Method for dyeing silk cotton blended spinning knitted fabric

A dyeing method and technology for knitted fabrics, which are applied in the field of knitted fabric dyeing and can solve the problems of poor homochromaticity, difficulty, and light color of blended fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

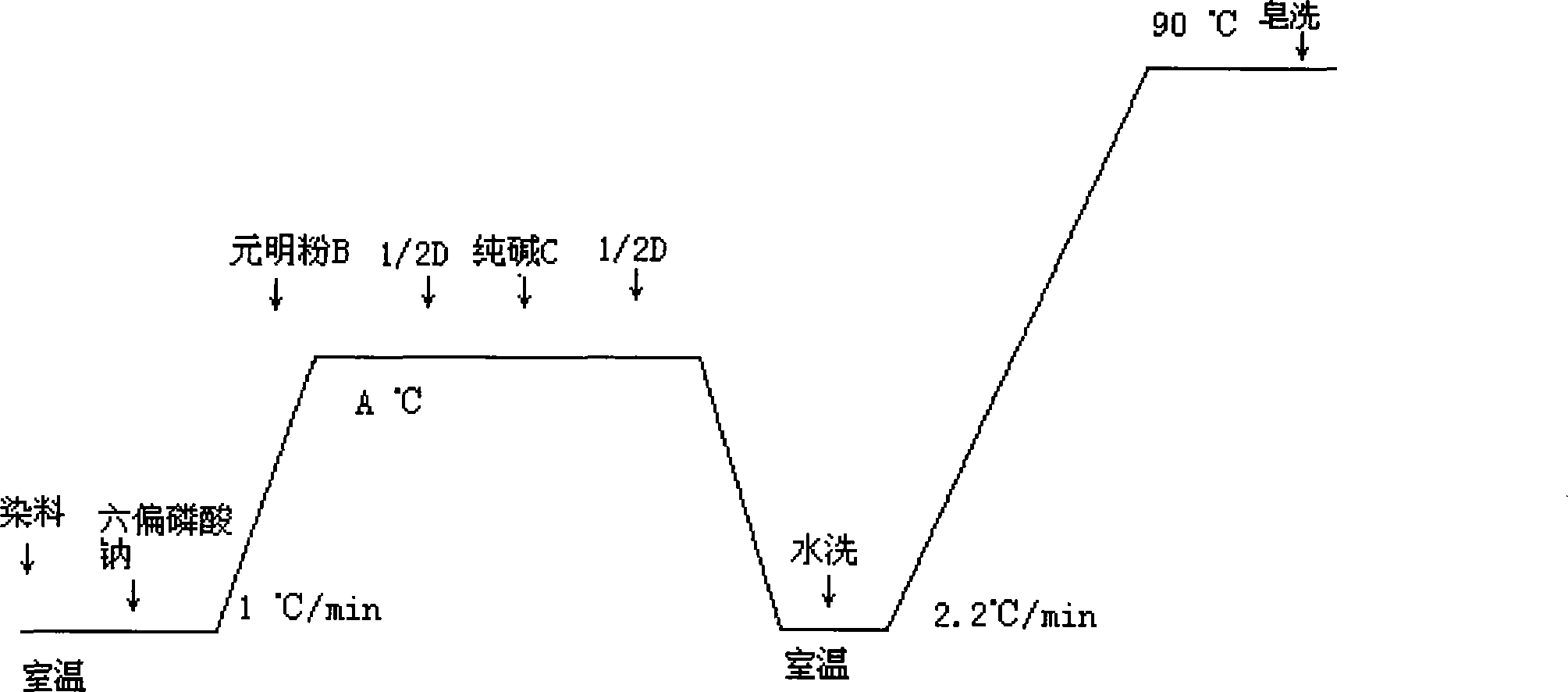

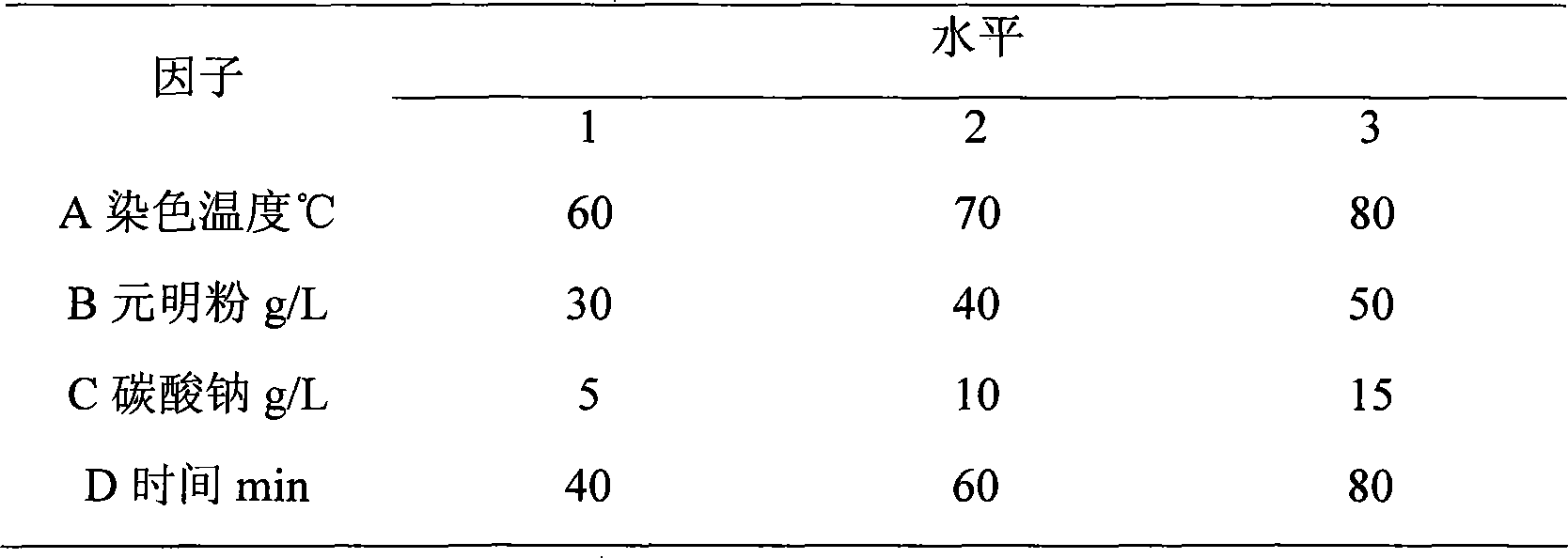

Method used

Image

Examples

Embodiment 1

[0033] Before dyeing, spun silk / cotton blended fabrics must be pre-treated to remove impurities from the fabric. In this example, weakly alkaline soda ash was selected in the scouring process, and an oxygen bleaching process was adopted.

