Easy-dyeing modified polyamide fiber

A nylon fiber and modification technology, which is applied in the field of dyeable modified nylon fiber, can solve the problems of decreased dye uptake, unstable quality control, and decreased dyeing performance, and achieves reduced shrinkage in boiling water, improved physical stability, and improved The effect of taking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

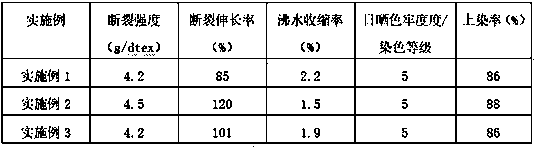

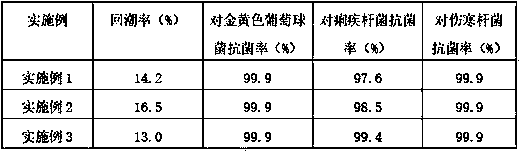

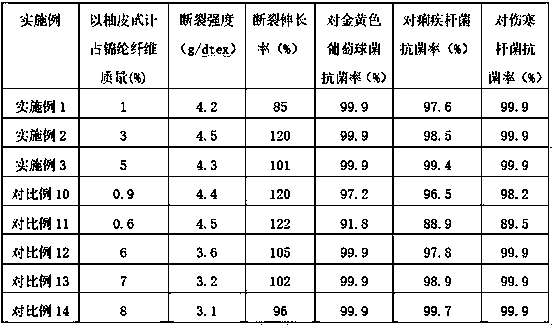

Examples

Embodiment 1

[0045] The preparation method of embodiment 1 easy-to-dye modified polyamide fiber, comprises the following steps:

[0046] (1) Preparation of functional composition containing naringin: Mix the following raw materials in parts by weight: 5 parts of naringin, 1 part of montmorillonite, 0.7 part of zeolite powder, 0.5 part of airgel, porous nano-TiO2 microspheres 0.1 part; weigh montmorillonite, zeolite powder, aerogel, porous nano TiO2 microspheres, then add naringin, add in the pulverizer, stir evenly with the speed of 30rad / s, then pass through a 10000 mesh sieve to obtain Functional composition of naringin;

[0047] Naringin is naringin, also known as isohesperidin, citrusin 7-O-neohesperidin, weight loss on drying ≤0.5%, light yellow powder or off-white powder, belonging to flavonoids;

[0048] The average particle size of montmorillonite is 1-1.5 μm, and the expansion degree is ≥13.5%; the zeolite powder is 50-80 mesh;

[0049] Airgel is silica powder, specific surface ...

Embodiment 2

[0064] The preparation method of embodiment 2 dyeable modified polyamide fiber, comprises the following steps:

[0065] (1) Preparation of functional composition containing naringin: Mix the following raw materials in parts by weight: 5 parts of naringin, 1 part of montmorillonite, 0.7 part of zeolite powder, 0.5 part of airgel, porous nano-SiO2 microspheres 0.1 part; Weigh montmorillonite, zeolite powder, aerogel, porous nano-SiO2 microspheres, then add naringin, add in the pulverizer, stir evenly with the speed of 30rad / s, then cross 10000 mesh sieves to obtain Functional composition of naringin;

[0066] The naringin is naringin, also known as isohesperidin, that is, citrusin 7-O-neohesperidin, with a weight loss on drying of ≤0.5%, light yellow powder or off-white powder, belonging to flavonoids;

[0067] The average particle size of the montmorillonite is 1-1.5 μm, and the expansion degree is ≥ 13.5%; the zeolite powder is 50-80 mesh;

[0068] The airgel is silicon diox...

Embodiment 3

[0084] The preparation method of embodiment 3 easily dyeable modified polyamide fiber, comprises the following steps:

[0085] (1) Preparation of functional composition containing naringin: Mix the following raw materials in parts by weight: 5 parts of naringin, 1 part of montmorillonite, 0.7 part of zeolite powder, 0.5 part of airgel, porous nano-SiO2 microspheres 0.1 part; Weigh montmorillonite, zeolite powder, aerogel, porous nano-SiO2 microspheres, then add naringin, add in the pulverizer, stir evenly with the speed of 30rad / s, then cross 10000 mesh sieves to obtain Functional composition of naringin;

[0086] The naringin is naringin, also known as isohesperidin, that is, citrusin 7-O-neohesperidin, with a weight loss on drying of ≤0.5%, light yellow powder or off-white powder, belonging to flavonoids;

[0087] The average particle size of the montmorillonite is 1-1.5 μm, and the expansion degree is ≥ 13.5%; the zeolite powder is 50-80 mesh;

[0088] The airgel is silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com