Patents

Literature

84results about How to "High dyeing rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

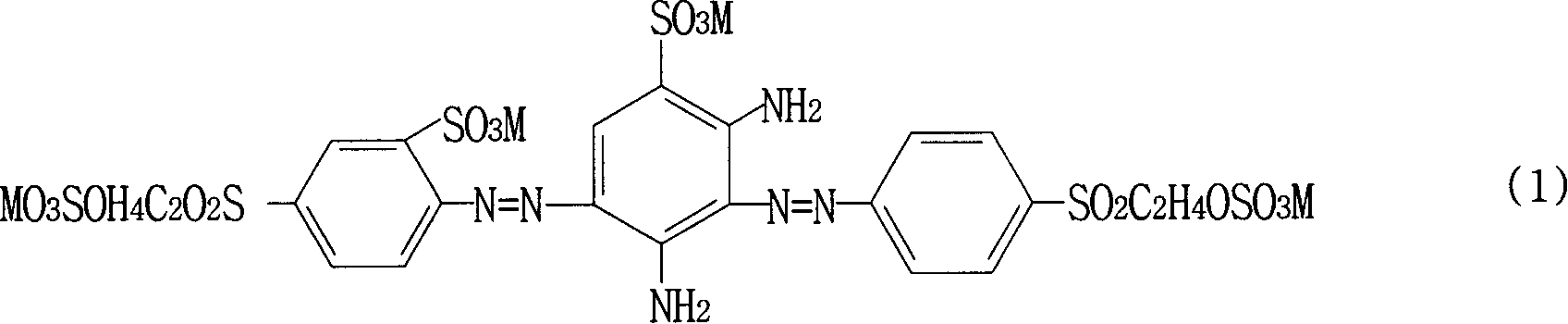

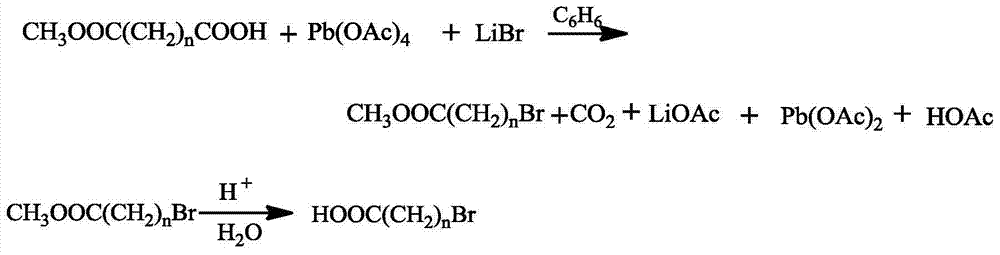

Active composite dye

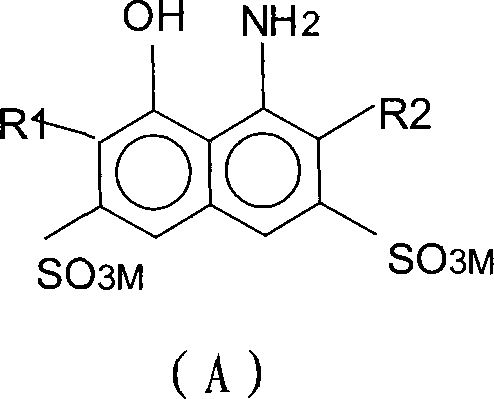

ActiveCN1858118AGood synchronization of dyeingGood level dyeingOrganic dyesDyeing processCelluloseCompound c

The active composite dye includes at least one of compound A, at least one of compound B and at least one of compound C, with the compounds A, B and C being shown. The active composite dye is suitable for dyeing cellulose or protein fiber, and has the composition meeting the environmental and ecological requirement of Oeko-Tex Standard 100. The active composite dye has high build-up, good level dyeing property, good color reproduction, high dye uptake and other excellent performance.

Owner:ZHEJIANG RUIHUA CHEM

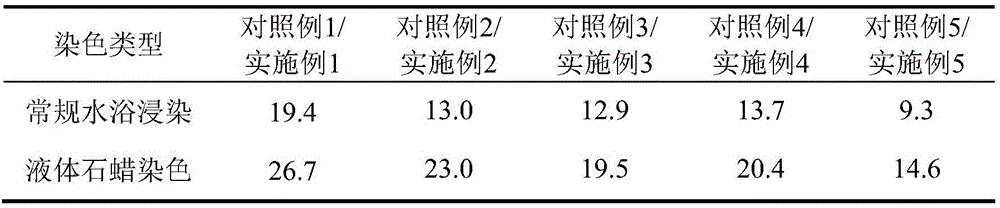

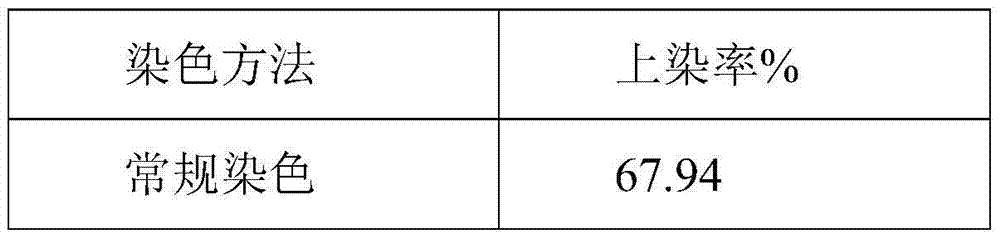

Reactive dye dyeing method for cotton fabric

ActiveCN106337303AHigh dyeing rateSolve the large amount of saltDyeing processParaffin waxRoom temperature

The invention discloses a reactive dye dyeing method for a cotton fabric. The reactive dye dyeing method comprises the following steps of 1 pretreating of the cotton fabric, wherein the cotton fabric is padded in a sodium carbonate solution with the concentration of 10-100 g / L, the pickup rate is controlled to be 100%-200%, and dyeing is prepared; 2 dyeing, wherein dye liquor is prepared by utilizing liquid paraffin as a continuous phase medium for dyeing, and the cotton fabric obtained in the step 1 is placed into reactive dye / a liquid paraffin bath (dye liquor) at room temperature to be dyed for 20-60 min; 3 fixation, wherein the mixture system obtained in the step 2 is heated to 50 DEG C to 100 DEG C, and heat preservation is conducted for 20-50 min; 4 soap boiling, wherein the cotton fabric is taken out, and soaping is conducted to remove the unfixed dye on the surface of the cotton fabric. According to the reactive dye dyeing method for the cotton fabric, the liquid paraffin is selected to replace water to serve as the reactive dye dyeing medium, neutral salt is not needed for accelerating dyeing in the dyeing process, the dyeing rate of the dye is high, and the fixation rate is high.

Owner:ZHEJIANG SCI-TECH UNIV

Milk protein fiber or its filament or its blended yarn dyeing method and coloured woven fabric producing method

ActiveCN1865574ASolve the problem of not being able to dyeHigh dye utilization rateHeating/cooling textile fabricsWoven fabricsAlcoholPolyvinyl acetate

The invention discloses a manufacturing method of milk protein fiber or filament or blended yarn dyeing and yarn-colored product, which is characterized by the following: changing coiling density of yarn; controlling heating temperature; adopting segmented contraction in the cylinder yarn dyeing course; adding self-producing milk protein fiber dyeing specific adjuvant; utilizing polyacrylonitile or polyvinyl acetate alcohol as carrier realize active dyeing technology of milk protein fiber; solving the difficulties of flower color, weak color and bad fastening degree problem to produce excellent washing shrinkage and stable size yarn-dyed product through weaving, shrinking and softening and final disposal.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

