A kind of pla/phbv blended silk dyeing method at low temperature

A low-temperature dyeing and blending technology, which is applied in the field of disperse dyeing technology, can solve the problems of damaged fiber mechanical properties and poor heat resistance, and achieve energy saving, good rubbing fastness, and improved hand feeling.

Inactive Publication Date: 2018-05-15

ZHEJIANG TEXTILE & FASHION COLLEGE +1

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Polylactic acid fiber is a relatively successful bio-based fiber in industrialization, but its poor heat resistance makes the mechanical properties of the fiber severely damaged after heat treatment (spinning, dyeing, ironing, etc.)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

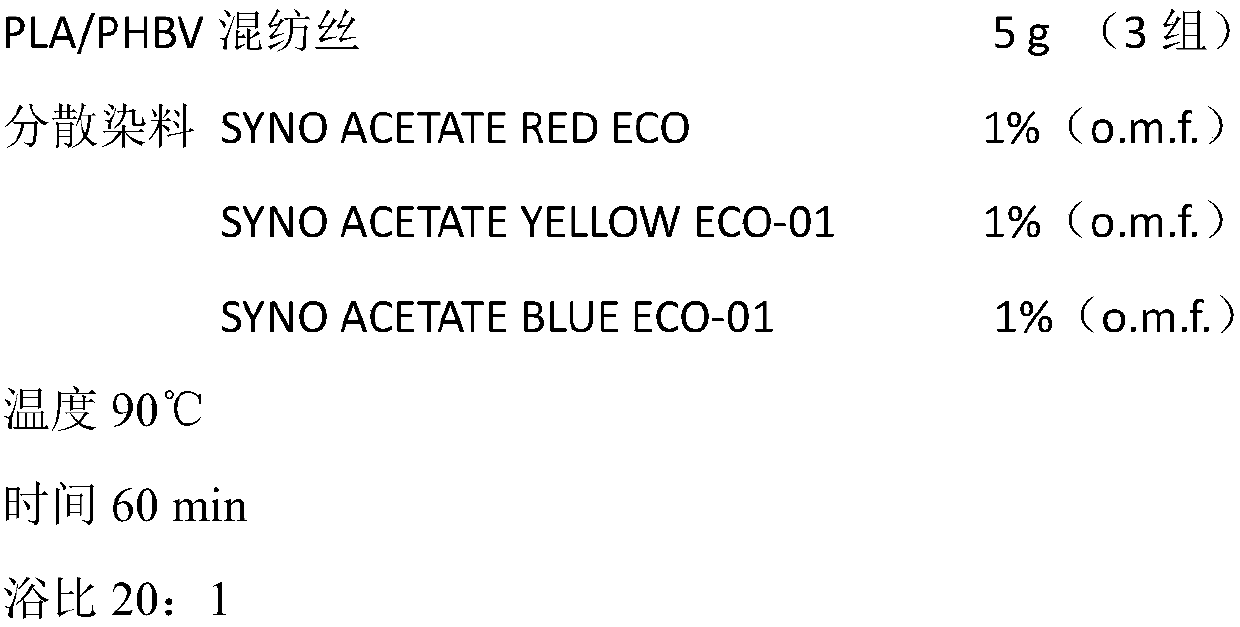

[0019] Dyeing process prescription

[0020]

[0021] Reduction cleaning process prescription

[0022]

Embodiment 2

[0031] Dyeing process prescription

[0032]

[0033] Reducing cleaning process prescription

[0034]

Embodiment 3

[0043] Dyeing process prescription

[0044]

[0045] Reducing cleaning process prescription

[0046]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A low-temperature dyeing method of PLA / PHBV blended yarn comprises steps of: wetting the PLA / PHBV blended yarn into deionized water of 60-90 degrees centigrade, cleaning for 15-30min; taking disperse dye of 0.5%-2% of the weight of the blended yarn, dissolving the disperse dye into the deionized water to form a dye liquor, putting the blended yarn into the dye liquor, dyeing as per a bath ratio of 20-30:1, firstly heating up the dye liquor to 65-75 degrees centigrade by 2-4 degrees centigrade / min, heating up to 90-100 degrees centigrade by 1-2 degrees centigrade / min, maintaining the temperature for 40-60min; then cooling down to 50 degrees centigrade by 3-5 degrees centigrade / min, and taking out the blended yarn; reduction clearing the blended yarn, wherein the reduction clearing solution comprises 0.5-1g / L of sodium hydrosulfite and 0.5-1g / L of anhydrous sodium carbonate; the temperature of the reduction clearing solution is 75-90 degrees centigrade; the bath ratio is 20-30:1; and the reduction clearing duration is 20-30min. The low-temperature dyeing method of PLA / PHBV blended yarn solves the low-temperature dyeing problem of the PLA / PHBV blended yarn; the method saves energy and reduces production cost, and it has the advantages of deep dye color, uniform dyeing effect, washing fastness, and good crockfastness.

Description

Technical field [0001] The invention relates to a low-temperature dyeing method for PLA / PHBV blended yarn, and belongs to the technical field of disperse dye dyeing technology. technical background [0002] In recent years, people have gradually realized that the production of traditional synthetic fibers is completely dependent on non-renewable resources-petroleum, which will lead to a large amount of energy and material consumption, and is not sustainable. Therefore, degradable bio-based polymers and their blended products, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) have gradually developed. Polylactic acid fiber is a kind of bio-based fiber that has been successfully industrialized. However, its poor heat resistance makes the mechanical properties of the fiber seriously damaged after heat treatment (weaving, dyeing, ironing, etc.). The PLA / PHBV blended yarn made by melt blending spinning by Ningbo Institute of Materials Technology and Engineering, Chinese A...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06P1/16D06P3/54D06P5/10

CPCD06P1/16D06P3/54D06P5/10

Inventor 杨梅王炜董超萍

Owner ZHEJIANG TEXTILE & FASHION COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com