Patents

Literature

50results about How to "Low boiling water shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-enhanced polylactic acid fiber and preparation method thereof

ActiveCN102634866AHigh normal temperature mechanical strengthLow boiling water shrinkageArtificial filament heat treatmentMelt spinning methodsFiberSpin speed

The invention relates to a self-enhanced polylactic acid fiber and a preparation method thereof. The self-enhanced polylactic acid fiber provided by the invention is a uniform mixture of a vertical compound crystal polylactic acid micro-fiber and a polylactic acid substrate. In 100 weight parts of self-enhanced polylactic acid fiber, 1-30 parts of vertical compound crystal polylactic acid micro-fiber and 70-99 parts of polylactic acid substrate are contained. The preparation method of the fiber comprises the following steps: firstly, respectively carrying out vacuum drying on PLLA (poly L lactic acid) and PDLA (poly D lactic acid); physically mixing PLLA with PDLA after being dried; fusing the mixture; collecting primary fibers under the conditions that a spinning temperature is 225-245 DEG C and a spinning speed is 500-2500 meters per minute; and thermally drafting and thermally shaping the primary fibers. Compared with the common polylactic acid fiber, the self-enhanced polylactic acid fiber disclosed by the invention has the advantages of higher constant temperature mechanical strength, higher high temperature mechanical strength and lower boiling water shrinkage, so that the use demand is met and the application field is expanded.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

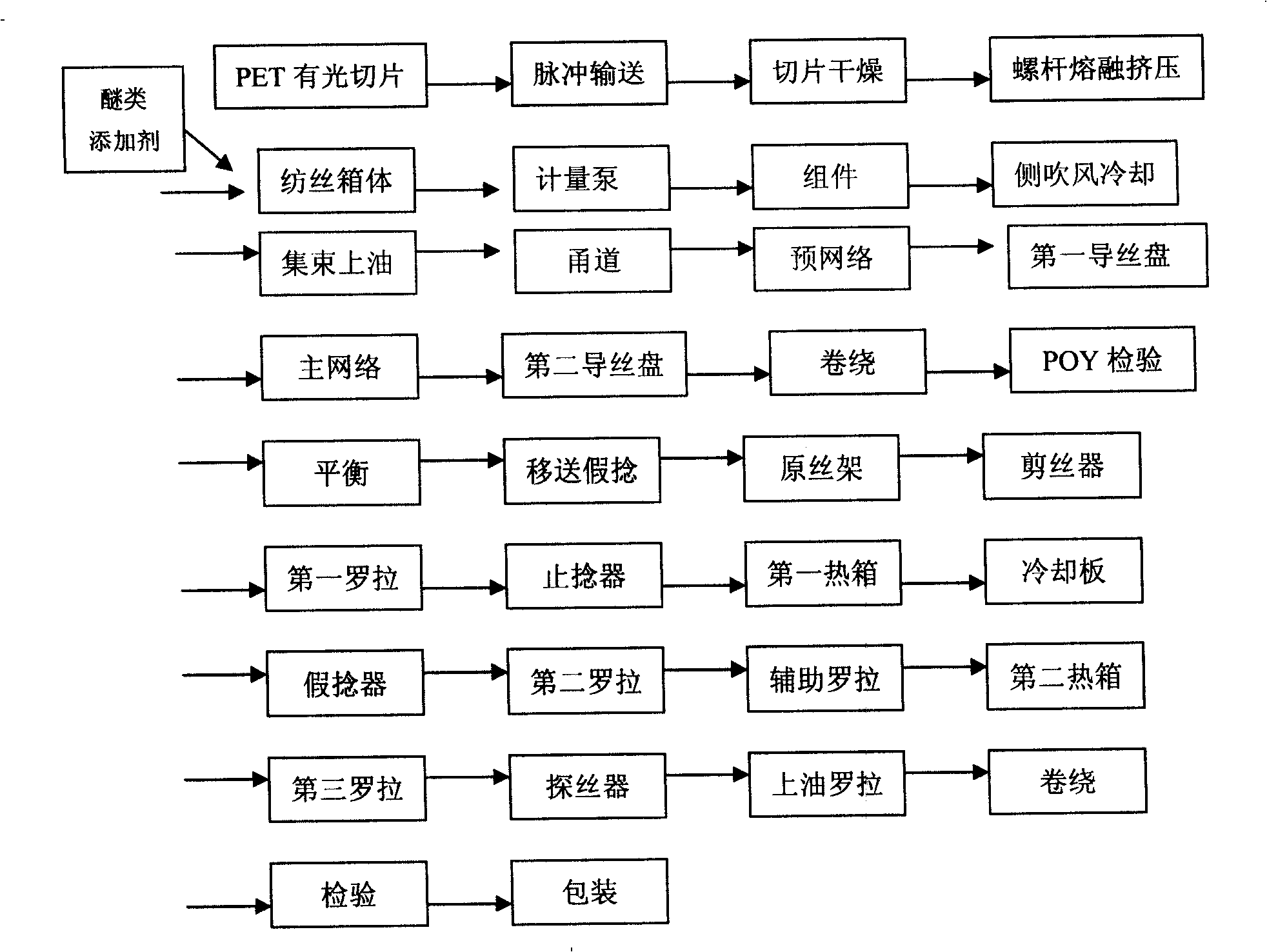

Method for producing modified cation polyester filament and product thereof

ActiveCN102094256ABionic features are obviousLow boiling water shrinkageMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterPolymer science

The invention belongs to the field of manufacture of chemical fibers, in particular to a method for producing a modified cation polyester filament imitating a cellulose fiber. The method comprises the following steps of: preparing modified cation polyester; carrying out melting spinning by aiming at the characteristics of the modified cation polyester to obtain an orientated filament; and carrying out false twisting on the orientated filament under the condition of a special elasticizing process. The invention also provides a modified cation polyester filament prepared with the production method. The cation polyester filament disclosed by the invention has favorable fuzzing and pilling resistance, can be dyed at normal pressure without high-temperature and high-pressure conditions, saves the dyeing cost and has bright color after being dyed and high skin intimacy, and the hygroscopicity is better than that of common cation terylene filament.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

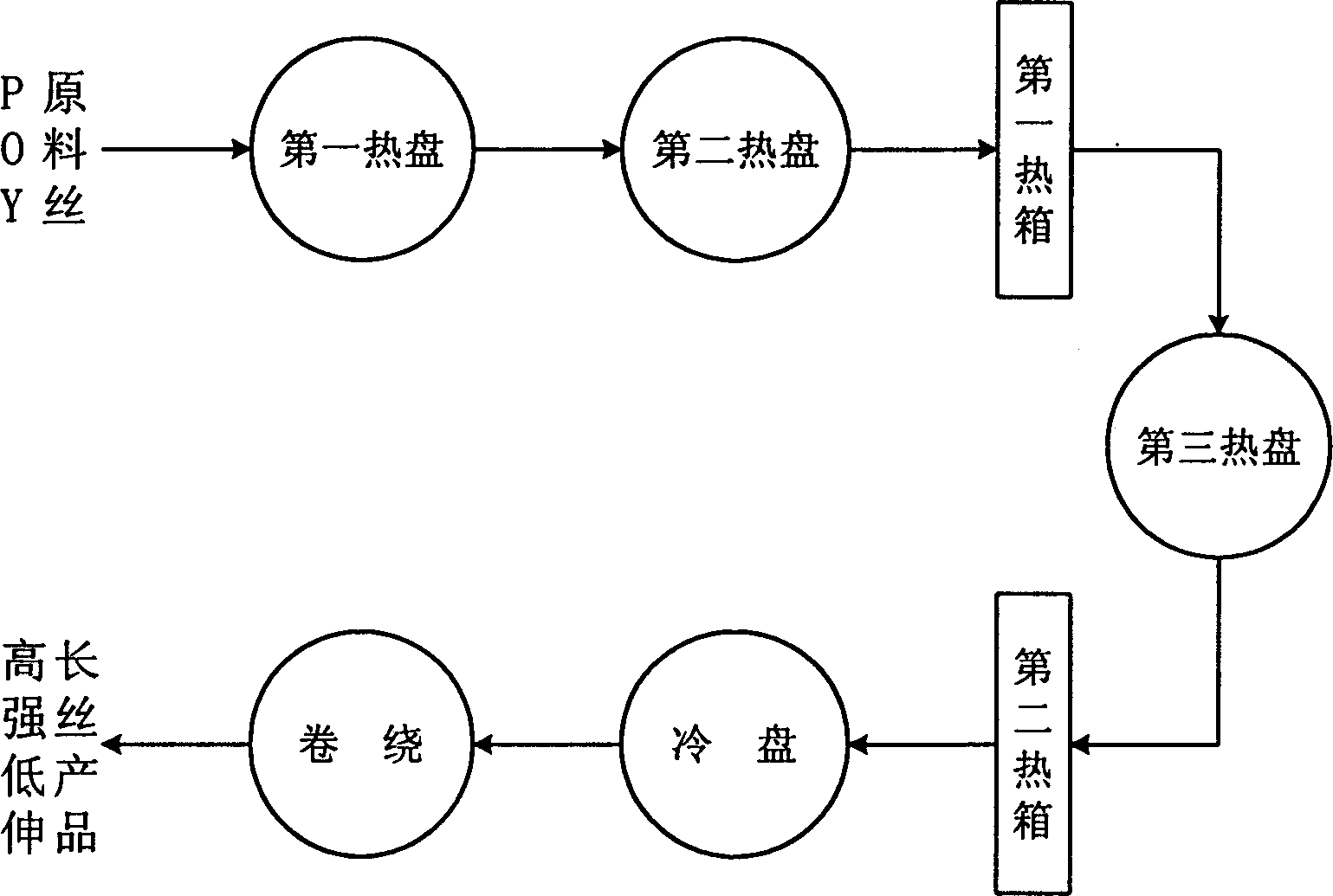

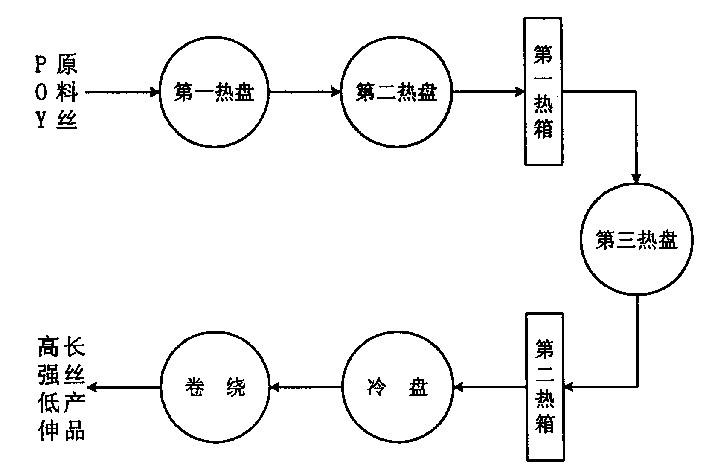

Manufacture of high tenacity low-stretch polyester filaments

InactiveCN1448547AWide variety of sourcesIncrease production capacityMelt spinning methodsYarnHigh intensityUltimate tensile strength

The present invention relates to Dacron producing process, and is especially preparation process of high-strength and low-elongation Dacron filament for sewing thread. The preparation process with routine pre-oriented POY filament includes successive first high-power drafting in the first and the second heating discs, high temperature tensed heat setting in the first heating box and the third heating box, the second drafting and the high temperature relax heat setting in the second heating box. In the process, POY filament has good drafting performance, no teasing and breaking, and the final product has high strength, low elongation and less heat shrinkage.