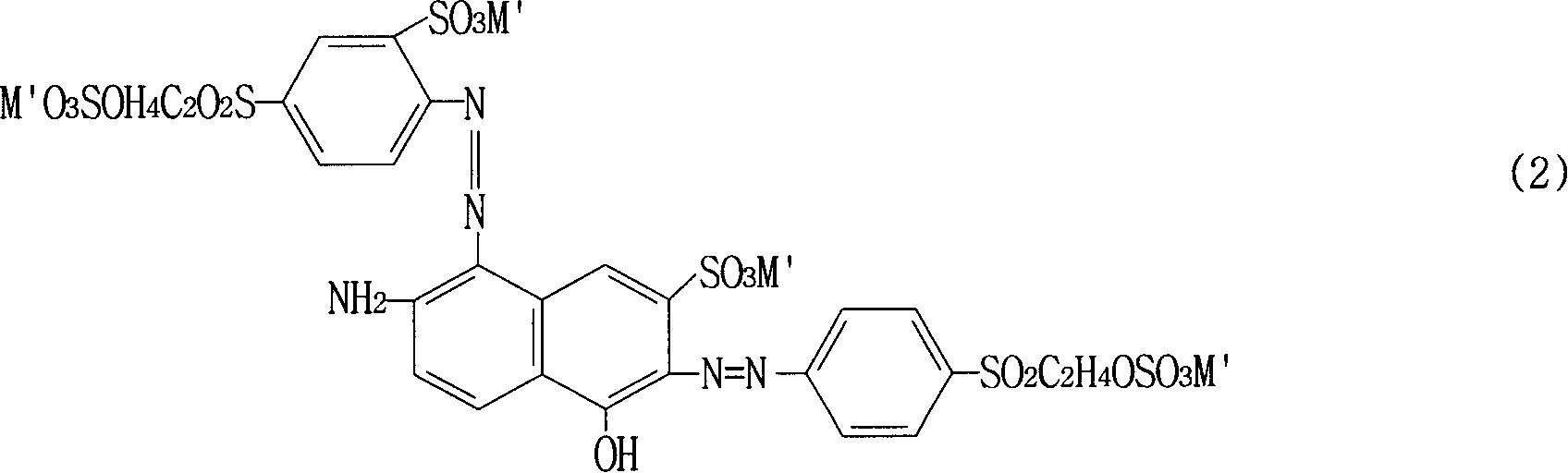

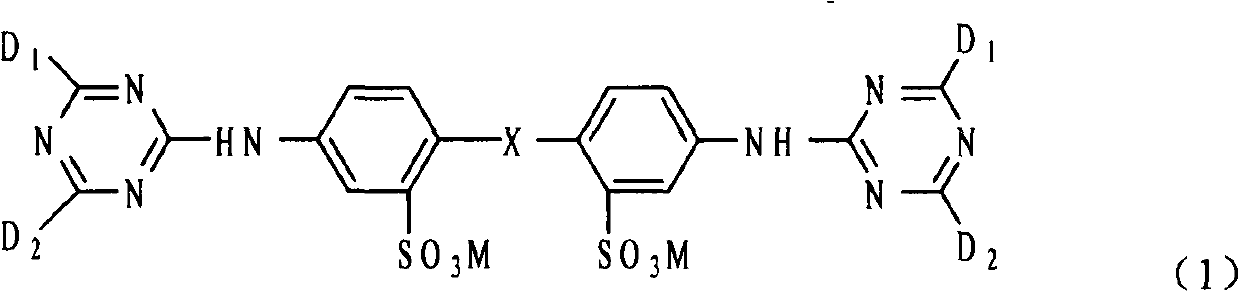

Reactive dye composition and preparing process and application thereof

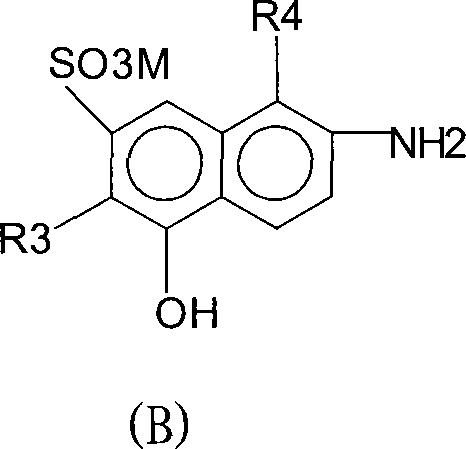

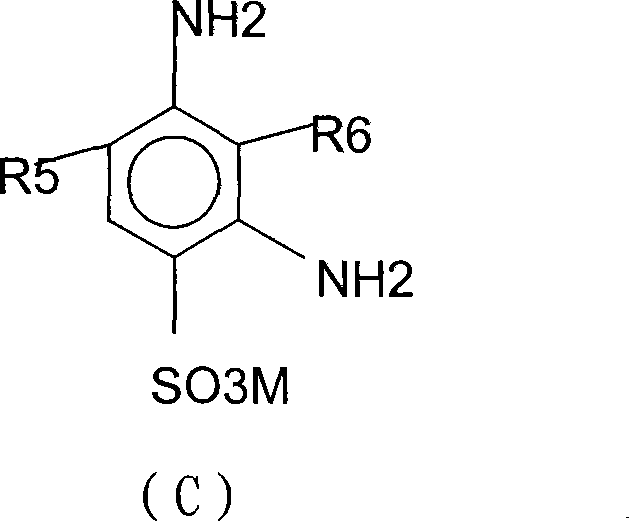

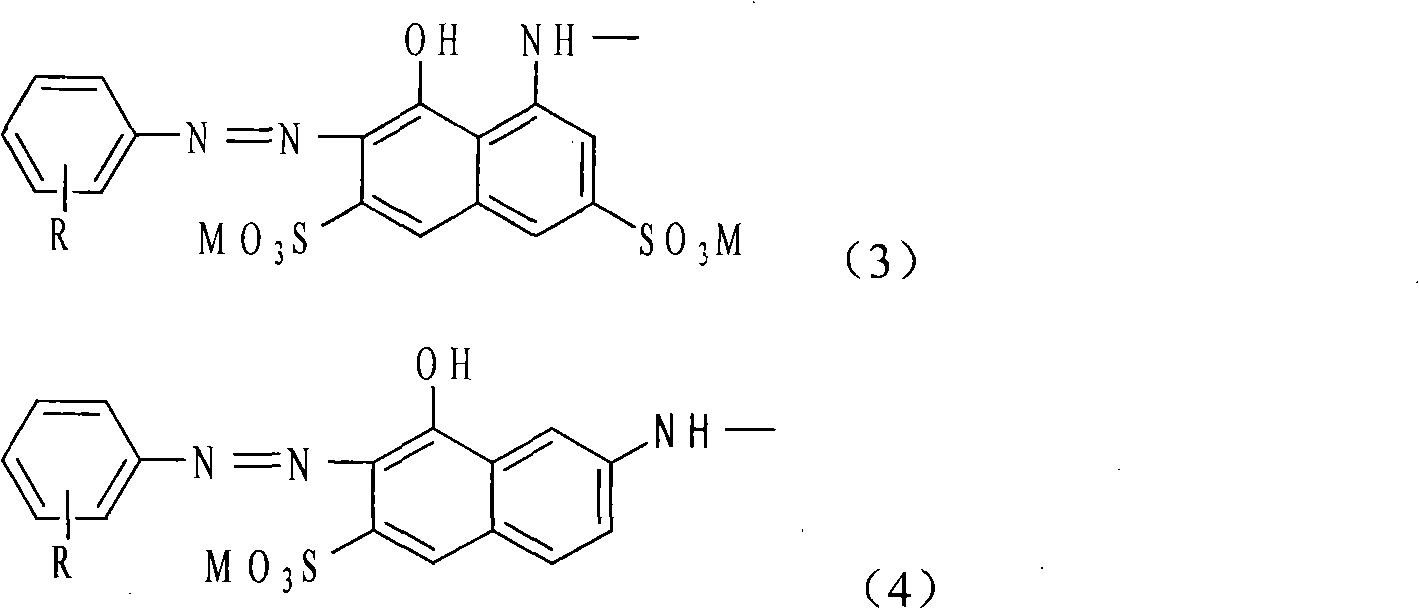

InactiveCN101143972AHigh color fixing rateGood synchronization of dyeingOrganic dyesDyeing processCelluloseOil water

The invention discloses an active dye composition, which includes compound as showed in formula (A), formula (B), formula (C) and formula (D) and additive. 4 components of the active dye composition of the invention active dye composition are medium temperature dye, wherein the oil-water ratio, dye curve, affinity to cellulose, degree of dyeing, color fixing rate, sensitivity to salt and base, effect on bath ratio and sensitivity to temperature are very close. The composition has good dyeing synchronism and level dyeing property, and much higher color fixing rate, thereby being applicable for dip dyeing, continuous dyeing, cold dome, and printing and embossing of cellulose or protein fiber.

Owner:ZHEJIANG RUIHUA CHEM

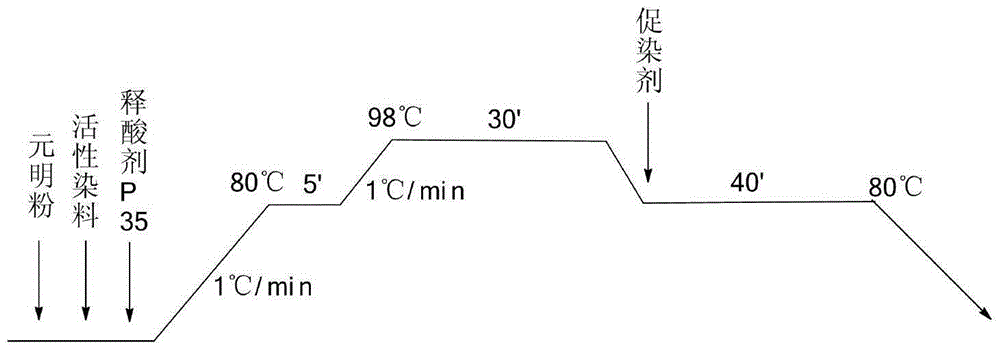

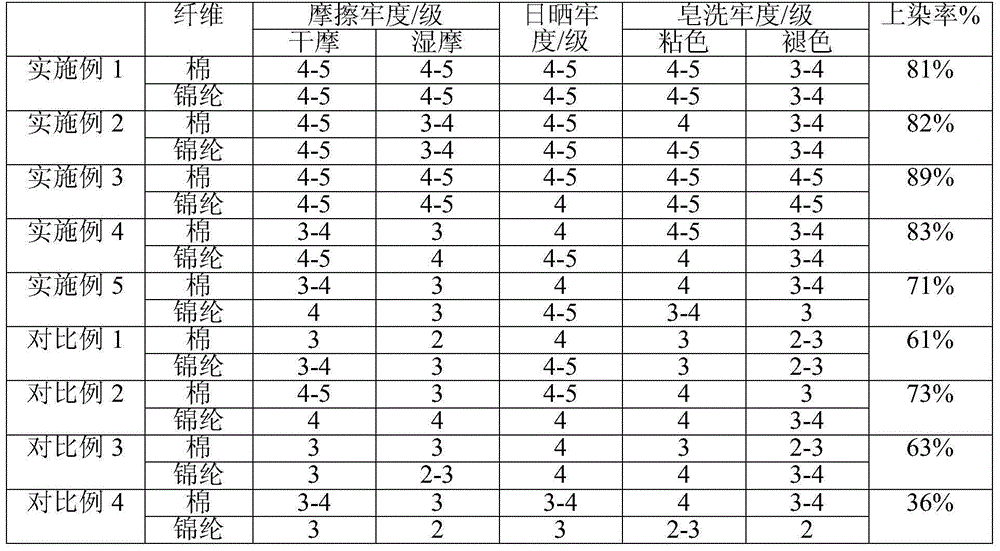

One-bath dyeing method for brocade cotton through reactive dyes

The invention discloses a one-bath dyeing method for brocade cotton through reactive dyes. The method comprises steps as follows: step (1), brocade cotton cloth is pretreated, dye liquor is added, and the bath ratio of the brocade cotton cloth to the dye liquor is 1: (4-6); step (2), the dye liquor is gradiently heated to 95-100 DEG C, the cloth is kept at the temperature to be dyed for 30-40 min, the dye liquor is cooled to 80-85 DEG C, a dyeing accelerant solution is added, and color fixation is performed for 40-50 min; step (3), the dyed brocade cotton is obtained through aftertreatment after dyeing in the step (2) is completed. One-bath dyeing of the brocade cotton is realized through coordination of the temperature, an acid-releasing agent, anhydrous sodium sulphate and the reactive dyes, a process is simple, energy is saved, and the prepared dyed brocade cotton has high washing fastness and small chromatic aberration.

Owner:浙江劲光纺织科技有限公司

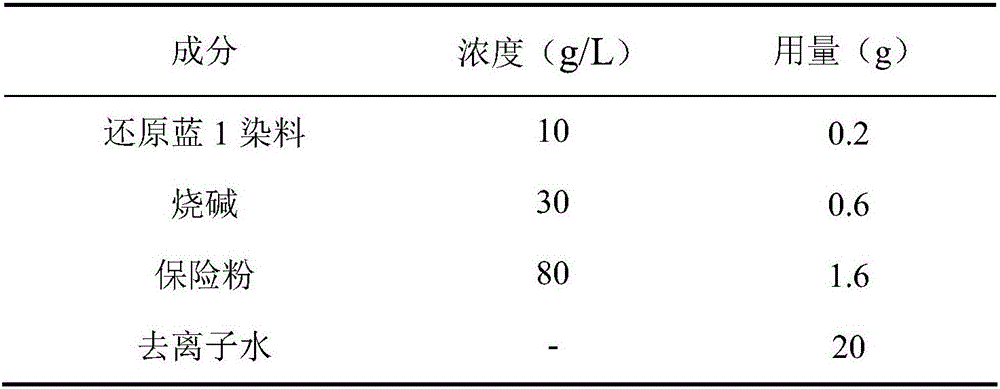

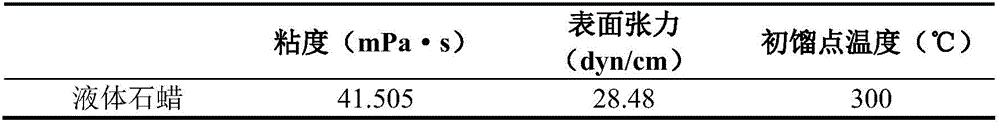

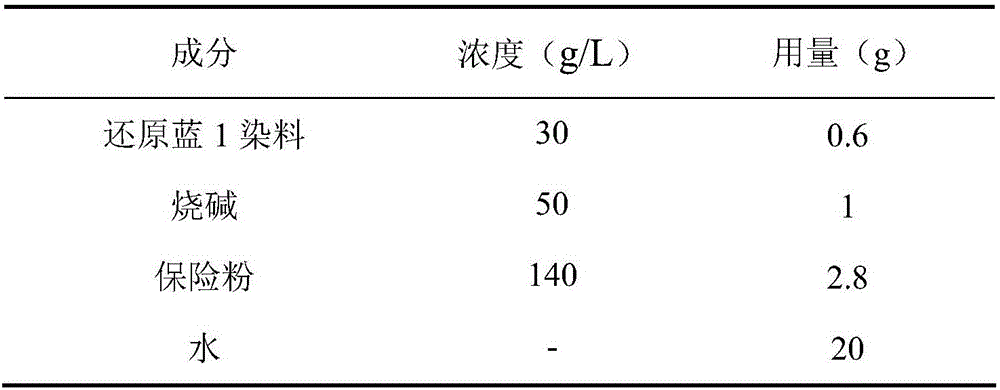

Liquid paraffin bath dyeing method of cotton fiber

The invention discloses a liquid paraffin bath dyeing method of cotton fiber. The method is applied to a liquid paraffin bath for performing reduction dye dyeing on the cotton fiber, due to the fact that liquid paraffin and water are completely immiscible, both the cotton fiber and a reduction dye leuco body have the good compatibility with water, and leuco body droplets dispersing in the liquid paraffin have the intense tendency of being repellent to the liquid paraffin and compatible to the cotton fiber, and the reduction dye leuco body can be spontaneously transferred to the surface of the fiber from the liquid paraffin solution and then dispersed into the fiber. The adopted liquid paraffin is low in cost, safe, environmentally friendly and recyclable. According to the method, the dye-uptake rate of the reduction dye is greatly increased, the leuco body and oxidizing substances are isolated in the dyeing process, oxidation of the leuco body and losses of sodium hydrosulfite are effectively avoided, and the production cost is remarkably reduced. More importantly, the method greatly reduces water for dyeing and wastewater discharge and meets the development requirement for ecological dyeing and finishing.

Owner:ZHEJIANG SCI-TECH UNIV

Polyester fiber DTY (draw textured yarn) with high dyeing rate and preparation method thereof

ActiveCN104499082AImprove dye uptakeGood flexibilityNew-spun product collectionMelt spinning methodsYarnPolyester

The invention relates to a polyester fiber DTY (draw textured yarn) with high dyeing rate and a preparation method thereof. The polyester fiber polyester fiber DTY with high dyeing rate is made from modified polyester, the modified polyester is composed of polyester and aminoadipic acid gylcol ester, the aminoadipic acid gylcol ester is dispersed among molecular chains of the polyester, hydrogen-bond interaction exists between the aminoadipic acid gylcol ester and the molecular chains of the polyester, and the relative position of the aminoadipic acid gylcol ester and the molecular chains of the polyester is fixed; the free volume space among the molecular chains inside the fiber is increased by 20-30v / v% when the polyester fiber DTY with high dyeing rate is at 90-130 DEG C, the dying rate of the polyester fiber DTY with high dyeing rate is higher than that of the common fiber when the polyester fiber DTY with high dyeing rate adopts the same dyes such as disperse red 3B, disperse blue SE-2R, disperse bright blue S-GL and the like, less surface dyeing is formed after dyeing, and the polyester fiber DTY with high dyeing rate can be used for garment materials, bedding article decoration and the like.

