Textured yarn and processing method, special device and applications thereof

A processing method and a technology of stretching yarn, applied in textiles and papermaking, fiber treatment, yarn, etc., can solve the problems of poor dimensional stability, large shrinkage of processed yarn, high production cost of equipment, etc., and achieve a simple and easy processing method , good fluffiness, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

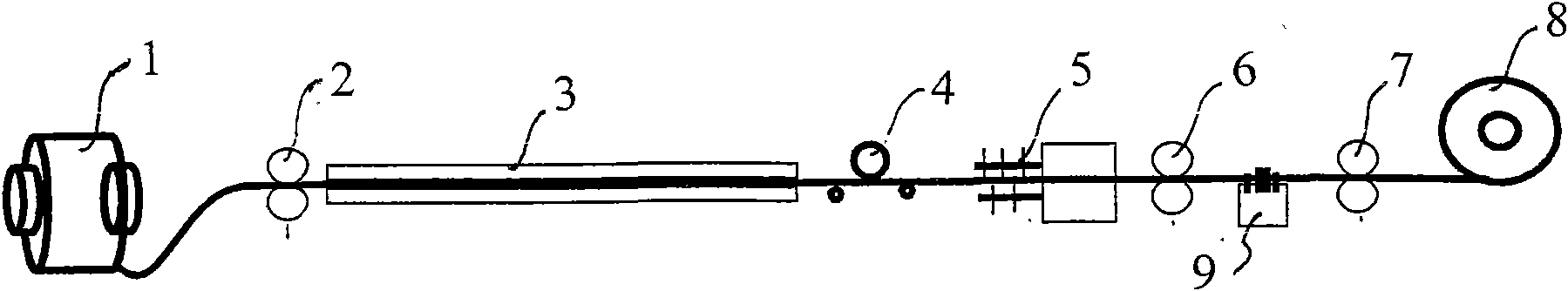

[0055] Through composite spinning, the skin is C-type polyethylene terephthalate (PET), the core is a skin-core structure of alkali-soluble copolyester (COPET) and the cross-section is a circular 36-hole unstretched wire, The raw material yarn respectively passes through the hot box between the first wire feed roller and the second wire feed roller, a special device, and a false twister. The temperature of the hot box is 200°C, and the twist number provided by the false twister is 3700T / M. After the device is disturbed, the actual number of twists in the hot box drops to 160T / M. The starting point of yarn twisting is the first roller at the front of the hot box. The processing speed is 500m / min. The stretching between the second roller and the first roller The ratio is 1.72, the yarn is blown and twisted by the compressed air of 0.15Kpa provided by the network device in the state of 3% overfeeding between the second and third wire feed rollers to form a network, and the stretch...