Owner:SINOPEC YIZHENG CHEM FIBER

Textured yarn and processing method, special device and applications thereof

InactiveCN101824689ALow section deformationLow boiling water shrinkageFibre treatmentYarnYarnEngineering

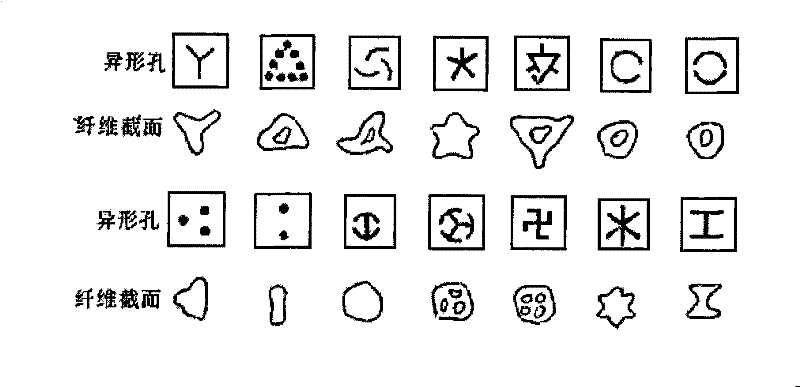

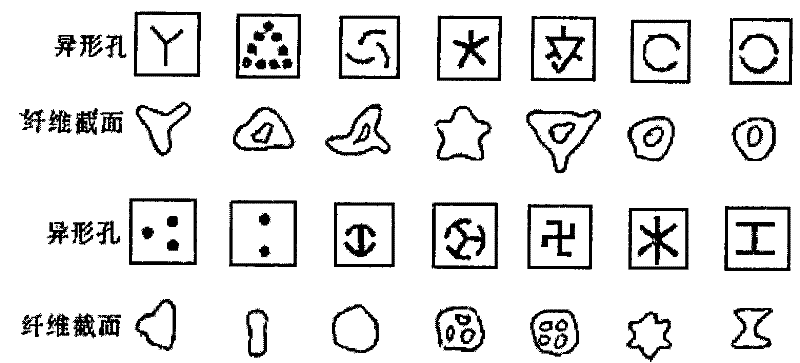

The invention discloses a textured yarn and a processing method, special device and applications thereof. The textured yarn has lower cross-section deformability and boiling water shrinkage. The processing method is to use the special device to disturb the number of turns of the yarns in a thermosetting box in the twisting area of a texturing device to obtain the textured yarn characterized by low elastic recovery rate and cross-section deformability. The textured yarn prepared by the method fills the gap of low crimp textured yarn between the draw yarn and the low stretch yarn, the processed yarn is characterized by low cross-section deformability, smoothness and good luster and the processing method of the invention is especially suitable to process the tri-differential filament with irregular section which has low cross-section deformability to maintain the cut surface characteristic of the yarn. The processed yarn not only has a certain inherent crimp characteristic of the textured yarn, but also the low cross-section deformability characteristic of the draw yarn, thus expanding the process range of the existing texturing device.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

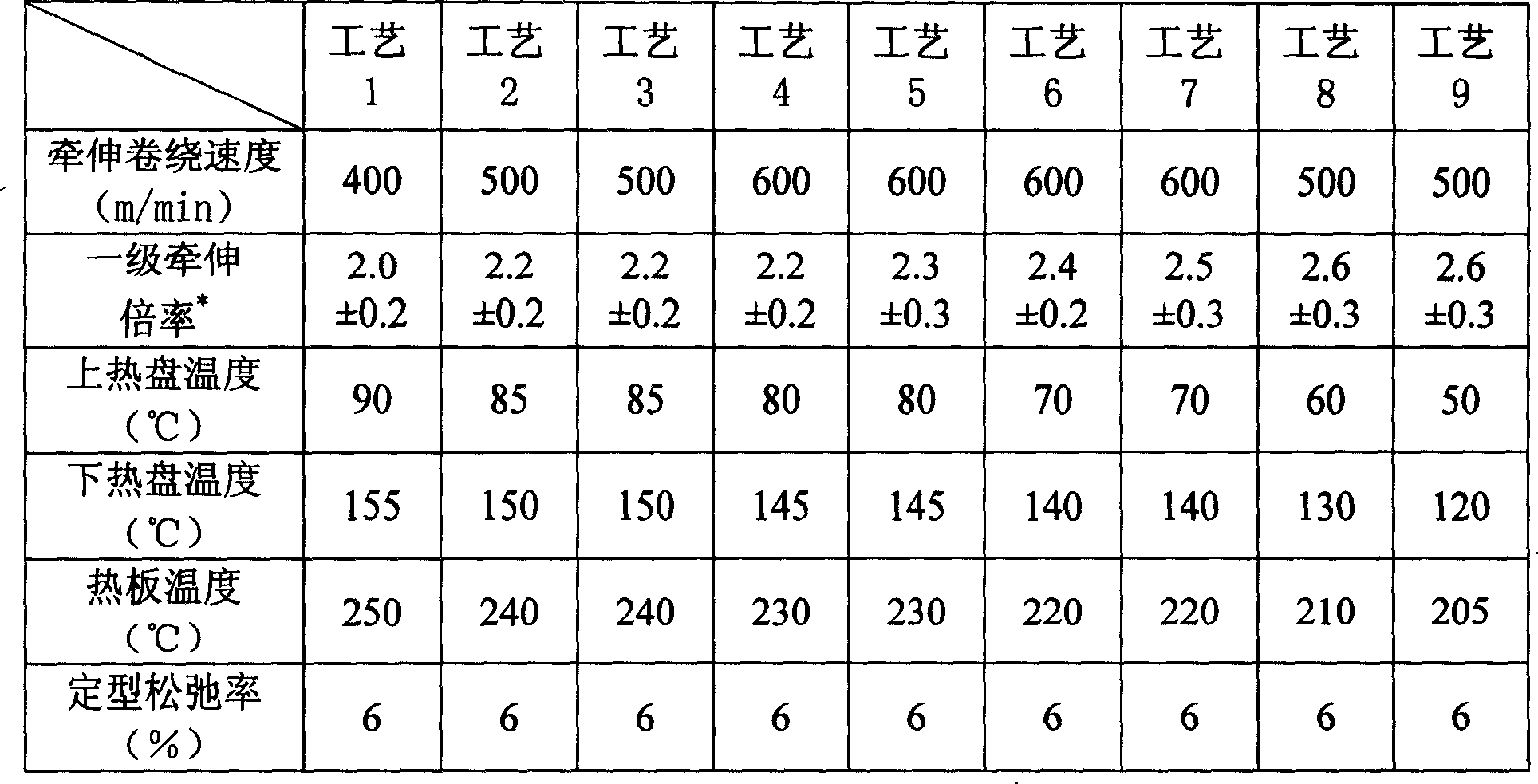

Fine denier high intensity low shrinkage polyester filament yarn processing method

ActiveCN101086086AWide variety of sourcesReduce manufacturing costFilament/thread formingMonocomponent polyesters artificial filamentMagnificationHigh intensity

The invention provides a processing method of fine denier, high-strength and low-shrinkage polyester filament. The method uses the ordinary POY polyester pre-oriented silk as pre-processing raw materials which is obtained in spinning speed of 2500 - 3300m / min and in the condition of need not be increased control-cooling, improves the prior dual-heat-discs horizontal traction machine, adjusts the design of traction technology, processes consecutively through several procedures of first level drafting, one-shot relaxed heat forming and rolling to control the drafting temperature, drafting magnification and shaping relaxation rate accurately, then produces fine denier, high-strength and low-shrinkage polyester filament which denier is 30D-200D. The strength of products can reach 8.0 +- 0.5g / d (7.0 +- 0.4cN / dtex), the broken elongation is 14.0% +- 3.0% and the boiling-water shrinkage ratio is below 2.0%, it meets the requirements of producing high and middle grade polyester filament sewing thread.