Owner:JIANGSU HENGLI CHEM FIBER

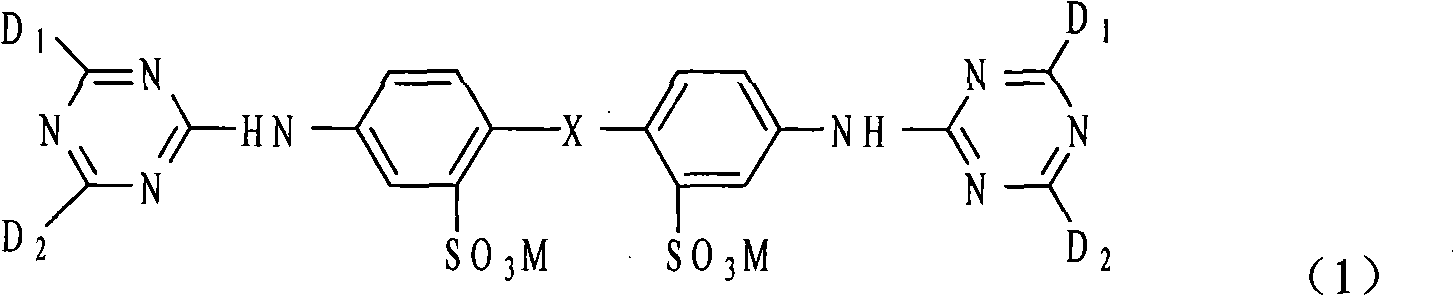

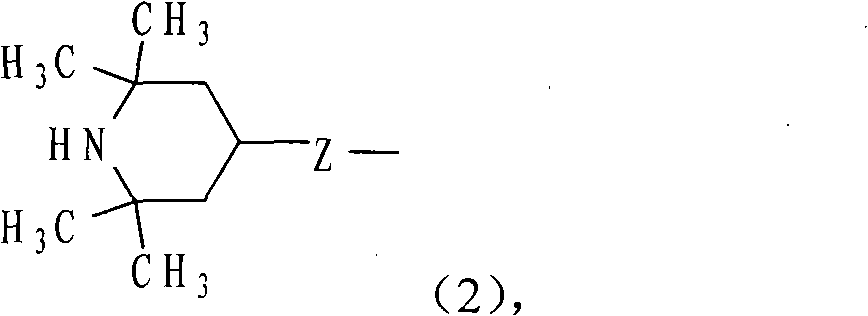

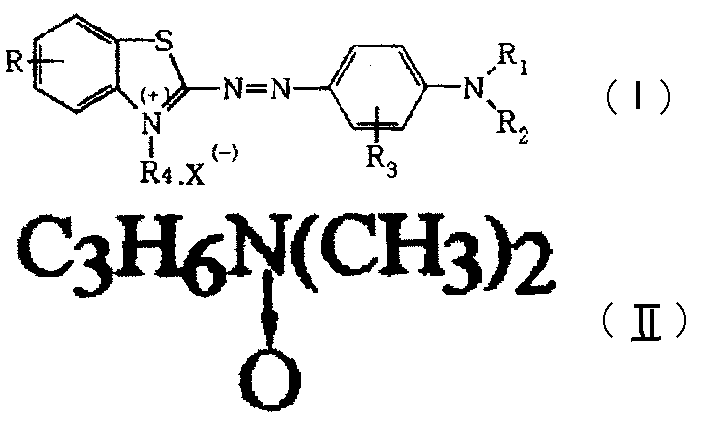

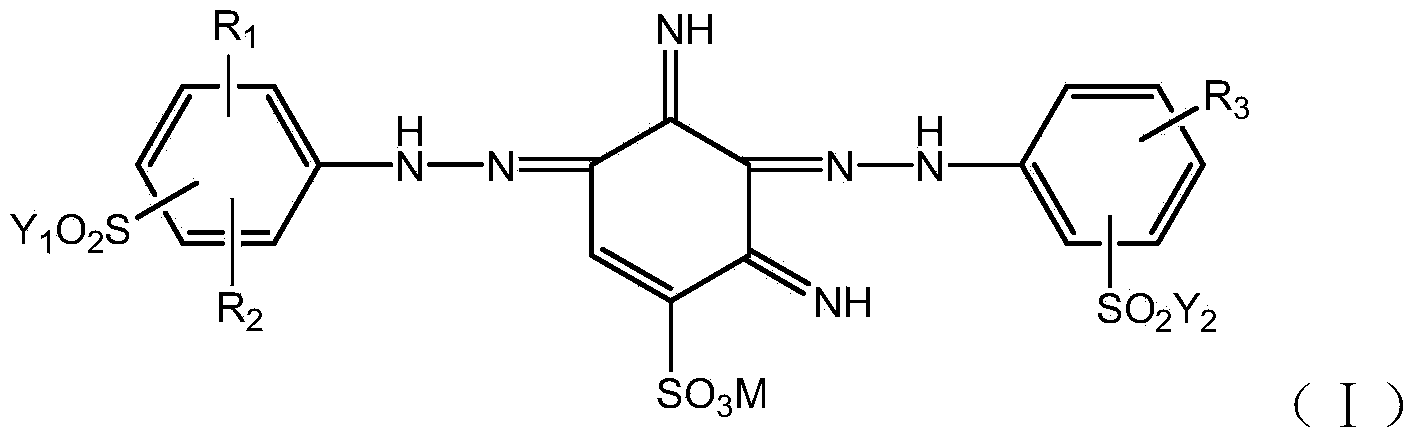

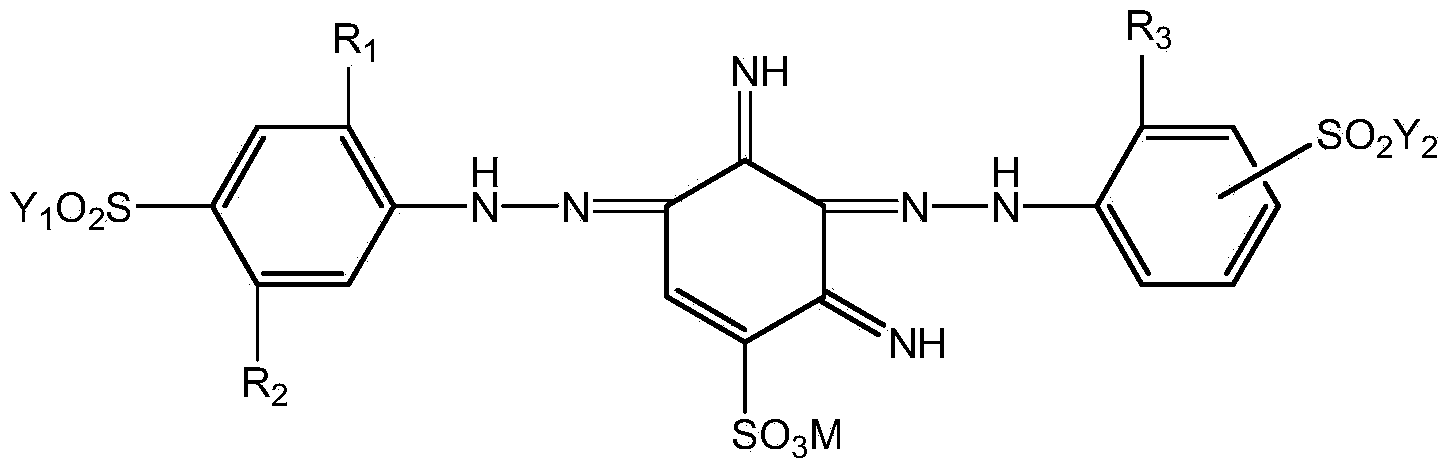

Weather-resistant azo-dyes, preparation and use thereof

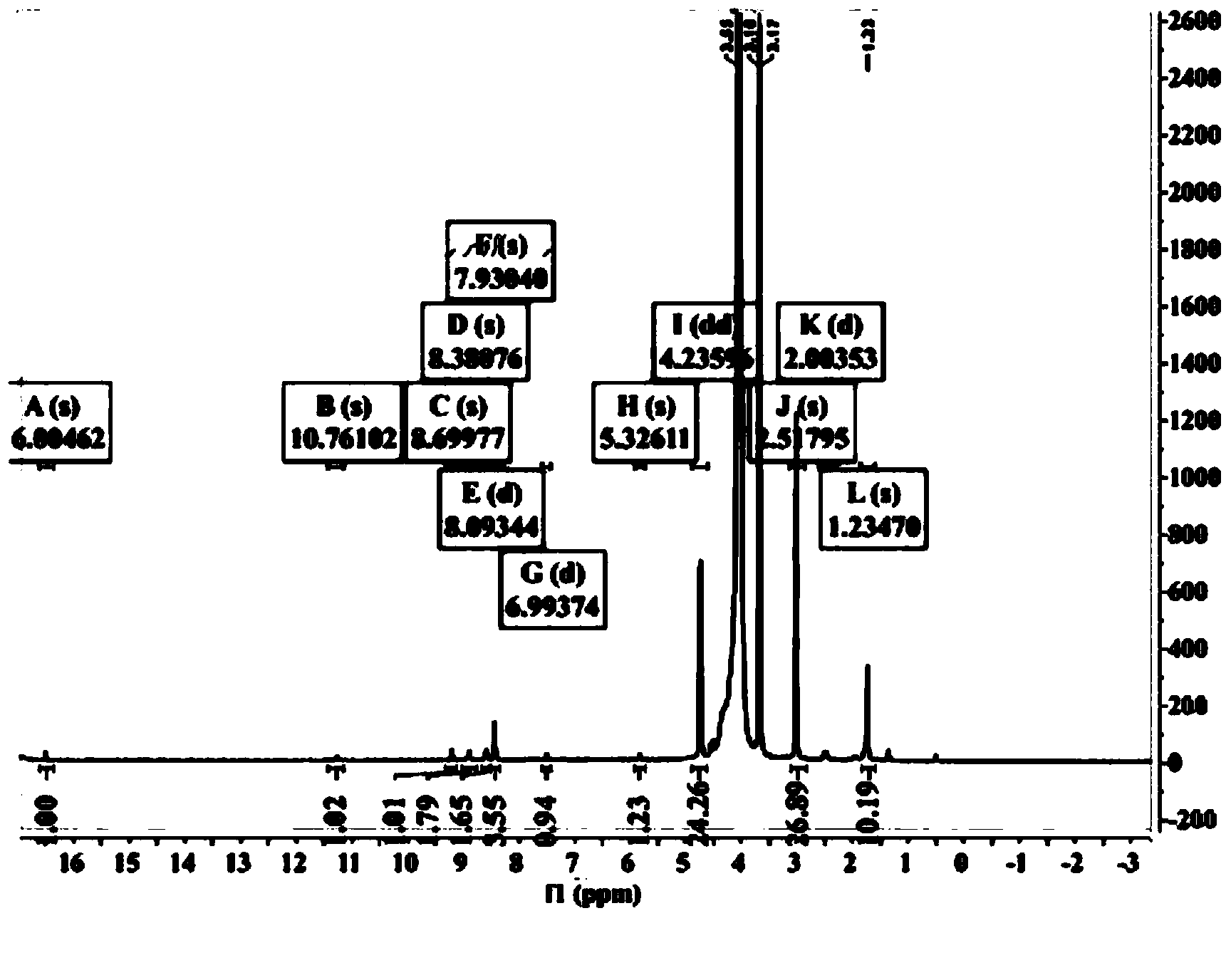

InactiveCN101280118ADyeing speed is fastHigh dyeing rateAzo dye preparationMonoazo dyesEnergy transferHindered amine light stabilizers

The invention relates to a weather-resistant azo dye with the following general formula (I) and the preparation method and application. The invention introduces chlorinated triazine groups based on common azo dyes and then after a series of condensation reactions, a novel azo dye is obtained. The azo dye contains multiple chromogenic groups, wherein, hindered amine can absorb the infrared; DSD acid (that is, 4,4'-diaminostilbene-2,2'-disulfonic acid) can absorb the ultraviolet rays; therefore, the azo dye has good light-resistant and weather-resistant properties and can be used alone or with other dyes; the azo dye can be used in textiles, paper, leather, wood, ink-jet printing ink and other aspects, which is also a good energy transfer agent. As a result of a variety of functional groups, the azo dye of the invention has better weather-resistant performance than common azo dyes.

