Spray humidifier and chemical fiber spinning machine

A humidifier and humidification tube technology, applied in the field of textile processing, can solve problems such as damage to equipment and electrical components, low fiber moisture absorption, damage to the spinning environment, etc., to improve quality, solve energy waste, and solve problems with low dye uptake. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0018] In the embodiment of the present invention, since the spray humidifier is mainly used for humidifying the fiber belt inside the spinning tunnel. Therefore, the present invention first introduces the chemical fiber spinning machine equipped with the spray humidifier.

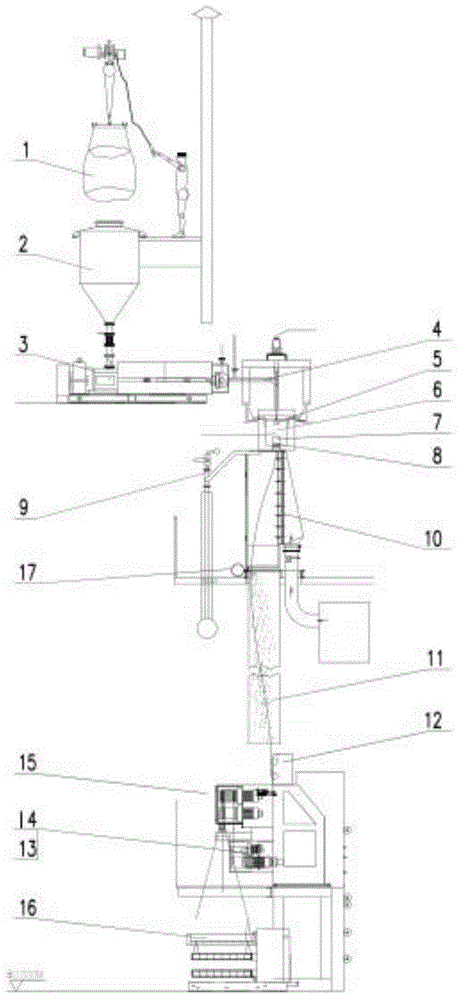

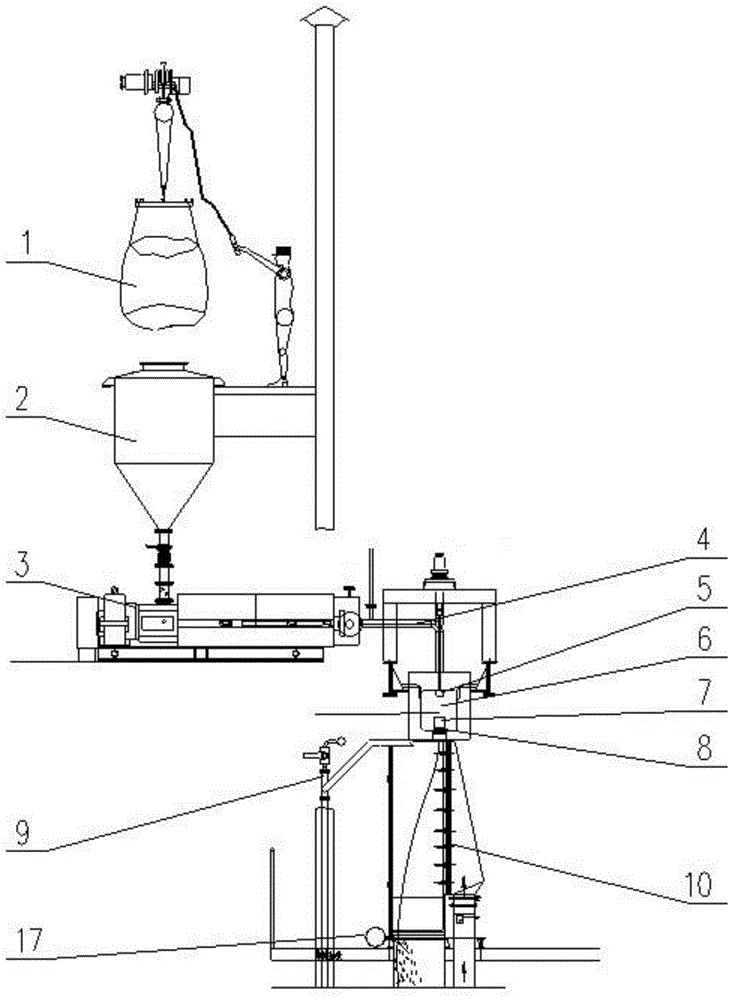

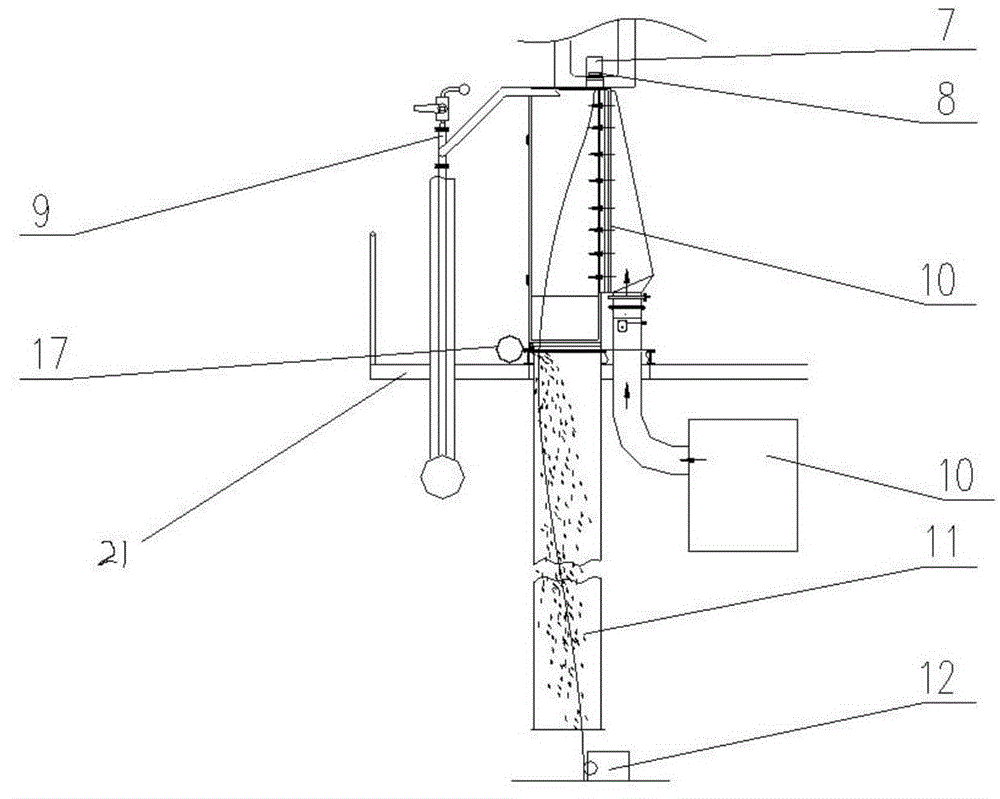

[0019] For details, please refer to figure 1 , is a schematic diagram of the chemical fiber spinning machine, which mainly includes: material bag 1, silo 2, extruder 3, melt pipe 4, metering pump 5, spinning box 6, spinning assembly 7, spinneret 8. Monomer suction 9, side blowing 10, spinning tunnel 11, oiling device 12, first drafting roller 13, second drafting roller 14, third drafting roller 15, winding head 16, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com