Owner:SINOPEC YIZHENG CHEM FIBER

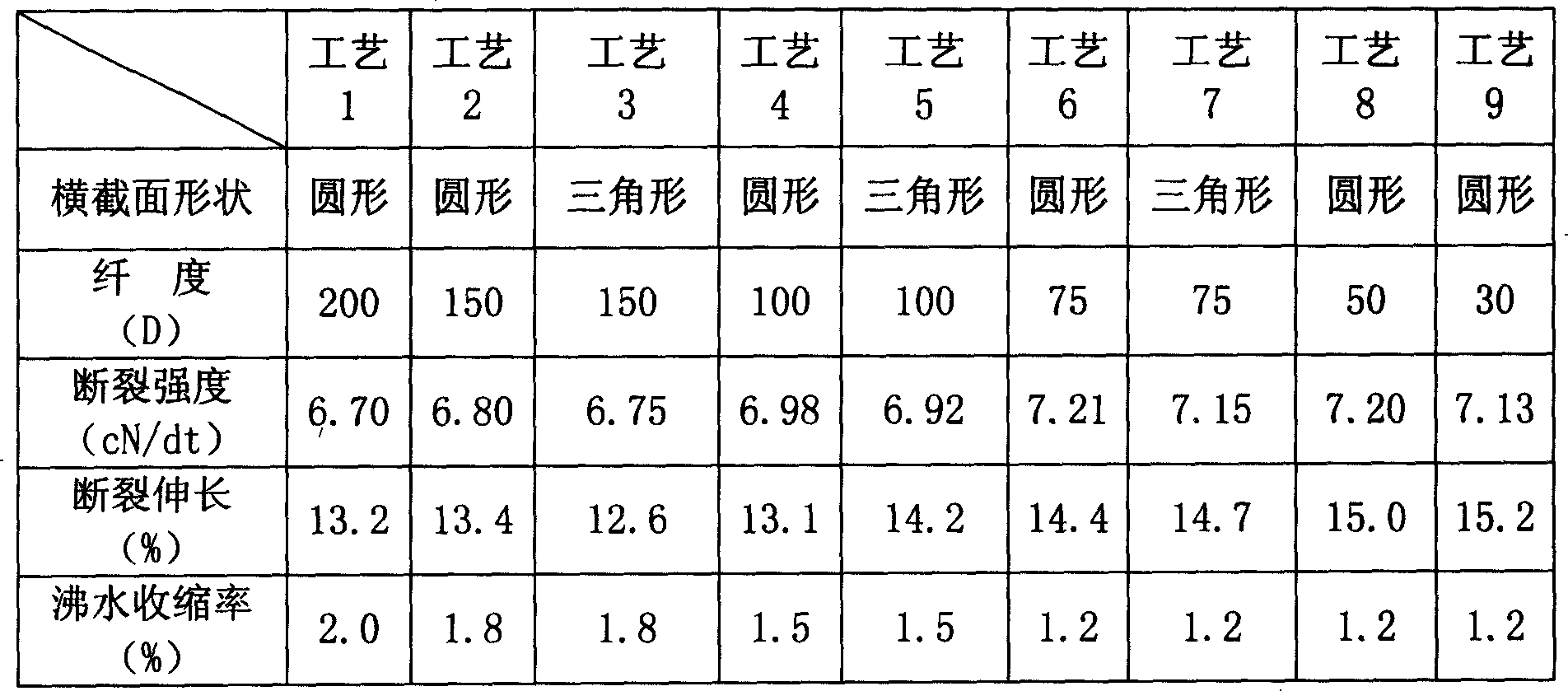

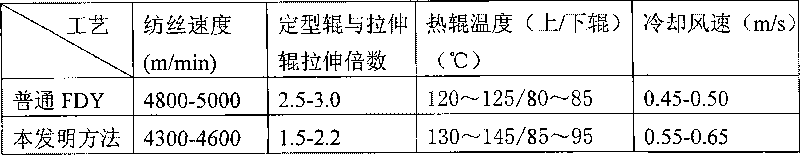

Fully drawn polyester fiber and methods for preparing the same

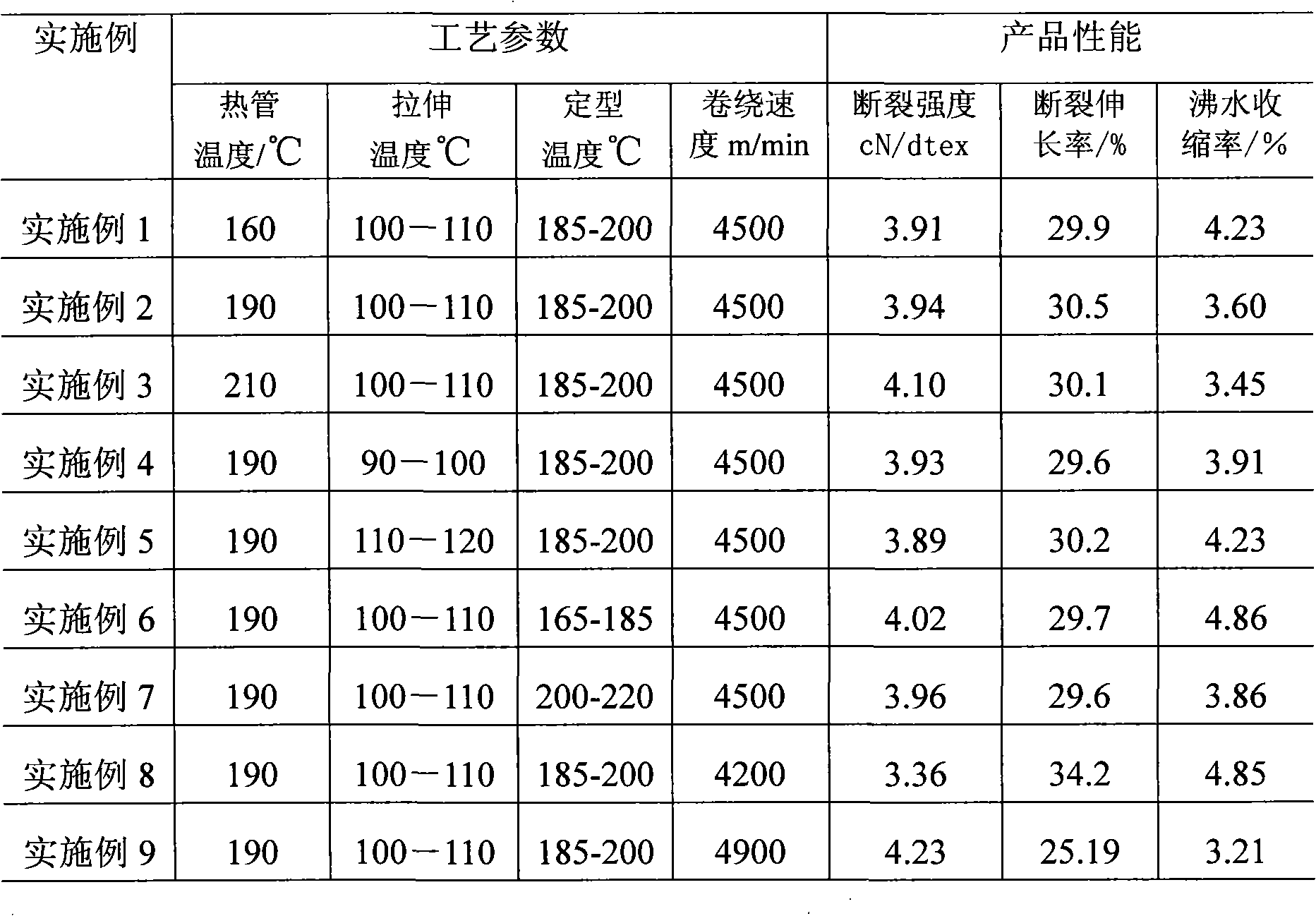

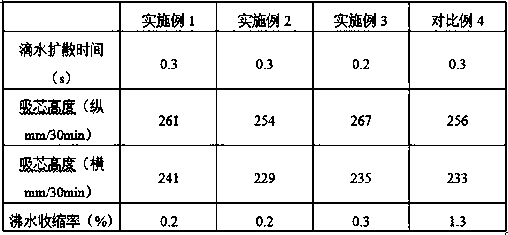

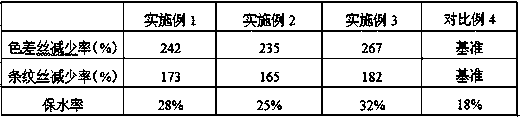

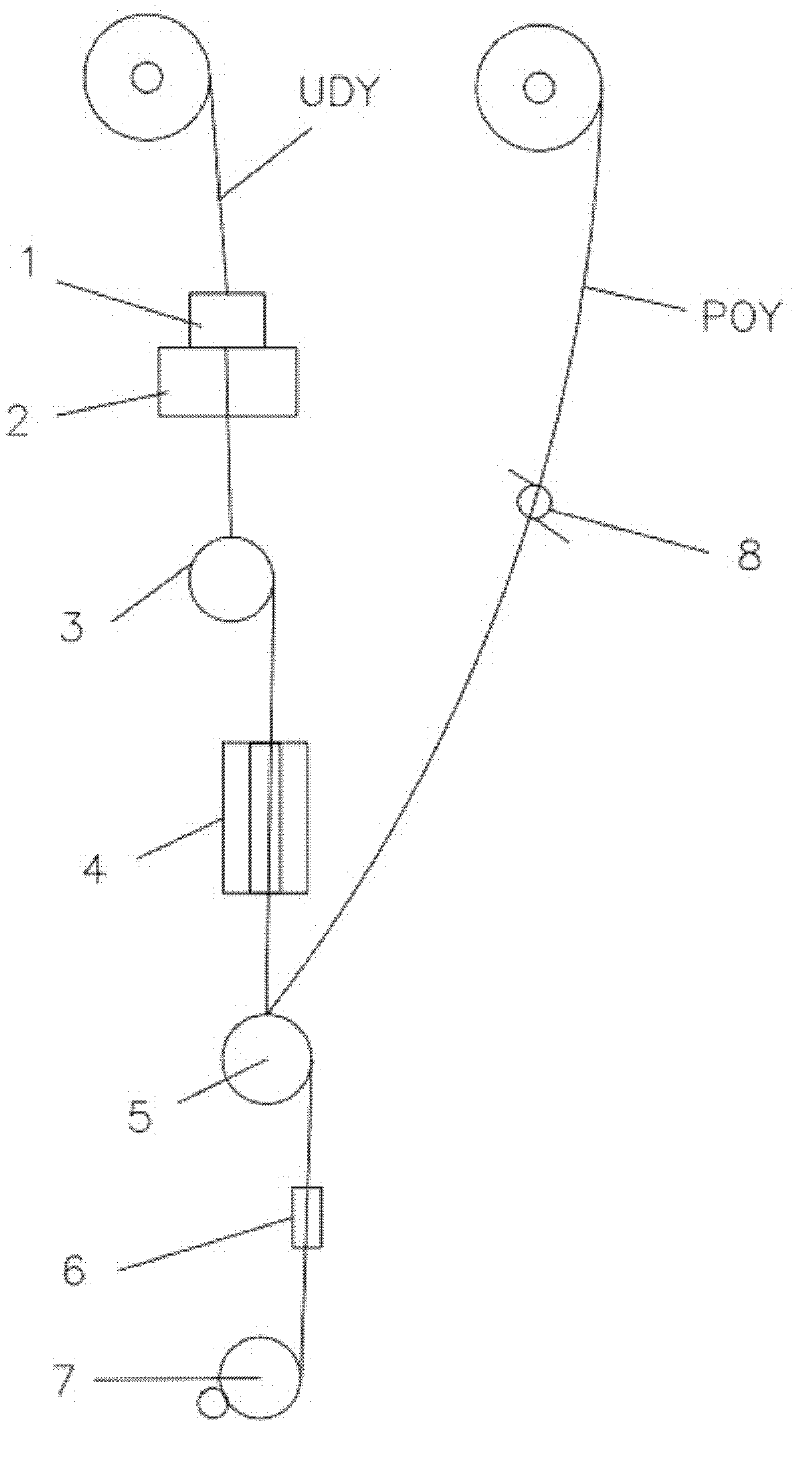

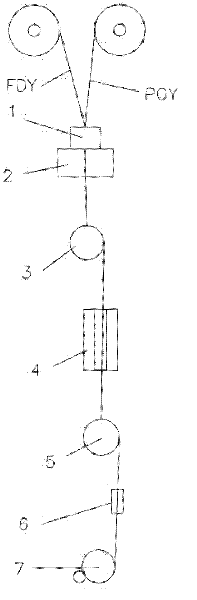

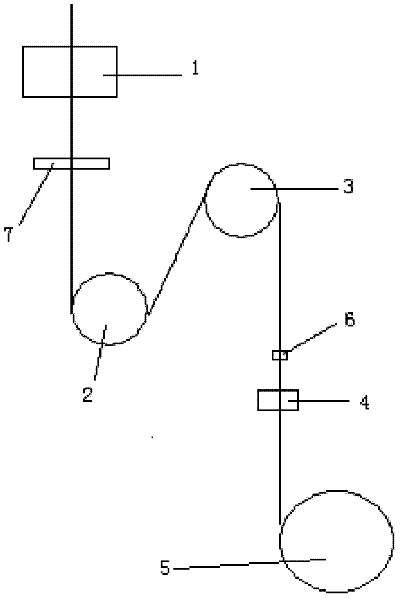

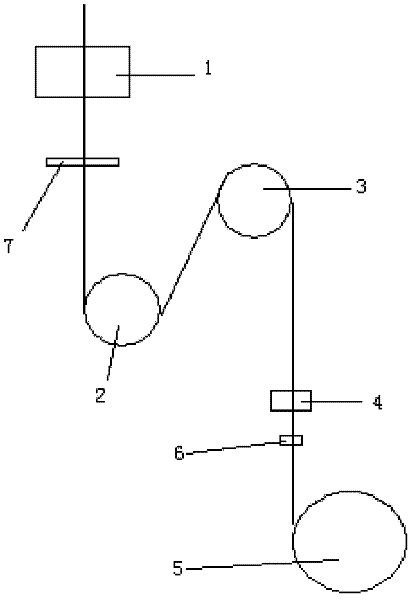

InactiveCN101328622AImprove production rateImprove performanceFilament/thread formingArtificial filament heat treatmentPolyesterHeat pipe

The invention relates to a fully drawn polyester fiber and a preparation method thereof. The technical problem to be solved by the method is to improve the size stability of polyester FDY products and widely apply the polyester FDY products in the weaving field with high size stability requirement. The boiling water shrinkage of the fiber is between 2.0 and 5.0. The method mainly comprises the following steps: firstly, a heat pipe (2) provided with a heating medium for heating is arranged under a spinneret plate of a spinning component (1) of equipment for producing FDY through the hot-roller method; and secondly, a nascent fiber spun from the spinneret plate (1) is cooled and directly added into the heat pipe (2), passes through an oil tanker (3) and then through two or two groups of hot rollers (4) and (5), enters into a network nozzle (6), and finally is wound into an FDY wire cylinder (7).

Owner:ZHEJIANG HENGYI GRP CO LTD

Seaweed polyester fiber and preparation method thereof

InactiveCN109763191AGood moisture absorptionGood skin affinityMonocomponent polyesters artificial filamentArtifical filament manufactureFiberPolyester

The invention provides seaweed polyester fiber. The fiber is characterized in that the raw materials comprise polyester slices, seaweed extract, a modifier and a regulator which are in a mass ratio being (90-110):(3.3-5.7):(4.1-6.2):(3-5). According to the seaweed polyester fiber, the seaweed extract is added, so that the prepared seaweed polyester fiber has good moisture absorption and skin affinity, has lower boiling water shrinkage rate besides good moisture absorption, the boiling water shrinkage rate is lower than or equal to 0.5%, and the problem of technical prejudice is solved.