Owner:上海汇友精密化学品有限公司

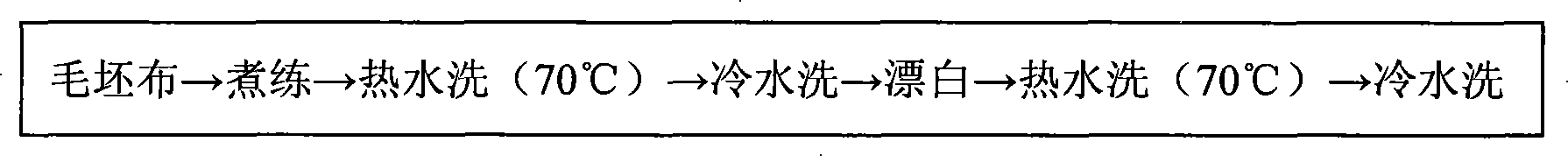

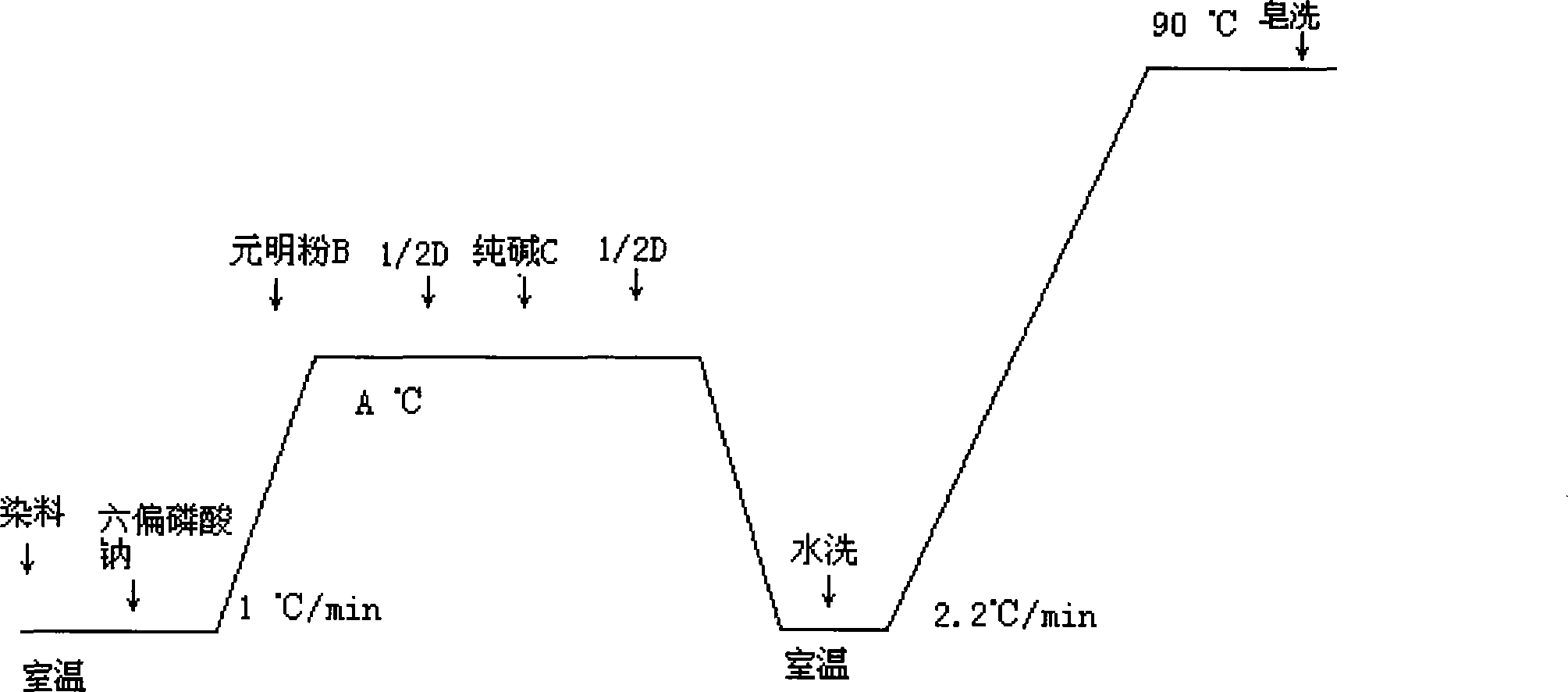

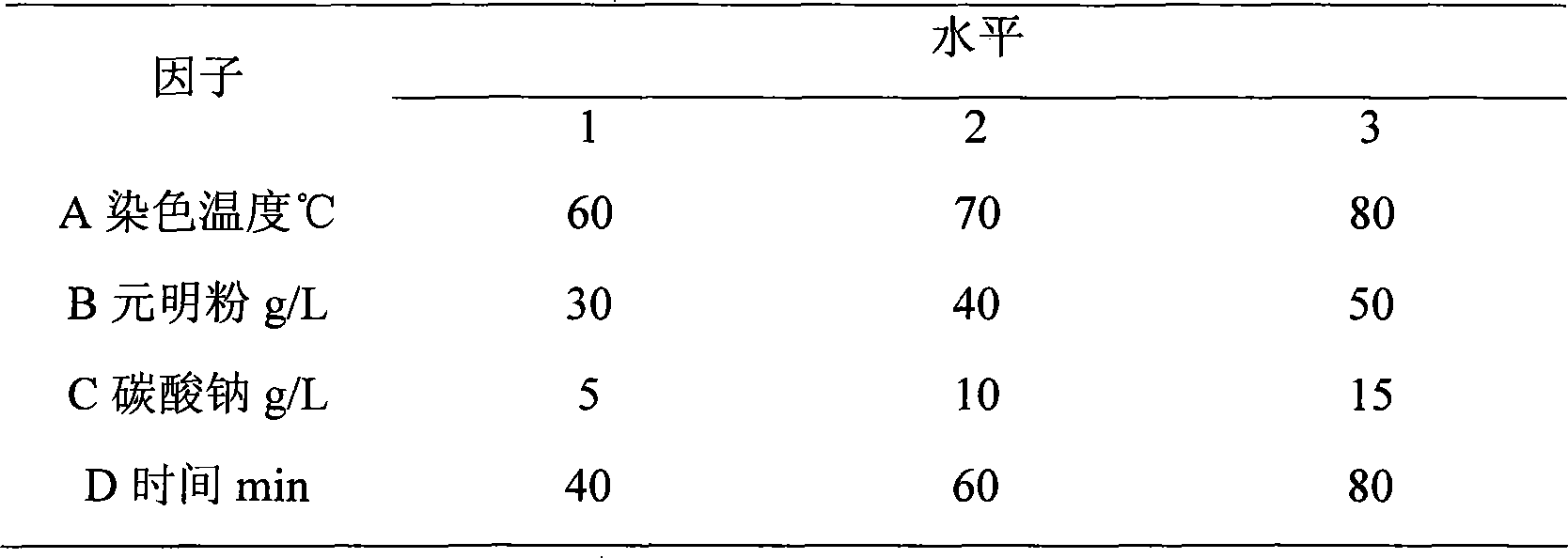

Method for dyeing silk cotton blended spinning knitted fabric

The invention relates to a dying method for silk / cotton blended knitted fabric, determining dying technique condition based on different silk / cotton blending ratio of the knitted fabric, comprising: (1) pretreatment process flow: boiling off the silk-cotton blended knitted fabric grey cloth, rinsing in hot water of 70 deg., rinsing in cold water, bleaching, rinsing in hot water of 70 deg., rinsing in cold water; (2) adding dye into the silk-cotton blended knitted fabric grey cloth at room temperature, then adding hexametaphosphate, heating to dying temperature (A) with a heating rate of 1 DEG C / min, adding a dyeing auxiliary agent anhydrous sodium sulfate (B), adding dyeing auxiliary agent sodium carbonate (C) after half of the dying period (D), cooling to room temperature after another half of dying period (D), rinsing, heating to 90DEG C with a heating rate of 2.2 DEG C / min, and soaping. The invented method overcomes shortcomings in prior art which are low silk dye-uptake, light color and unsatisfying blended knitted fabric concolores property, so that the concolores property of the blended knitted fabric is improved.

Owner:DONGHUA UNIV

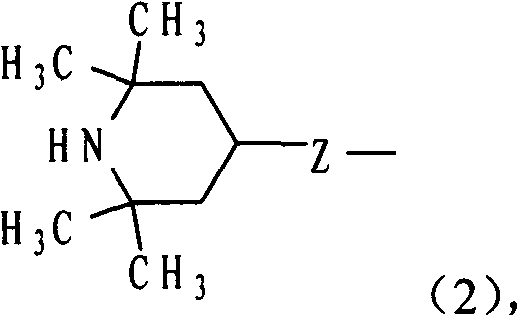

Olive green cationic dye and its preparing method

A cationic olive-green dye for polyacrylonitrile fibres and its blended fabrics is prepared through diazotizing reaction bentween 2-amino substituted benzothiazole and nitrosyl sulfate, adding substituted phenyl amino compound, coupling reaction, dissolving the resultant in inertial organic solvent, adding quaternary ammonifying agent, quaternary ammonifying reaction, distilling, decolouring, filtering and drying. Its advantages are high colouring intension, excellent color fastness and good color compatibility.

Owner:上海市染料研究所

Triazine type azo dye and preparation method thereof

InactiveCN103305023ADyeing speed is fastHigh dyeing rateStyryl dyesMethine/polymethine dyesWeather resistanceHindered amine light stabilizers

The invention relates to a triazine type azo dye with the general formula (I) shown in the specification and a preparation method of the azo dye. A novel azo dye is obtained by introducing a chloro-s-triazine group into a general monoazo dye and performing a series of condensation reaction. The azo dye comprises a plurality of color-development groups, wherein the contained hindered amine is capable of adsorbing infrared, the DSD acid (namely 4,4'-diamino stilbestrol-2,2'-disulfonic acid) is capable of adsorbing the ultraviolet in the sunlight, and the azo dye is provided with good illumination resistance and sunshine resistance, can be singly or together used with other dyes, and can be applied to the aspects of textile, paper, leather, wood, ink-jet printing ink, and oil ink. The azo dye is a good energy transfer. By containing a plurality of functional groups, the azo dye provided by the invention has more excellent weather resistance than that of a general azo dye.

Owner:上海汇友精密化学品有限公司

Carrier dyeing method of para-aramid fibers

ActiveCN103498214AEasy to dyeGood for adsorption and dyeingCarding machinesDyeing processDye absorptionCarding

The invention discloses a carrier dyeing method of para-aramid fibers. The carrier dyeing method comprises the steps that mechanical carding is conducted on the para-aramid fibers to be dyed; the carded para-aramid fibers are dyed. Mechanical carding has the two functions that firstly, by observing the surface appearances of the fibers through a scanning electron microscope, the facts that after the fibers are carded, under the action of mechanical force, the surfaces become rough, most macromolecular chains are fractured, punctiform pots are produced, and dye absorption and uptake are facilitated can be discovered; secondly, by means of mechanical carding, impurities in the fibers are removed, the fibers become fluffy, the specific surface area of the fibers making contact with dye is increased, and dyeing of the fibers is facilitated. Through research on a dyeing process, the problems that when para-aramid dyeing is conducted at present, the dye-uptake rate is low, dye penetration cannot be achieved, and neutral and deep color dyeing cannot be achieved are solved. Conventional equipment is used in the carrier dyeing method, and the carrier dyeing method has the advantages that processes are simple, environmental friendliness is achieved, procedures are short, and inherent excellent performance of the fibers will not be damaged.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

All-cotton fabric dyeing method adopting two-phase medium

The invention discloses an all-cotton fabric dyeing method adopting a two-phase medium based on a dyeing system consisting of an oil phase medium and a water phase medium which are not incompatible. The oil phase medium consists of a cyclic polymer of dimethyl siloxane and a lipophilic nonionic surfactant; the lipophilic nonionic surfactant is low in turbidity point, so that the oil phase medium and the water phase medium can be mixed under lower temperature to form one phase; with the increase of the temperature, the phase can be divided into two phases to ensure successful dyeing and facilitate recycling of the oil phase medium. The method comprises the following steps: weighing a textile with a certain weight, preparing the oil phase medium and the water phase medium, adding a fiber textile, performing dyeing curing treatment, soaping and drying the product. According to the all-cotton fabric dyeing method adopting the two-phase medium, the steps are simple, convenient and feasible; water consumption is greatly reduced; meanwhile, dyeing wastewater emission is relieved, the dyeing rate and the curing rate are greatly improved, and energy consumption is reduced.

Owner:ZHEJIANG SILK TECH

In-vitro separation and purification method for tree-shrew corneal endothelial cells

ActiveCN106244549AEnhance cell viabilityTypical endothelial cell morphologyCell dissociation methodsMicrobiological testing/measurementHigh cellPurification methods

The invention discloses an in-vitro separation and purification method for tree-shrew corneal endothelial cells. The in-vitro separation and purification method includes the steps that tree-shrew corneal endothelial cells are separated, purified and subjected to passage cultivation through CECs, and corneal endothelial cells are obtained. The separated corneal endothelial cells have high cell activities, purification of the corneal endothelial cells can be achieved in the passed P3 generation is passed, the purified cells have typical endothelial cell morphology, and are identified through NSE immunofluorescence, and the dyeing rate is high. The purification efficiency of the method is greatly improved, the cost is low, using is convenient, and the large quantity of tree-shrew corneal endothelial cells can be obtained. In-vitro cultivation of the tree-shrew corneal endothelial cells is achieved, and the void that a specific corneal-endothelial-primary-cell in-vitro cultivation technology for a tree-shrew species does not exist ate present is filled; the material taking and purification methods of primary cells are easy to operate, the cost is low, and in-vitro cultivation tree-shrew corneal endothelial cells can be kept the good cell states in the long-term passage cultivation process.

