Circulation steam denim spraying dyeing device

A dyeing device and technology for denim, which is applied to the equipment configuration of textile materials, spray/jet textile material processing, ultrasonic/sonic fiber processing, etc. Achieve high performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

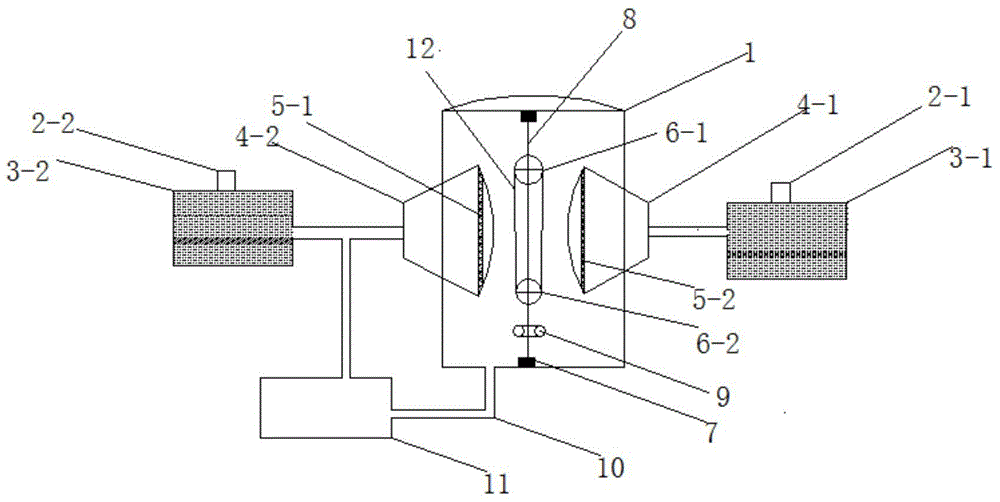

[0015] The circulating steam denim spraying and dyeing device consists of the dyeing device main body (1), the dosing port (2-1, 2-2), the dye box (3-1, 3-2), the plasma generator (4-1, 4 -2), plasma nozzle (5-1, 5-2), movable shaft wheel (6-1, 6-2), rotary drive machine (7), support rod (8), bearing seat (9), steam conduit (10), steam engine (11), denim (12), it is characterized in that: described dyeing device main body (1) outer two sides are provided with plasma generator (4-1,4-2), in described The plasma generator (4-1, 4-2) is provided with a plasma shower head (5-1, 5-2), the dye box (3-1, 3-2) and the plasma generator (4-1, 4- 2) communicated, the dye box (3-1, 3-2) is provided with a dosing port (2-1, 2-2); the lower left corner of the main body (1) of the dyeing device is provided with a steam engine (11), and The steam conduit (10) is connected with the main body (1) of the dyeing device and the steam engine (11); the support rod (8) is arranged on the bearing sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com