Owner:ZHONGKE TEXTILE RES INST QINGDAO CO LTD

Colored special-shaped size-stabilized type polyester monofilament and preparation method thereof

InactiveCN104532388AImprove heat resistanceGood dimensional stabilityArtificial thread manufacturing machinesFilament/thread formingPolyesterPolyethylene terephthalate glycol

The invention relates to a colored special-shaped size-stabilized type polyester monofilament and a preparation method thereof. The colored special-shaped size-stabilized type polyester monofilament is composed of, by weight, 84.5 parts to 99.75 parts of polyethylene terephthalate (PET), 0.2 part to 5 parts of color master batches, 0.1 part to 10 parts of poly(ethylene 2,6-naphthalate) (PEN) and 0.05 part to 1 part of barium sulfate powder. By adding the PEN, the thermal resistance of fiber is improved, and no roller sticking phenomenon can occur even when the heat setting temperature is above 245 DEG C; nanometer barium sulfate plays a role of plasticizer, the slippage among high polymers is improved, the drawing ratio is increased, the fiber contraction rate is decreased, and meanwhile the colored fiber can be more uniform and brighter in color and luster; the high drawing ratio is achieved in the fiber drawing process, induced crystallization produced in the fiber drawing process is improved, and the boiling water shrinkage is decreased; the fiber preparing process is simple, dry strands are uniform, fiber is uniform in thickness, woven fabric is smooth, grids are exquisite and uniform, and a colored special-shaped filament is softer and richer in color so that stylized reflection can be facilitated.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD +1

Production method of spunbonded polyester embroidery thread and product of same

ActiveCN102080285ALittle strengthLow boiling water shrinkageDyeing processMelt spinning methodsPolyesterYarn

The invention belongs to the chemical fiber manufacturing field, and particularly relates to a production method of a spunbonded viscose polyester embroidery thread. The production method comprises the following steps: preparing bright modified polyester; carrying out melt spinning, drawing and winding to obtain modified polyester drawn yarns according to the characteristics of the bright modified polyester; and twisting the modified polyester drawn yarns, and dyeing the yarns to obtain the colored polyester embroidery thread product. The invention further provides the colored polyester embroidery thread prepared by the production method. The colored polyester embroidery thread is bright polyester fibers with a triangular cross section, and has bright color; the obtained embroidery thread has the advantages of complete color spectrum, rich color and higher color fastness, and is not darkened after being washed; and meanwhile the embroidered pattern is not deformed due to low boiling water shrinkage and stable structure.

Owner:浙江双兔新材料有限公司

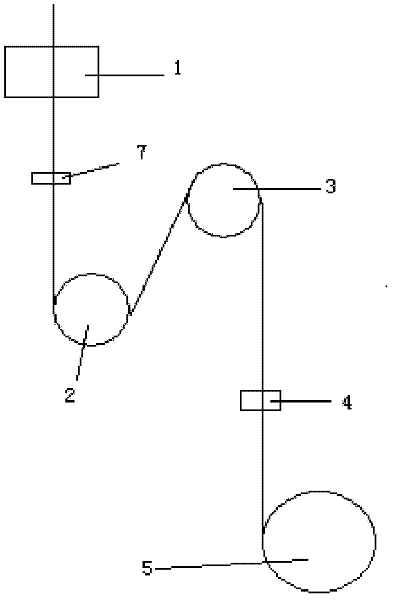

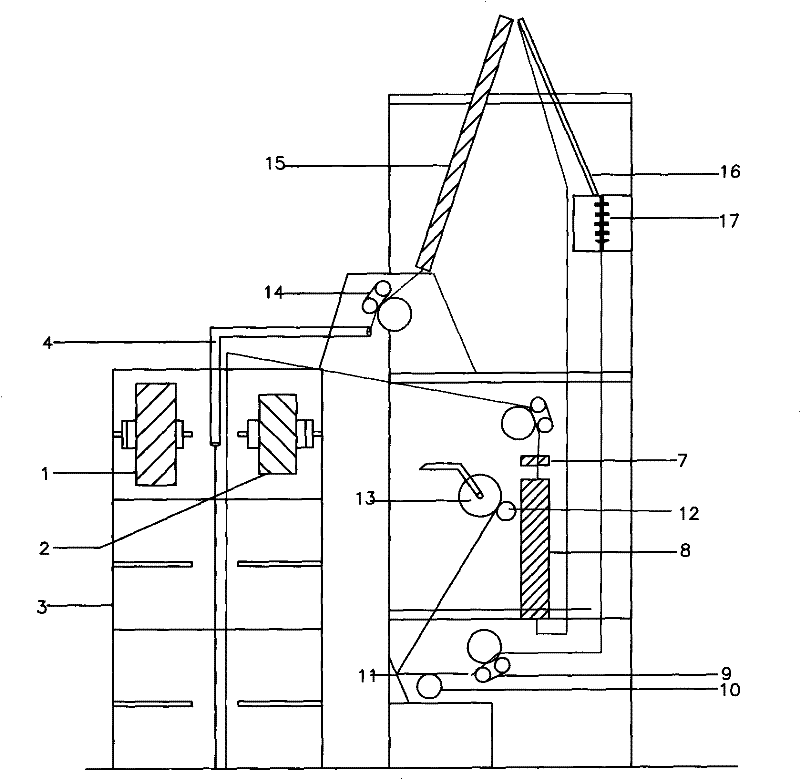

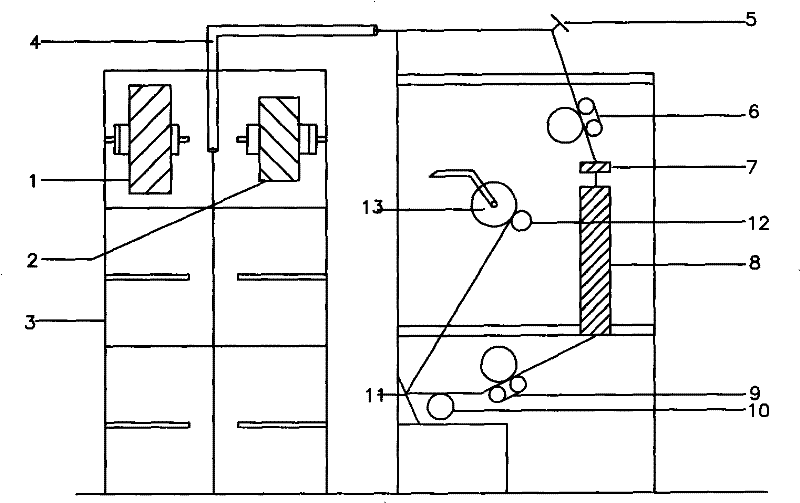

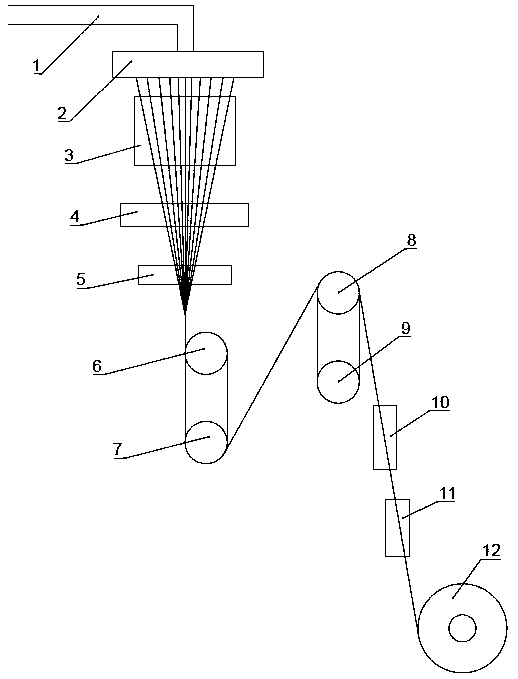

Low boiling water contraction rate polyester fiber drafting textured filament yarn and its producing method and use

ActiveCN1554816ALow boiling water shrinkageAchieve the purpose of the inventionYarnPolymer sciencePolymer chemistry

The present invention relates to drafting deformed dacron filament with low boiling water shrinkage and its production process and application. The POY material filament is processed successively through the first drafting roller, the first heating box, cooling plate, false twisting unit, the second drafting roller, network forming unit, 2bis roller, the second heating box, filament guide unit and filament breaking detector; adding weak network in the resilience increasing process; oiling and winding steps to obtain DTY filament. The present invention has lower deformation temperature, higher settling temperature, short process, reasonable technological control and stable production operation; and the product has boiling water shrinkage not higher than 1.0%, excellent built-in curling elasticity and wrapping. The product may be used in making embroidery string and trademark string.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

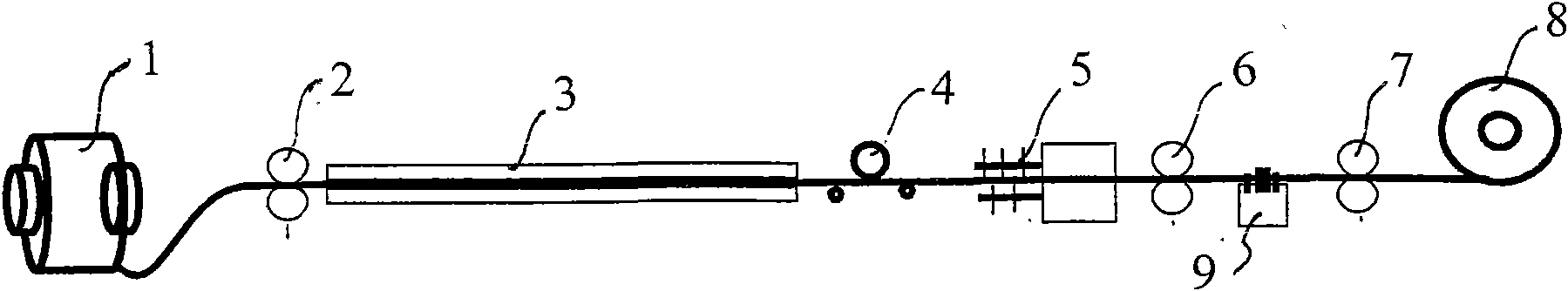

Method for producing polyester ITY (Interlaced Texture Yarn) through flat drafting

The invention discloses a method for producing polyester ITY (Interlaced Texture Yarn) through flat drafting. The method adopts a drafting machine to mix and combine FDY (Full Drawn Yarn) and POY (Polyester Pre-Oriented Yarn); the drafting machine comprises a yarn feeding pressure roller, a yarn feeding tension controlling roller, a first drafting disc, a hot plate, a second drafting disc, an interlacer and a winding roller; the yarn feeding pressure roller is pressed on the yarn feeding tension controlling roller; the method is characterized in that the finished FDY is produced by one stage process, the FDY and the POY together pass through the yarn feeding pressure roller and the yarn feeding tension controlling roller to realize yarn feeding, and together pass through the first drafting disc, the hot plate, the second drafting disc and the network device in sequence to finish the winding finally; and during the process, the first drafting disc is in a heating state, the hot plate and the second drafting disc are in a non-heating state. The ITY produced by the method has the advantages that the interlacing degree is high; the boiling water shrinkage is low and can be adjusted as needed; and the dyeing uniformity is good. Therefore, the ITY can be used to produce high-grade fabrics products, particularly knitted fabrics.

Owner:TONGKUN GRP

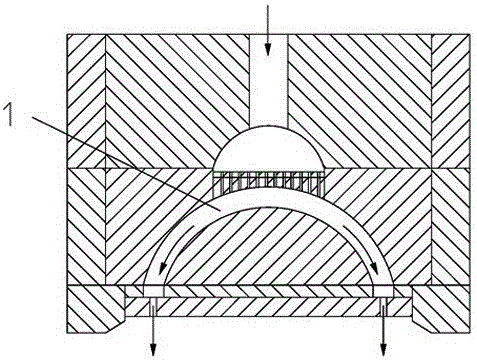

Spinning process and die head of chinlon 66 monofilament of high-strength and high-precision industry

InactiveCN105908277AHigh strengthLow boiling water shrinkageSpinning head liquid feederArtificial thread manufacturing machinesEngineeringSizing

The invention discloses a spinning process and a die head of a chinlon 66 monofilament of high-strength and high-precision industry. The method comprises the following steps: drying; heating to smelt; measuring; spinning; cooling; stretching; sizing; oiling; coiling; inspecting; packing for selling, wherein a flow guide plate of the die head is of an arc-shaped structure. A spinning yarn processed by the spinning process is high in diameter and roundness, high in strength, low in boiling water shrinkage, free of slub filament yarns, and high in production efficiency.