Owner:INST OF MEDICAL BIOLOGY CHINESE ACAD OF MEDICAL SCI

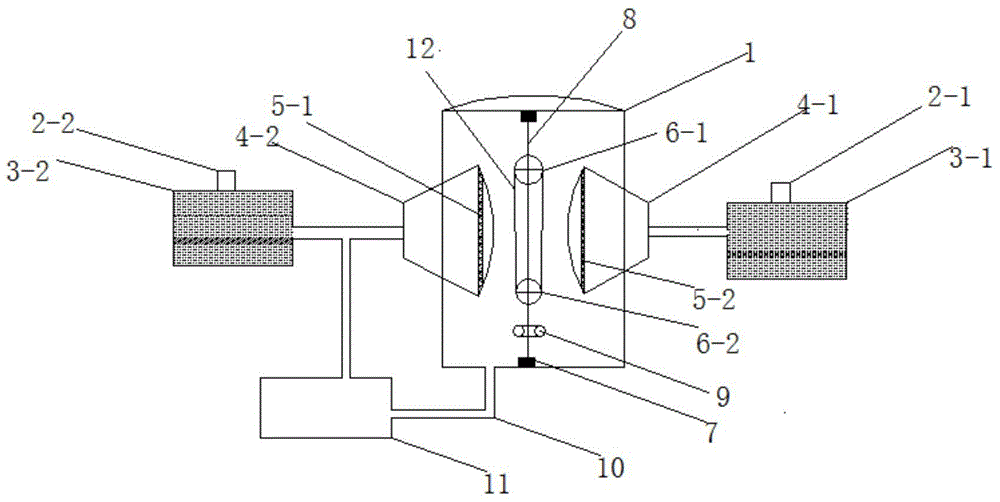

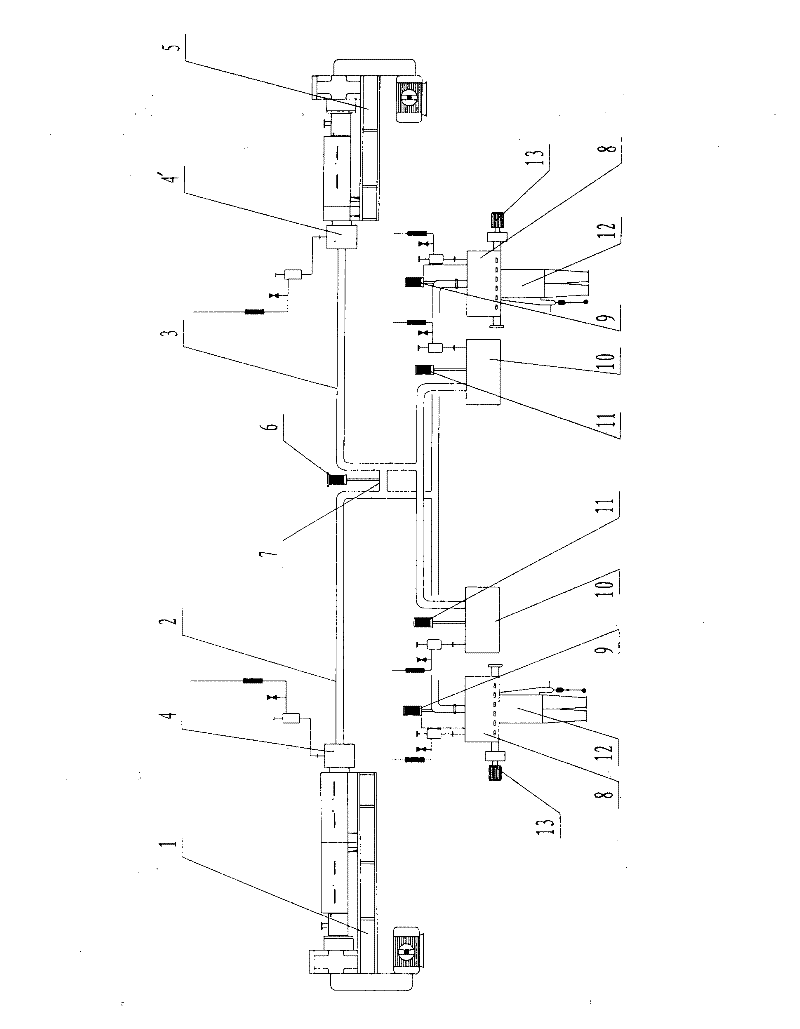

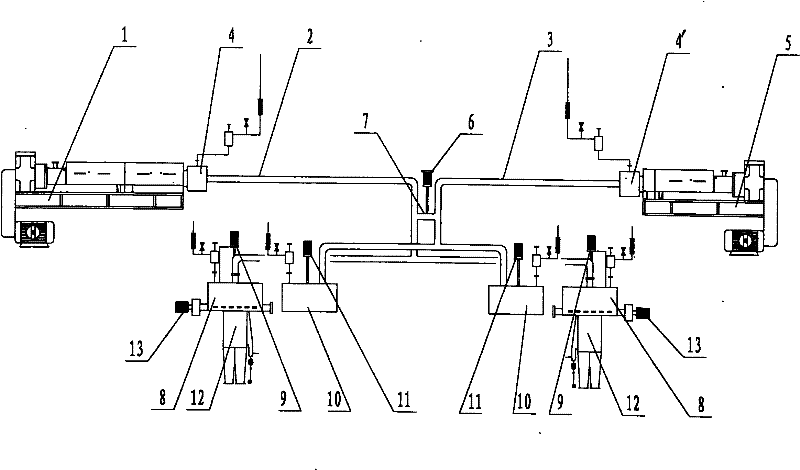

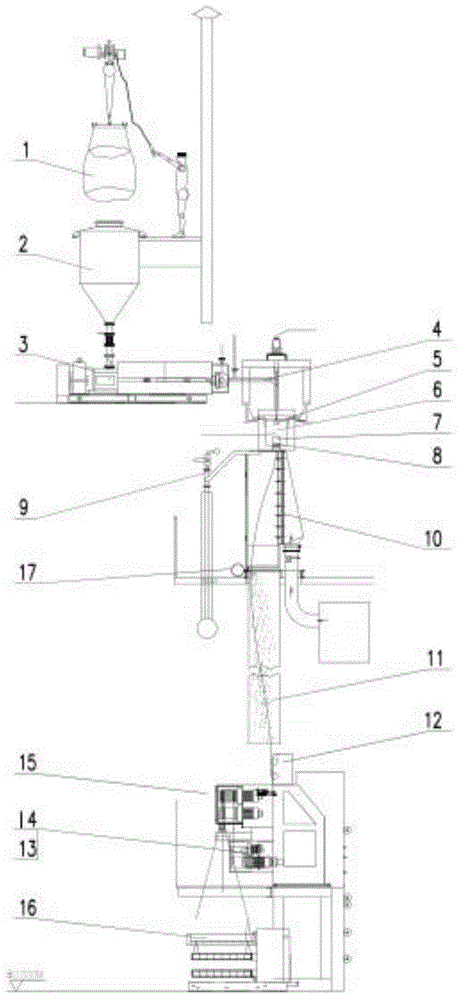

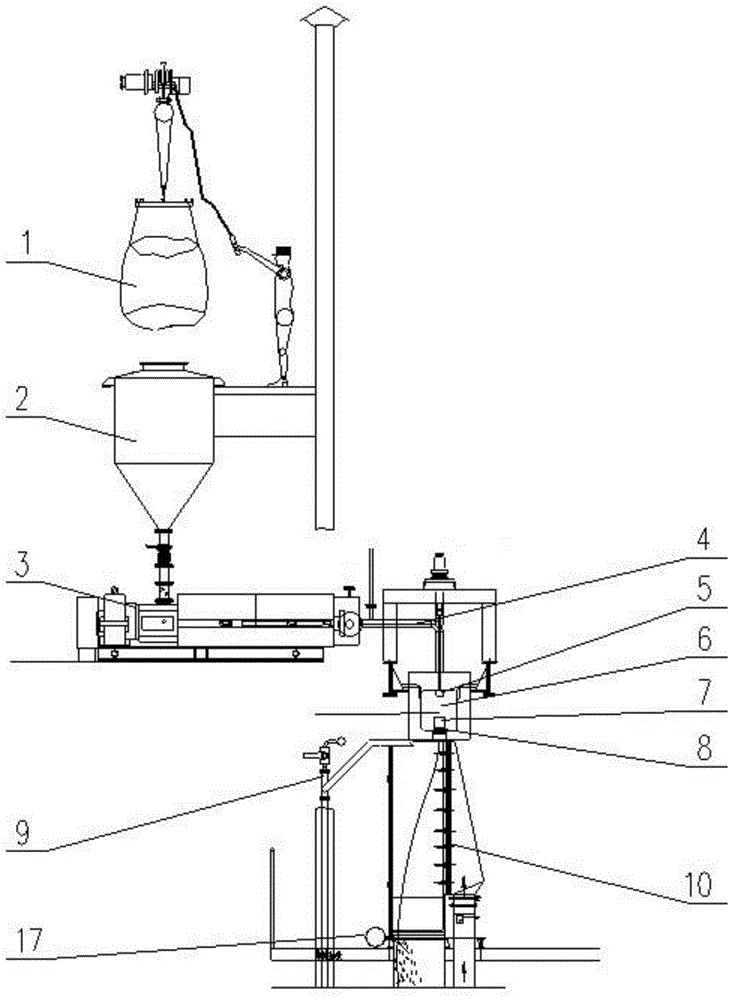

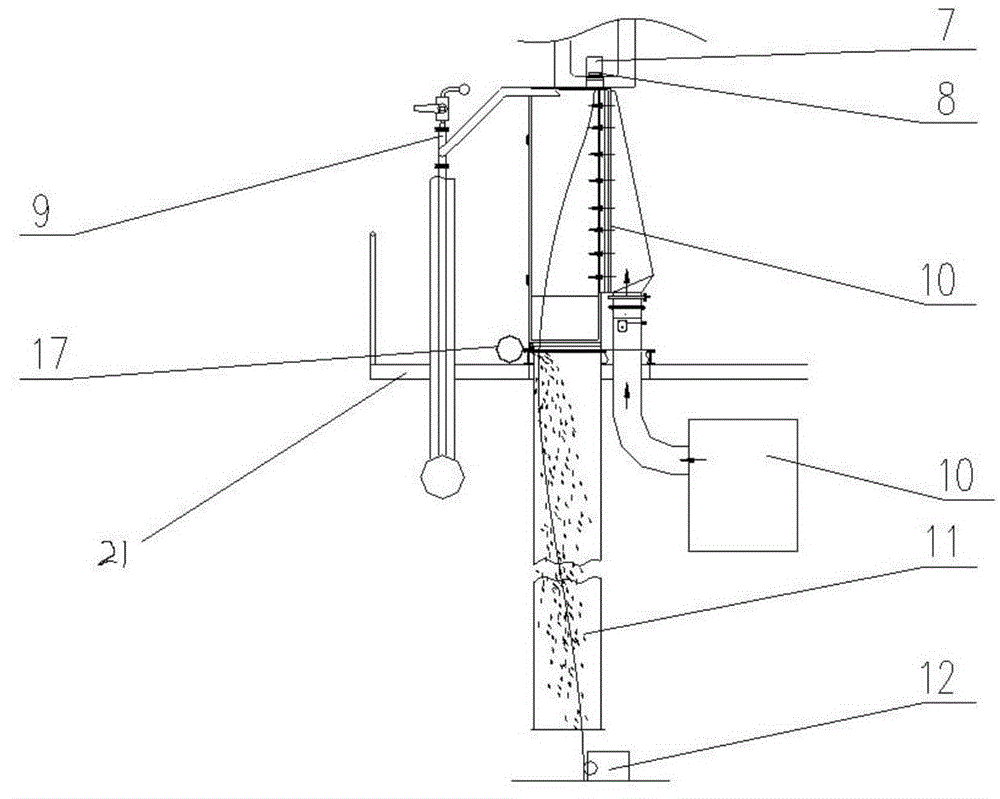

Circulation steam denim spraying dyeing device

InactiveCN104911845AReduce energy consumptionNo pollution in the processTextile treatment machine arrangementsUltrasonic/sonic fibre treatmentDyeingEngineering

The invention discloses a circulation steam denim spraying dyeing device, which belongs to the textile field, and comprises a dyeing device main body (1), a dosing port (2-1,2-2), a dye box (3-1,3-2), a plasma generator (5-1,5-2), a moving shaft wheel (6-1,6-2), a rotating driver (7), a support rod (8), a bearing seat (9), a steam guide pipe (10), a steam machine (11) and a denim (12). The circulation steam denim spraying dyeing device solves the problems that denims are close and thick in texture, is easy to have uneven dyeing, has poor wet rubbing fastness translucency and hard fabric feel, achieves the advantages of low energy consumption, no pollution, high performance and full automation and the like, can effectively improve dyeing efficiency and dyeing degree, and prevents color of denims from fading and losing.

