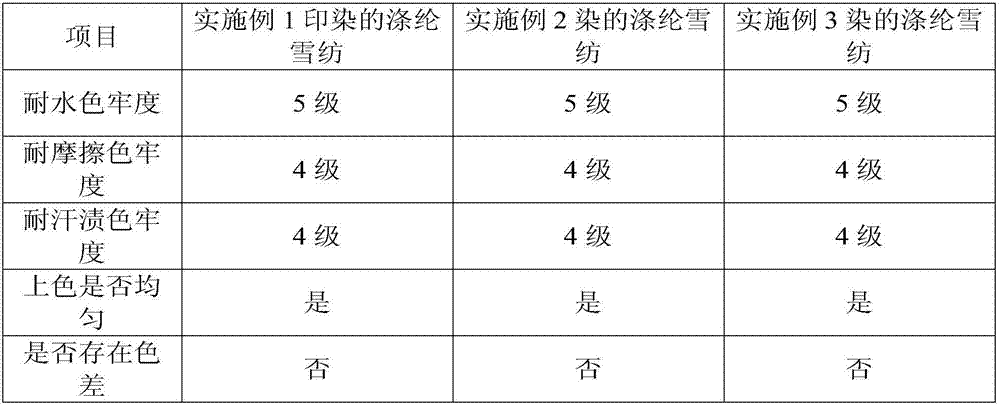

Embodiment 1

[0029] A polyester chiffon printing and dyeing process, including pre-treatment, dyeing treatment and post-treatment, the specific dyeing process is: put the polyester chiffon in a low-concentration dyeing solution at room temperature for 40 minutes, take out the polyester chiffon, and directly put it in the temperature Dip-dye in a high-concentration dye solution at 85°C for 60 minutes. After the high-concentration dye solution cools down naturally, take out the polyester chiffon to complete the dyeing; the mass ratio of the polyester chiffon to the low-concentration dye solution is 1:30; the low-concentration dye solution The pH value of the solution is 6.5; the mass ratio of polyester chiffon and high-concentration dye solution is 1:40; the pH value of high-concentration dye solution is 4.5;

[0030] The post-treatment is as follows: dry the dyed polyester chiffon, add octadecyl dimethyl tertiary amine with a concentration of 3.33g / L, polyether modified silicone oil with a c...

Embodiment 2

[0034] A polyester chiffon printing and dyeing process, including pre-treatment, dyeing treatment and post-treatment, the specific dyeing process is: put the polyester chiffon in a low-concentration dyeing solution at room temperature for 80 minutes, take out the polyester chiffon, and directly put it in the temperature Dip-dye in a high-concentration dye solution at 95°C for 30 minutes. After the high-concentration dye solution cools down naturally, take out the polyester chiffon to complete the dyeing; the mass ratio of the polyester chiffon to the low-concentration dye solution is 1:20; the low-concentration dye solution The pH value of the solution is 7.5; the mass ratio of polyester chiffon to the high-concentration dye solution is 50; the pH value of the high-concentration dye solution is 5.5;

[0035] The post-treatment is as follows: dry the dyed polyester chiffon, add octadecyldimethyl tertiary amine with a concentration of 5g / L, polyether modified silicone oil with a ...

Embodiment 3

[0039] A polyester chiffon printing and dyeing process, including pre-treatment, dyeing treatment and post-treatment, the specific dyeing process is: put the polyester chiffon in a low-concentration dye solution for 60 minutes at room temperature, take out the polyester chiffon, and directly put it in the temperature Dip dyeing in the high-concentration dye solution at 90°C for 45 minutes. After the high-concentration dye solution cools down naturally, take out the polyester chiffon to complete the dyeing; the mass ratio of the polyester chiffon to the low-concentration dye solution is 1:25; the low-concentration dye solution The pH value of the solution is 7; the mass ratio of polyester chiffon and high-concentration dye solution is 1:45; the pH value of high-concentration dye solution is 5;

[0040] The post-treatment is as follows: dry the dyed polyester chiffon, put in octadecyldimethyl tertiary amine with a concentration of 5.56g / L, polyether modified silicone oil with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com