Owner:WUXI DINUO WEIYE TECH CO LTD

Low-shrink polyester fully drawn yarn FDY and production method thereof

InactiveCN102352540AGood dimensional stabilityLow boiling water shrinkageMonocomponent copolyesters artificial filamentMonocomponent polyesters artificial filamentYarnPolyester

The invention relates to polyester fully drawn yarn FDY and a production method thereof, and in particular to low-shrink polyester fully drawn yarn FDY and production method thereof. The technical problem to be solved is as follows: oiling through a posterior drawing and sizing oil nozzle or pre-oiling through an oil wheel, and oiling through the posterior drawing and sizing oil nozzle to the necessary value to realize high-temperature high-drawing and high-temperature thermal-sizing so as to produce shrink polyester FDY; the size of the textile is stable, so that the textile can be used on blanket home textile and in the industrial field; meanwhile, the invention is used for solving the problems of severe fuming of oil, production environment affect and industrialization difficulty caused by high-temperature production. The important steps of the method comprise: coating nanometer nickel-cadmium-chromium alloy on the surfaces of a first hot holler and a second hot roller and yarn guiders used by the same to reduce the friction coefficient to be smaller than 0.1, directly oiling through the posterior drawing and sizing oil nozzle or pre-oiling through the oil wheel, and oiling to the necessary value through the oil nozzle after the drawing and sizing procedures.

Owner:DONGHUA UNIV

High temperature-resistant flame retardation polyacrylonitrile fiber and production method thereof

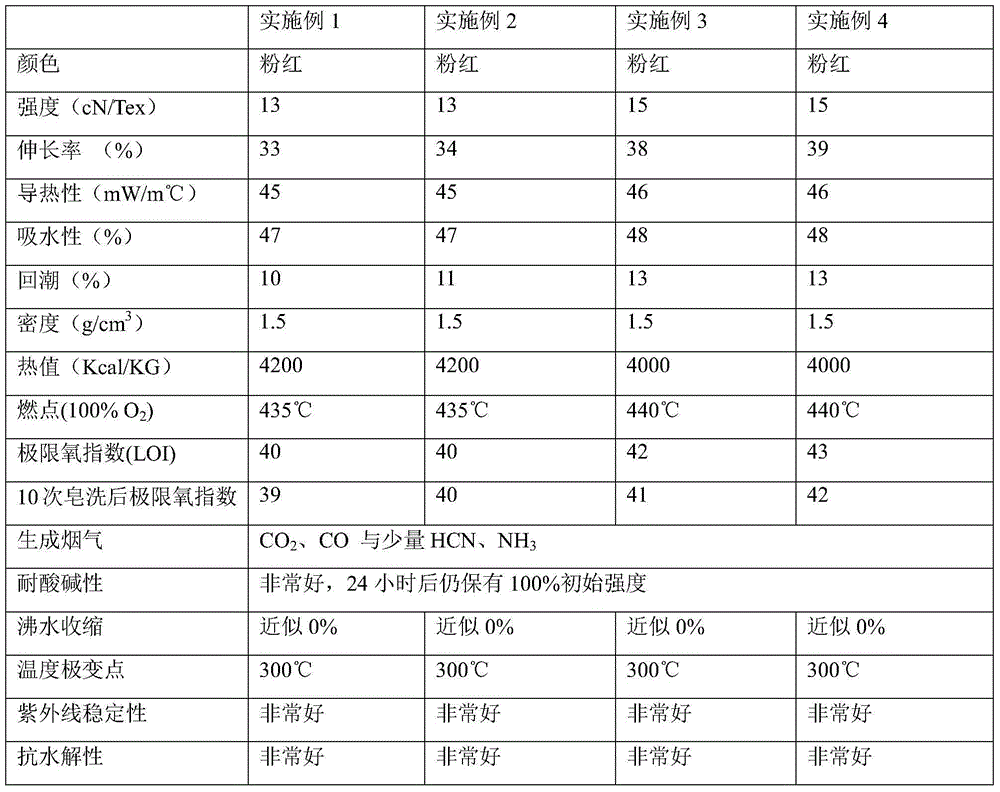

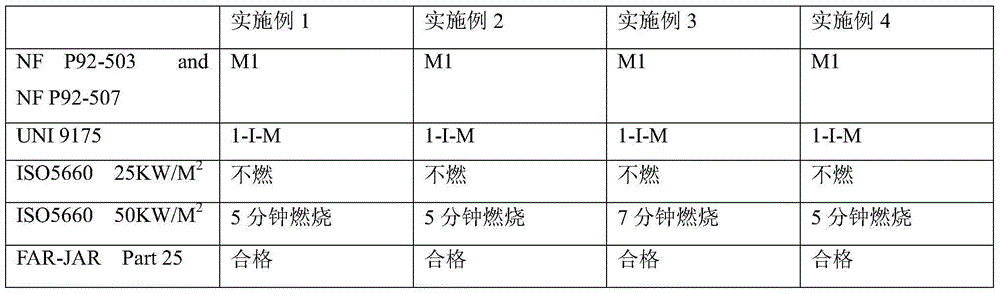

ActiveCN105986474AHigh limiting oxygen indexWon't meltFibre typesDyeing processPolymer scienceMoisture regain

The invention relates to a polyacrylonitrile fiber, and concretely relates to a high temperature-resistant flame retardation polyacrylonitrile fiber and a production method thereof. The method concretely comprises the following steps: processing a polyacrylonitrile fiber in a hydrazine solution with the concentration of 7-20wt%, processing the hydrazine processed fiber in an alkaline solution with the concentration of 3-10wt%, washing the alkali processed fiber with water until the fiber is neutral, processing the neutral fiber in an aqueous metal ion salt solution with the concentration of 3-10wt%, oiling the metal salt processed fiber, dehydrating the oiled fiber, and drying the dehydrated fiber to obtain the high temperature-resistant flame retardation polyacrylonitrile fiber. The flame retardation performance LOI of the flame retardation fiber obtained in the invention can reach 40-45, the flame retardation grade is M1, and the amount of smoke generated in the combustion process is very small, the grade of toxic gases is FO, and the smoke amount of the flame retardation fiber in the invention is lower than that of other flame retardation fibers. The flame retardation fiber in the invention has the advantages of high moisture regain rate, high water absorption rate, good dyeability and low shrinkage in boiling water.

Owner:JILIN ACRYLIC FIBERS CO LTD

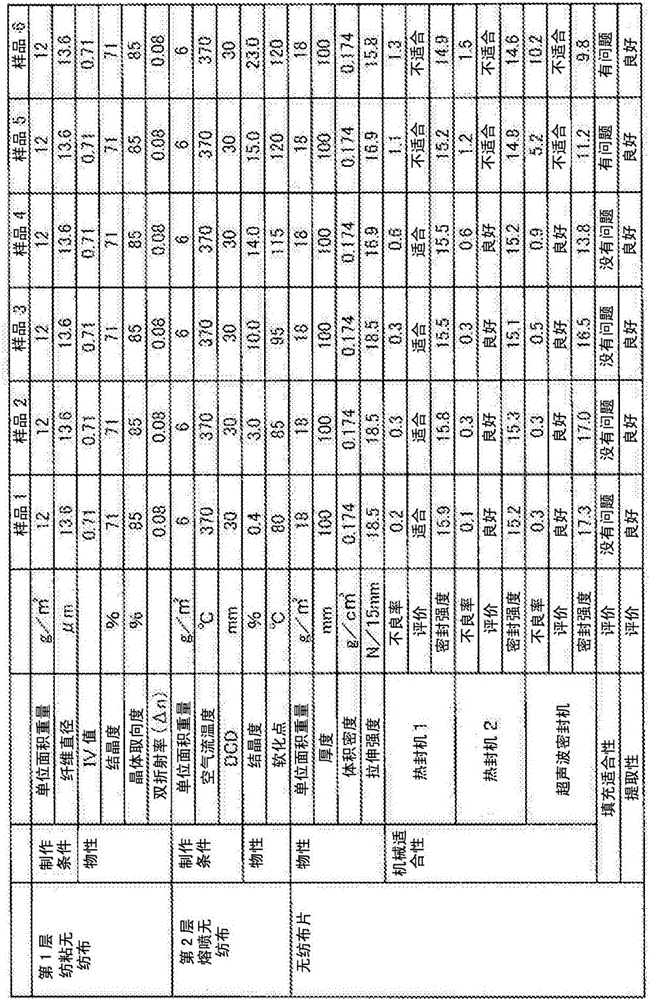

Nonwoven fabric sheet, and extraction-use filter and extraction-use bag using same

The present invention provides a nonwoven fabric sheet used in an extraction-use filter, etc., with which it is possible to obtain great seal strength, and also provides an extraction-use filter, etc., manufactured using the nonwoven fabric sheet. Such a nonwoven fabric sheet is provided with: a first layer comprising a spun-bonded nonwoven fabric formed from fibers of a polyester-based resin in which the IV value is 0.60-1.00, the crystallinity is 30-80%, the crystalline orientation is 60-95%, and the birefringence ([Delta]n) is 0.040-0.100, the spun-bonded nonwoven fabric having a partial thermocompression bonding section in which the thermocompression bonding area rate is 5-30%; and a second layer comprising a melt-blown nonwoven fabric formed from fibers of a polyester-based resin blown onto the surface of the first layer and solidified to a crystallinity of 0-14%. The extraction-use filter, etc., are formed by placing the second layer of the nonwoven fabric on the inside and sealing a prescribed portion by fusion.