Owner:CHANGZHOU UNIV

Method for dyeing silk vegetable dye

InactiveCN107419557AGood antibacterial effectHigh dyeing rateBiochemical fibre treatmentDyeing processMoistureMordant

The invention discloses a method for dyeing silk vegetable dye. The method comprises the following steps: (1) degumming and washing, executing the secondary degumming treatment to the degummed silk by using diluted hydrochloric acid solution and sodium hydroxide solution, and washing by using washing soaking solution; (2) drying, drying the silk until the moisture content is 11%-14%; (3) dyeing the silk, executing the dyeing treatment to the silk by using a mordant and dyeing solution, and alternately and circularly dyeing for 2-3 times; (4) heating-fixation, treating the dyed silk by using the high-temperature and low-temperature alternated fixation; and (5) drying: drying the fixation silk in the low temperature until the moisture content is 4%-6%. The method for dyeing the silk vegetable dye has the high dyeing efficiency, the dyeing defect proportion is reduced by 3.52%, the fixation effect is good, the color fading is not easy, and the color uniformity is good.

Owner:HEFEI JUFENG THROWING

Dyeing process of reactive dye

The invention belongs to the technical field of dyeing processes and particularly provides a dyeing process of a reactive dye. The dyeing process of the reactive dye comprises the following steps of 1 pretreatment including water washing and acid pickling, 2 dyeing, 3 accelerating through salting, 4 fixation through calcined soda adding and 5 aftertreatment including two-time soap boiling, water washing and drying. The dyeing process of the reactive dye is simple in operation, even in dyeing and quick in dyeing and coloring, and an M-type dye can have higher dye-uptake rate and fixation rate, dyeing depth is better, water washing times are decreased, water resources are saved, production cost is reduced, and dyeing efficiency is improved.

Owner:JIANGSU SHUANGYING TEXTILE TECH

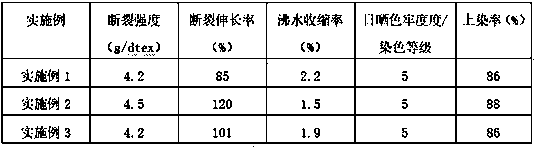

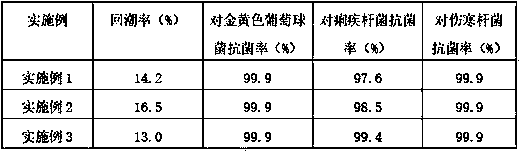

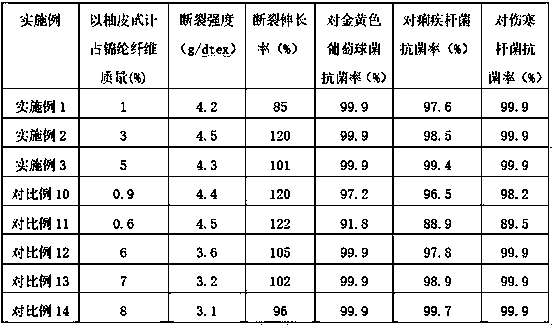

Easy-dyeing modified polyamide fiber

PendingCN111304773ALow boiling water shrinkageImprove performanceMelt spinning methodsArtifical filament manufactureNaringinPolymer science

The invention discloses an easy-dyeing modified polyamide fiber. The easy-dyeing modified polyamide fiber contains 1-5% of naringin; the preparation method of the easy-dyeing modified polyamide fibercomprises the following steps of preparing a naringin-containing functional composition, preparing a modified functional composition, preparing naringin-containing functional master batch, and spinning. The coloring modifier is preferably added in the preparation of the naringin-containing functional composition, the dyeing performance of the prepared fiber can be greatly improved by adding the coloring modifier, the dyeing grade is greater than or equal to 5 grade, the dyeing rate is greater than or equal to 86%, the dyeing rate of the fiber is remarkably improved, and the dyeing unevenness of the fiber is greatly reduced.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