[0034] The fabrics used are scoured and bleached using the following techniques:

[0035] Scouring and bleaching equipment: RY-12000 high temperature dyeing prototype

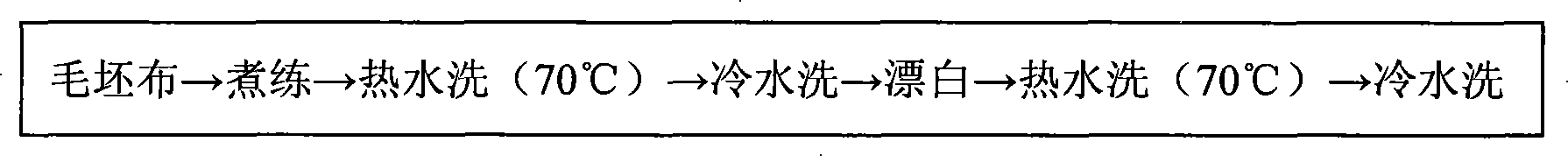

[0036] Process flow: rough cloth → scouring → hot water washing (70°C) → cold water washing → bleaching → hot water washing (70°C) → cold water washing scouring process conditions:

[0037] Prescription g / L

[0038] Scouring agent w100 4

[0040] Soda ash 1.5

[0041] Hydrosulfite 0.5

[0042] Bath ratio 1:20

[0043] Temperature and time 95°C, 40min.

[0044] Bleaching process conditions

[0045] Prescription g / L

[0048] Pingping plus O 0.3

[0049] Bath ratio 1:20

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com