Owner:OHKI

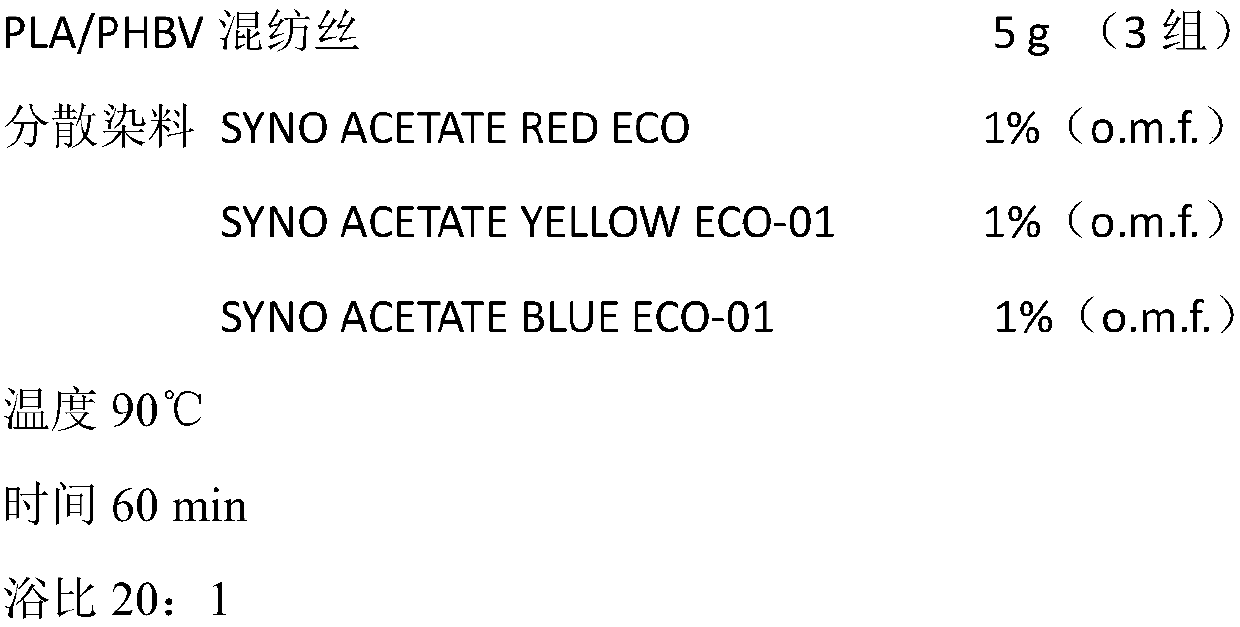

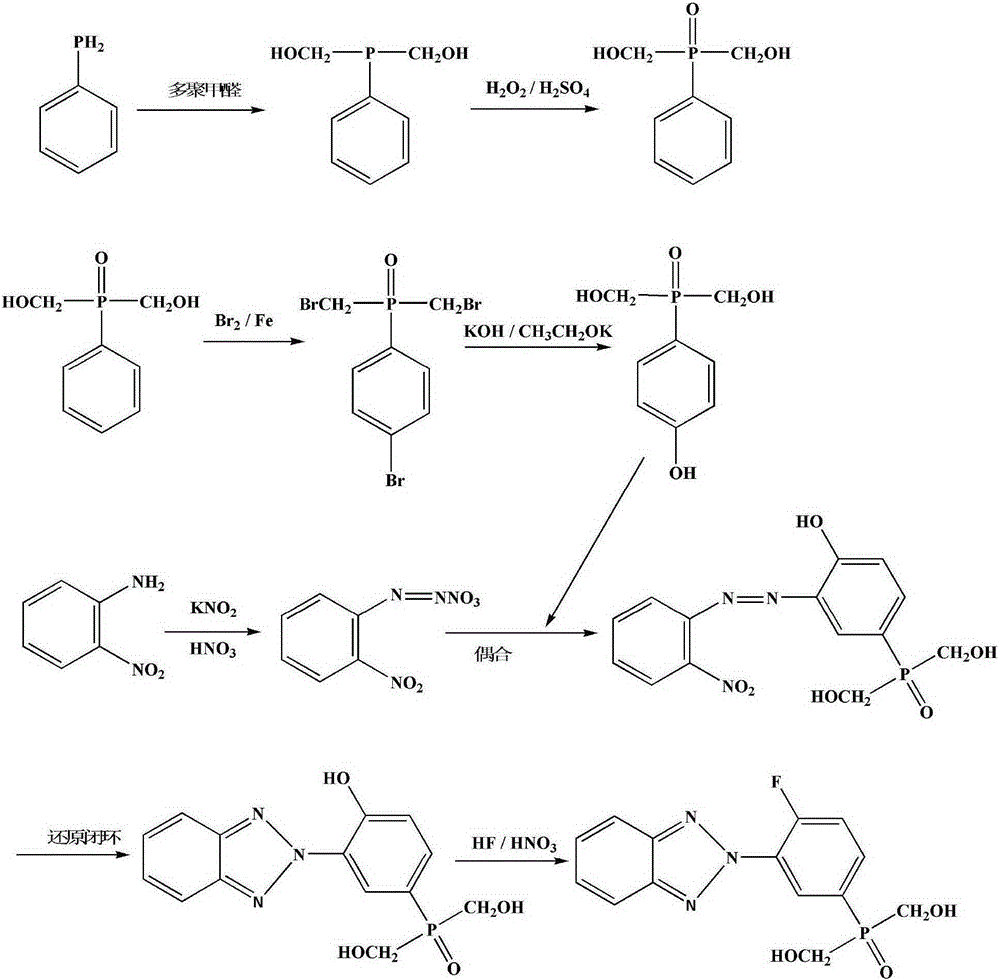

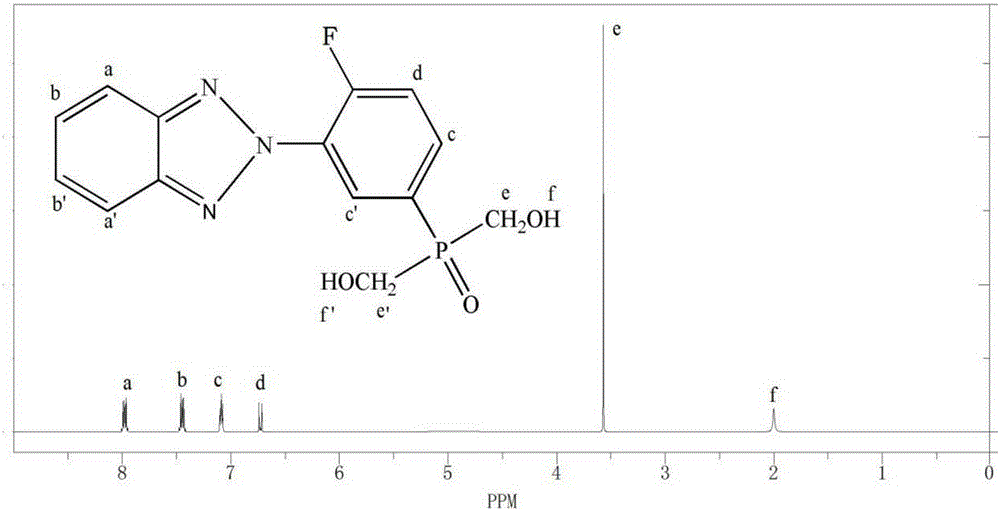

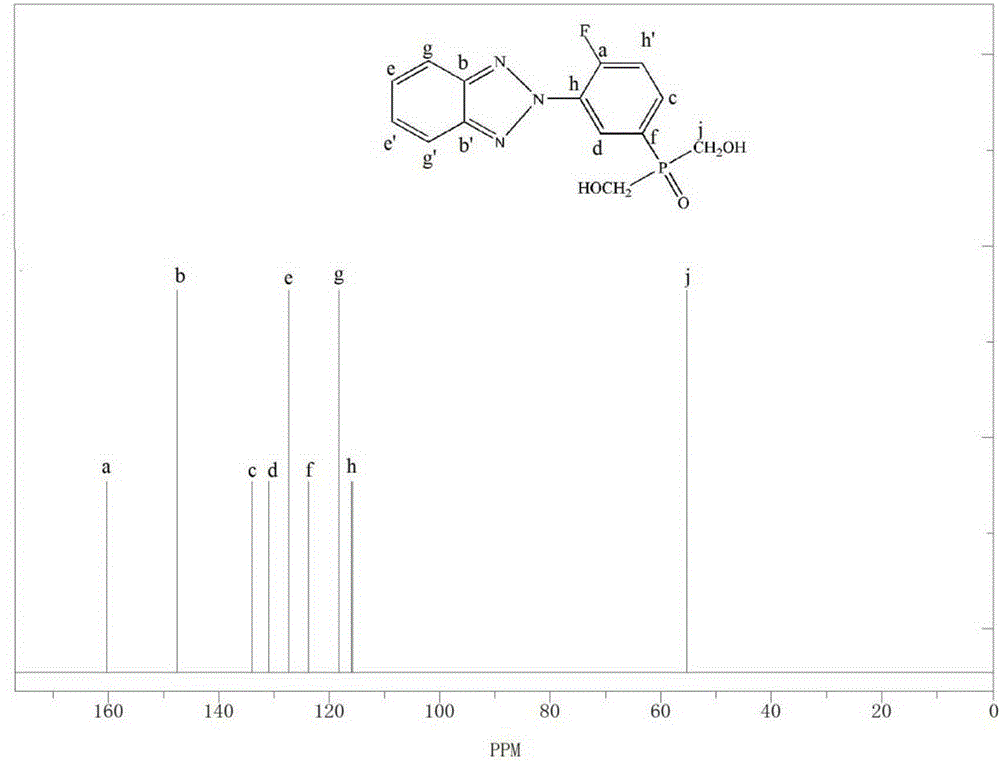

A kind of pla/phbv blended silk dyeing method at low temperature

A low-temperature dyeing method of PLA / PHBV blended yarn comprises steps of: wetting the PLA / PHBV blended yarn into deionized water of 60-90 degrees centigrade, cleaning for 15-30min; taking disperse dye of 0.5%-2% of the weight of the blended yarn, dissolving the disperse dye into the deionized water to form a dye liquor, putting the blended yarn into the dye liquor, dyeing as per a bath ratio of 20-30:1, firstly heating up the dye liquor to 65-75 degrees centigrade by 2-4 degrees centigrade / min, heating up to 90-100 degrees centigrade by 1-2 degrees centigrade / min, maintaining the temperature for 40-60min; then cooling down to 50 degrees centigrade by 3-5 degrees centigrade / min, and taking out the blended yarn; reduction clearing the blended yarn, wherein the reduction clearing solution comprises 0.5-1g / L of sodium hydrosulfite and 0.5-1g / L of anhydrous sodium carbonate; the temperature of the reduction clearing solution is 75-90 degrees centigrade; the bath ratio is 20-30:1; and the reduction clearing duration is 20-30min. The low-temperature dyeing method of PLA / PHBV blended yarn solves the low-temperature dyeing problem of the PLA / PHBV blended yarn; the method saves energy and reduces production cost, and it has the advantages of deep dye color, uniform dyeing effect, washing fastness, and good crockfastness.

Owner:ZHEJIANG TEXTILE & FASHION COLLEGE +1

Production method of low boiling water contraction rate polyester fiber drafting textured filament yarn

ActiveCN100489168CLow boiling water shrinkageAchieve the purpose of the inventionYarnContraction rateEngineering

The present invention relates to drafting deformed dacron filament with low boiling water shrinkage and its production process and application. The POY material filament is processed successively through the first drafting roller, the first heating box, cooling plate, false twisting unit, the second drafting roller, network forming unit, 2bis roller, the second heating box, filament guide unit and filament breaking detector; adding weak network in the resilience increasing process; oiling and winding steps to obtain DTY filament. The present invention has lower deformation temperature, higher settling temperature, short process, reasonable technological control and stable production operation; and the product has boiling water shrinkage not higher than 1.0%, excellent built-in curling elasticity and wrapping. The product may be used in making embroidery string and trademark string.

Owner:SINOPEC OILFIELD SERVICE CORPORATION

Colored special-shaped super fine denier polyester monofilaments and production method thereof

InactiveCN105297169AImprove heat resistanceGood dimensional stabilityFilament/thread formingMicroballoon preparationPolyesterHeat resistance

The invention relates to colored special-shaped super fine denier polyester monofilaments and a production method thereof. The colored special-shaped super fine denier polyester monofilaments are prepared from, by mass, 1-5% of anti-aging capsules, 5-10% of pigment, 5-10% of PEN slices, 1-3% of a dispersing agent and the balance polyester slices. The PEN slices, the polyester slices, the anti-aging capsules, the pigment and the dispersing agent are extruded and mixed together through a screw machine and then melted, melt is prepared and subjected to melt spinning through a special-shaped spinneret plate, and the colored special-shaped super fine denier polyester monofilaments are obtained. Due to the fact that PEN is added, the heat resistance of fibers is improved, and thus the roll sticking phenomenon is avoided when the heat setting temperature is higher than 245 DEG C; meanwhile, due to the higher heat setting temperature, disorientation of an orientation structure of an amorphous area is accelerated, the internal stress of the fibers is reduced, and thus the dimension stability of the fibers is improved; the setting temperature is raised, the mobility of macromolecular chains in the fiber structure is enhanced, the degree of crystallinity is increased, the content of an amorphous area is reduced, and the boiling water shrinkage is reduced.

Owner:上海金霞化纤有限公司 +1

Method for preparing sewing-thread polyester filaments with high strength and low dry-heat shrinkage

InactiveCN101519811AIncrease production capacityIncrease manufacturing costMelt spinning methodsFilament-forming treatmentPolyesterDry heat

The invention discloses a method for preparing sewing-thread polyester filaments with high strength and low dry-heat shrinkage. The method is characterized in that common slices are tackified through solid-phase polymerization; the tackified common slices are dried to remove moisture and then enter a screw extruder so as to be melted; the obtained material is spun, cooled and oiled; and the obtained material is stretched through four times of hot rolling and then wound into a spinning cake. The polyester filaments with high strength and low dry-heat shrinkage, which are processed by the method, have the advantages of high strength, low dry-heat shrinkage, low boiling-water shrinkage, low elongation, few broken filaments, few broken ends and other good qualities, along with steady simple production operation and low production cost.