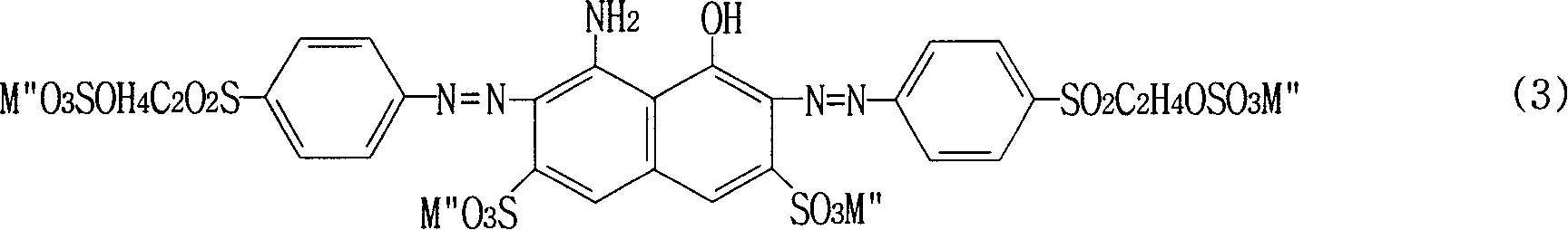

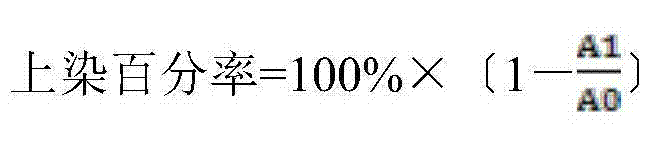

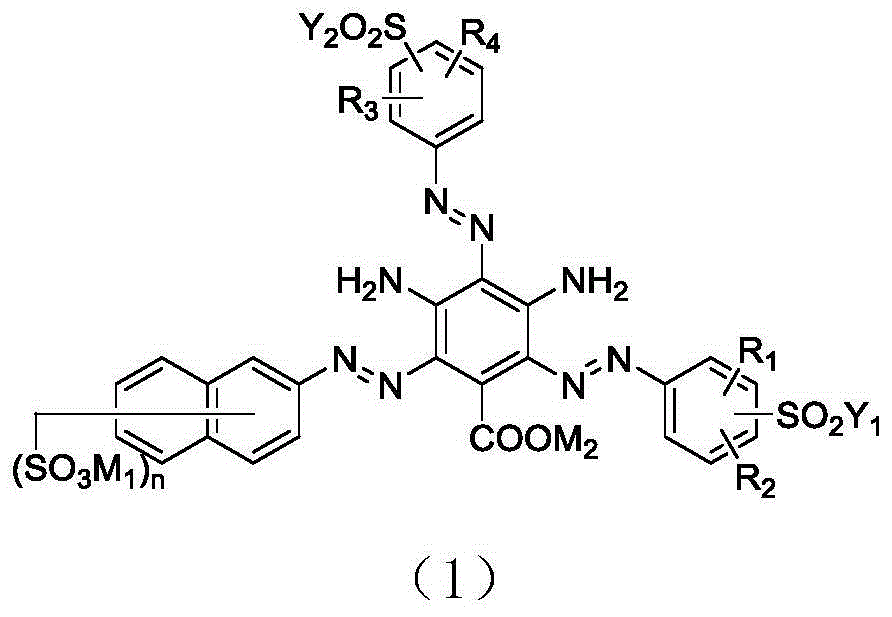

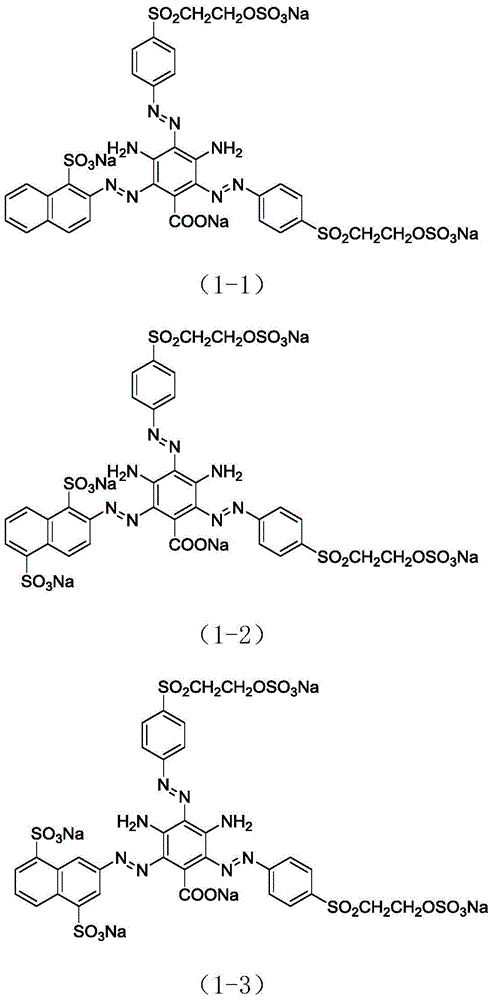

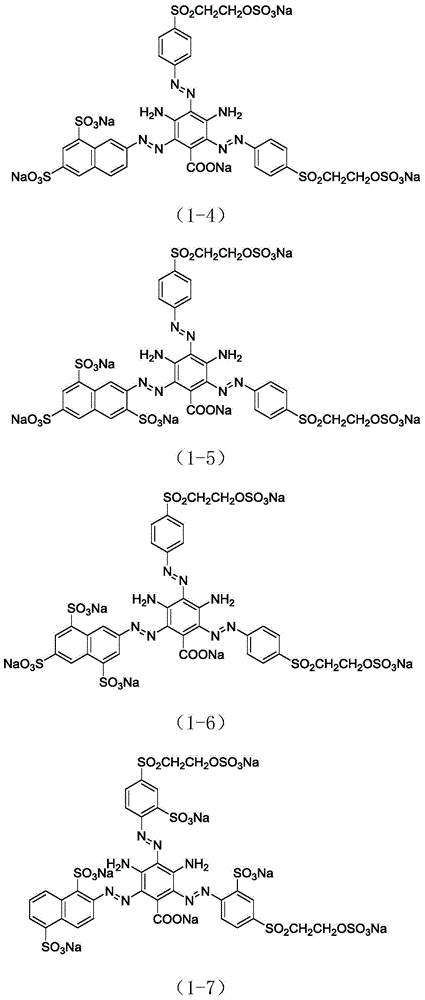

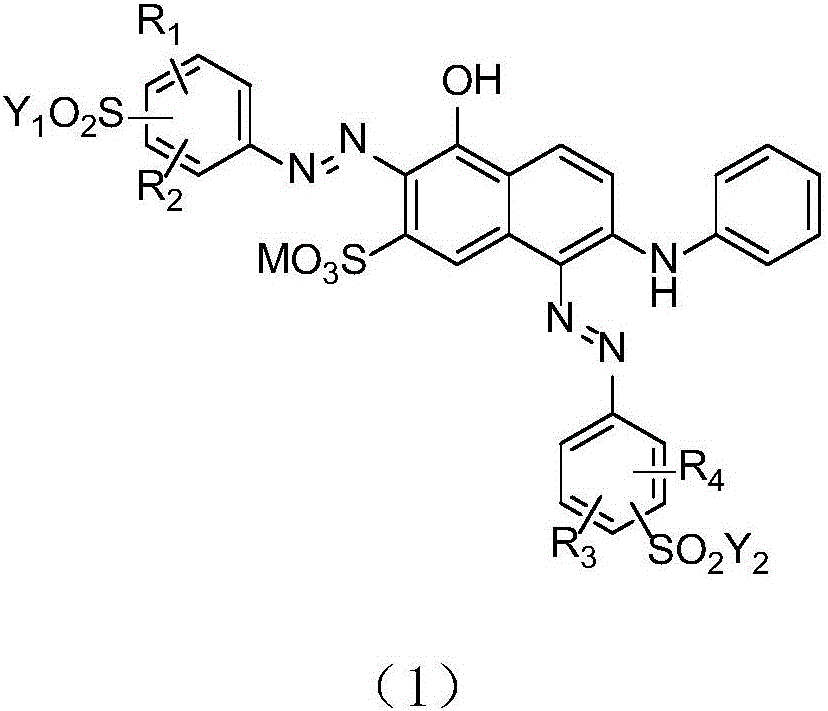

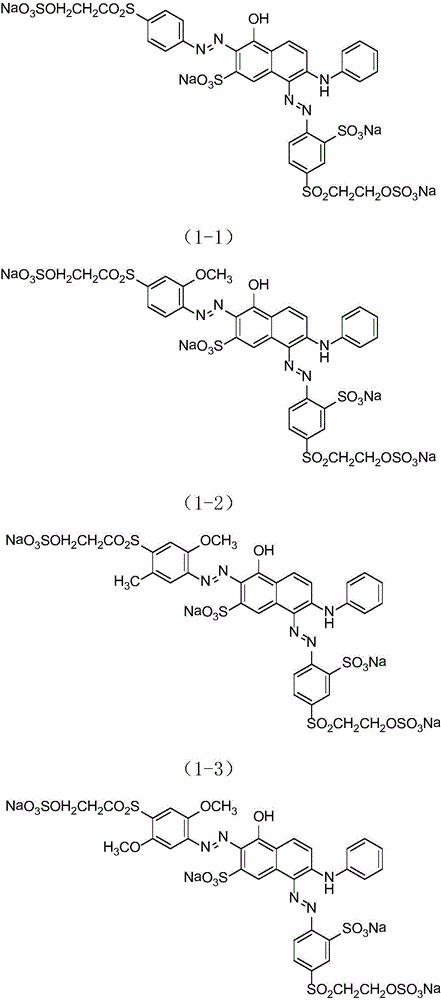

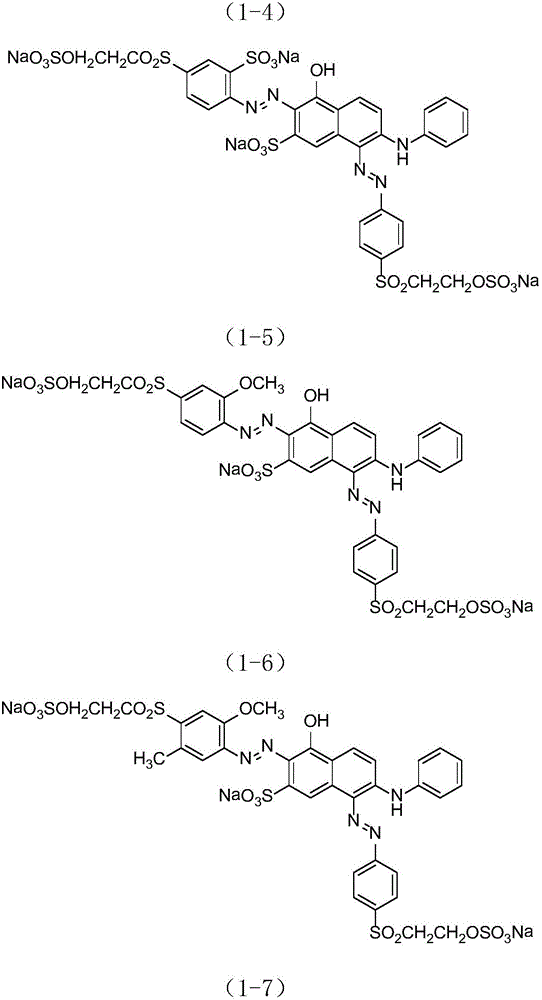

Yellow reactive dye and preparation method thereof

InactiveCN104893357AGood lifting effectGood dyeing depthReactive dyesPolymer sciencePolymer chemistry

The invention relates to a yellow reactive dye and a preparation method thereof. The reactive dye comprises any one compound selected from a general formula (1) or a mixture of any more than two compounds with any proportion selected from the general formula (1) through complex formulation; wherein in the formula (1), R1, R2, R3, R4 are respectively and independently represented as -H, -CH3, -OCH3 or -SO3M1; Y1 and Y2 are respectively represented as -CH=CH2 or -C2H4OSO3M1; M1 and M2 are respectively and independently represented as hydrogen or alkali metal, and n is 1, 2, 3. The yellow reactive dye has excellent coloring synchronicity, high dyeing rate and color fixing rate, good level-dyeing property, excellent solarization and excellent friction fastness.

Owner:华新珍

Staining reagent for staining hematology samples in an automated staining apparatus

InactiveUS20050148083A1Improve concentrationReduce concentrationPreparing sample for investigationBiological testingMedicine.hematologyRomanowsky stain