Embodiment 2

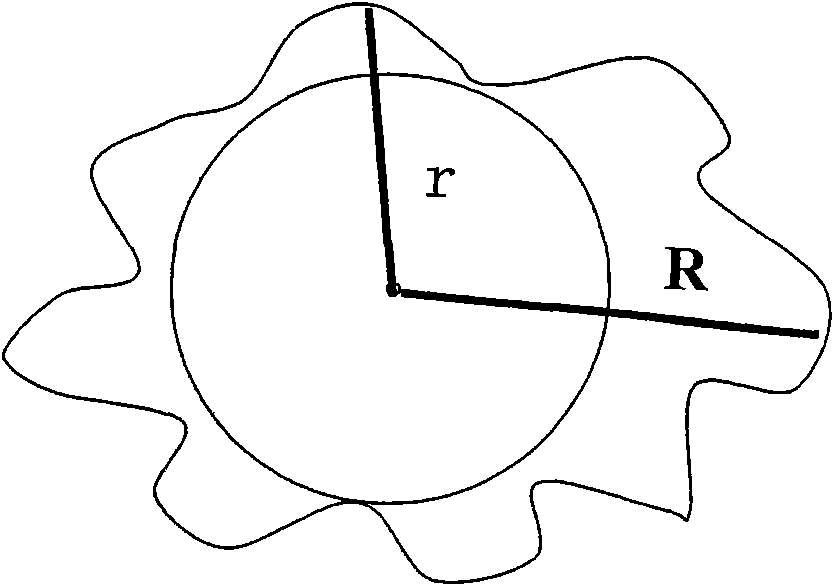

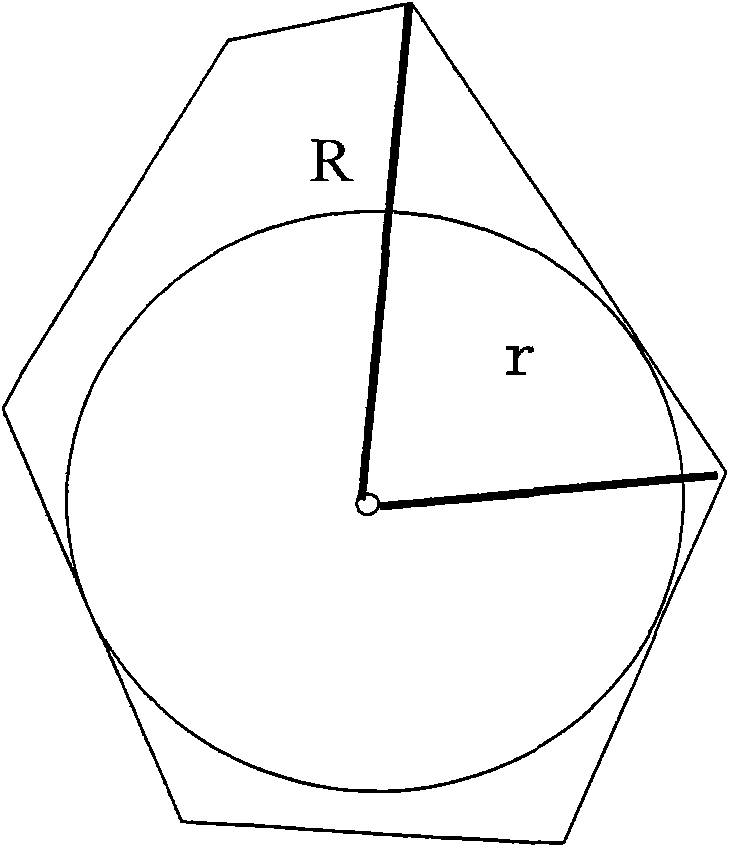

[0059] Use the 36-hole polyethylene terephthalate (PET) unstretched yarn obtained by spinning at a speed of 2800M / min. The 24-hole section of the raw silk is circular and the 12-hole section is gear-shaped, and the processing speed is 450m / min , the temperature of the hot box is 185°C, the stretch ratio is 1.67, and the twist number provided by the false twister is 3700T / M. After the interference of the special device, the actual twist number in the hot box drops to 1800T / M. The state of overfeeding 3.5% between the wire feeding rollers is blown and twisted by the compressed air of 0.30Kpa provided by the networker to form a network, and the yarn is heated by a reheating box with a temperature of 170°C provided between the second roller and the third roller After secondary heating and setting to improve the stability of the crimp, the stretched yarn is wound and formed by a coiling mechanism.

[0060] The prepared textured yarn calculates its cross-sectional deformation (JB) v...

Embodiment 3

[0062] Use polyethylene terephthalate (PET) spinning to obtain cross-section as circular 36 hole unstretched silk as raw material silk, by the processing method described in embodiment 1, processing speed 370m / min, draw ratio is 1.82, the temperature of the hot box is 205°C, and the actual twist number in the hot box is reduced to 1900T / M by means of a special rotary device. The calculated value of the cross-sectional deformation (JB) of the obtained stretched yarn is 15%, and the stretch recovery rate CR value It is 17%, the boiling water shrinkage is 6.2%, and the monofilament fineness is 2.7dtex. The fabric made of the stretched yarn as a warp and weft plain weave has suitable softness and soft luster that conventional stretched yarn does not have.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament denier | aaaaa | aaaaa |

| Number of twists | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com