Owner:QINGDAO WEIFENG FIBER

Method for producing modified cation polyester filament and product thereof

ActiveCN102094256BBionic features are obviousLow boiling water shrinkageMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterPolymer science

The invention belongs to the field of manufacture of chemical fibers, in particular to a method for producing a modified cation polyester filament imitating a cellulose fiber. The method comprises the following steps of: preparing modified cation polyester; carrying out melting spinning by aiming at the characteristics of the modified cation polyester to obtain an orientated filament; and carrying out false twisting on the orientated filament under the condition of a special elasticizing process. The invention also provides a modified cation polyester filament prepared with the production method. The cation polyester filament disclosed by the invention has favorable fuzzing and pilling resistance, can be dyed at normal pressure without high-temperature and high-pressure conditions, saves the dyeing cost and has bright color after being dyed and high skin intimacy, and the hygroscopicity is better than that of common cation terylene filament.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

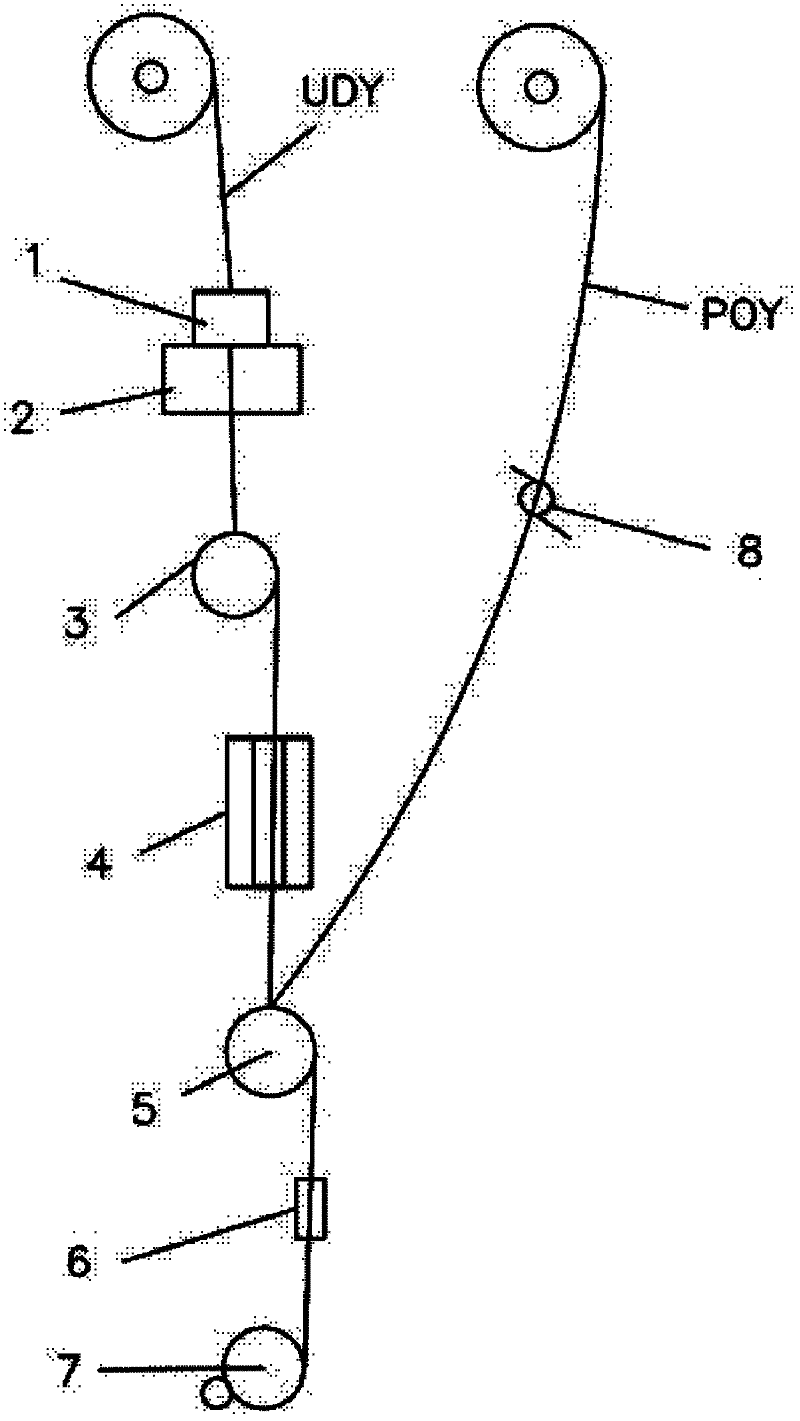

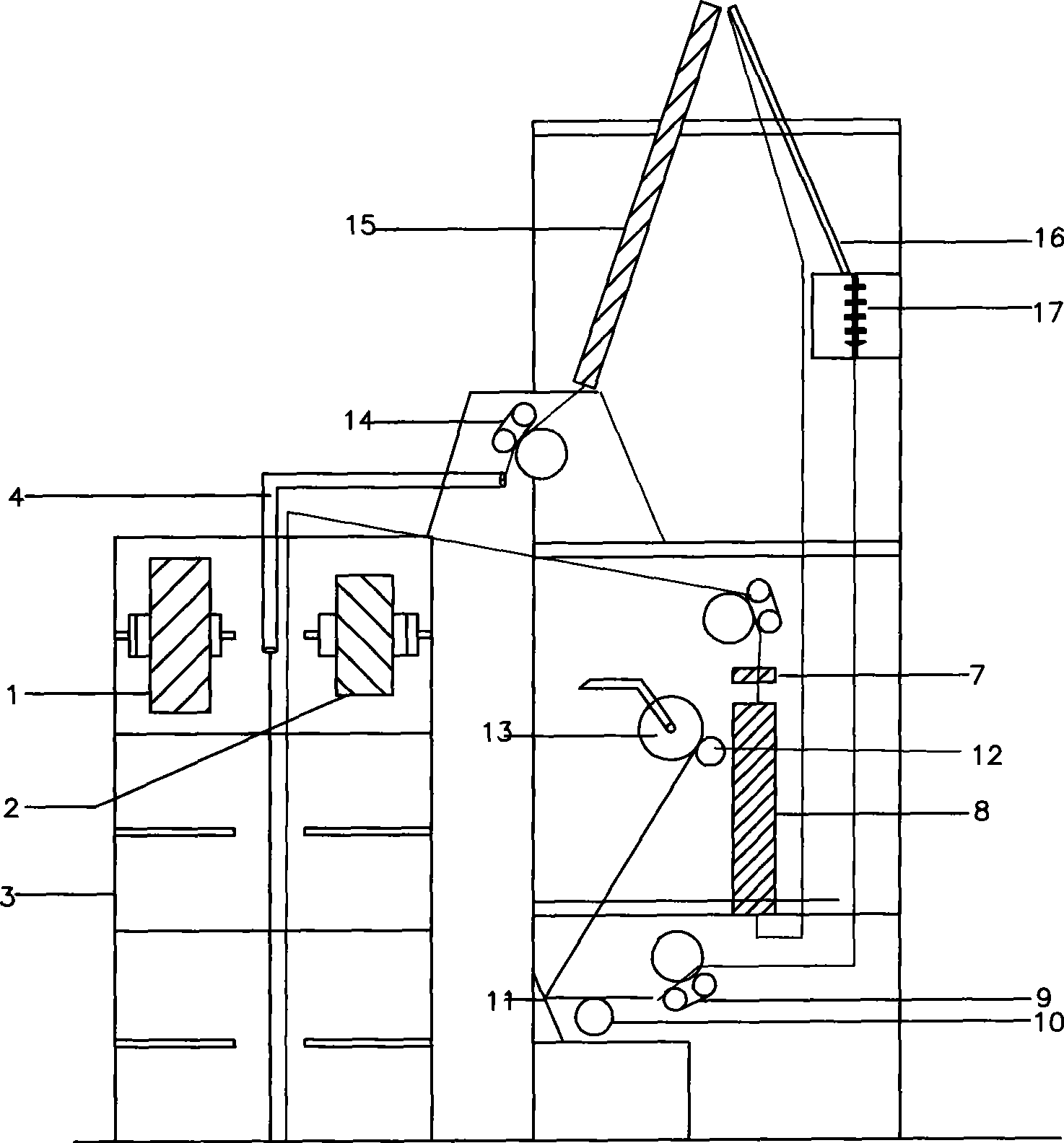

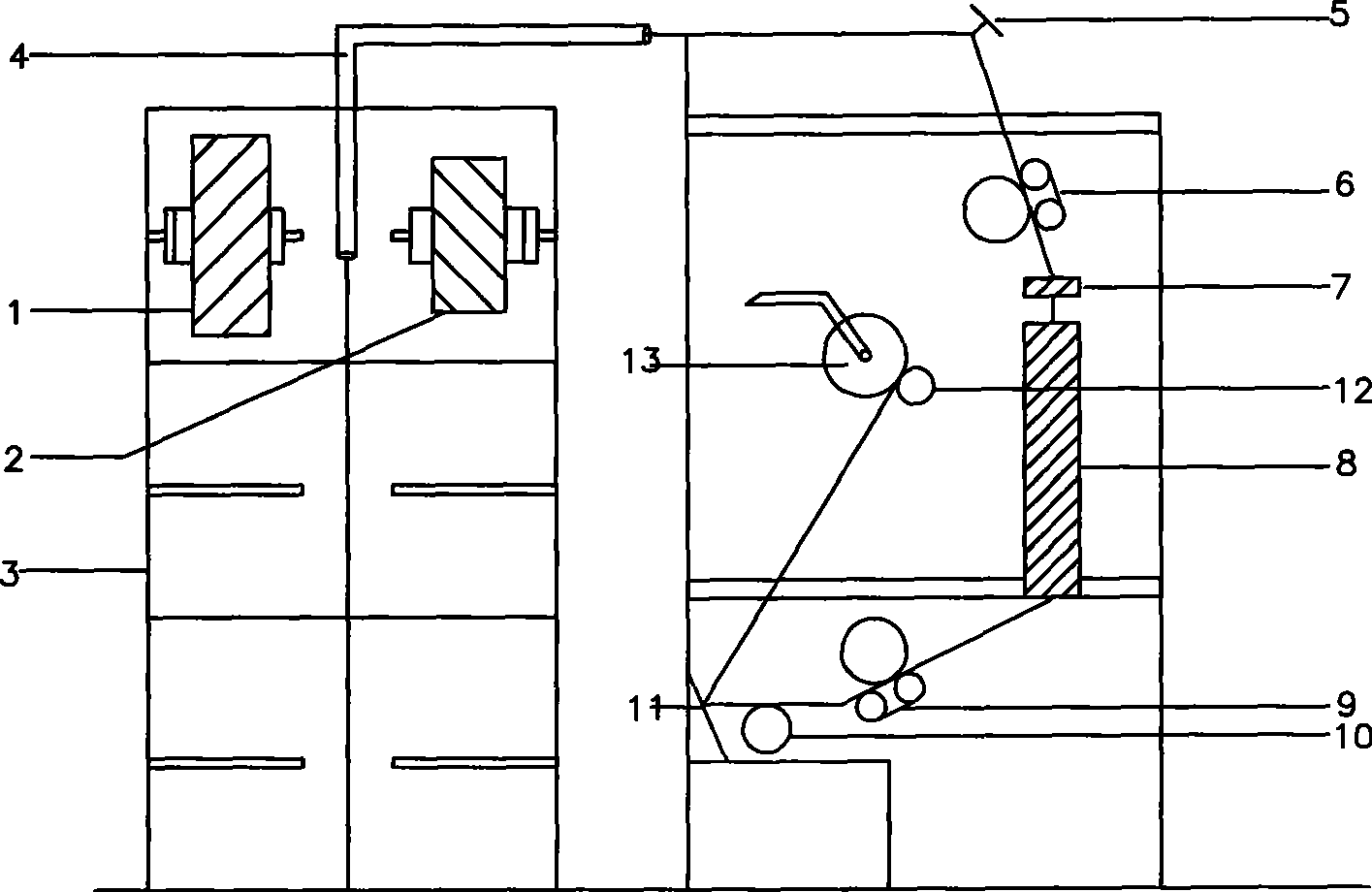

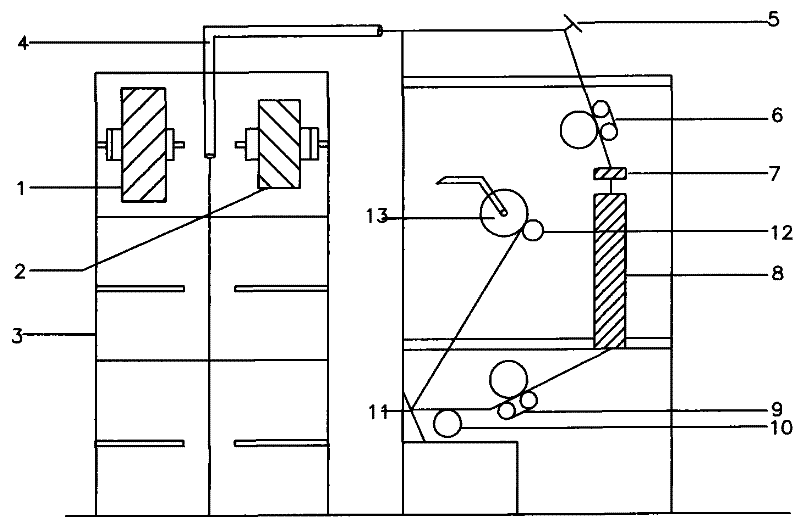

Method for producing ultra-low-shrinkage composite crystal fibrilia and apparatus thereof