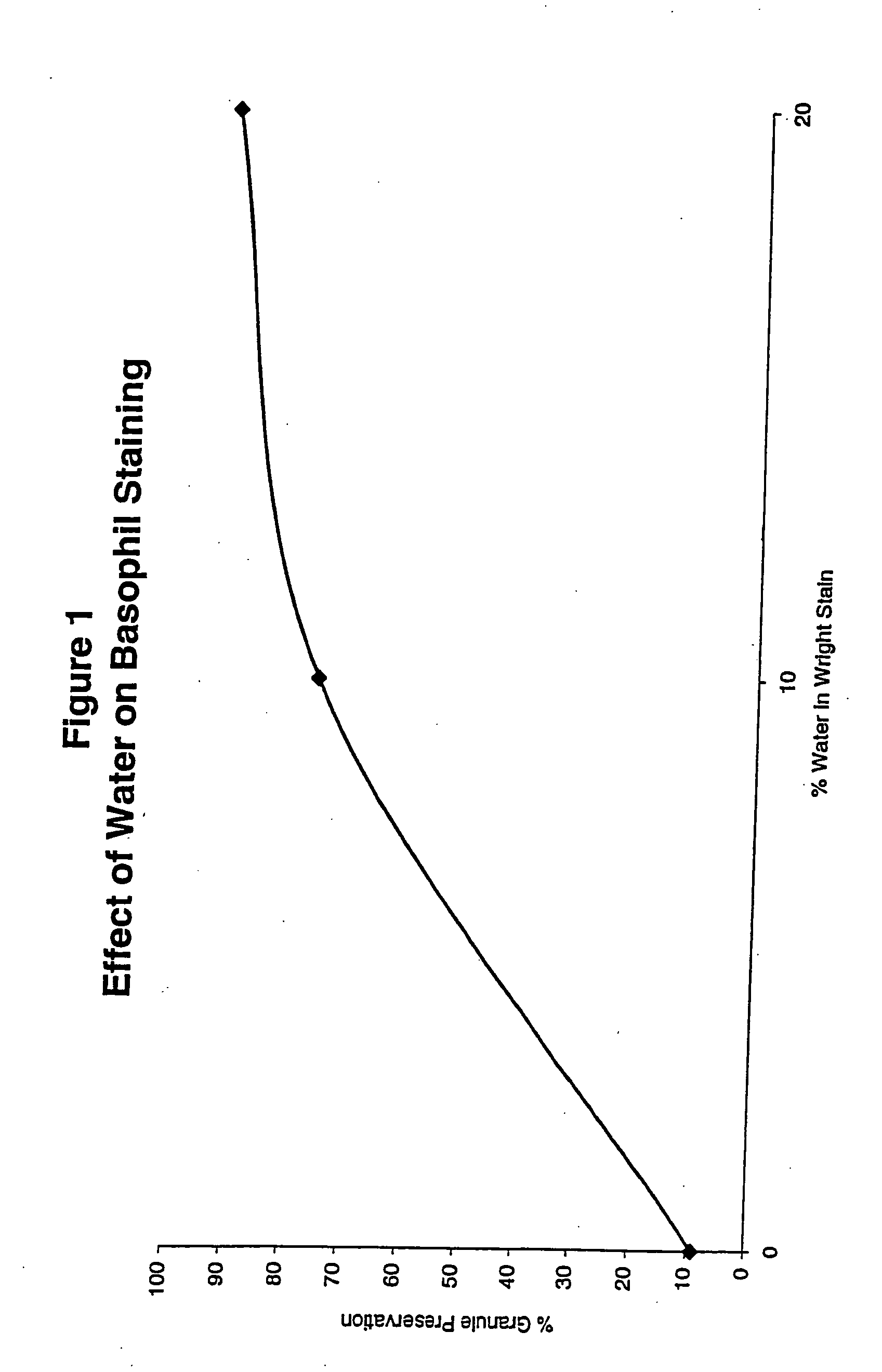

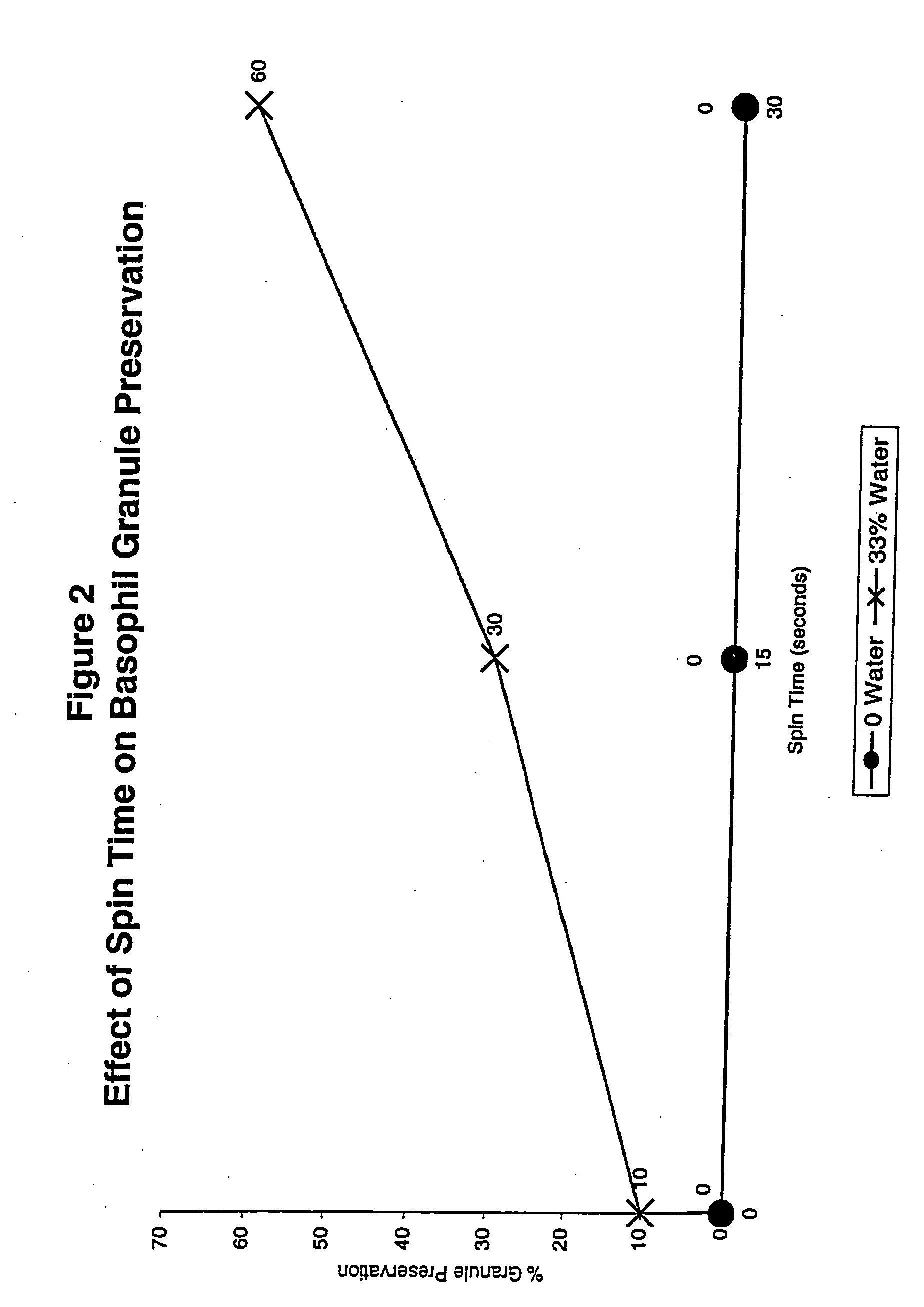

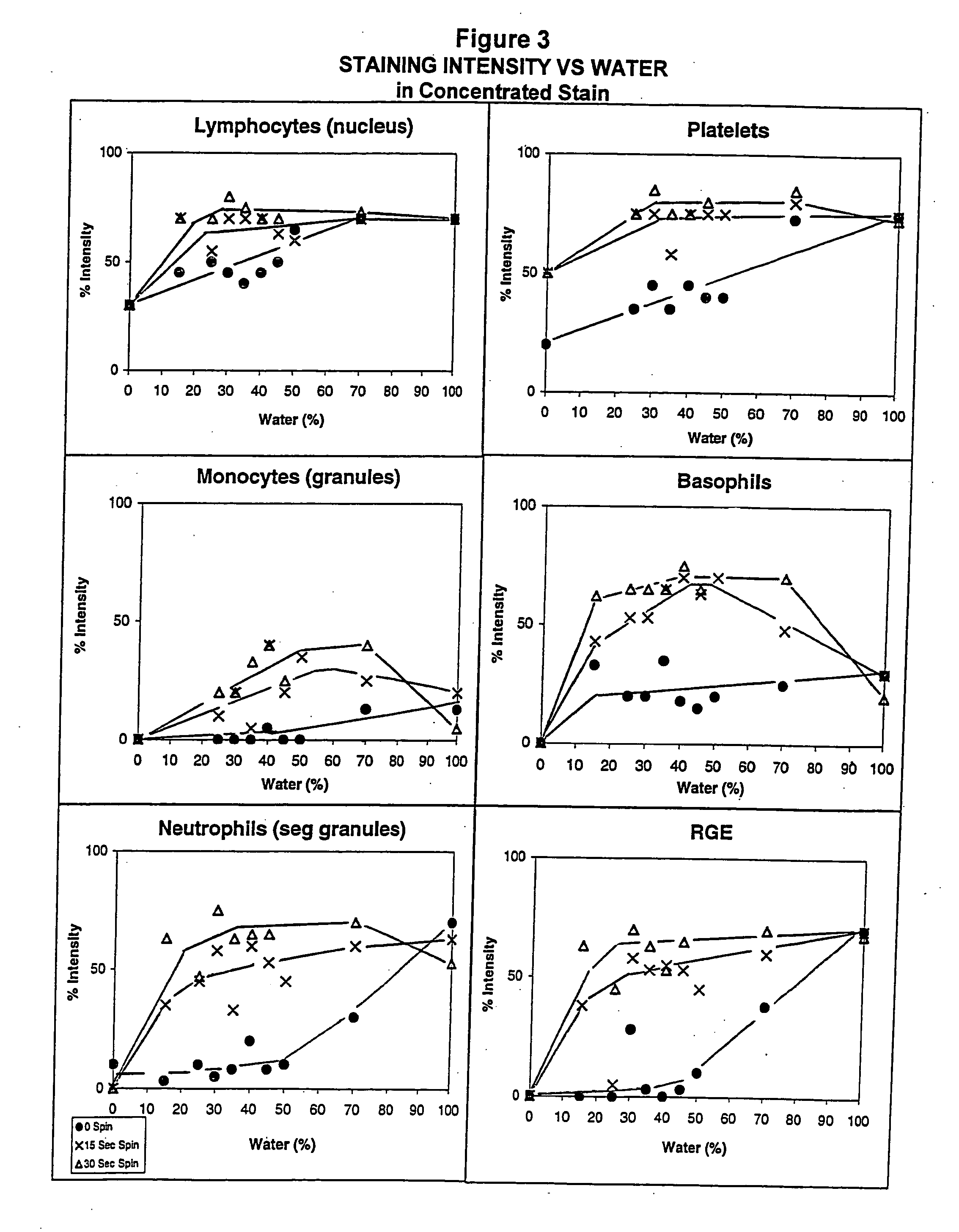

Automated staining equipment that can mix reagents is used to spray a Romanowsky stain onto slide mounted specimens which are then briefly centrifuged. The centrifugation step removes excess stain leaving only a thin film. Depending on the time of the centrifugation step, most of the organic solvent and part of the water in the stain are evaporated by airflow through the equipment. This greatly accelerates the staining reaction and preserves water soluble structures such as the granules in basophilic leukocytes. For optimal performance, this staining procedure requires a thiazin-eosin stain with about 90% to about 40% organic solvent, such as methanol, and only about 10% to about 60% water. This is a unique staining reagent in Romanowsky staining.

Owner:WESCOR

Dyeing and finishing technology of grey cloth

InactiveCN107558041AEasy to operateReduce manufacturing costHeating/cooling textile fabricsDyeing processAfter treatmentEngineering

The invention discloses a dyeing and finishing technology of grey cloth. The technology comprises the following steps that 1, the flat grey cloth is selected to be pretreated; 2, the grey cloth obtained after pretreatment is subjected to steaming; 3, ingredients are added into a dye vat to be fully stirred and mixed; 4, the grey cloth obtained after treatment is put into the dye vat, low temperature heating is conducted, and the PH is adjusted; 5, dye liquor is heated to keep constant temperature; 6, the grey cloth obtained after dyeing is subjected to setting. The adopted dyeing and finishingtechnology is easy to implement, low in production cost, high in dyeing rate and good in dyeing effect, and the production efficiency is improved.

Owner:江苏欣捷纺织科技有限责任公司

Process for producing modified PET/PTT elastic fiber

ActiveCN102127821AAdvanced and reasonable production technologySpinning process is stableArtificial filament physical treatmentFilament/thread formingElastic fibresYarn

The invention discloses a process for producing a modified polyethylene terephthalate / polytrimethylene terephthalate (PET / PTT) elastic fiber, relates to a process for producing a modified elastic fiber, and mainly aims to solve the problems of spinning instability and the like of a product produced by the conventional process. The method comprises the following steps of: tackifying PTT slices and PET slices in a ratio of 40:60; adding the PET slices into a screw extruder for extruding and melting, and heating in five areas; adding the PTT slices into the screw extruder for extruding and melting, and heating in three areas; and mixing a PET melt in a PET melt distributing pipe and PTT fed by a PTTa melt distributing pipe in a weight ratio of 90:10, producing by the conventional process to obtain a partially oriented yarn (POY) bobbin yarn semi-finished product, and showing elasticity by using a draw winder to obtain a draw textured yarn (DTY) finished product. The process has the advantage that: the modified PET / PTT elastic fiber which has spinning stability and high elastic recovery property can be produced.

Owner:辽宁际华新材料制造有限公司

Natural dye and dyeing method

The invention provides natural dye and a dyeing method. The natural dye is prepared in the step as follows: after being aired and smashed, senecio cineraria petals are added to water and subjected toultrasonic extraction. The natural dye has stronger affinity for various fabrics and has the advantages of high dyeing coloring rate, good color fastness and concise process, and meanwhile, the fabrics are endowed with special healthcare performance, and the natural dye has broad application prospects.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

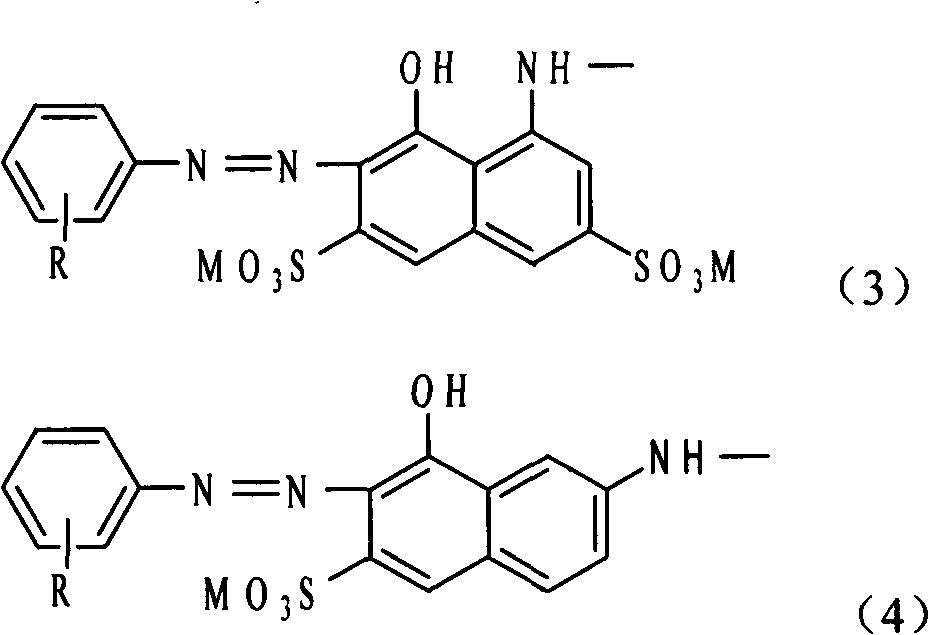

Dark red reactive dye and preparation method thereof

InactiveCN106634045AHigh liftHigh color fixing rateReactive dyesDyeing processHydrogenHeat stability

The invention discloses dark red reactive dye and a preparation method thereof. The dark red reactive dye is one material selected from general formulas of the formula (I) or is a mixture obtained through compounding two or more structures selected from the general formulas of the formula (I) according to any proportion. One material shown by the formula (I) is selected from any one of materials of the following structure general formulas or is a mixture of two or more materials of the structural general formulas, wherein R1, R2, R3 and R4 in the formula (I) respectively and independently represent -H, -CH3, -OCH3 or -SO3M; Y1 and Y2 respectively and independently represent -CH=CH2 or -C2H4OSO3M; M represents hydrogen or alkali metal. The dark red reactive dye has the advantages that the lifting performance is good; the friction firmness, the water washing firmness, the light fastness and the heat stability are high. The formula (I) is shown as the accompanying drawing.

Owner:ZHEJIANG YIDE CHEM

Fabric dyeing process

InactiveCN102852007AFully swollenHigh dyeing rateFibre treatmentDyeing processMaterials scienceDyeing

The invention provides a fabric dyeing process comprising the steps of: a pre-treating process, a water washing process, a dyeing process, a color fixing process, and a bake drying process. According to the fabric dyeing process, the pre-treatment is carried out by using an alkali solution, such that the fabric is sufficiently swelled, and fabric dyeing rate is improved. A color fixing agent is simultaneously added during the dyeing process, such that a fabric dyeing effect is further improved.

Owner:KUNSHAN JIEMING TEXTILE

Orange reactive dye compound and application thereof

InactiveCN104119692AExcellent sweat-light resistanceHigh dyeing rateReactive dyesDyeing processPerspirationReactive dye

The invention provides an orange reactive dye compound (I) with a hydrazone type structure and an application thereof. The compound not only has excellent perspiration-light fastness but also has extremely high fixation rate, better dye depth and better levelling property and wet processing fastness, and the non-fixation part is easy to wash out. When applied to printing and dyeing of fiber materials, the reactive dye compound has excellent perspiration-light resistance, high dye uptake and fixation rate, good improving property, levelling property and dyeing stability and bright and full color.

Owner:ZHEJIANG KEYONG CHEM CO LTD

Spray humidifier and chemical fiber spinning machine

ActiveCN104947217AHigh dyeing rateSolve for uniformityArtificial thread manufacturing machinesWater filterInlet valve

The invention discloses a spray humidifier. The spray humidifier is used for humidifying a fiber belt inside a spinning channel instead of humidification on the whole spinning environment. The spray humidifier comprises a tank, a water inlet valve, a water filter and a channel humidification tube. Water mist is sprayed through cooperation of all components and is brought into the spinning channel via the fiber belt which moves downwards, so the fiber belt can fully and evenly absorb moisture in the spinning channel, and local humidification can be performed according to a fiber movement track. According to the spray humidifier, the problems that due to humidification on the whole environment, energy waste, equipment damage and staff injury are caused are solved, and meanwhile the problems that the dye uptake of existing fibers is low, and dyeing is uneven can be solved. Moreover, local humidification has little influence on the humidity of the environment, will not harm equipment or staff and can guarantee the dye uptake and the dyeing effect, thereby improving product quality.

Owner:BEIJING CHONGLEE MACHINERY ENG

Leather dyeing method

The invention relates to a leather dyeing method, comprising the following steps: accurately weighing Deksol black B, Deksol orange R and Deksol yellow 3RS, fully pulverizing, mixing, and then evenly stirring to obtain the dyeing composition; weighing the dyeing composition, dissolving with water, and evenly shaking to obtain the dye solution; weighing leather, fully soaking with distilled water to be fully drenched; adding water and the leather into a dye jar, stirring for 5-10min, adding the dye solution, fully stirring, placing into a XW infrared-ray sample dyeing machine, adding ethylic acid and heating to 50-60 DEG C, wherein, the heating rate is 1-2 DEG C / min, keeping the temperature for 30-50min, adding formic acid to dye for 30-60min, cooling to 30-40 DEG C, taking out from the pot, washing with flowing water and baking or naturally drying at the temperature of below 50 DEG C.

Owner:TIANJIN DEK CHEM

Straw plaited article dyeing method

InactiveCN107584601AIncrease ionization rateHigh viscosityWood treatment detailsReed/straw treatmentVacuum pumpingFiber

The invention relates to the technical field of straw plaited article processing, in particular to a straw plaited article dyeing method. The method comprises treatment steps as follows: a dyeing solution I with certain concentration is prepared from basic dye and water, locust bean gum is added to the dyeing solution I, a dyeing solution II is obtained after high-speed grinding, a to-be-treated straw plaited article raw material is soaked in the dyeing solution II and subjected to vacuum pumping for 12-16 min, then a vacuum pump is closed, the straw plaited article raw material is subjected to pressurizing treatment, the treated straw plaited article raw material is placed in an environment with temperature being 38-40 DEG C and relative humidity being 43%-46% until water content of strawplaited fiber is reduced to 9%-10%, and the straw plaited fiber is sent to a treatment tank again and subjected to vacuum pumping again. On the premise that no dyeing auxiliary is added, higher dyeing rate and dyeing fastness can still be guaranteed.

Owner:阜南佳利工艺品股份有限公司

Levelling agent and preparation method and application thereof

The invention provides a levelling agent and a preparation method and application thereof. The levelling agent comprises, by weight, 10-30 parts of fatty alcohol polyoxyethylene ether, 5-10 parts of toluene, 1-3 parts of sodium benzoate, 3-5 parts of ethoxylated lanolin, 0.5-3 parts of sodium sulfate, 0.5-2 parts of sodium acetate, 1-5 parts of N-methyl pyrrolidone and 100-250 parts of water. Thepreparation method includes: adding various raw materials into water at normal temperature, and stirring at high speed to obtain an emulsion; heating the emulsion to 50-60 DEG C while stirring, fast cooling to -2-0 DEG C, and slowing heating to normal temperature. The levelling agent is used for fabric dyeing. The levelling agent does not aggregate with dye and is good in levelling effect. The preparation method is simple to operate, and the prepared levelling agent is good in stability and wide in application range.

Owner:方富(广州)高新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com