The invention provides a production method of an ultra-low-shrinkage composite crystal flax fiber. The production method comprises the following steps: semi-dull FDY raw yarn and semi-dull POY raw yarn are adopted as main raw materials, the two different types of raw yarn are simultaneously introduced into a tow traction tube, a tow directly enters a yarn inlet and feed roller through a yarn guide and enters a compressed air network below the yarn inlet and feed roller, then the high-temperature shaping is carried out after the tow enters a lower hot box, the composite tow after shaping is sent out by a yarn outlet and discharge roller, and the winding and the shaping are carried out by guiding the composite tow to a spindle friction roller through the yarn guide after full oiling on an oil wheel. The production method of the ultra-low-shrinkage composite crystal flax fiber and a device thereof provided by the invention carry out the production on the traditional 1000 type polyester stretch yarn machine, and the melt direct spinning semi-dull FDY and the semi-dull POY are taken as the raw yarn for producing the composite crystal flax fiber, thereby changing the traditional process idea and leading the traditional stretch yarn machine to play a new production role. The device omits a first roller, an upper hot box, a cooling plate, a false-twister and other parts of the original device and is further provided with the yarn inlet and guide device, thereby not only changing the process route, but also saving energy.

Owner:TONGKUN GRP

Preparation process of polyester for spinning filament by heat tube drafting technique

A process for preparing the polyester used to spin high-gloss hot-tube drawn silk features the semi-continuous direct esterifying process is used, and the nucleator (SiO2 superfine particles) is used in condensatino step for high crystallizing degree. The resultant polyester is used to prepare the high-glass silk by the hot tube drawing technique. Its advantages are high fracture strength, low shrinkage in boiling water, and good hand feeling and uniform dyeing of its fabric.

Owner:WUJIANG SILK

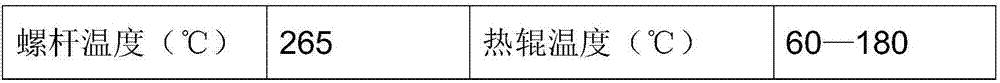

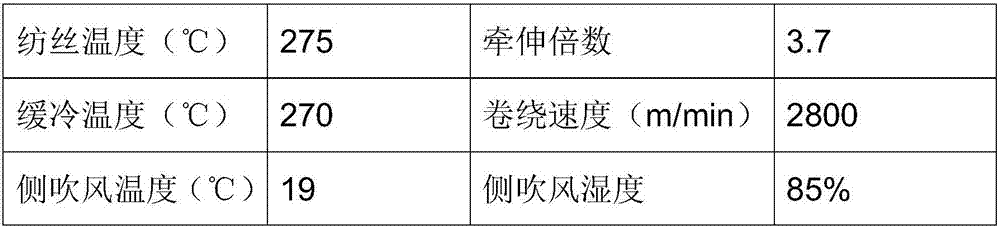

12ends spinning polyamide-6 fine denier low shrink industrial yarn production technology

ActiveCN107043959ALow boiling water shrinkageArtificial thread manufacturing machinesSpinning head liquid feederYarnPolyamide

The invention provides a 12ends spinning polyamide-6 fine denier low shrink industrial yarn production technology comprising the following steps: 1, importing polyamide-6 dry slice raw material into a screw extruder through a bunker, fusing the raw material into a fusion type to form a spinning melt, and allowing the melt to enter a melt pipeline; 2, spinning: inputting the spinning melt into a spinning box, controlling the metering pump revolution speed, metering the material and pressing into an assembly, thus forming a filament bundle through a spinneret; 3, cooling: allowing the filament bundle to pass a heat retarder, and using side blowing and a channel to cool off the filament bundle; 4, oiling: allowing the filament bundle to pass an oil tanker, and controlling the oil tanker rotating speed so as to control the oiling rate; 5, hot roller drawing: using hot rollers of different temperature and speed to draw the filament bundle, thus obtaining intensity and fracture elongation indexes; 6, moulding: interlacing the cooled filament bundles, adjusting winding tension, and realizing wining formation. The production technology uses a high moulding temperature to obtain a low boiling water shrinkage.

Owner:HAIAN HUARONG CHEM FIBER

Technique for preparing bright polyester filament yarn with high extension

InactiveCN101270509ALow boiling water shrinkageNormal intensityMonocomponent polyesters artificial filamentArtifical filament manufactureManufacturing technologyEconomic benefits

The invention relates to a manufacture technology of a high stretching bright polyester filament which is a bright polyester filament product manufactured by adopting a common chip spinning manufacture flow with a micro-injection method to add a special aether additive in a melt through a special technique. The high stretching bright polyester filament manufactured by the method has the qualities of normal intensity, more than 40 percent of crack stretching rate, low boiling water shrinkage factor and few broken filament end cracking; besides, the manufacture operation is more stable. As a common terylene high speed spinning technique line is adopted, the invention has low requirements on the device; the output is high, the additive value of the product is high, the investment cost can be reduced and the economic benefit can be improved.

Owner:JIANGSU HUAYA FIBER

Method for producing ultra-low-shrinkage composite crystal fibrilia and apparatus thereof

Owner:TONGKUN GRP

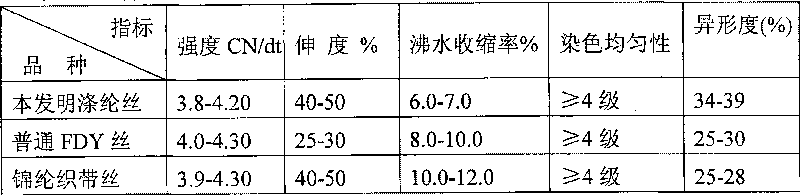

Single stage drawing method for terylene continuous yarn filament in use for meshbelt, and preparation

InactiveCN101050552BEasy for production managementHigh color fastnessFilament/thread formingMonocomponent polyesters artificial filamentColour fastnessPolymer science

The present invention relates to an improved one-step drawing method for preparing polyester filament for weaving tape. Said polyester filament is characterized by that it cross section is made into the form of trefoil, heterogeneous degree is 34-39%, extensibility is 40-50% and shrinkage in boiling water is 6.0-7.0%.

Owner:江苏三鑫化纤有限公司

Multifunctional health care sarcandra glabra mica ice-cold yarn and preparation method thereof

The invention relates to a health care yarn, in particular to a preparation method and application of a multifunctional health care sarcandra glabra mica ice-cold yarn which can suppress bacteria, protect and nourish skins, and resist aging. The multifunctional health care sarcandra glabra mica ice-cold yarn includes the following raw materials, by weight, 20-75% of fine staple cotton fibers, 25-80% of sarcandra glabra fibers, 15-75% of lightmax fibers, and 25-85% of copper modified polyester fibers. Fabrics and various high-grade products made of the sarcandra glabra mica ice-cold yarn is bright in color, is cool in hand feeling, is soft and elegant, has excellent anti-static, heat-conductive, breathable, cold, stink-removing, antisepsis and anti-inflammation, wind-dispelling and dampness-eliminating, blood-activating, and pain-stopping characteristics, can relive and shrink lumps, prolong the lift, and improve sleep, has a lasting antibacterial, sterilizing and germ-suppressing effect, is safe and harmful to human bodies, is low in boiling water shrinkage of fabrics, and will not deform.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Production method of high-elongation lustrous polyester filament yarn

InactiveCN101880919AReduce broken endsLow requirements for production equipmentFilament forming substance formingArtificial filament heat treatmentEtherTexture processing

The invention discloses a production method of a high-elongation lustrous polyester filament yarn, which comprises the steps of raw material melting and spinning, cross air blow cooling, false twisting texturing processing, oil cooling and winding. The production method is characterized in that the step of melting and spinning comprises the following actions: melting lustrous polyester chips as a raw material to form lustrous polyester melt, and injecting an ether additive with the mass content of 0.5%-0.95% into the melt. The production method of the high-elongation lustrous polyester filament yarn has the advantage of low production equipment requirements; and the produced high-elongation lustrous polyester filament yarn has high elongation at break greater than or equal to 40%, low boiling water shrinkage, few broken filament yarns and better product quality.

Owner:ZHONGRUN SCI & TECH

Production method of black antibacterial low-shrinkage FDY fibers

InactiveCN110965141AImprove antibacterial propertiesLow boiling water shrinkageFilament forming substance formingArtificial thread manufacturing machinesPolyesterPolymer science

The invention relates to the technical field of fiber preparation, and particularly relates to a production method of black antibacterial low-shrinkage FDY fibers. An optical polyester melt is used asa raw material, and the optical polyester melt is pressurized by a booster pump through a melt conveying pipeline and then enters a melt cooler; after the melt is cooled by using the melt cooler, black antibacterial master batches are added online, and are fed into a spinning box body after passing through a dynamic mixer; after being metered by a metering pump, the mixture is filtered by the spinning assembly in the spinning box body and then is extruded; after the spinning is cooled by a side air blowing process, the fibers enter a winding oil wheel for being subjected to oiling, pre-networking, hot roller heating process and a main network; and next, the fibers are subjected to supplemental heat setting through a rear heating plate device, and finally the fibers are rolled and formed through an ACW winding head. According to the production method of the black antibacterial low-shrinkage FDY fibers, the product has high antibacterial performance, and meanwhile, the boiling water shrinkage rate of the product is reduced from 5% to about 2.5%. The product is suitable for novel fields such as suede fabric, fiber blending and the like.

Owner:新凤鸣集团股份有限公司 +1

Colored profiled polyester multifilament fiber with stable dimension and preparation method thereof

ActiveCN101525786BHigh strengthLow shrinkageMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyesterYarn

The invention relates to a colored profiled polyester multifilament fiber with stable dimension and a preparation method thereof. The preparation method comprises the following steps: adjusting contents of polyester, pigment masterbatch and an additive in a fusant according to a certain proportion, drying and dehydrating, forming after melting, extrusion, spinning and cooling, and obtaining finished filament after oiling, coiling, heating, tensioning, heat setting, inspection and grading. The fiber can be prepared with conventional spinning equipment, has even multifilament bundle yarn and even color distribution, can be widely applied to fields of clothing, decoration and industry. Fabric is smooth, is characterized by soft luster, high breaking strength and low breaking elongation, can ensure stable geometric dimension of the fabric without easy deformation; and the fiber has the advantages of good fabric elastic resilience, less creep and relaxation and low boiling water shrinkage,and can improve the stability due to hard deformation at high temperature.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com